Vertical mill suddenly stopped working during crushing

The Common Faults and Troubleshooting for Vertical Complex

The particle size is too big during the discharging of complex crusher First of all, should adjust the clearance between front and rear impact plates or replace worn liner plates and flat hammers; Moreover, should adjust the position of impact frame to achieve relative clearance between its 10 Difficult Problems about Raw Grinding with Vertical Roller Mill Systems and their solutions First : High vibrations Potential causes: Too many fines in mill feed Material bed on grinding 10 Difficult Problems about Raw Grinding with Vertical Roller Mill When vertical roller mill is in normal operation, its vibration is weak When the mill is vibrating strongly, it should be stopped and checked to ensure the equipment is working properly There may be some reasons for the excessive vibration, and How to Improve Grinding Efficiency of Vertical Roller 2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the (PDF) Performance Evaluation of Vertical Roller Mill

Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

2014年10月1日 The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operation2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimationVertical roller mill for raw Application p rocess materials2022年5月31日 Mineral crushing is the main source of energy consumption in mineral processing According to statistics, this consumption accounts for about 35–50% of the total cost of the mine (Curry et al, 2014), or even higherIt may also account for 18% of the global electrical energy consumption (NapierMunn, 2015)More efficient crushing equipment needs to be Analysis of vertical roller mill performance with changes in

Energysaving and Efficient Vertical Roller Mill Fote Machinery

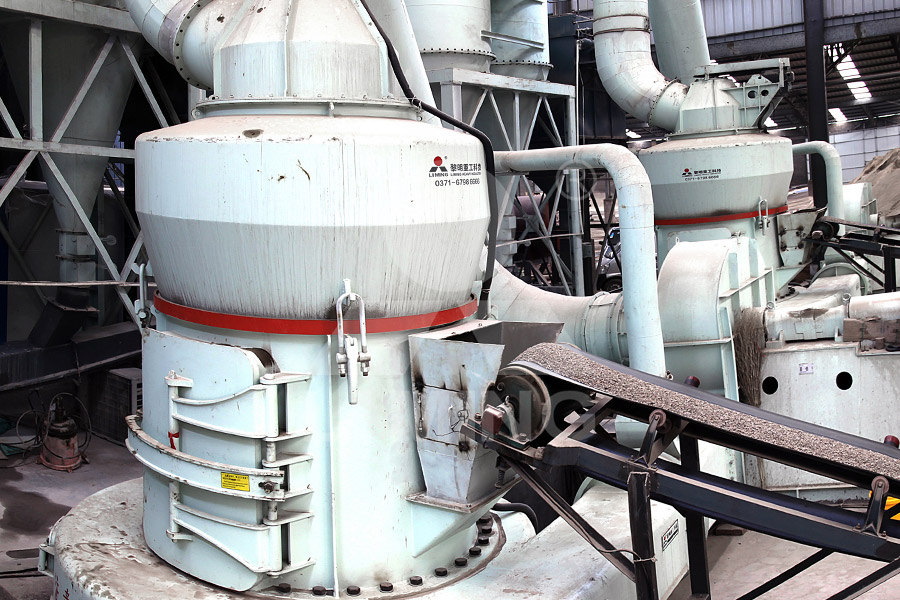

A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill 2017年4月1日 In the airswept mode, the verticalrollermill and a high efficiency dynamic classifier are suited above each other as a single unit (Fig 1) Material is fed to the grinding chamber and transported by table rotation to the grinding gap between the fixed grinding rollers and the mill table Crushing and grinding take place by compressive grindingOperational parameters affecting the vertical roller mill The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal Pulverization

Vertical Roller Mill PDF Mill (Grinding) Industrial

Verticalrollermill Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses vertical roller mills, which integrate crushing and grading into a single machine They provide efficient powder 3 Double PositionLimiting Technology Makes Operation More Stable In the CLUM series ultrafine vertical roller mill, the contact point between roller shell and millstone liner plate adopts electronic limiting technology and mechanical CLUM Series Ultrafine Vertical Roller Mill2024年9月25日 Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plantsWe can offer you a free design and completed solutions according to your project Baichy Heavy Industry has grown into a hightech mining equipment comprehensive enterprise, integrating RD, manufacturing, sales, Working Principle And Application Exploration Of Vertical Shaft Raymond Mill Working Principle In the Raymond mill, a Raymond mill spring with a pressure of 10001500 kg is fastened to the grinding roll hanger After starting work, the grinding roller rotates around the main shaft and rolls close to the grinding ring under the action of the Raymond mill spring and centrifugal forceRaymond Roller Grinding Mill Vertical Roller Grinding Mill

Numerical Investigation of Vertical Roller Mill Operation Using

2023年12月4日 A vertical roller mill is a grinding equipment for many industries such as minerals, cement, and ceramics It is also used to grind slag and nonmetallic ores The VRM decreases the number of equipment in the grinding circuit by combining the drying, crushing, grinding, and particle segregation in one unit Working principle and characteristics of vertical mill Working principle The working principle of a vertical mill involves the rotation of a grinding table with rollers attached to it Raw materials are fed into the table and ground between the rollers and table The ground materials are then blown by hot air through an outlet in the mill's Working principle and characteristics of vertical millCLUM series calcium carbonate ultrafine vertical mill, a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging, focusing on the largescale production field of nonmetallic mineral ultrafine powder processingCalcium Carbonate Ultrafine Vertical Mill SBM Ultrafine 2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical Compression crushing is also the main crushing mechanism in the VRM, but there is also shear force between grinding roller and particlesAnalysis of vertical roller mill performance with changes in

Performance Evaluation of Vertical Roller Mill in Cement

FIGURE 11 Comparison of measured and calculated data for Survey1 and Survey 2 PERFORMANCE EVALUATION STUDIES 80 In this part of the study, performance of the grindingVertical shaft impact (VSI) crusher is widely used for quaternary, tertiary, and secondary applications of crushing rock, cement clinker, quartzite, and concrete aggregate and especially for the sand making and road pavingVertical Shaft Impact Crusher AF Minerals Equipment2023年12月13日 Despite being a toptier video editing application, DaVinci Resolve 18 exhibits a few issues from time to time, including the crashing problem Although the issues can be solved in multiple ways, as mentioned 6 Fixes for the DaVinci Resolve Keeps Crashing Issue2014年8月25日 1 Usage and Maintenance of vertical roller mill Zenith vertical roller mill is totally different from the common hammer crusher, cone crusher and roller crusher in structure and working principle And it is also quite different Usage and maintenance of vertical roller mill PDF

}@~3SRDG`IA1KP_ICWAA.jpg)

Calcium Carbonate Ultrafine Powder Vertical Mill

In the calcium carbonate superfine powder vertical mill, the contact point between the grinding roller shell and the grinding disc liner adopts electronic limit technology and mechanical limit protection technology, which can avoid the destructive effects caused by machine vibration (such as the direct crushing of the grinding roller and the grinding disc) ( Such as the grinding roller 2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven QC tools2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of Operation parameters multiobjective optimization method of Vertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementVertical Roller Mill Summary

.jpg)

Crushing roller mill for the industry AMANDUS KAHL

The counterrotating crushing rollers are provided with a "sharp to sharp" corrugation and have different speeds so that a cutting effect is obtained instead of a crushing effect The speed of the rollers and the grinding gap can be adjusted during operation Our crushing roller mill WSB is very appropriate for grain and other feed components2017年9月1日 A potential increase of 10–20% in the throughput of a conventional cement grinding circuit (twocompartment dry ball mill in closed circuit with an airswept classifier), as well as potential energy savings in the whole clinker grinding circuit with the incorporation of a fine precrushing stage using a Barmac crusher, which may result in a lower capital investment Mathematical modeling of a vertical shaft impact crusher using This project is all about Hammer mill failure during flux crushing The Hammer Mill consists of roller; hammer beams and hammers type of configuration Each Hammer Mill consists of a hammers housing assembly The Hammer Mill housing assembly in turn, contains the rolls, guides, associated electrical components, oil lubrication, cooling water GLOBAL CEMENT: GRINDING Major vertical roller mill 2013年5月6日 A low cut in wind speed at 2 m/s at every position the central wind speeds of a Category 2 hurricane or cyclone vertical wind mill gusts and gyroscopic vertical gyroscopic cyclone mill Mining Quarry Plant

Analysis and Optimization of Grinding Performance of

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersVertical Roller Mill Brand SINOMALY Product origin Liyang, Jiangsu, China Delivery time 7 months Supply capacity 10800tph 1 The vertical roller mill is a highefficiency and energysaving grinding equipment widely used in Supply Vertical Roller Mill Customized Factory2021年6月15日 As the mainstream equipment for grinding powder processing, vertical mills have a direct relationship with the interests of enterprises in their production and operation links Vibration produced by the vertical mill not only Characteristics and Cause Analysis of Vibration in Compared with the ball mill system, the energy consumption of the vertical mill system can be reduced by 30% to 40% The vertical grinding mill does not have the metal impact sound of the steel balls colliding with each other and the liner in the ball mill, so the noise is low, which is 2025dB lower than that of the ball millIndustrial Vertical Grinding Mill

.jpg)

Vertical roller mill Hengtu Machinery

Brief description of vertical roller mill operation: The most basic reason why vertical roller mill is widely used is that it has low power consumption, and several units are operated in one machine, and it exhibits excellent operational flexibility and can produce various kinds of The different highquality products are now briefly described as follows:Therefore, when the vertical mill is operated, the control of the inlet and outlet dampers should be balanced by the kiln mill When the vertical mill inlet and outlet dampers are balanced, the system's wind will be balanced and will not affect the pressure at the kiln end Precautions for Starting and StoppingImportant Operation Tips For Cement Vertical Mill2021年1月12日 This problem is occurring on a system that was working for +1 years and suddenly stopped working last night Specs intel 10700 z490 asus agaming thermaltake 1200 gold 80+ psu rtx 2070 ( blower style because I committed a terrible sin by buying a prebuilt so I moved it to my new pc) [SOLVED] GPU suddenly stopped working mid game last night Read this indepth blog to learn about the working principle of Vertical Grinding Mill, its application, and its advantages +91 226796 9655 sales@macawberindia 130131, Hindustan The Vertical Grinding Mill working principle is simple and begins with the jaw crusher crushing the raw material to the required size The crushed material Vertical Grinding Mill: How it Works, Application And Advantages

.jpg)

PowerMill crashes during a closure with an error message

2023年10月8日 PowerMill has stopped working A problem caused the program to stop working correctly Please close the programHRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal Mill