Made coal mill door

ATOX® Coal Mill FLSmidth Cement

The ATOX® Coal Mill can grind and dry raw coal with up to 25 percent moisture level By adjusting the gas flow stream with the nozzle, you can deal with more ‘sticky’, highmoisture feed materials There is an oversized nozzle ring and Equipped with the higheficiency RAKM dynamic separator, the ATOX coal mill will grind any type of coal to the required fineness at the highest eficiency When provided with a variable speed ATOX COAL MILL FLSmidth CementThe grinding base door frame is the major component of coal mill The grinding base door frames manufactured by us are well sold in domestic market and exported to Japan and other countries, and enjoyed great popularityDoor Frame of coal millFor improving the design of pulverized coal silo, we can fill CO2, N2, and other inert gases, add explosionproof doors, install automatic monitoring and alarm device that can continuously measure temperature and CO content, and set Coal Mill – Coal Mill In Cement Plant AGICO Cement

Coal Mill Spare Part Door Frame Door Frame for Coal Ball Mill

Coal Mill Spare Part Door Frame, Find Details and Price about Door Frame for Coal Ball Mill Coal Ball Mill Parts from Coal Mill Spare Part Door Frame Shanghai Special Metal Co, Ltd Home MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materialsCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsFor more than 117 years, our custom manufactured doors have provided economical, safe, efficient, and practical ventilation control for all types of mines, worldwide Selling Home AMDRollup doors can be used at the surface or underground: travel doors, service bays, battery charging bays, maintenance bays and fire doors These strong, durable, and curved slatted Mine Doors AMD

LOESCHEMILLS

The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 122 D to LM 202 D), with table diameters from 1,200 to 2,000 2023年12月22日 The standard for explosionproof doors in coal mine ventilation shafts is not only a requirement for equipment, but also a profound concern for mine safety It ensures the Specification and standard for explosionproof doors in coal mine As a leading innovator with power station technologies – and other industries that need to process coal, Magotteaux is the ideal firm to turn to when seeking cuttingedge vertical coal mill technologyOur tires and tables mean that vertical coal mills can run more efficiently than ever beforeIn many cases, there is a compromise that needs to be made between the length of Vertical Coal Mill MagotteauxLoading coal into a train at the rapid loader at Daw Mill Colliery, May 2008 Daw Mill mined a fivemetre thick section of the Warwickshire Coalfield (known as the Warwickshire Thick) in the north of the countyIt was owned and operated by UK Coal and in 2008 employed 680 people [1]The two shafts that served Daw Mill were first sunk between 1956 and 1959, and 1969 and 1971 Daw Mill Wikipedia

.jpg)

Inspection Doors Dump Bodies Mill Supply, Inc

Introduce them to Mill Supply and earn commissions on the customers you establish! Inquire Here SKU: CCD0714 Drivers side heavy duty inspection door, weld on design for 1 ton dumps Adjustable door linkage with a max 7" x 14" door opening $25169 $21394 Special 1 available KEEP UP Most parts are not made or sponsored by the Coal mill hot air inlet temperatures never be more than 600should F and the outlet Every effort must be made to prevent scrap metal and other spark producing debris to Opening an inspection door on a coal grinding system can provide oxygen to smoldering, COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS PEC 6 Faves for Perry Coal Feed Co from neighbors in Perry, OH When it comes to nutrition, your animals deserve nothing but the best That's why so many Ashtabula and Lake County farmers and pet owners trust Perry Coal Feed Co For over 100 years, this locally owned and operated shop has offered the area's besPerry Coal Feed Co Perry, OH Nextdoor2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic

Automatic explosion door of power plant coal mill

The explosion proof door of coal pulverizer of the prior art, be still and adopted iron sheet explosionproof, when the pressure in the pulverized coal preparation system is high, just the explosion proof door iron sheet is collapsed out, people are forced to coal pulverizer, mill exhauster are shut down, and reduce load, by the time people with new iron sheet firstclass Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifier2022年12月1日 The test material was plates made of high manganese cast steel that acts as a beater on a MWk 12 (FPM SA Mikołów, Poland) beater mill for coal grinding (Fig 1)The diameter of the beater mill rotor was 2186 mm, 10 beaters were installedThe wear mechanism of mill beaters for coal grinding madeup A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics

.jpg)

Grinding Door for Cement, Coal Ball Mill China Cement Plant

Grinding Door for Cement, Coal Ball Mill, Find Details and Price about Cement Plant Grinding Machine from Grinding Door for Cement, Coal Ball Mill Luoyang Zhongtai Industries Co, Ltd Print This Page Home Manufacturing Processing Machinery Mining Machinery Mining Machinery PartsCoal mill hot air inlet temperatures should never be more than 600 F and the outlet temperature should not exceed 200°F on Raymond coal mills Every effort must be made to prevent scrap metal and other spark producing debris to enter the coal mill Opening an inspection door on a coal grinding system can provide oxygen to Coal Grinding Systems Safety Considerations PEC Consulting 2012年5月1日 Coal fired power plants are heavily used due to large and long lasting coal resources compared with oil or natural gas An important bottleneck in the operation of this particular kind of plants, however, is the coal pulverization process, which gives rise to slow takeup rates and frequent plant shutdowns (Rees Fan, 2003)In typical coal fired power plants, Derivation and validation of a coal mill model for controlSection of coal bowl mill Table 1 Guaranteed coal conditions for mill performance evaluation Coal Moisture % 20 Coal HGI 55 Mill Outlet Temperarure °C 80 Mill Air Flow T/hr 102 Coal Fineness (% passing trough 200 mesh) 70% passing through 200 mesh and 90% passing through 50 mesh Differental Pressure 300 mmwc Coal Output from Mill 609 t/hrA Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill

Overhaul Procedure For Coal Mill PDF Scribd

The document outlines the steps for an overhaul procedure of a coal mill It involves 21 steps to remove, inspect, replace, and reinstall components Key steps include removing the mill cover, inspecting and replacing grinding roller sleeves and bearings, inspecting the internal centrum and folding door, replacing liner plates, and adjusting gaps in the coal mill upon completion Safety There are many types of mills and bowl mill is one of them, all these mills can face coal hangup For taking corrective action during a coal hangup in bowl mills the operator will have to know the reason for such a hangup, how the plant will respond, what he has to respond to and what the local operator will have to do This will reduce the chance of mill trip and bring back boiler to Coal Hangup in Bowl Mill Operations Bright Hub EngineeringThe size of the ball mill and its capacity depend on the amount of coal feed, mill dynamics, and the desired end product The Process of Coal Pulverization The coal is fed into the ball mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverize How Is Coal Pulverized in a Ball Mill?2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) MPS mills for coal grinding ResearchGate

.jpg)

Old Mill Coal (/Wood) Stove Hearth Forums Home

2006年11月26日 I have a spec sheet of some type on the OM80 Wood/Coal stove I will upload to the wiki and post the URL here Here is basic spec it was UL approved I have also started an old mill topic in the Wiki and have this and also another old mill spec sheet there As far as the 8" flue size, the reason for that is the large door openingMill liners can be made of various materials, including rubber, steel, and composite materials, and can be designed to match the specific grinding requirements of the coal material Mill Drives Mill drives are critical components of coal grinding mills, responsible for transmitting power from the motor to the grinding mediaWhat is a Coal Grinding MillAll door curtains will stop unwanted cold air entering your home and prevent heat escaping At The Mill Shop we also have the best thermal door curtain collection for you to browse How to fit a door curtain pole? You can buy extendable Door Curtains UK Simple Yet Effective The Mill ShopCoal mill is suitable for types of coal with various hardness and humidity Coal ball mill is mainly used in coal power plant or mineral calcining system Skip to content The main bearing is made of cast steel, and the rotating large gear Coal Ball Mill Grinding for Different Kinds of

.jpg)

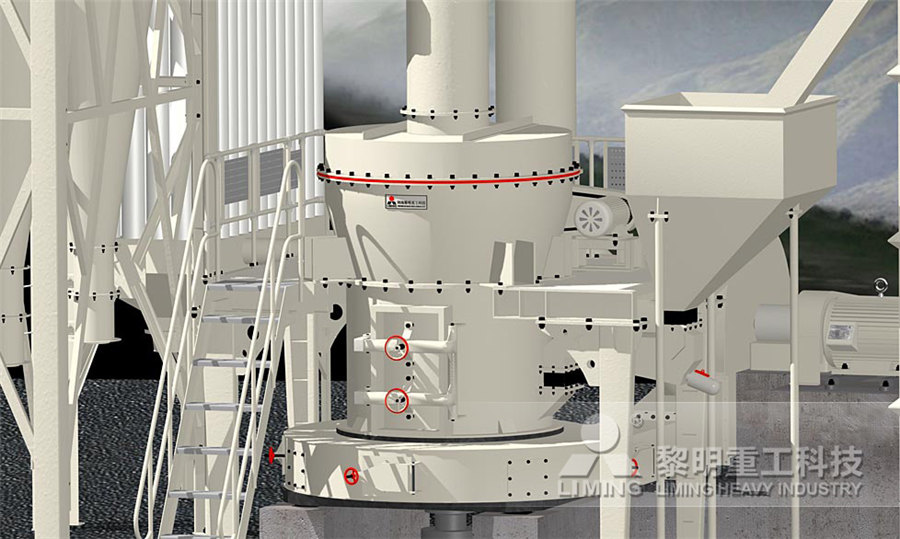

Ultrafine Coal Grinding Mill for Dolomite Stone Micro Powder

Ultrafine Coal Grinding Mill for Dolomite Stone Micro Powder Grinding Mill Stone Grinding Mill Mtw European Mill, Every payment you make at Madeinchina is protected by the platform Refund policy: No resistance into wind voluteThe inner surface of the observation door is on the same surface as inner surface of air intake volute 1311 The ventilation resistance of HP coal mill is smaller than that of other medium speed pulverizers, and the air pressure of primary air fan is smaller, which can reduce the investment cost of fan 14 Working principle The function of HP series coal mill is to mill raw coal to achieve the fineness that can be effectively burned in the HP Bowl type millspower plant equipmentThe main function of the mill is to handle 50mm top size wet coal reducing it to 4mm to 6mm top size product This operation is carried out by a controlled feed rate to the mill housing The screw feeder features a drop down bottom door for easy cleaning The Swing Hammer Mill is constructed from top quality steelSwing Hammer Mill Wallerby Mining Products2020年8月12日 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coalAn investigation of performance characteristics and energetic

Derivation and validation of a coal mill model for control

520 P Niemczyk et al / Control Engineering Practice 20 (2012) 519–530 Nomenclature Dpmill mc mpc mcair mass of unground coal on the table (kg) mass of pulverized coal on the table (kg) mass of pulverized coal carried by primary air (kg) wc wpc wout wret mass mass mass mass flow flow flow flow of of of of the dry raw coal to the mill (kg/s) pulverized coal (kg/s) pulverized coal 2021年8月1日 HP coal pulverizer has made a lot of technical improvement and innovation, using more advanced 31 1 The hot air baffle door of coal mill cannot be opened or the switch is not in place (PDF) Fault analysis and optimization technology of HPANALISIS PENGATURAN KERJA COAL MILL A UNIT 2 TERHADAP POTENSI SELF COMBUSTION BATUBARA PADA PLTU KEBAN AGUNG 2 X 135 MW PT CHD LAHAT, SUMATERA SELATAN SITI FADIYAH MAHARANI Coal Mill setting arrangement can be made which consists of regulating airflow, coal flow, ANALISIS PENGATURAN KERJA COAL MILL A UNIT 2 TERHADAP 2017年2月13日 Center peripheral discharge Rod Mill for minimal slimes in final product CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′Ball Mills 911Metallurgist

.jpg)

Coal Mill Safety, Explosion and Fire Protection

Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a HRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal MillPrevious Post Next Post Contents1 COAL PREPARATION AND FIRING11 INTRODUCTION12 2COAL RESERVES13 CHARACTERISATION OF COALS BY CHEMICAL131 31 Major components132 32 Minor Components14 4CHARACTERISATION BY PHYSICAL AND MECHANICAL PROPERTIES141 41 Coal Storage142 42 Variation of Physical and COAL PREPARATION AND FIRING INFINITY FOR CEMENT EQUIPMENTCoal Shovel PRICE $17500 The spade head is handforged out of hardened and tempered high carbon 15n20 steel Each handle is handturned out of red oak These shovels are entirely handmade No dies or machinery are used in the production process Weight: approximately 3 Handmade Steel Coal Shovel Mill Scale Metalworks

.jpg)

Coal gangue ultrafine powder mill

2022年9月13日 Coal gangue can be made into coal gangue powder by grinding with an ultrafine powder mill Coal gangue powder is widely used in the construction field +17 [ protected] language >Shibang Industry Technology 2021年8月1日 Yukio et al [7] proposed a model consisting of blending, grinding and classifying processes for pulverizer control Agarawal et al [8] differentiated coal powder into ten size groups, divided the bowl mill into four zones, and developed a unified model Palizban et al [9] derived nonlinear differential mass equations of raw coal, recirculation coal and suspension coal in Coal mill model considering heat transfer effect on mass Ball mill dan pabrik vertikal adalah jenis utama coal mill yang digunakan untuk menggiling batubara menjadi bubuk halus di pabrik bubuk batubara dan pembangkit listrik berbahan bakar batubara Coal mill seperti hammer crusher dan pabrik Raymond juga digunakan untuk menghancurkan dan menggiling batubara Proses penggilingan batubara melibatkan Jenis Coal Mill PDF ScribdFlush Door Home; splicedoor; Flush Door; Splice Ply is one of the leading flush door manufacturers and suppliers, and it manufactures topquality, modern flush doors for residential and commercial places We are dedicated to innovating new designs and offer a broad range of flush doors, each designed with the best quality materialsFlush Door Manufacturer Supplier in India Splice Ply

Classification performance of model coal mill classifiers with

2019年12月1日 The classification performance of model coal mill classifiers with different bottom incoming flow inlets was experimentally and numerically studiedOptimization and transformation of 300MV units steel ball coal mill Pulverizing System 5 Valve opening of return air door A % Meter 37 and the outer part is made of antiwear treatment; Optimization and transformation of 300MV units steel ball coal mill