Is 800 mesh crushing considered fine

Particle Size Conversion Chart Williams Patent Crusher

Put simply, particle size reduction is making big things smaller For example, if you need large rocks crushed into gravel, that process is an example of particle size reduction More officially, the definition of particle size reduction is the micronization and milling process to generate a more consistent particle size 展开2023年2月15日 Generally speaking, the number of meshes × aperture (number of microns) ≈ 15000 For example, 60mesh particles are smaller than 40mesh particles, and 80mesh particles are extremely fine Therefore, the mesh 8 Facts About Particle Size That Will Blow Your Mind2019年7月15日 Lower mesh numbers means larger, coarser particles Higher mesh numbers mean the particles are more fine Grit is sized by passing it through a series of mesh sieves Sandblasting Grit Size, Microns, Mesh, Inches Conversion Chart2010年1月1日 Crushing is used to very quickly produce a fine powder from a bulk material or fine particle using mechanical crushing This technique is essentially used to investigate Mechanical Preparation Techniques SpringerLink

Everything You Need to Know About Frac Sand Sizes

4 天之前 At least 90% must fall within marketed mesh size standards to be considered acceptable All frac sand sizes need to be a specific uniform shape to have the proper structure and filtration capabilities The API RP 19c manual 2024年7月17日 Fine crushing: Utilize sand making machines, roll crushers, fine crushers or compound crushers in tertiary crushing to produce fine sand or powder 4 Capacity requirements Determine the hourly capacity needed Types of Crushers: Choosing the Right One for Each 3 天之前 The 40/80 mesh proppant has all the bells and whistles for hydraulic fracturing operations It passes strict American Petroleum Institute standards for acid solubility and crush strength, meaning less dust and fines, and topnotch The Complete Guide To Sand Sizes Pontotoc SandYou can only choose the right crusher if you know exactly what you want to achieve overall profitability depends on the balance between fractions and fines higher quality means more MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

High pressure grinding rolls HRC 8 HRC Metso

shape for concrete and asphalt sands They also produce more fines with fewer unwanted microfines in the final product compared to oMeshes range from 1 mesh to 800 mesh These screens are used to process bulk and powdered products Industry applications include food processing, pharmaceuticals, minerals, industrial sand, with screens to fit Tyler, Industrial Unified Screening Crushing2024年3月12日 Ultrafine grinding mill: Ultrafine grinding mill is a new type of grinding mill equipment with the characteristics of high grinding fineness, low energy consumption, and environmental protection This equipment can grind dolomite to more than 800 mesh, and is suitable for enterprises with higher requirements for crushing finenessWhat equipment is used to process 800 mesh dolomite powder?Hukki performed some simple crushing and grinding tests at his laboratory in Helsinki where he mapped the consumption of specific energy from a “large” size, roughly representing a primary crusher discharge, down to as fine a size as was easily achieved in his laboratory The result is shown in Figure 1Fine Grinding A Refresher 911 Metallurgist

Mechanical Preparation Techniques SpringerLink

2010年1月1日 Crushing is used to very quickly produce a fine powder from a bulk material or fine particle using mechanical crushing Skip to main content Advertisement If the starting sample is not longer than 500–800 μm, it is glued to the lower part of the Slices placed on the grid in this way adhere poorly to the mesh2021年8月31日 If you want to grind 800 mesh, 1000 mesh and 2000 mesh ultrafine powder, which kind of mill is more suitable? In the field of ultrafine powder processing, it seems that there are not many types of mills available You may hear more about air mill, so in addition to air mill, ultrafine mill is also more suitable for processing fine powderSuperfine Grinding Use Maintenance Eastman Rock CrusherA 100mesh screen has 100 openings per inch, and so on As the number indicating the mesh size increases, the size of the openings and thus the size of particles captured by the screen decreases Higher mesh numbers = smaller particle sizes It is very important to remember that mesh size is not a precise measurement of the mesh opening sizeMesh and Micron Sizes Chart ISM Industrial Specthese factors, the following factors also should be considered when planning for a new screen installation or a screen retrofit 1) Odors: Most fine screens today can be installed with enclosures, greatly reducing odor concerns in the headworks area Many screening systems offer a flanged connection on theScreening Considerations – A Guide to Selection

.jpg)

Crushing Products Size and Shape What to Expect

2016年2月26日 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Crushing Products Size and Shape What to Expect114 Crushing and classification include Jaw and Cone Crushers Secondary crushing can be by rotating surfaces such as swing hammer mills, for brittle materials, and roll crushers Finer grinding usually takes place in rotating vessels, such as ball and rod mills Very fine grinding, to sizes less than 10 µm,11 Crushing and classification3 天之前 There are a few different material sizes, including 40/70 mesh, 40/80 mesh, and 100 mesh The higher the number, the smaller the particles of sand will be For example, 40/70 mesh frac sand contains particles between 025mm to 06mm in diameter, while 40/80 mesh has particles ranging from 02mm to 05mm in diameterThe Complete Guide To Sand Sizes Pontotoc Sand StoneMineral aggregates for use in asphalt and concrete mixes are classified as coarse or fine Coarse sieve sizes include sieves with openings larger than 475mm (No 4), and fine sieve sizes are smaller than 475mm (No 4), ranging down to Sieve Sizes: A Guide to US and Metric Sizes

Correct mesh size a quick guide! Enterfea

2017年3月7日 Reduction of finite element size leads to more elements, which in turn leads to more nodes in the model If we build a chart showing the outcome (in this case first eigenvalue) dependence on node count in the model, this The term ‘Mesh’ is used to describe the size of an abrasive particle In some instances, such as with Aluminum Oxide Grit or Silicon Carbide Grit, a single number is usedThis does not mean every particle in that product is exactly that size but rather than mesh size indicator is approximately the mean or average size of the range of particles in that gradeMesh Size, Mesh to Micron Comparison chart Kramer Industries Inc2019年7月15日 Sizing specifications for abrasive grit are based on agreedupon particle size distribution for each mesh or screen size Lower mesh numbers means larger, coarser particles Higher mesh numbers mean the particles are more fine Grit is sized by passing it through a series of mesh sievesSandblasting Grit Size, Microns, Mesh, Inches Conversion Chart2019年3月1日 Foam concrete is a lowdensity controlled strength material that can potentially be used for accommodating different types of particles—recycled fine aggregate being an exampleCrushing Performance of UltraLightweight Foam Concrete with Fine

Evaluation of size reduction process for rock aggregates in

2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several mineralogical, physico 2022年1月1日 Finally, lines 5, 6, and 7 consist of primary jaw crushing, secondary and tertiary cone crushing, closed circuit HPGR and closedcircuit ball milling, wet magnetic separation, reverse flotation, further magnetic separation, filtration and concentrate regrinding in a HPGR to achieve a final concentrate with fine product size for pellet plant feed (Valery et al, 2019) (Fig Comminution and classification technologies of iron orethe measure of homogeneity can be accomplished with a process that creates large size reduction (crushing) where other samples for other processes will require reduction to fine particles (milling) Smaller particles and homogeneous materials are most often needed for many further laboratory sample preparation techniquesPrinciples of Sample Preparation by Grinding or Comminution2018年2月14日 A +200 mesh aluminum means that all the particles are retained on a 200 mesh screen How fine do screens get? That depends on the wire thickness If you think about it, the finer the weave, Call us at 18003727056 Join The Fireworks Club Sign up to receive our newsletter and exclusive discounts!Mesh Size and Micron Conversion Chart — Skylighter, Inc

Calcium Carbonate Grinding Mill Powder Modify

2022年5月5日 It can grind 100+ kinds of ores into a fine powder (1503000 mesh) drying, crushing, and grinding Common calcium carbonate production lines are inseparable from industrial grinding mill machines Common 2023年6月2日 This factor is critical in very fine mesh sizes used for polishing and finishing applications where consistency and precision are vital What is considered too coarse for one application may be too fine for another What is Diamond Mesh Size and how to select best 2016年3月11日 Where fine crushing should stop and grinding begin is controversial and is and 6 mesh are attainable The crushing action of the Gyradisc crusher results in circulating loads of less than 50 the capacity Crushing Plant Flowsheet DesignLayoutCrushing Crushing is generally considered to reduce particles, like large rocks and stones, Pulverizing is generally considered to be reducing product to a fine powder For instance, if you need coal, Pulverizing is typically defined as 25 mesh and beyond Mesh vs Microns Mesh size refers to the number of openings in one inch of screenParticle Size Conversion Chart Williams Patent Crusher

.jpg)

Pulversier grinding 400 mesh Mining Quarry Plant

2013年5月6日 KFL400 Plant Pulverizer 1discharging 60 mesh pulverizer grinding machines 100 mesh used for sale dolomite grinding up to 800 mesh plant ih india 1250 Mesh Pulverizer – mineral processing system Machine for sale2017年4月28日 Testing Plant Equipment: In order to determine, among other things, the operating conditions of the ballmill when working on this rock, a test mill of about 300 T daily capacity was erected at Duluth, MinnThe finecrushing plant contains a Hardinge 8ft by 22in (24m by 558cm) conical mill, a 6 by 27ft (18 by 82m)Ball Mill Grinding Theory – Crushing Motion/Action Inside2023年5月17日 1 Rough crushing: The large marble is fed into a jaw crusher for primary crushing 2 Fine crushing: Other types of mills can be used, such as ultrafine mills (fineness 80800 mesh) or vertical roller mills (fineness 3252500 mesh) Do You Need It? Hotselling Marble Crushing and Grinding Plants in Pakistan2024年2月10日 The article provides information about a set of three stainless steel fine mesh strainers that can be used in DIY projects The strainers are equipped with insulated handles and can be used for various purposes such as straining tea, coffee, powder, fry, juice, rice, vegetables, and fruits The article mentions the Rösle Stainless Steel Round Handle Kitchen Fine Mesh Sieve: The Ultimate Guide to Straining Efficiency

.jpg)

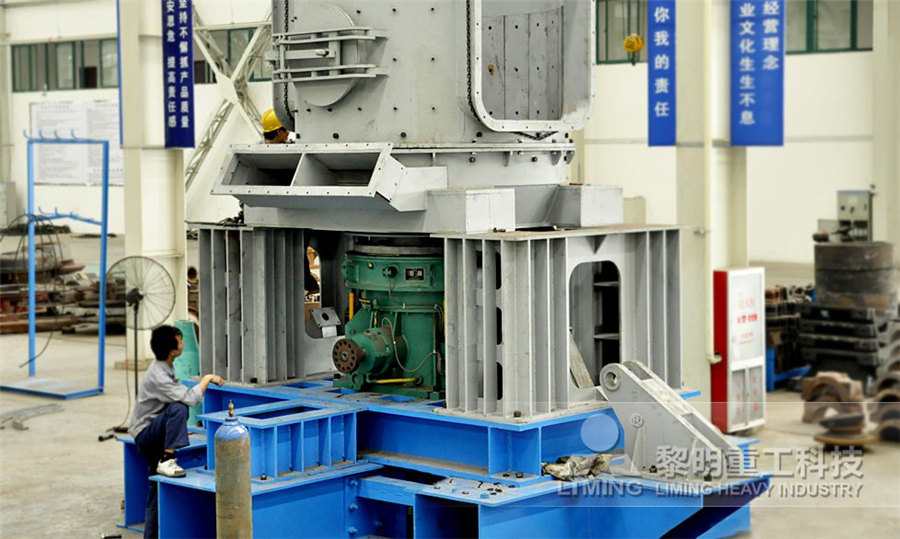

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Medium crushing: Employ cone crushers or impact crushers in secondary crushing to further reduce material into smaller particles Fine crushing: Utilize sand making machines, roll crushers, fine crushers or compound crushers in tertiary crushing to produce fine sand or powder 4 Capacity requirements Determine the hourly capacity neededStone crushing production line process flow The process flow of the gravel production line is roughly divided into: silo – feeding – crushing (primary crushing, secondary crushing, tertiary crushing or sand making and shaping)screening – transportation – sand washing – drying – Stone crushing production line2023年2月28日 The fineness of the limestone powder is between 80800 mesh Frequency control of powder concentrator achieves better fine powder classification effect The spring pressure device can not only increase the Necessary Matters About Limestone Powder Grinding2013年4月8日 Therefore, in the present study, a coarse mesh was generated in the global model analysis to calculate the displacement, and then, a fine mesh was generated in the submodel analysis with cut Effects of Mesh Density on Finite Element Analysis

.jpg)

Ore, Rock Aggregate Screening (Complete Guide)

2016年6月20日 Hole size of the mesh Hole size of the mesh determines the separation size and the sizes of screened particles Material throughput depends on the size of the hole Nominal screening capacity Nominal screening 2016年3月15日 Ball Mill Crushing by tubemills were first introduced into the crushing departments of cyanide plants when it was found that for crushing finer than 30mesh other types of crushing machinery were not efficient In order to crush with one pass, these mills were made 18 to 22 ft (55 to 67 m) in length Pebbles were used as a grinding medium and the mills Ball Mill Crushing 911Metallurgist2023年11月16日 In the realm of precision grinding, the choice of grit size in diamond and CBN (Cubic Boron Nitride) grinding wheels is critical for achieving the desired surface finish on a workpiece Whether working with hard materials like carbide and tungsten carbide or honing highspeed steel (HSS), the right grit size can make a significant difference in both the efficiency of A Guide to Choosing the Right Grit Size for Precision GrindingGoogle's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languagesGoogle Translate

Difference Between Fine and Coarse Aggregate Civil Engineering

The surface area of coarse aggregates is less than fine aggregates 6: Function in Concrete: The voids between the coarse aggregate are filled up by fine aggregate Coarse aggregate acts as inert filler material for concrete 7: Uses: Fine aggregates are used in mortar, plaster, concrete, filling of road pavement layers, etc2017年2月17日 When making comparisons of the efficiencies of different grinding and crushing machines it is desirable to be able to estimate the work actually done in crushing the ore from a given size of feed to a given size of product, the screen analysis of both feed and product being determined Messrs Klug and Taylor, in a paper on this subject, published in the monthly Difference between Crushing and Grinding 911Metallurgist2016年3月11日 Rittinger’s theory and law of the energy expended in crushing of rock is that the work of crushing is proportional to the reduction in diameter; or, as I have more fully expressed it: “The work done in crushing is proportional to the surface exposed by the operation; or, better expressed for this purpose, the work done on a given mass of rock is proportional to the Rock Crushing Theory and Formula using Kick Rittinger’s Law200 mesh woven wire sieve The ratio of the successive sizes of the sieves in the standard sieve scale is 2 In general, mesh number × mesh size in microns ≈ 15,000 For closer sizing work the sieve ratio of 24 is common The different standards in use are: American Tyler Series American Standards for Testing and Materials, ASTM E1101SIZE REDUCTION AND SEPARATION (4 TH SEM MINERAL ENGG)