Processing cement clinker

Clinker Production an overview ScienceDirect Topics

Clinker consists of calcium oxide and other mineral oxides (iron, aluminum, and silicon) and has cementious activity when reacted with water Clinker is produced by pyroprocessing in large 2023年10月16日 This study proposes a raw meal proportioning methodology for optimising coprocessing of natural feedstocks with alternative raw materials in clinker production, intending Thermodynamic modelling of cements clinkering process as a tool 2021年7月15日 Developing a dry production process for recycled cement will reduce the CO 2 emissions to only 13% of the clinker The cement industry is presently facing the demanding Comparison of energy consumption and carbon emissions from Cement production and concrete as building material The properties of concrete make it a primary building material where reliability and durability are required Depending on the application ~ Process characteristics of clinker and cement production SINTEF

Cement clinker Wikipedia

Cement clinker is a solid material produced in the manufacture of portland cement as an intermediary product Clinker occurs as lumps or nodules, usually 3 millimetres (012 in) to 25 Lowtemperature electrochemical cement clinker (eclinker) production is a promising technology for reducing carbon dioxide (CO 2) emissions in the cement industry This Perspective provides an overview of the process and the LowTemperature Electrochemical Cement Clinker 2014年1月1日 The main goal of the clinkering process is to produce the material of designed phase composition, which is called Portland cement clinker Under the action of high Portland Cement Clinker SpringerLinkThe main part of the manufacturing process of clinker takes place in the kiln The stages in the kiln phase are as follows: Evaporation of free water: A pressure above atmospheric is required Cement Clinker Manufacturing Process with Reactions

Optimization of the Clinker Production Phase in a Cement Plant

2020年9月9日 The most significant process of the cement production chain, in terms of energy efficiency and quality of the product, is represented by the production of the main component New types of cement clinkers are being developed that are chemically different from conventional Portland cement clinker In addition, sufficient access to biomass and nonrecyclable waste should be guaranteed for coprocessing in Our 2050 Roadmap The 5C Approach: ClinkerClinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color It is produced by heating limestone and clay to the point of liquefaction at about 1400°C1500°C in the rotary kiln What is Cement Clinker? Composition, Types Uses2019年1月3日 Clinker grinding technology is the most energyintensive process in cement manufacturing Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy Clinker grinding technology in cement manufacturing

.jpg)

Clinker Production an overview ScienceDirect Topics

They are mainly limestone, clay, slate, chalk, and marl The next stages of production are the preparation of raw meal and its calcination, and then the processing of clinker into a cement product (Fig 101) (‘ VDZ Environmental Data of the German Cement Industry’, 2019)2013年4月1日 The diameter of the grinding chamber D = 200 mm was the same as its length L The mill chamber was constructed of porcelain and the grinding body stock consisted of 133 corundum balls of 251 mm diameter and 11,500 steel beads of 49 mm diameterThe grinding stock formulation arose as a result of many years development of ultrafine cement clinker Efficiency of grinding stabilizers in cement clinker processing 2015年2月1日 Based on the data in Table 3, the processing energy demand for producing cement clinker using a microwave power level of 500 W and 2000 W are presented in Table 4 The composition of the clinker phase was based on a report by The British Geological Survey [27] and typical compositions of OPC cement clinker given by Taylor [28]Microwave processing of cement and concrete materials – Continuous high temperature process in the cement industry: Calcination and cement clinker burning Calcination of raw material CaCO 3 => CaO + CO 2 Process emissions of raw material: = 054 t CO 2 /t clinker Endotherm reaction at 950 °C ca 1700 MJ/t clinker ≈ 50% of energy Cement clinker burning at 1450 °C formation of hydraulicProcess characteristics of clinker and cement production SINTEF

.jpg)

An overview of alternative raw materials used in cement and clinker

2020年9月29日 Introduction Portland cement underpins modern global development As such, it is the most abundantly produced material in the world (Deolalkar Citation 2016)The world has an abundance of the primary raw materials for cement manufacturing and, compared to other construction materials, cement’s cost is low and it has good durability (Hewlett Citation 2003)2019年8月27日 The major raw materials used as a source of CaO for cement manufacturing are limestone, chalk, marl, etc These raw materials by virtue of their natural occurrence contains other mineral impurities eg, MgO, SiO 2, Al 2 O 3, Fe 2 O 3, alkali compounds, and sulfidesThese impurities play an important role to influence the cement manufacturing Cement Manufacturing and Process Control SpringerLinkThe clinker nodules are then cooled and stored for further processing Cement Production 1 Clinker Grinding: The clinker nodules are ground into a fine powder using a ball mill or vertical roller mill This process enhances the reactivity of clinker and allows it Cement vs Clinker What's the Difference? This vs That2024年1月20日 The wide use of multicomponent cement of highly reduced Portland clinker factor is largely impeded by detrimental changes in the rheological properties of concrete mixes, a substantial reduction in the early Novel Processing Methods of LowClinker Multi

.jpg)

Cement Production Process Cement Manufacturing

2020年8月25日 A full cement production process includes the cement crushing process, raw mill process, clinker process, and cement grinding process, cement packing process, and related process Find more! Skip to content +86 A number of phases are formed in the clinker feed before the burning zone proper is reached These intermediate phases dissociate in the burning zone and are not therefore found in clinker but assist in forming the final clinker minerals Reactions in the cement kiln clinkering2014年1月1日 This chapter is composed of five sections: 21 Portland cement clinker burning, 22 The phase systems important for cement chemistry, 23 The clinkering process in industrial mixes, 24 Thermochemistry of clinkering process, 25 Phase composition of PortlandPortland Cement Clinker SpringerLink2022年9月21日 The cement and clinker produced by indirect mechanosynthesis (15 min of mechanical activation and heat treatment 900 C or 1200 C) were characterizedCement and Clinker Production by Indirect Mechanosynthesis

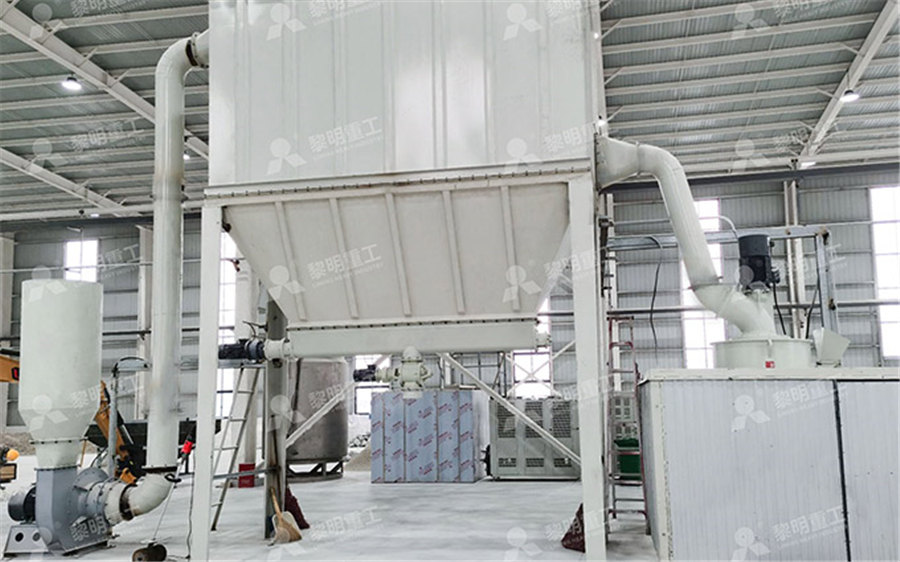

Clinker Production Clinker Manufacturing Cement

Cement Kiln In Cement Plant AGICO offers different types of cement kilns from 105000t/d with steady running, high efficiency and large output We adopt the most advanced calcination technology so that the production investment of clinker is small and the income is highGlobal cement production has reached 39 billion tons However, the clinkerization process, which is the basis of cement production, is responsible for an approximate annual global CO2 emission of 2 billion tons As part of CEMBUREAU’s 5C strategy, the European cement industry aims to achieve carbon neutrality throughout the cementconcrete value chain by 2050 This article is Cement and Clinker Production by Indirect Mechanosynthesis 2022年9月30日 In this paper we report the maximum potential for cement substitution with secondary materials to reduce CO2 emissions globally (13 Gt CO2eq in 2018) and on a countrybycountry basisCement substitution with secondary materials can reduce annual The use of alternative fuels in both combustion and production processes is known as coprocessing in cement manufacturing Waste is now being used to substitute primary fuel sources like coal, petroleum, and gas in the combustion process They are usually from combustible municipal waste, refusederived fuels, biomass, or nonhazardous industrial and commercial Sustainable Clinker and Cement Production by Using Alternative Fuels

Pyro processing cement kiln bypass dust : enhancing clinker

3 66 Cement production is on the rise and with it, the production of CBPD Further utilisation of 67 CBPD is therefore advantageous in order to minimise its negative influence over the 68 environment and the cost of landfilling The aim of the title study is to explore the pyro 69 processing of CBPD with/out additives for potential manufacture of lowcarbon cementFor example, there has been a significant increase in cement clinker and other raw materials prices, totaling $20 per ton due to the significant shift in its global market value Typically, the processing of raw materials and strict quality control throughout the manufacturing process of cement are in specialized cement plantsCement Prices – Historical Graph [Realtime Updates]Portland cement clinker was first made (in 1825) in a modified form of the traditional static lime kiln [2] [3] [4] The basic, eggcup shaped lime kiln was provided with a conical or beehive shaped extension to increase draught and Cement kiln WikipediaCement clinker alone is not suitable for use without further processing because it lacks the desired characteristics of a usable cement product The clinker needs to be finely ground and mixed with additives to achieve the necessary properties for construction applicationsCement Clinker: Types and Uses of Cement Clinker JK Cement

.jpg)

Modelling the cement process and cement clinker quality

2013年1月1日 Studies on cement production optimisation have been carried out on clinker simulation using AspenTech [36], cement raw materials blending using a general nonlinear timevarying model [37], cement 2014年4月30日 The solidification of heavy metals in cement kiln coprocessing wastes typically occurs by two processes, cement hydration and calcination There has been much research on the solidification theory of heavy metals as a result of hydration [9]In the cement hydration process, Cd is solidified by the formation of a mixed Ca/Cd hydroxide or Cd undergoes an Studies on the solidification mechanisms of Ni and Cd in cement clinker Reaction (1), the decarbonation of limestone, is the cause behind the largest source of CO 2 emissions in cement production Thus, reducing the amount of CaO in the binder results directly in a reduction of CO 2 emissions The second one is the hydraulic ability, or reactivity, of the phases that are present in the CaOSiO 2 system Besides the main oxides, CaO and SiO 2, in their Alternative Clinker Technologies for Reducing Carbon Emissions 2022年3月6日 In Peru, the GWP of the cement industry and the partial replacement of clinker with other additions, such as pozzolan, slag, and calcareous filler, has been studied using LCA methodology in bags of cement (425 kg) from 3 different plants, having results between 24–32 kg CO 2Eq/cement bag (425 kg); adapting this result to tons, it is 564–752 kg CO 2Eq/ton of The Environmental Profile of Clinker, Cement, and Concrete: A

A machine learning approach for clinker quality prediction and

2022年7月13日 A cement plant of our industry partner is used in this study As shown in Figure 1, the cement kiln takes the raw kiln feed and thermally transforms this into cement clinkerThis process uses multiple heat exchangers represented by four main production zones: a 5stage SingleString Preheater Tower, a PyroClon Calciner (Precalciner) and Tertiary Air, a KHD Pyro 31 Cement clinker production On an industrial scale, the coprocessing of sludge in cement kiln has been considered as a sustainable way to dispose sludge in China, and 65,000 tons of sludge had been successfully used in a new cement plant during 2008–2012 (Li et al, 2012)Cement Clinker Production an overview ScienceDirect Topics2023年3月29日 Reliability analysis of cement manufacturing technique in computerized clinker processing method March 2023; The work makes th e cement clinker calcinat ion handle more f easible by laying the (PDF) Reliability analysis of cement manufacturing technique in 2020年9月22日 In this Review, we first examine the environmental impacts of cement and concrete production, use and disposal We then look at potential areas for improvement, investigating what can be Environmental impacts and decarbonization strategies in the cement

.jpg)

(PDF) Characterization of Portland Cement Clinker by

Determination of Clinker Sample Phase Amount with Microscope Clinker phases % Alite C3S 5168 Belite C2S 1731 C3A+C4AF+Free CaO+ Alkaline Sulphate) 3101 In order to produce good quality cement clinker, the firing of From a cement performance viewpoint, faster cooling of the clinker enhances silicate reactivity The cooled clinker is then conveyed either to the clinker store or directly to the clinker mill The clinker store is usually capable of holding Manufacturing the cement kiln Understanding during the coprocessing of natural and alternative feedstocks for clinker production ˛e method comprises thermodynamic modelling and heating microscopy as tools for system simulation and Thermodynamic modelling of cements clinkering process as a tool Clinker substitution and novel clinkers The effort in reducing the amount of clinker in cement is progressing well and the clinker to cement ratio has been reduced to 76,4% The uncertain sustainable availability of clinker substitutes is the main constraint CEMBUREAU has projected the clinker to cement ratio at 70% by 2050Clinker Cembureau

Cement Clinker an overview ScienceDirect Topics

Report of UNEP SBCI WORKING GROUP ON LOWCO2 ECOEFFICIENT CEMENTBASED MATERIALS Ellis Gartner, Tongbo Sui, in Cement and Concrete Research, 2018 1 Introduction The term “alternative cement clinker ” as used here refers to a manmade mineral material that, when ground to a fine powder, is capable of reacting sufficiently rapidly with water and/or CO 2 10 alternative raw materials for cement manufacture [3, 4] Environmental concerns are also 11 promoting the development of lowercalcium clinker formulations, such as calcium 12 sulfoaluminate cement clinker which contain volatile species and involve gassolid reactions 13 not normally encountered in Portland cement (PC) clinkering [5]Thermodynamic data for cement clinkering White Rose 2021年11月17日 Coprocessing involves utilizing waste materials as alternative fuels and raw materials (AFRs) Their role in cement kilns, Three types of methods are used to undertake quality control of the raw materials, fuels, clinker, and Cement product 1 Chemical analysis, 2Fundamentals of Cement Chemistry, Operations, and Quality 2020年4月7日 The proportions of cement clinker phases produced by the pyroprocessing of a rawmaterial mix are often predicted through the Bogue equations, established in the 1930s; however, the Bogue Thermodynamic data for cement clinkering ResearchGate

.jpg)

Transformation and Characterization of Cement Clinker Prepared

2019年4月12日 The results show the transformation of CC residue into the effective components (Ca3SiO5, Ca2SiO4, Ca2FexAl2–xO5 and Ca3Al2O6) of the cement clinker The chemical composition, fCaO content and cement strength met the Chinese national standards Therefore, sintering CC residue provides a promising solution to the problem of red mud