Main production areas of desulfurized limestone

Recent advances in process and materials for dry desulfurization of

Common calciumbased desulfurizers include limestone, lime, traditional slaked lime, and highspecific surface area slaked lime The primary mechanism of these desulfurizers involves 2022年1月15日 Cordoba et al studied the characteristics of limestone, desulfurization byproducts and the flow direction of trace elements in the limestonegypsum desulfurization Summary of research progress on industrial flue gas Flue gas desulfurization gypsum (FGDG) is an industrial byproduct generated during the flue gas desulfurization process in coalfired power plants Due to its abundance, chemical and Recent advances in flue gas desulfurization gypsum processes and 2018年10月15日 according to the different raw materials of desulphurization Limestone / lime magnesium oxide method in me tal oxide are widely used The main contents absorption Comparison of flue Gas Desulfurization Technologies ResearchGate

.jpg)

(PDF) A Review of Desulfurization Technology using Limestone in

2015年10月30日 Limestonebased desulfurizing agent is one of the superior elements which are optimal at around 850950^ {\circ}C on high temperature desulfurization2023年7月29日 Surface analysis revealed that the SFGDA possesses a substantial specific surface area of approximately 7940 m 2 ∙kg −1, indicating its pronounced chemical reactivityAdvances on resource utilization of semidry desulfurization ash 2022年7月14日 The specific surface area, pore distribution, and other physicochemical parameters were analyzed by XRD and SEM, which explained the changes of products and Desulphurization mechanism and engineering practice of carbide 2021年1月14日 Comparative analysis of limestone sludge in recycled water and desulfurization limestone is made in the chemical composition, reaction activity, crystallization properties and Feasibility Analysis and Key Issues of Using Limestone Sludge in

A brief review on flue gas desulfurization gypsum recovery toward

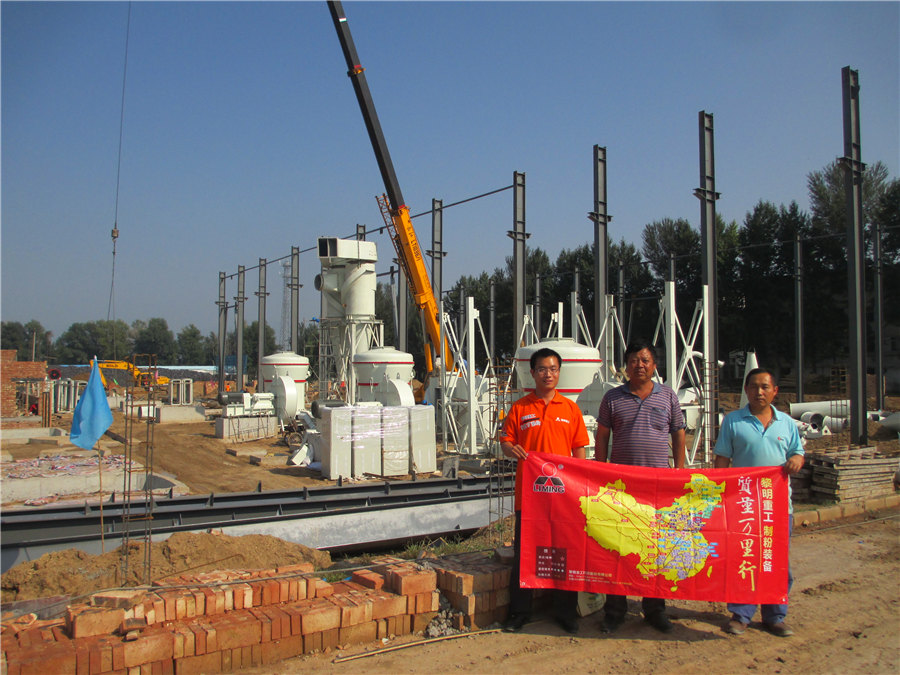

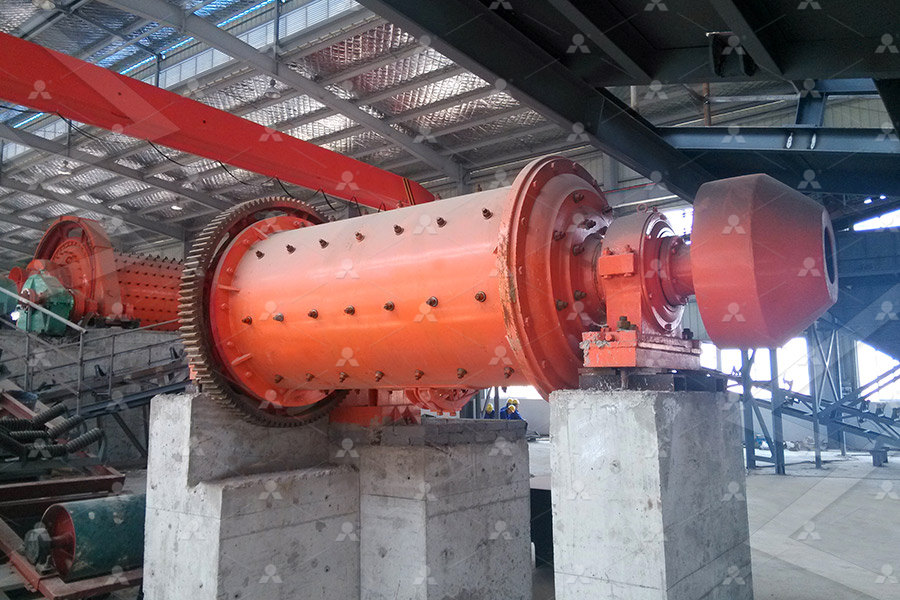

In addition, plants need large quantities of limestone as a desulfurizer Limestone mainly comes from mining, and the mining process causes significant damage to the regional ecological 2023年8月22日 Specifically, FGD gypsum production had lower energy consumption, CO 2 emissions, and water consumption per unit of material produced However, the study also identified areas for improvement, including reducing the amount of waste generated during FGD gypsum production [159]A comprehensive review of flue gas desulphurized gypsum: Production 2023年12月28日 Effect of Na2CO3 on production of NaHCO3 using desulfurized Na2SO4 d by comparing the area of Xray peaks around 2 θ = 303°, 315°, and 164°, which cor respond to the main peak (PDF) Effect of Na2CO3 on production of NaHCO3 Raymond limestone grinding mill plays a vital role in the preparation of desulfurized limestone powder The quality of Raymond limestone grinding mill directly Home; About Us Main factors affecting limestone desulfurization Limestone Raymond mill produces desulfurized

.jpg)

Summary of research progress on industrial flue gas desulfurization

2022年1月15日 In the industrial production of China, the processing of phosphate rock, volcanic eruptions, kerosene combustion and aluminum smelting will lead to flue gas emissions containing a large amount of SO 2SO 2 is a highly irritating gas Because SO 2 is freely soluble in water and enters the respiratory tract, it can generate corrosive sulfurous acid, sulfuric acid, and sulfate Usually, limestone (CaCO 3) and lime (CaO) are used as Ca(OH) 2 sources thanks to their abundance and low cost Due to its low solubility, limestone needs to be pulverized in order to be used in the FGD process, adding cost and energy expenditure to the process Kikkawa et al (2002) tried to scrub SO 2 from FGD without limestone size reductionRecent advances in flue gas desulfurization gypsum processes and Commercially, the term limestone includes dolomite, dolomitic limestone, oolitic limestone, and travertine (Dolley 2007), a porous calcitic rock that is commonly formed near hot springs The leading stone produced in the US, limestone accounts for 42% of total domestic productionLimestone Quarrying and Processing: A LifeCycle Inventory2004年6月30日 The lower Eocene (Ypresian) Sui Main Limestone (Sui Main) is the most prolific gas reservoir in Pakistan south of latitude 29°N It does not outcrop anywhere in PakistanSui Main Limestone: Regional geology and the analysis of

.jpg)

Development of slagbased filling cementitious materials and their

2024年11月2日 The carbon emissions from the production of desulfurized gypsum originate from net energy emissions during the production process, energyrelated carbon emissions from transportation, and nonenergy carbon emissions during production, with a carbon emission factor of 0237 kg CO 2 eq/kg [69] Furthermore, statistical data on the carbon emission factors for 2023年10月7日 In Malaysia, limestone is essentially important for the economic growth as raw materials in the industry sector Nevertheless, a little attention was paid to the physical, chemical, mineralogical STUDIES ON THE INDUSTRIAL APPLICATIONS OF LIMESTONE 2020年5月8日 Limestone is greatly used in the steel industry, specifically in the production process In this process, limestone is used for absorbing, and hence removing, impurities in the steel metals 4) Sewage Disposal System When 25 uses of limestone2019年3月18日 This paper details the main factors influencing the performance of limestone calcined clay cements (LC3) The kaolinite content plays a major role in the rheological properties as well as strength development Even in the presence of secondary phases, kaolinite can be accurately quantified by thermogravimetric analysis The performance of LC3 is slightly Impacting factors and properties of limestone calcined clay

.jpg)

Resource utilization of flue gas calciumbased Springer

2023年2月11日 Calciumbased desulfurization ash (CDA) is mainly produced in dry and semidry flue gas desulfurization processes The property of CDA is extremely unstable because its main component, calcium sulfite, makes it difficult to be directly applied to the field of building materials The modification of desulfurization ash can be realized by hightemperature Download scientific diagram Map of Pakistan showing main cement raw resources (limestone, shale/clay, gypsum), agrominerals (rock phosphate, gypsum), marble, construction, dimension and décor Map of Pakistan showing main cement raw resources (limestone 2021年7月15日 Three keywords (ie, industry, society, and limestone mining) are important to describe this chapter in continuation of the preceding chapter, which explained the mining or excavation process If we analyse the above three aspects, the relationships that existLimestone Mining, Industry, and Society SpringerLink2022年4月22日 standard (EN 197) limestone used as a main constituent in cement production shall meet the following requirements i) The Cacao 3 content shall be ≥ 75% by m assGeochemical Assessment of Antalo Limestone for Cement

Production and Performance of Desulfurized Rubber Asphalt

2017年2月1日 Desulfurized rubber powder and SBS were used as asphalt modifiers to study the rheological properties and performance of desulfurized rubber powder/SBS compositemodified asphalt (DR/SBSCMA)2021年7月1日 Currently, highgrade limestone with a CaCO3 content of 94 wt% or more is used to produce desulfurized gypsum with a purity of 93 wt% or more However, highgrade limestone resources are depleting Optimization of wet flue gas desulfurization system using recycled 2021年7月15日 Limestone is the main and essential raw material for number of industries, which include cement, iron and steel through modern approaches and innovative technologies in cementmaking processes or through the economy in raw material production cost Such limestone mining areas where cost could be minimized are referred to here as Excavation of Limestone SpringerLink2023年8月22日 This paper provides a comprehensive review of flue gas desulphurized (FGD) gypsum production, property, and applications in the construction industry In 2020, global FGD gypsum production reached an estimated 255 million tons, primarily in Asia (55%), followed by Europe (22%), North America (18%), and the rest of the world (5%)A comprehensive review of flue gas desulphurized gypsum: Production

VWHP IOPscience

2021年1月16日 the main components of the limestone sludge and desulfurized limestone, the pH value, the reactivity, the reaction crystallization performance, etc are analyzed and compared, and the research is applied to the wet flue gas desulfurization system of thermal power plant [2][3] 2 Production of limestone sludge in water2020年1月1日 This paper analysed and summarised the significant research outputs published on the environmental impact assessment of mining and mineral processing industries through life cycle assessmentA case study of the life cycle impact of limestone 2024年4月4日 Despite the prevalence of discharge of large volumes of heavymetalbearing seawater from coalfired power plants into adjacent seas, studies on the associated ecological risks remain limited This study continuously monitored concentrations of seven heavy metals (ie As, Cd, Cr, Cu, Hg, Pb, and Zn) in surface seawater near the outfall of a coalfired power plant Ecological risk assessment of heavy metals in desulfurized 2021年2月15日 Red mud (RM), fly ash (FA) and desulfurized gypsum (DG) are harmful solid wastes that need to be treated In this study, RM, FA, DG were used as the main raw materials to prepare road base materials based on the different (CaO + Na 2 O)/(SiO 2 +Al 2 O 3) molar ratio, and its mechanical properties, durability, microstructure and environmental performance were Preparation, characterization and application of red mud, fly

(PDF) Progress of Desulfurization and Denitration Technology of

PDF On Mar 30, 2019, Liu Xiaowen published Progress of Desulfurization and Denitration Technology of Flue Gas in China Find, read and cite all the research you need on ResearchGate2024年6月1日 The cement industry significantly contributes to global CO 2 emissions, with a notable portion attributed to limestone calcination during cement clinker production To promote carbonneutral building practices, alternative approaches are being explored to replace raw materials in cement manufacturing and mitigate CO 2 emissions Steelmaking slag, enriched Utilization of steelmaking slag in cement clinker production: A Download scientific diagram Map of Pakistan Showing main cement resources (limestone, shale/clay, gypsum), agrominerals (rock phosehate gypsum), marble, construction, dimension and décor stone Map of Pakistan Showing main cement resources (limestone, 2024年10月30日 Limestone, sedimentary rock composed mainly of calcium carbonate, usually in the form of calcite or aragonite It may contain considerable amounts of magnesium carbonate (dolomite) as well; minor constituents also commonly present include clay, iron carbonate, feldspar, pyrite, and quartzLimestone Characteristics, Formation, Texture, Uses, Facts

Changes in Soil Quality in Limestone Mining Area of Meghalaya

2017年6月1日 Limestone mining in East Jaintia Hills, Meghalaya, India is being carried out extensively for the production of cement Extraction of limestone is done mainly by adopting opencast method of mining2024年3月20日 Desulfurization wastewater is industrial wastewater with a high salt content, high metal ions, and high hardness produced by flue gas desulfurization of the limestonegypsum method in coalfired power plants This paper summarizes the source of desulfurization wastewater, water quality characteristics, water quality impacts, and other factors, combined Current Status of Zero Liquid Discharge Technology for MDPI2021年8月4日 The second pilot production of Limestone Calcined Clay Cement (LC3) was carried out in India A survey of several clay mines in Gujarat was carried out and a suitable clay was selected based on LIME CALCINED CLAY CEMENT (LC3): A Review2023年6月14日 Portland cement is one of the most used materials on earth Its annual production is responsible for approximately 7% of global carbon dioxide (CO 2) emissionsThese emissions are primarily associated with (1) the burning of fossil fuels to heat cement kilns and (2) the release of CO 2 during limestone calcination One proposed strategy for CO 2 reduction Structure and Properties of PortlandLimestone Cements

Advances on resource utilization of semidry desulfurization ash

2023年7月29日 The semidry flue gas desulfurization ash (SFGDA) is an industrial waste generated by the semidry desulfurization process, and its resources have been continuously attracted attention Through the method of heat decomposition, the SFGDA decomposed into CaO and SO2 has emerged as a prominent research topic This paper summarizes various of 2019年11月1日 The annual production of desulfurized ash from newly added byproducts in China is approximately 15 million tons, and it will accumulatively reach several billion tons by 2020 approximately [13], [14], [15] It usually contains calcium sulfite, dihydrate gypsum, calcium carbonate and unreacted calcium hydroxide [7]Utilization of lowquality desulfurized ash from semidry flue 2021年1月14日 limestone sludge is 1227% lower than that of the desulfurized limestone, and the reaction rate is low (3) The reclaimed water limestone sludge contains more elements than desulfurized limestoneFeasibility Analysis and Key Issues of Using Limestone Sludge in 2019年8月25日 Desulfurized ash contains about 2133% hemihydrate calcium sulfite, 1811% calcium carbonate, 2855% dihydrate gypsum, 2581% calcium hydroxide, 185% calcium oxide Particle size distributions of hemihydrate gypsum and desulfurized ash are given in Fig 1 A The specific surface areas of desulfurized ash and hemihydrate gypsum are 351 andUtilization of lowquality desulfurized ash from semidry flue gas

Potential for Selected Kenyan Clay in Production of Limestone

2020年4月14日 Moreover, the availability of volcanic ash is low compared to that of clays The present study aimed at investigating the potential of selected clays from Kenya for production of Limestone Calcined Clay Cement (LC 3) The cement is potentially affordable in Kenya due to low clinker content and abundance of raw materials such as clay and limestone2022年1月15日 In the industrial production of China, the processing of phosphate rock, volcanic eruptions, kerosene combustion and aluminum smelting will lead to flue gas emissions containing a large amount of SO 2SO 2 is a highly irritating gas Because SO 2 is freely soluble in water and enters the respiratory tract, it can generate corrosive sulfurous acid, sulfuric acid, and sulfate Summary of research progress on industrial flue gas Wet flue gas desulfurization, which is performed in many thermal power plants, has a high desulfurization efficiency and produces desulfurized gypsum as a byproduct Currently, highgrade limestone with a CaCO 3 content of 94 wt% or more is used toOptimization of wet flue gas desulfurization system using recycled 2020年9月10日 The gypsum decomposition and formation mechanisms of calcium ferrite are the main focus areas of theoretical research (Higuchi et al, 2016; Dilner et al, 2017; Zheng and Ning, 2013) related to desulfurization gypsumIn a study on gypsum decomposition, Zhang (Zhang and Ren, 2015) evaluated the reduction of CaSO 4 using coke as a reducing agent, and concluded The mechanism of preparation calcium ferrite from desulfurization