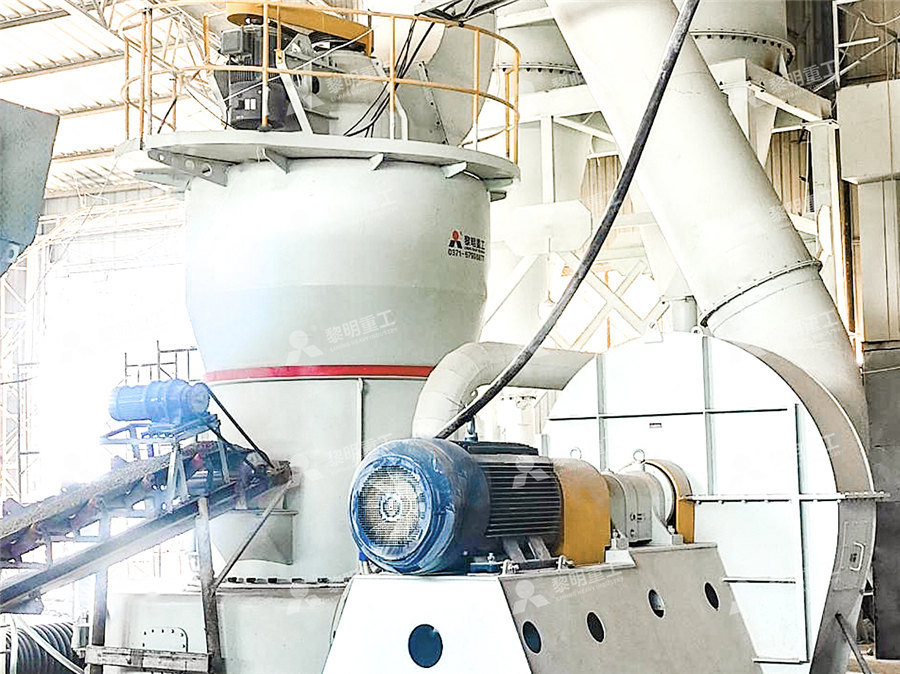

Operation skills of reverse raymond grinding method for phosphate rock

.jpg)

The importance of phosphate milling Bradley Pulverizer

Simply stated, the role of the mill in fertilizer processing is to crush/grind/pulverise the raw phosphate rock Typically, the aim is to reduce quarter inchsize crushed rock into fine particles to meet the required specification for downstream processing or acidulationThe major emission sources for phosphate rock processing are dryers, calciners, and grinders These sources emit particulate matter (PM) in the form of fine rock dust and sulfur dioxide (SO 1121 Phosphate Rock Processing US EPAMaintaining continuous production rates with minimal downtime across the variety of interconnected machinery is essential to profitable phosphate fertilizer manufacturing The Mill Optimisations for Low Grade Phosphate2024年10月4日 For this reason, reverse flotation is the preferred method for separating valuable phosphate minerals from carbonate gangue, selectively removing carbonates and silicates Evaluation and Optimization of Phosphate Recovery from Coarse

.jpg)

Waste rock reprocessing to enhance the sustainability of

2022年12月25日 This paper aims to discuss the available techniques for phosphate ore processing and their adaptability for phosphate mine waste rock and lowgrade phosphate 1998年3月5日 Development of technologies for phosphorus removal started in the 1950s in response to the issue of eutrophication and the need to reduce the levels of phosphorus Review: Phosphorus removal and recovery technologies2023年12月16日 This paper is aimed at studying and predicting qualitatively and quantitatively the industrial performances of four grades of mineral phosphates A, B, C, and D coming from Prediction and study of the industrial performances of phosphate 2014年1月1日 Calcination and heavy media separation practices for carbonaceous phosphate ores have been discontinued gradually, leaving fine grinding followed by flotation as the Comprehensive Recovery and Sustainable Development of

.jpg)

Review on Beneficiation Techniques and Reagents Used for

Many beneficiation techniques can be employed to upgrade the P2O5 grade of phosphate ores based on their characteristics in chemical composition and texture The flotation process is 2019年4月25日 Phosphate ore is an important raw material for manufacturing fertilizers and phosphorous chemical products While most of the phosphate resources cannot be directly treated as feed stock due to Review on Beneficiation Techniques and Reagents 1996年11月7日 Phosphoric acid (H 3 PO 4 ), which is the base material for the industrial production of phosphoruscontaining products, is produced from phosphate rock through both wet and dry processes (Al (PDF) Fundamentals of the WetProcess Phosphoric 2018年12月30日 168% of phosphate ore from operation B1, 942% of phosphate or e from operation B2 and 7378% of phosphate ore from operation C Whilst the phosphate ore of 22% P 2 O 5 will only be obtained by Optimization of blending operation for Aswan

.jpg)

7 Methods of Phosphate Beneficiation miningpedia

2021年12月28日 Flotation has always been regarded as the most effective method in phosphate rock beneficiation Phosphate flotation methods include positive flotation, reverse flotation, positive and reverse flotation, doublereverse flotation processes For the phosphate rock with a very fine particle size, the hierarchical flotation process can be used2021年9月1日 Estonia holds the largest unexploited sedimentary phosphate rock reserves in the EU Compared to other sedimentary and also igneous phosphate rocks the Estonian phosphorite is particularly Evaluation of Estonian phosphate rock by flotationPDF On Mar 1, 2018, B Li and others published Prediction of Future Phosphate Rock: A Demand Based Model Find, read and cite all the research you need on ResearchGatePrediction of Future Phosphate Rock: A Demand Based Model2010年1月1日 Phosphate ores are in high demand around the world because they are the primary raw materials used in the manufacturing of phosphatic fertilizers and other chemicalsEconomic preferences of mechanical activation over mineral

36.jpg)

Striving Toward a Circular Economy for Phosphorus: The Role

2018年9月8日 Equipment and methods for phosphate rock mining are usually very similar to those for coal mining Phosphates are mined either above the surface (ie, openpit, opencast mining), whereA method is disclosed for the manufacture of phosphoric acid directly from phosphate rock wherein the crushed phosphate rock is mixed with dilute phosphoric acid to form a slurry and the slurry is then heated to produce calcium monophosphate Thereafter, oxalic acid is added to the slurry to precipitate the calcium therein as calcium oxalate which is separatedMethod for manufacture of phosphoric acid from phosphate rock2022年12月25日 Phosphorus (phôs: light and phoros: bearer in Greek), which is an essential element for all life forms, is a major and vital nonrenewable resource (Elbendary et al, 2019; Sis and Chander, 2003)Phosphorus was discovered by Henning Brand in 1669 (Huminicki and Hawthorne, 2002)Phosphate rock is mainly used as a raw material for fertilizer manufacturing Waste rock reprocessing to enhance the sustainability of phosphate 2023年10月19日 The grinding process of a phosphate ore dressing plant generally forms a closed circuit with the classifier or hydrocyclone Phosphate rock grinding can adopt onestage grinding or stage grinding The number of grinding stages and processes generally need to be determined based on the characteristics of the phosphate ore, the requirements of the Grinding Methods for Four Kinds of Phosphate Ores Xinhai

Phosphate Rock: Origin, Importance, Environmental Impacts and

2016年6月24日 Phosphate rock (PR) is an important mineral resource with numerous uses and applications in agriculture and the environment PR is used in the manufacture of detergents, animal feed, and phosphate 2022年1月21日 To improve the sustainable management of phosphorus, numerous LCA studies, using primary data, have been conducted for phosphorus recovery technologies from wastewater, but not for phosphate rock miningThis article addresses this issue by conducting a cradle to gate assessment of beneficiated phosphate rock production using primary data This Cradletogate life cycle assessment of beneficiated phosphate rock 2010年2月9日 The two major methods to process phosphate rock are the wet method and the thermal method, each of which produces different products Fig 41 presents the two major processing methods for phosphate rock, their products, byproducts, and typical end uses of the products (Corbridge, 1995; Goldwhite, 1981; Yapijakis Wang, 2004)Phosphate Rock an overview ScienceDirect Topics2006年5月1日 For comparison, ash from phosphate rocks from Khouribga rock phosphate (Morocco) contained 33 wt% of P 2 O 5 (Kley et al 2003) while the chemical composition of the phosphate rocks provided by Chemical analysis of phosphate rock using different methods

.jpg)

The potential for mining trace elements from phosphate rock

2015年3月15日 Despite this potential, REE recovery as byproducts from the existing mining operations has been overlooked with only a few exceptions, including Bayan Obo in China, the world's largest source of 2000年2月1日 The midlow grade of phosphate ore, rich by the silicate and carbonate gangue minerals needs a special treatment using the flotation process Where the collectors play a pivotal roleReverse flotation of sedimentary calcareous/dolomitic rock phosphate 2023年8月30日 This blog will introduce the phosphate rock grinding process, equipment, and application You can learn about phosphate ore beneficiation methods Phosphate rock mill is the key to success and vertical mill Each mill has its unique features and advantages for grinding phosphate rock 1 Raymond mill Get Latest PriceHow Phosphate Rock Grinding Can Help You Succeed2017年1月9日 LOESCHE technology is at the heart of the plant, helping to develop the largescale phosphate rock deposit – the most important raw material for the production of phosphatecontaining fertilizers EuroChem selected a LOESCHE mill type LM 242, with the proven vertical roller mill technology, for the production of ground phosphateLOESCHE grinding plant LM 242 for phosphate rock successfully

Method for preparing yellow phosphorus from phosphate rock

1, the method that the purpose of this invention is to provide a kind of preparing yellow phosphorus from phosphate rock is P with grade 2 O 5 〉=17% Rock Phosphate (72Min BPL) is as raw material, adds silica and carbonaceous reductant, and mixing grinds, and adds entry again or/and the coal remix is pressed into agglomerate after evenly, inserts and carries out sintering Download scientific diagram Method for total phosphorus determination in phosphate rock from publication: Determination of mineral phosphate species in sedimentary phosphate rock in Mardin, SE Method for total phosphorus determination in 2020年8月1日 For the subject study rock phosphate was collected from Hazara area ground at 160 mesh level with 26% total P2O5 content for manual preparation of single super phosphate fertilizerStandardization of Single Super Phosphate Fertilizer 2019年2月18日 Enhanced Phosphorus Release from Phosphate Rock Activated with Lignite by Mechanical Microcrystallization: Effects of Several Typical Grinding Parameters February 2019 Sustainability 11(4):1068(PDF) Enhanced Phosphorus Release from Phosphate Rock

Beneficiation of lowgrade carbonated phosphate ore by reverse

2024年8月2日 The aim of this work is to develop lowconcentration carbonate phosphate from the Sra Ouertane region Indeed, the Sra Ouertane lowgrade phosphate ore needs an efficient process to remove the impurities, such as carbonates, silicates as well as clay minerals, to meet the requirements of the phosphate industries Froth flotation is considered as the prevalent Reverse flotation: The development of the beneficiation methods of phosphate with carbonatic gangue using reverse flotation involves carbonate recovery in the froth and phos phate recovery in the residue It can broadly be assigned to: • a search for a moderately selective collector with a phosphate depressant for an efficient or selective deReverse flotation of sedimentary calcareous/dolomitic rock phosphate SP, Brazil) Western phosphate rock, SRM 694, and trace elements in multinutrient fertilizer, SRM 695, from the National Institute of Standards and Technology (NIST, Gaithersburg, MD, USA) were the CRMs used to accuracy evaluation For the QCM production, 10 kg of phosphate rock (apatite) from Morocco, a commercial product purchasedPreparation and characterization of phosphate rock as quality phosphate rock, while the single anionic reverse flotation is preferred to beneficiate the calcareous phosphate rock A twostep flotation process, named directreverse flotation (Figure 2) or doubleReview on Beneficiation Techniques and Reagents Used for Phosphate

Phosphate Rock Processing Methods Xinhai

2024年4月16日 This method has the advantages of relatively simple operation process, no chemicals added in the entire process, and no environmental pollution The main process is to remove impurities on the mineral surface through water washing, and then screen out highquality phosphate rock step by step 03 Gravity separation for phosphate rock processing2017年1月9日 The LOESCHE mill is the technological heart of the new EuroChem crushing and processing plant for the production of ground phosphate in Zhanatas LOESCHE grinding plant LM 242 for phosphate rock LOESCHE grinding plant LM 242 for phosphate rock1121 Phosphate Rock Processing 11211 Process Description15 The separation of phosphate rock from impurities and nonphosphate materials for use in fertilizer manufacture consists of beneficiation, drying or calcining at some operations, and grinding The Standard Industrial Classification (SIC) code for phosphate rock processing is 1475 The 1121 Phosphate Rock Processing US EPA2019年1月30日 Phosphate ore is an important raw material for manufacturing fertilizers and phosphorous chemical products While most of the phosphate resources cannot be directly treated as feed stock due to the low grade of Review on Beneficiation Techniques and Reagents

The Blue Molybdenum Reaction for the Determination

2023年10月2日 Background: The ideal reaction conditions for the quantitative detection of phosphate in various natural water and detergent samples were carefully researched in order to produce and preserve the 2022年12月1日 The leaching of rare earth elements (REEs) from Egyptian Abu Tartur phosphate rock using phosphoric acid has been examined and was subsequently optimized to better understand if such an approach could be industrially feasible Preliminary experiments were performed to properly define the design of experiments Afterward, 24 full factorial design was Leaching of rare earths from Abu Tartur (Egypt) phosphate rock 2016年7月19日 he characterization of Sokoto phosphate rock for its beneficiation has been investigated and established 50 kg of blended Sokoto Phosphate nodules obtained from Fifty (50) Sokoto Phosphate ore Characterization of Sokoto Phosphate Rock for Beneficiation2023年10月13日 Introduction: Taking Yunnan Phosphate Group Co, Ltd Kunyang Phosphate Mine No 2 as the engineering background, this study aims to explore mining methods for deep ore bodies in phosphorus minesOptimization of mining methods for deep orebody of large phosphate

.jpg)

Phosphate rock formation and marine phosphorus

2011年8月1日 Phosphate rocks, also referred to as phosphorites, are sedimentary deposits with high phosphorus (P) concentrations These rocks are one of the primary ore sources for P (Fig 1), which in turn is a critical and nonrenewable element for fertilizer production, upon which global fertility dependsThe startling limitation of phosphate rock reserves has led to a renewed 2021年11月3日 Phosphate Rock Processing Process Phosphate ore processing and production processes mainly include three processes: crushing, grinding, and beneficiation In the crushing process, the threestage closedcircuit crushing is more modern and suitable for the crushing of highhardness phosphate orePhosphate Mineral Powder Grinding Mill SBM Ultrafine Sci, 2018, 8(2) Phosphate Rock Upgradation by Combination of Shaking Table and High Intensity Magnetic Separator: Ghari Habibullah, Pakistan Table 2: Geochemistry of Phosphate Rock from Hazara division Constituents L1(%) L4(%) L2(%) L3(GHU) (%) SiO2 23 30 20 40 Fe2O3 18 6 5 6 Al2O3 11 2 2 2 P2O5 278 15 28 2285 CaO 386 30 45 2315 MgO 028 2 1 3 F 27 1 08 1 Phosphate Rock Upgradation by Combination of Shaking Table 2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove impurities The eighth chapter of this book deals with mining and beneficiation of phosphate ore The principle and operating conditions of important Mining and Beneficiation of Phosphate Ore IntechOpen

The effect and mechanism of improved efficiency of

1 Introduction Phosphate rock (PR) is an essential raw material for phosphorus fertilizer production, an important strategic nonrenewable resources, is significant for the promotion of food production and sustainable agricultural development (Cordell et al, 2011; Schroder et al, 2011; Taheri et al, 2012) As the large number of phosphate fertilizer products were inputted in