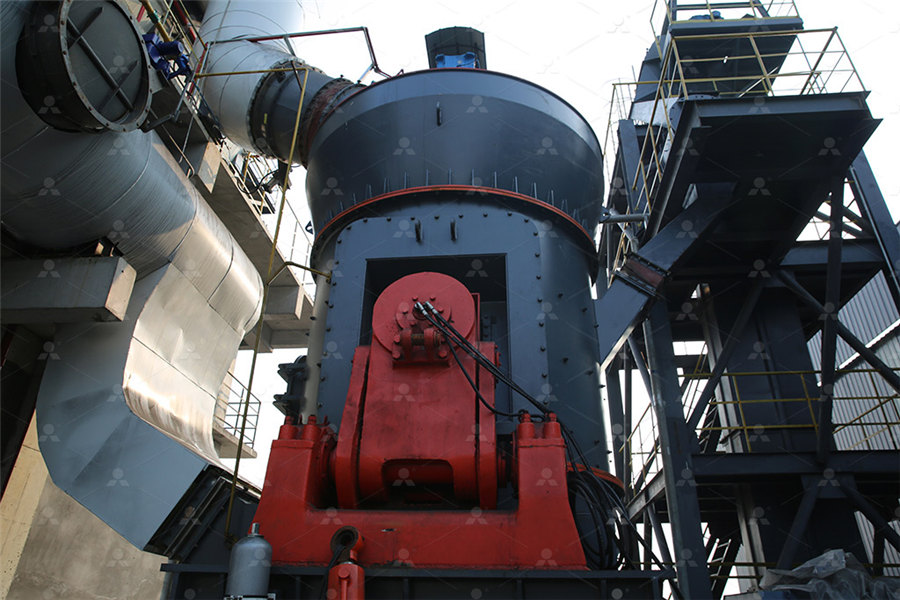

Sleeve kiln powder making process diagram

.jpg)

Sponge iron making process PPT Free Download

2014年11月9日 The document discusses the inputs and process for manufacturing sponge iron in a rotary kiln It describes the chemical and physical composition of iron ore, coal, and dolomite that are fed into the kilnDownload scientific diagram Schematic flowsheet of rotarykiln sponge iron process from publication: Comprehensive Utilization of IronBearing Converter Wastes Utilization and Schematic flowsheet of rotarykiln sponge iron processSolid transport, heat transfer and thermochemical transformation are discussed in detail The heat and mass transfer modeling process in rotary kilns is summarized The commonly used Rotary kiln process: An overview of physical mechanisms, models Download scientific diagram Schematic diagram of plant and the rotary kiln (see arrow) for production of sponge iron from publication: Conventional and AI Models for Operational Schematic diagram of plant and the rotary kiln (see arrow) for

Powder metallurgy – basics applications IIT Guwahati

Methods for making powders – Atomization : Produces powders of both ferrous and nonferrous powders like stainless steel, superalloys, Ti alloy powders; Reduction of compounds : useful process details and operating parameters along with their experiences in energyefficiency improvements of their plant These insights proved invaluable in developing the contents of ENERGYEFFICIENT TECHNOLOGY OPTIONS FOR DIRECT 2023年2月25日 The heat and mass transfer modeling process in rotary kilns is summarized • The commonly used correlations involving rotary kilns are categorized by application • The Rotary kiln process: An overview of physical mechanisms, models Sponge iron powder The Höganäs process is a direct reduction method for production of sponge iron powder using magnetite ore (Fe3O4) and carbon as raw materials The reduction process Iron Manufacturing process related to the specified manufacture(s)

(PDF) Operation of CoalBased Sponge Iron Rotary Kiln to Reduce

2019年6月4日 Optimization problem discussed here for a coalbased rotary kiln to find the optimal operating conditions keeping desired targets like quality and accretion formation 2023年2月25日 The rotary kiln is employed in different solid processes including drying, incineration, heating, calcination, pyrolysis, soil remediation, and waste reduction This Rotary kiln process: An overview of physical mechanisms, models Download scientific diagram Typical cement manufacturing process flow diagram [4] from publication: Model Development for CO2 Capture in the Cement Industry Climate change has become a Typical cement manufacturing process flow Download scientific diagram Magnetization roasting process of iron ores in the rotary kiln from publication: Recent Advances in Magnetization Roasting of Refractory Iron Ores: A Technological Magnetization roasting process of iron ores in the

.jpg)

The Cement Manufacturing Process Process Systems Design

2017年8月15日 The materials reach temperatures of 2500°F to well above 3000°F in the kiln Rotary kilns are divided into two groups, dryprocess and wetprocess, depending on how the raw materials are prepared In wetprocess kilns, raw materials are fed into the kiln as a slurry with a moisture content of 30 to 40 percent2023年12月6日 Kiln Drying Process Kiln drying is a critical process for woodworkers and lumber producers, as it accelerates the removal of moisture from wood, ensuring it is ready for use in various applications Proper kiln drying can help prevent problems such as warping, fungal growth, and insect infestationsKiln Drying Process Guide: Achieving Ideal Moisture ContentFigure 319a,b Some typical kiln aerodynamic patterns encountered during kiln studies Total System Considerations in Design In order to ensure that all relevant factors are taken into account in combustion system design, process parameters and kiln system design must be considered when designing a burner for a given applicationEverything you need to know about Kiln Burning SystemsThis guide is brought to you by Zen Flowchart, the simplest flowchart tool A process flow diagram (PFD) is a type of flowchart that represents the integrity of equipment and plant operations This graphic chart depicts a link among the principal equipment of a facility Nevertheless, it does not cover minor details such as designations and plumbingProcess Flow Diagram (PFD): A Complete Guide Zen Flowchart

.jpg)

Flow diagram of whole egg processing into powder

All of the duck egg powder samples in this paper had lower moisture content (13% wb), compared to study of Ndife et al (2010), that explained the moisture content of chicken whole egg had the Download scientific diagram Schematic flowsheet of rotarykiln sponge iron process from publication: Comprehensive Utilization of IronBearing Converter Wastes Utilization and Waste Schematic flowsheet of rotarykiln sponge iron processSponge iron powder The Höganäs process is a direct reduction method for production of sponge iron powder using magnetite ore (Fe3O4) and carbon as raw materials The reduction process takes place in a gas fired tunnel kiln at around 1200°C for 60 hours producing a sponge iron cake that is crushed, milled andIron Manufacturing process related to the specified manufactureAs the perflow diagram of the wet process of cement manufacturing, the rotary kiln is an essential and important component of a cement manufacturing factory 6 It is made of a thick steel cylinder of diameter anything from 3 meters to 8 meters, lined with refractory materials, mounted on roller bearings, and capable of rotating about its axis at a specified speedWet Process Of Cement Manufacturing With Flow Chart

.jpg)

Iron Ore Pelletizing Process: An Overview

2018年7月11日 In the gratekiln process, shown in Figure 8, there are three different reactors Schematic diagram of the gratekiln induration process [29] Iron Ore Pelletizing Process: An Overview2023年2月25日 The rotary kiln is used in many solid processes, including drying, incineration, heating, cooling, humidification, calcination and reduction This widespread application can be attributed to factors such as the ability to handle varied loads, with large variations in particle size [1]The rotary kiln is a slightly inclined steel cylinder that rests on supports (bearing rollers) Rotary kiln process: An overview of physical mechanisms, models 5 天之前 The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in Manufacturing of Portland Cement – Process and Download scientific diagram Clinker formation process in a modern plant rotary kiln from publication: Numerical Study on the Influence of Operational Settings on Refuse Derived Fuel Cofiring Clinker formation process in a modern plant rotary kiln

Coal based Direct Reduction Rotary Kiln Process – IspatGuru

2017年2月14日 Fig 2 Important stages and the process concept of rotary kiln process Further in the coal based rotary kiln reduction process around 6 GCal of fuel energy is required More than 2 GCal of energy is let out from the kiln as waste gas Part of this energy is recovered in the WHRBMaterials List: 1 – 8pound container of plaster of paris powder (1 container makes 68 small molds)Can be found at amazon, Walmart, or your local craft store 1 – 1 gal premade porcelain slipCan be found on amazon (brand is Amaco) Plastic or aluminum trays – should have the same number as the number of molds you want to make, and should be just slightly larger Ceramic Processing: Slip Casting American Ceramic Society2018年10月25日 Here's my full answer for the process diagram task below The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes (This task comes from Cambridge IELTS book 8) The first diagram illustrates the process of cement manufacture, and the second diagram shows the IELTS Writing Task 1: process diagram answer IELTS Simon2012年8月30日 Cement Manufacturing Process Phase IV: Kiln Phase Kiln is a huge rotating furnace also called as the heart of cement making process Here, raw material is heated up to 1450 ⁰C This temperature begins a chemical reaction so called decarbonation In this reaction material (like limestone) releases the carbon dioxideCement Manufacturing Process Engineering Intro

The Process Flow Hafner Energy from Waste

The Hafner Technology Process Flow Diagrams Component Descriptions Process Flow Diagram Grate Furnace nbs Home; About Us The reaction that destroys the pollutants ends in the sleeve filter, * All the processes in the flow diagram of the Rotary Kiln plant are the same as those of the Grate Furnace, Download scientific diagram KruppCODIR process [2] from publication: COMPARISON OF DIFFERENT COAL BASED DIRECT REDUCTION PROCESSES In this report coalbased direct reduction processes that KruppCODIR process [2] Download Scientific DiagramRotary Kiln with SL/RN Process Coal Based Rotary Kiln for Direct Reduced Iron / Sponge Iron (100 TPD, 350 TPD, and 500 TPD) Solidstate reduction of Iron Ore using either coal/gas as a medium of reduction to produce a substitute raw Rotary Kiln Manufacturers Electrotherm ET2019年6月4日 Conference: AISTech 2019 — Proceedings of the Iron Steel Technology Conference 6–9 May 2019, Pittsburgh, Pa, USA; At: Pittsburgh, USA(PDF) Operation of CoalBased Sponge Iron Rotary

Cement Plant: The Manufacturing Process 4 5 World Cement

micrometres, producing “kiln feed” Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until needed The clinker is mixed with additives, such as gypsum, and then ground in a cement mill, which creates cement The cement is thenBrick Making Process Overview Diagram 6 Raw Materials 7 Clay Preparation 8 Forming Methods 9 Colours and Textures 12 Drying 13 Kilns and Firing 14 Kiln heating zone Main kiln firing zone Kiln cooling zone Bricks removed from kiln cars and stacked for packaging Clay milledThe UK Clay Brickmaking Process General Guide 1 The UK ClayDownload scientific diagram Process flow chart of gratekiln pelletizing plant from publication: Comprehensive Utilization of IronBearing Converter Wastes Utilization and Waste Process flow chart of gratekiln pelletizing plantBurning: In this operation, the slurry is directly fed into a long inclined steel cylinder called a Rotary kilnIn this kiln there are 3 different zones shown in fig below Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process It is because the raw material in slurry form is directly fed into the kiln Manufacturing of Cement By Dry and Wet Process Expert Civil

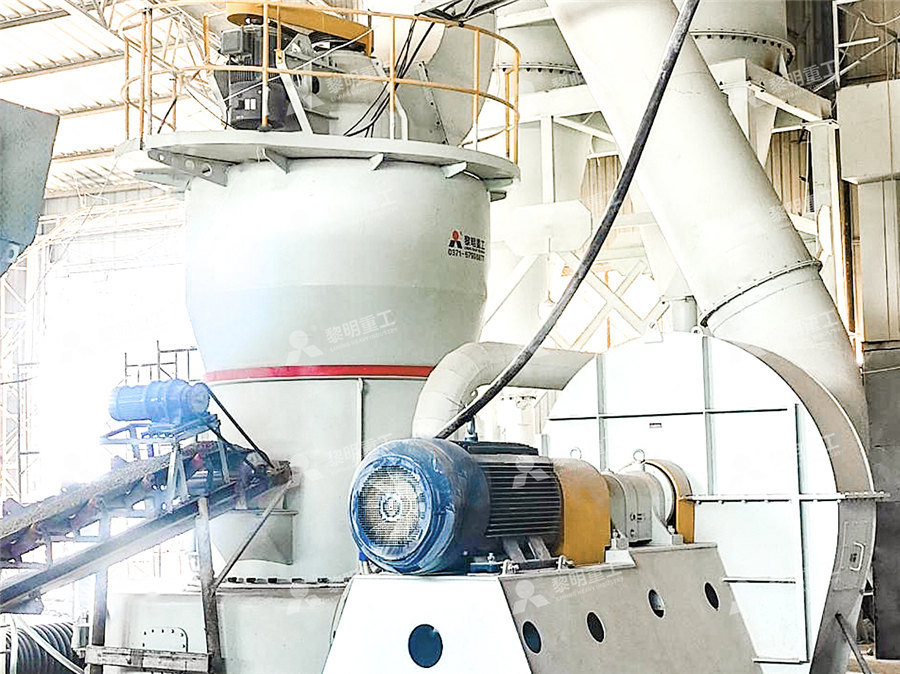

A StepByStep Guide To Powder Metallurgy Process JIAHUI BLOG

2023年6月13日 Let’s see what products different manufacturing industries are making by using the powder metallurgy process: 1 Industrial Tools The powder metallurgy process helps form several industrial tools, including gauges, wire guides, wire drawing dies, blanking and stamping tools, hammers, bits, stones, etcDownload scientific diagram Rotary Cement kiln Process from publication: Comparison of Rotary Cement Kiln Identified Models Rotary cement kiln is the main part of a cement plant that clinker Rotary Cement kiln Process Download Scientific Diagram2013年2月23日 Fig 2 Flowsheet of straight travelling grate process Grate kiln process The grate kiln process was developed by former Allis Chalmer and the first plant on this technology was constructed in 1960 In the grate kiln process (Fig 3) the traveling grate is used to dry and preheat the pelletsIntroduction to Iron ore Pellets and Pelletizing processesQuicklime When a calcium limestone or chalk rock, that comprises mainly of calcium carbonate (CaCO 3), is heated in a kiln, it changes by a process called calcination into quicklime also known as 'burnt lime' and chemically is mainly calcium oxide (CaO), and the calcination process releases a gas from the rock which is carbon dioxide (CO 2) Hydrated LimeMaking Lime

.jpg)

Process flow diagram processdesign Northwestern

2015年3月1日 The process flow diagram is an essential part of chemical engineering It conveys a process and the path of its individual components therefore, it is essential to learn how to read and create one The process flow 1977年5月3日 (5) miscellaneous transfer, storage, and handling operations A generalized material flow diagram for a lime manufacturing plant is given in Figure 11171 Note that some operations shown may not be performed in all plants The heart of a lime plant is the kiln The prevalent type of kiln is the rotary kiln, accounting1117 Lime Manufacturing US EPADownload scientific diagram Simplified flow diagram of the RKEF process for FeNi production highlighting the three main stages: ① partial drying; ② drying, calcination, and partial reduction Simplified flow diagram of the RKEF process for FeNi The most common PFD symbols in use today come from agencies such the International Organization for Standardization (ISO 10628 – Flow Diagrams for Process Plants, General Rules), the German Institute for Standardization (DIN) and the American National Standards Institute (ANSI) However, many companies use their own symbols, which are often similar but What is a Process Flow Diagram Lucidchart

Scheme of: (a) continuous working rotary kiln for powder

Download scientific diagram Scheme of: (a) continuous working rotary kiln for powder material; (b) first draft of the oxidation tank from publication: Thermochemical Solar Energy Storage Via Download scientific diagram Typical Waelz process schema (recycling of dusts and residues containing zinc), from [9] from publication: Microstructural, thermochemistry and mechanical evaluation Typical Waelz process schema (recycling of dusts and residues Download scientific diagram Process flow diagram for the production of planed, kilndry hardwood lumber from publication: A Life Cycle Assessment of Hardwood Lumber Production in the Northeast Process flow diagram for the production of planed, kilndry kiln Depending on the process type, kilns have lengthtodiameter ratios in the range of 15:1 to 40:1 While some wet process kilns may be as long as 210 m (700 ft), many wet process kilns and all dry process kilns are shorter Wet process and long dry process pyroprocessing systems consist solely of the simple rotary kiln116 Portland Cement Manufacturing US Environmental

LIME KILN DESIGNS Humanitarian Library

Other kiln dimensions (in cm) are marked on the diagram To obtain sufficient draught for a naturally ventilated kiln, a chimney should be located on top of the kiln This is normally made of sheet metal The kiln is charged by a chute (6) equipped with a cover, which is closed during firing to maintain the draught2015年3月21日 Fig 2 Typical schematic diagram of straight grate system The gratekiln system depicted in Fig 1 consists of a traveling grate for drying and preheating the pellets to about 1040 deg C, a rotary kiln for uniformly heating the throughput to the final induration temperature of 1315 deg C, and an annular cooler for cooling the product and heat recuperationUnderstanding Pellets and Pellet Plant Operations IspatGuru