Water cement crushing equipment

Cement Crusher Crushers for Cement Plant AGICO

AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher The hammer crusher is a kind of crushing machine which uses impact energy to crush materials It is mainly AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher The hammer crusher is a kind of crushing machine which uses impact energy to crush materials It is mainly Cement Crusher Crushers for Cement Plant AGICO 2017年6月24日 The fastrunning hammer or impact crusher is nowadays the most frequently selected machine to crush the limestone component of cement raw materials The maximum Everything you need to know about Crushers in Cement industryThe Rebel Crusher is the perfect compact mobile crushing screening machine Crush rock, limestone, brick, concrete, asphalt Made in the USA!Rebel Crusher For Sale Rebel Concrete Crusher RR

StrikeBar™ Crusher FLSmidth Cement

Reduce the effect of wear, lower impact crushing operating costs with the FLSmidth StrikeBar™ Crusher With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor operation, HAZEMAG’s concrete process knowhow, coupled with highquality reliable machinery and service, plays an important part in the crushing and processing of raw materials that ultimately CEMENT AGGREGATES HAZEMAG2019年10月30日 Common cement crushers include jaw crusher, cone crusher, impact crusher, and hammer crusher In recent years, mobile crusher is popular in the cement plant The raw material can be broken by extrusion, shearing, How To Choose Cement Crusher? Jaw Crusher, Cone 2022年10月31日 Using a crusher to eliminate oversize material can minimize plugging in loading spouts when filling trucks or railcars The Dual Rotor Crusher from Machine Process Design is made with heavy duty plate steel, robust Cement Crusher: Enhance Efficiency in Cement

.jpg)

Cement Crusher Crushers for Cement Plant AGICO

Jaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crushers are a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric power, water A brand of aggregate crushing equipment engineered via the voice of the customer: Liberty™ Jaw Three Cone Crushers Alliance® Low Water Washer; Cement Clinker, Chips, Concrete Rock, Cubicle Products, Fractured Crushing Equipment Superior Industries USConcrete Machinery offers you every solution to your concrete equipment project, from a fully automated batch plant, bagging operations, bulk cement silos, screw conveyors, and hoppers to truck mixers, cranes, lifting equipment to concrete Concrete Equipment Concrete MachineryAGICO supplies different cement equipment used in the cement production line, such as impact crusher to 40) so the crushing process can be simplified The threestage crushing can be converted into twostage or onestage crushing so that the equipment cost is reduced HOTSALE EQUIPMENT Cement Kiln Solution For Clean And Safe WaterImpact Crusher Impact Rock Crusher AGICO Cement Plant

.jpg)

Cement Extraction, Processing, Manufacturing Britannica

2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by 2024年10月14日 Here, you'll discover 11 stone crushing equipment needed for stone crushing, from primary crushers to fine crushers and conveyor belts 1 Jaw crusher Suitable for dry grinding stones that can react with water, like cement and marble, or products needing Valuable in arid areas to save water, What Machines Do Stone Crushing Plants Need? Fote MachineryWelcome to our New and Used Crushing and Screening Equipment Page View our range of Jaw Crushers, Cone Crushers Impact Crushers that will keep you crushing Marsay Equipment specialises in the buying, refurbishing and selling of new and used crushing equipment SADC region We have a vast network of suppliers and over 50 years in the industryCrushing and screening equipment, frontend crushing equipmentCement manufacturing equipment needs to withstand the heat and the abrasive material from which cement is made Making cement involves combining raw materials including limestone, clay, and shale, which are milled into a very fine powder after being mined These materials are then mixed with other ingredients according to their enduse This mixture is then fired in a kiln Cement Making Process: Equipment Manufacturing

.jpg)

Everything you need to know about Stacker and reclaimer systems

TO buy the Most Important Books in Cement Industry + more than 30 excel sheets related to cement industry • The stacker and reclaimer systems are designed for heavy duty operation and accept products from all types of crushing This function ensures that the machine can be adjusted without having to use programming equipmentThe Cement plant was specially designed and built for the South African market, easy to operate, where basic instructions can be followed and the manufacturing processes are not complicated The maintenance of the plant is also very easy and systems have been put in place to keep machinery running at all times Major refurbishments/upgrades have been made recentlyCement Equipment For Sale Concrete MachineryPrevious Post Next Post Contents1 Coarse size reduction of raw materials in Cement Industry11 Size reduction machinery and methods111 A Machinery for size reduction in the coarse range (crushers) by application of compression:112 B Crushers for size reduction by impact:113 C For comminution in the fines range (grinding mills) by application of impact:114 D Mills where Complete Lecture about Crushers in Cement IndustryTypes of Cement Kilns: Overview of wet, dry, semidry, and semiwet process kilns Components of a Cement Kiln: Detailed examination of the rotary kiln, preheater, precalciner, and cooler Kiln Operation and Optimization: Key Comprehensive Guide to Cement Kilns: Processes,

Everything you need to know about Cement Kiln Dust

Mineralogy From the Müller (1977) study of nearly 100 European CKDs, it was found that the dusts are particulate mixtures of four major components: (1) unreacted raw feed, (2) partially calcined feed and clinker dust, (3) free lime, Cement mills are sensitive to water, and water plays an important part in the production of cement, from the crushing stage through the mill equipment Water comes from a variety of sources, including surface water from rivers and lakes, ground water from borewells, rainwater gathered, and so on, all of which have varied water qualitiesWhat is the Role of Waste Water TreatmentStage 2: Grinding, Proportioning, and Blending The crushed raw ingredients are made ready for the cementmaking process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture The composition of cement is proportioned here depending on the desired properties of the cement Generally, limestone is 80%, and the remaining 20% How Cement is Made Cement Manufacturing ProcessIn order to control dust in crushing machinery, techniques such as water spraying and advanced dust management systems are used The use of these dust control systems such as water sprays can reduce the amount of dust by almost 90%, helping the air remain clean In this blog we’ll have a look at some of the latest innovations in crushing equipment dust control systemsInnovations in Dust Control for Crushing Equipment

.jpg)

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Different types of crushing equipment are used at each stage to meet various crushing requirements It is commonly used for fine crushing in small to mediumsized cement plants In sand making, it is renowned for its high sand production ratio (0–5 mm)2017年12月11日 Highlighting the importance of water treatment for cement plant A cement plant wastewater treatment system has to be highly effective in order to remove the minute particulate that remains after cement production This task becomes even more important when a closed system – the industry standard – is in place and the waste water is reused over and Water treatment for cement plant OEM Update2024年3月5日 Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader Find Crusher Aggregate Equipment from KINGLINK, METSO, POWERSCREEN, Seller: Northeast Rock Crushing 2001 KPIJCI K400 Crusher Aggregate Equipment Featured Listing View DetailsCrusher Aggregate Equipment For SaleCement producers are constantly pursuing innovative, efficient, and environmentally responsible ways of producing highquality cement to realize carbon neutrality across the concrete value chain by 2050 Take a look at how cement, the main ingredient in concrete, is madeHow Cement is Made Portland Cement Association

Quarrying In the cement industry INFINITY FOR

Quarrying In the cement industry Specific gravity, the standard being water 3) Detonation Pressure: The pressure immediately behind the detonation front 4) Energy: A measure of the potential of an explosive to do work dependent 100 Tons – (3 x Silos) Dimensions for transport purposes: 11m x 380 diameter Approximately 7Tons each Estimated 90000lts • Includes Load Cells ScreensCement Silos For Sale Concrete MachineryRoll crusher, also called roller crusher machine, is a kind of traditional crushing mill, mainly used for the middle and fine processing of raw material applied in cement plant, chemical industry, building materials industry, etcIt is usually Fourroll Crusher Roll Crusher AGICO Roller Crusher %PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources

Cement Production Process Cement Manufacturing Process AGICO CEMENT

2020年8月25日 As we all know, there are two elements to affect the quality and efficiency of the cement production line: cement production process and cement equipment Cement equipment refers to all equipment in the cement plant, such as cement mill, cement crusher, cement kiln, cement silo, cement preheater, etc2024年8月18日 On the other hand, buying is more costeffective than renting for businesses requiring frequent or longterm use of rock crushing equipment Direct purchase and flexible financing options are available to assist businesses planning to buy or rent a small jaw crusherRegardless of the option chosen, quality remains a critical aspect, and sourcing from Portable Rock Crushers for OnSite Crushing Certified MTP BlogPrompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, Water spray System distribution and wholesale of supreme quality cement mill water spray System High Velocity water spray System is a well designed water System Description VEL Henan Mining Machinery and Equipment Manufacturer Water The structure design of a hammer crusher We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores It is mainly composed of a transmission device, rotor, lining Hammer Crusher Working Principle AGICO Cement Plant

Impact crushers FLSmidth Cement

Specifically designed for the needs of cement plant operations, our crushing equipment delivers reliable, heavyduty performance Our range of impact crushers includes hammer and strikebar impact crushers, as well as dryer crushers – and the easytoinstall, longlasting wear parts to keep them running smoothlyFind quality used concrete mixers for sale at Concrete Machinery Contact us for brands, models, and prices for your construction needsUsed Concrete Mixer For Sale Concrete MachineryIndustry: Cement, Mining Type: Equipment; Gyratory Crusher The Gyratory Crusher is widely used in mining, metallurgy, chemical, building materials, water conservancy and other industries It is one of the main equipment for crushing Crushing Equipment Industrial Crusher ProviderPortland cement clinker is the sintered component in cement which is responsible for it curing with the addition of water As complex and customised as the process of making cement, are the systems and technologies that are required, but one common factor always remains in place: The raw materials require crushingCEMENT AGGREGATES HAZEMAG

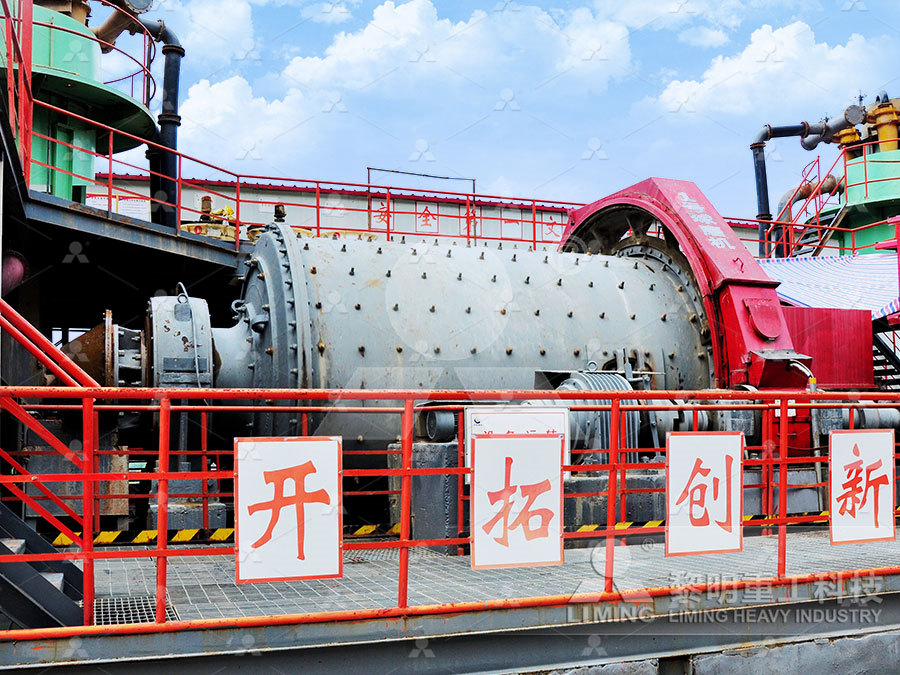

Ball Mill In Cement Plant Cement Ball Mill AGICO

Ball mill is the cement crushing equipment in the cement plant Compared with open circuit ball mill, the closedcircuit ball mill has high efficiency, high output, too much fine powder will increase the amount of water needed for cement Cement Kiln In Cement Plant AGICO offers different types of cement kilns from 105000t/d with steady running, high efficiency and large output We adopt the most advanced calcination technology so that the production investment of clinker is small and the income is highClinker Production Clinker Manufacturing Cement 2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw materials, homogenization of raw materials, clinker firing, cement grinding, etc Raw material conveying system The raw material, including limestone, 6 Cement Equipment For Dryprocess Cement Production LineThe moisture contained by cement raw materials can appear as: Free moisture, i e water appearing on the surface of the material particles Capillary water, e water filling the texture interstices of the material particles Adsorptionmoisture, e water which is adsorbed on the surface of the materialDrying of raw materials INFINITY FOR CEMENT EQUIPMENT

Brief Introduction of Jaw Crusher Productivity

Jaw crusher is an indispensable equipment in clay production line and an important material crushing equipment in cement plant Customer should choose a more reasonable choice of stone crusher equipment Below we will analyze 3 main aspects that will influnece working efficiency of jaw crusher Characteristics of raw materials(Jung, 1998; Brundick, 1998) When large volumes of water have to be evaporated, the gas temperatures at the mill inlet can sometimes be as high as 600°C The mill components exposed to the hot gas flow, “Crushing equipment from FLS,” Asian Cement and Construction Materials Magazine, June/July 1999, pages 1719 Flavel, M D, and Everything you need to know about cement Materials Preparation cement mill water spray system,cement mill separator,cement mill is the equipment used to to add a certain amount of water, cement mill with a water spray systems XSM (cement mill with a water spray systems) VM Mill is the best mining machineBall Mill for a variety of ores and other materials in the crushing millVM Millwater injection to cement millAGICO offers highquality Portland pozzolana cement plants and different Portland pozzolana cement equipment Skip to content Blog +86 REQUEST A QUOTE Just ask! Menu Cement Plant Solutions Cement Production Line; Stone Crushing Plant; Cement Grinding Unit; Fly Ash Processing The water requirement of PPC cement is large Portland Pozzolana Cement Manufacturing