Battery crushing and grinding equipment

Battery Crushing Machines Williams Crusher

Williams Patent Crusher designs and manufactures a unique line of industrial battery crushers to fit your battery recycling project From small batteries to larger vehicle batteries, our team can help you find the right machineStedman Machine Company offers highperforming, lowmaintenance hammer mills for escrap recycling for batteries and electronic scrap Contact us today for a quote!Battery Crushing Machines Stedman Machine CompanyThe waste lithium battery crusher uses a highspeed rotating hook knife and hammer to impact, shear and roll the materials entering the crushing chamber Finally, through the collision and Battery crusher machine Zhengzhou Quncheng Machinery Product introduction The machine is used for grinding waste lithium batteries (positive and negative material) Working principle The main structure of the machine is equipped with Grinding machine Zhengzhou Quncheng Machinery Equipment

.jpg)

GENOX RECYCLING TECH CO, LTD

The lithiumion battery crusher manufactured by Genox is specifically designed to crush lithiumion batteries into small pieces This crushing process can more easily extract valuable KERUI Machine’s Lithium Battery Recycling Machine specializes in dismantling and recycling various lithium battery types, including soft package, cellphone, shell, and cylindrical batteries Each type undergoes a unique recycling Lithumion Battery Recycling Machine – GongYi City Amey Engineers heavy duty shredders (SM and SM HD series) are ideally suitable for shredding mobile batteries and other E wastes Mobile phone batteries are shredded for volume Amey Engineers Mobile Batteries Shredder MachineThe STC Battery Breaking and Separation system is designed to treat lead acid batteries and to separate all the main components, each one with the lowest amount of impurities: Polypropylene chips ready for further upgrade to Battery Breaking and Separation STC

Grinding Dispersing NETZSCH Grinding Dispersing

Fine Grinding into the Micron and Submicron Range as a Service! Get to know the latest process technologies in the field of Grinding Dispersing Trends, knowhow, practical tips, dialog with experts and much more awaits for you2022年11月28日 The process equipment for crushing lithiumion batteries simplifies the traditional recycling process of positive and negative materials in waste lithiumion batteries It Process flow of lithium battery crushing and recycling equipmentOver the past few decades, battery crushing has become a major and important aspect of the recycling industry Batteries contain a variety of toxic chemicals that can contaminate soil or pollute water if disposed as waste and not recycled EScrap Hammer Mill Battery Crushing Machines2024年3月12日 The ultrafine grinding machine for dolomite powder has comprehensive mechanical crushing performance such as roller pressing, grinding, and crushing The equipment can form an independent and complete Dolomite Crushing Process And Grinding Equipment

Mechanical and physical processes of battery recycling

2022年1月1日 Mechanical liberation of LIBs can be distinguished into crushing the battery modules or cells, milling electrode mixtures, and grinding black mass The main purpose of crushing ( Section 311 ) in terms of automated cell opening is the liberation of the complex compound structure by breaking up the bonds between the individual components or materialsThe battery breaking and separation plant can be integrated with some optional units like: Battery precrushing unit (inline or with intermediate storage buffer); Metallic fraction separation of fine metallic fraction (fine grids) from coarse fraction (large grids, posts and poles); Polypropylene washing, grinding and extrusion line;Battery Breaking and Separation STCFuture Materials has crushing, grinding and classification equipment for various particle sizes ranging from cm to µm at its disposal After the crushing and grinding process is complete the sample could go through equipment to split the material into Crushing, grinding and classification Future Materials2019年2月15日 Measured specific mechanical stress energies for the crushing of complete battery cells are That is why the process chamber has to be sealed and equipped with appropriate dedusting equipment as figured out by Rumpf, 1976, Voller, 1983, Stamboliadis, 2002 Besides grinding fineness, the energy required for Crushing of large Liion battery cells ScienceDirect

.jpg)

Crushing Pulverizing Grinding Wear Resistant Technologies

Crushing, Pulverizing, and Grinding Components are essential to Wear Resistant Technologies Click here to learn how our products can help you Discover SaintGobain Performance Ceramics Refractories’ extensive range of costeffective wear resistance solutions for crushing, pulverizing and grinding componentsGrinder: For the grinding of the crushed materials Separation Machine: Separate the materials after being ground By adopting special processes and new designs, we provide WEEE recyclers with a complete set of used lithiumion battery crushing and sorting equipment to effectively and sustainably process used lithiumion battery wasteLithium Ion Battery Recycling LineProducts Henan Recycle Equipment 2024年6月19日 As a pivotal component in modern battery manufacturing, the selection of grinding balls holds paramount importance In this comprehensive guide, I delve into the intricacies of battery manufacturing and explore the critical requirements associated with grinding ballsFrom understanding their role to identifying key factors influencing selection and Battery Manufacturing and Grinding Ball Requirements2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as Crushing and Grinding Process JXSC Machine

.jpg)

China Leading professional mineral equipment

Henan Bailing Machinery Co, Ltd: As one of the China Leading professional mineral equipment manufacturers,we are mainly on jaw crusher, cone crusher, impact crusher, rotary dryer, flotation machine, ball mill beneficiation 2020年2月1日 Request PDF Enhancing cobalt recovery from Liion batteries using grinding treatment prior to the leaching and solvent extraction process The growing of cobalt demand for electric vehicle Enhancing cobalt recovery from Liion batteries using grinding 2023年5月5日 Grinding equipment is a type of mineral processing equipment that further reduces the ore particle size of crushed massive or granular ore to powdery material and gravel) and the impact, shearing, and grinding effects of ore In ancient times, the ore crushing and grinding operations were carried out by hard rocks and metal Grinding Equipment SpringerLink2017年2月17日 When making comparisons of the efficiencies of different grinding and crushing machines it is desirable to be able to estimate the work actually done in crushing the ore from a given size of feed to a given size of product, the screen analysis of both feed and product being determined Messrs Klug and Taylor, in a paper on this subject, published in the monthly Difference between Crushing and Grinding 911Metallurgist

How Does The Graphite Grinding Plant Process?

2024年9月20日 2 Impact crusher The impact crusher can process materials with a side length of 100500 millimeters or less, with a maximum pressure resistance of 350 MPA It has the advantages of a large crushing ratio and with cubic material particles This machine is widely used in building materials, ore crushing, railways, highways, energy, transportation, cement, mining, 2023年4月25日 A complete coppernickel sulfide ore processing production line is crushing, grinding, flotation, and tailings treatment 11 Coppernickel sulfide ore crushing stage Adopt a twostage closedcircuit crushing process ① Use a jaw crusher for primary crushing ② Use a cone crusher for fine crushing2 Types of Nickel Ore: Processing Methods and Equipment2019年11月1日 The South America grinding and crushing equipment in mining market size was evaluated to be $46784 million in 2018, and is estimated to be progressing at a CAGR of 443% during the forecast period of 20192025 The crushing equipment that includes products ranging from jaw crusher, cone crusher, and impact crusher to gyratory crusher is increasing rapidlyIncreasing Demand in Global Battery Market Driving the Growth 2014年7月1日 Lithium ion battery (LIB) is composed of valuable metals such as Li, Co, Ni and Cu, and less valuable metals of Al and Fe The toxic and flammable electrolyte, LiPF6, and organic solvents Recycling Technology for Lithium Ion Battery by Crushing and

A Comprehensive Guide to Lithium Processing Equipment

In the grinding and classifying stage of lithium ore, in order to ensure that lithium minerals are fully dissociated from gangue mineral monomers, a closedcircuit grinding and grading process can be adopted, and the firststage grinding equipment can use wet grid ball mills, rod mills, etcTable 1 General component of spent leadacid batteries Figure 1 Products after crushing and separating 2 Process description Figure 2 General diagram of automatic leadacid battery crushing and separating system 3 Main technical parameters of equipmentLeadacid battery crushing and separating systemAs a leading global manufacturer of crushing, grinding and mining equipment, ZENITH can offer advanced, reasonable solutions for any sizereduction requirements including crushing or grinding of quarry stone, aggregate and different kinds of minerals ZENITH can provide you the complete stone crushing and beneficiation plants Besides, standalone crushers, grinding mills and Crusher, Grinding Mills, Crushing and Grinding Equipment2021年4月20日 Lithiumion batteries (LIBs) have been widely used, since Sony manufactured the first commercial LIB that was comprised of a LiCoO 2 (LCO) cathode and a nongraphitic carbon anode in 1991 (Tarascon and Armand, 2001)Now LIBs are one of the most important energy storage devices, and they are employed as the power sources of mobile phones, A comprehensive review on the pretreatment process in lithium

.jpg)

5 Essential Lab Equipment for Crushing and Grinding Substances

2 Grinding Machines There are two common types of grinding equipment used in laboratories: vibratory mills and planetary mills Vibratory mills can grind samples to a fine powder and are available in different sizes and capacities Planetary mills are also used for grinding and can handle multiple samples simultaneously 3 Grinding Bowl2024年8月7日 Grinding Equipment: After crushing, grinding refines ore into a fine powder to liberate valuable minerals Key types include Ball Mills , which grind ore using steel balls in a rotating cylinder; Rod Mills, which use long rods for a coarser grind; and SAG Mills, which combine crushing and grinding for efficient processing of large volumes of hard materialsMineral Processing Equipment for Mining Industry2021年10月26日 Graphite Production Line Equipment Intro – Crushing Grinding Link The equipment configuration of the complete graphite powder production line is complicated, and the equipment selection can be planned and adjusted according to the actual production needs of customers, and the production line has a high degree of automationGraphite Grinding Machine Powder Mill EquipmentAt present, with the development of social green economy and the wide popularization and application of lithium batteries, a large number of waste lithium batteries are also produced Without correct, standardized and effective treatment methods, the potential hazards contained in lithium hexafluorophosphate, lithium carbonate, organic compounds, cobalt, copper and other Lithium battery crushing and recycling equipment

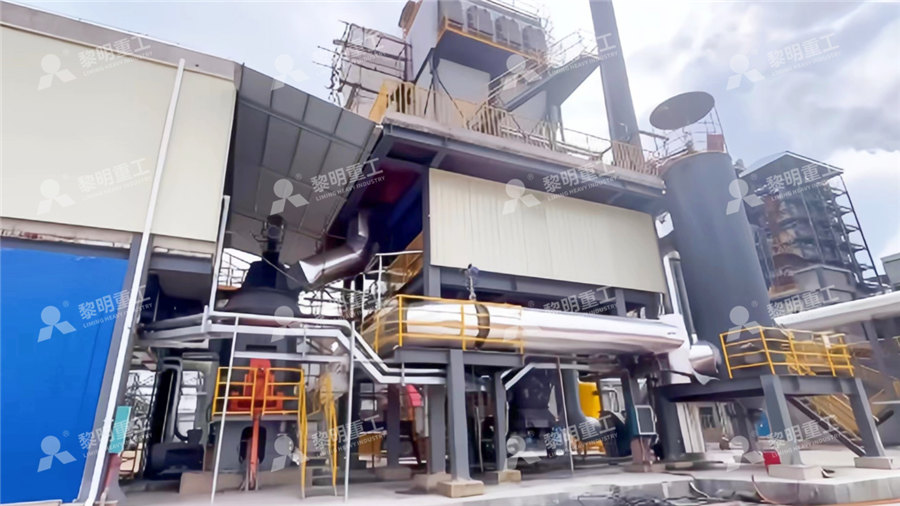

CFB石灰石脱硫剂制备96.jpg)

crushing and grinding machinery Italy europages

57 suppliers for crushing and grinding machinery Italy Find wholesalers and contact them directly B2B martketplace Find companies now!Wet Grinding Equipment for Pesticide Suspension: LONGLY Bead Mill and homogenizers The smart equipment covers nano new materials, electronic ceramics, batteries, biologicals, food the grinding media produces shear force, impact force, and crushing force getting the granular in the fluid crushed and dispersed, grinding Grinding Mill, Mixing Equipment/Machine, Dispersing MachineHigh hardness, can meet the vast majority of powder crushing and grinding needs with very low abrasion; WCCo grinding media balls with sizes from 2 mm to 20 mm are available to meet a broad range of requirements of planetary ball mills, 5mm Tungsten Carbide (WC) Balls for Grinding and Milling, 1kg– 2024年7月12日 EV Liion Battery Crushing Recycling Machine Time: 15:39:23 The separated valuable metals are further extracted by grinding, specific gravity sorting, electrostatic sorting and other deep separation techniques firstclass technical equipment and attentive aftersales service, EV Liion Battery Crushing Recycling Machine

.jpg)

Mining equipment and services FLS

Discover toptier mining equipment, machinery, and expert services at FLS As a premier provider in the mineral processing industry, we offer innovative solutions and unmatched expertise to enhance productivity From inpit crushing to ALPA Is Born For The Growth Of Ultrafine Grinding Customers ALPA is a wellknown provider of ultrafine powder solutions It has served 3000+ customers around the world and has actual operation experience of 100+EPC projectsALPA Powder Tech Specializing in the production and solutions Cathode material automated production line The entire production line include feeding and batching system, nanogrinding system, spray drying system, kiln sintering system, airflow crushing system, a screening and packaging system, Grinding Equipment Used In Battery Cathode Through processes such as shredding, drying, crushing, and screening, graphite powder, cobalt acid lithium, aluminum and copper can be separated from the lithium batteries The entire equipment set is designed with negative pressure, ensuring higher recovery rates, no dust pollution, and customization options based on customer requirements such Lithumion Battery Recycling Machine – GongYi City Kerui

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesWeifang Zhengyuan Powder Engineering Equipment Co, Ltd Home About Us Honor Manufacturing Center Patent Processing Machines Testing Center Lithiumion batteries materials solution Air Classifier Jet Mill Roller Mill Impact Mill a supersonic airflow is formed through the nozzle and injected into the crushing chamber, so that Zhengyuan Powder Equipment2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common equipment for lithium ore grinding is ball mill Onestage closedcircuit grinding and grading process can be adopted, and the onestage Ball Mill Is Indispensable For Lithium Ore Processing5 Ball mills are used for wet grinding iron ore, gold/copper ore, nickel ore and other ores, as well as lime/limestone for flue gas desulphurisation systems, coal and other raw materialsSIZE REDUCTION BY GRINDING METHODS By ResearchGate

Rock Crushers Pulverizers Williams Crusher

Once in the crusher, the material is broken down using a breaker plate and grinding chamber The reduced rock exits the crusher via a conveyor belt or is discharged into a hopper In some applications, primary crushing alone can suffice However, primary crushing is often followed by secondary crushing and tertiary crushingKey benefits More than 20 years of experience in providing marketleading lithium processing solutions Broad equipment offering and customisable solutions Full lifecycle partnership Cuttingedge technology Additional technologies not offered by other providers Bench and pilot testing facilities Superior pyro processing test facilities worldwideLithium processing technology Complete solutions that FLSmidth