HOME→How many meters away can the industrial grinding mill manufacturer of fluorinated gypsum be demolished

How many meters away can the industrial grinding mill manufacturer of fluorinated gypsum be demolished

MILLING ANALYSIS OF PARTICLES ETH Zürich

This is a big group of mill designs with freely moving tools such as spheres, sticks or short cylinders or also coarse grains of the milling good themselves (autogenous milling) The milling tools (also called grinding media) are located in a closed vessel and are accelerated by the Th ere are 49 MPS VRMs references for gypsum grinding and drying, plus 30 MPS VRMs for gypsum calcining Th ey are very fl exible, which of ers our clients enormous scope to refi ne GLOBAL GYPSUM: GRINDING Gebr PfeifferThere are essentially five different grinding mechanisms, and Retsch offers seven different types of mills that can be utilized The selection of a suitable mill depends on the application: Grinding Mills for reliable size reduction tasks RETSCH2015年1月1日 According to this four machine classes can be distinguished: Planar grinder Cylindrical grinder Gear grinder Form grinder resp coordinate grinder A separate class of Grinding Machines SpringerLink

.jpg)

Fine grinding: How mill type affects particle shape characteristics

2017年9月1日 Although fine and ultrafine grinding in the laboratory ball mill led to more elongated particles, Fig 11 suggests that shorter milling times in the laboratory ball mill roller mill, where it is ground to the extent that 90 percent of it is less 149 micrometers (µm) (100 mesh) The ground gypsum exits the mill in a gas stream and is collected in a product cyclone 1116 Gypsum Manufacturing US EPAHerein, we present a brief review of the recent development of fluorinated carbon materials in terms of structures, properties and preparation techniques Meanwhile, the applications in A brief review for fluorinated carbon: synthesis, properties and 2021年6月11日 Use of intelligent manufacturing systems (IMS) aim to transform maintenance into predictive reliability so that a consistent quality can be maintained throughout A study on intelligent grinding systems with industrial perspective

What is Grinding Process How It Works Different

2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision It is widely used in the machinery manufacturing industry The heattreated and quenched carbon 2023年7月12日 As a home baker and cook, I find the history of food in America fascinating Milling used to be a local affair, but grew as our country went through the Industrial Revolution, changing what and how we ate If you love the A history of milling in the United States: An overviewThe handling of a raw material in a grinding process will be closely linked to the nature of its particles The choice of an industrial mill depends mainly on three factors that must be taken into account: The nature of the raw material: is it abrasive, oily, hard, brittle, elastic, heatsensitive, hygroscopic? The particle size distribution (average size and variance) of the final product How to choose the right industrial mill? Palamatic ProcessPDF On Jan 16, 2013, Gheorghe Voicu and others published Grinding Characteristics of Wheat in Industrial Mills Find, read and cite all the research you need on ResearchGateGrinding Characteristics of Wheat in Industrial Mills

Grinding Mill MadeinChina

China Grinding Mill wholesale Mining 5t/H Small Dry Type Ceramic Used Ball Mill for Grinding Ceramic Gypsum Gold Cement Rock Stone Machine US$ 300035000 / Set 1 Set Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Grinding MillShanghai Clirik is a professional grinding mill machines manufacturer in China, Limestone Industrial Grinding Mill Raymond Mill Fineness:80600 mesh Yield:130 t/h read more >> + ultra fine grinding mill Fineness:3253000 mesh Yield:145 t/hGrinding Mill Manufacturer,Grinding Mill for Sale,Industrial grinding 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911MetallurgistMPS GC mill range, which can grind and calcine 100% natural, 100% synthetic or 100% recycled gypsum, or any combination of the three 26 Interview by Peter Edwards, Global Gypsum Magazine In discussion: A mill for all gypsum sources GLOBAL GYPSUM: GRINDING Global GypsumMagazine March 2020 Above: Patrick Heyd is GebrGLOBAL GYPSUM: GRINDING Gebr Pfeiffer

Industrial Grinding Machines: How it Works General Kinematics

2018年8月9日 Material grinding machines can be applied to various industrial processes As mentioned, the mining industry commonly uses milling machines to extract desired elements from the less desirable surrounding materials; however, grinding machines can be used for a variety of purposes outside of the mining industry as wellThe required power consumption of a grinding mill based on the calculations shown above can be estimated thanks to this free Excel calculator : Calculation Tool Grinding Mill Power Calculation Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design Grinding power : step by step calculation PowderProcess2023年3月15日 Richland Hills, Texas, September 12, 2024 AML, a USbased manufacturer of barcode data collection products, announces the launch of its latest Android ® product, the StrikerX mobile computer StrikerX is the The Evolution and Importance of Grinding Mills in 2023年6月21日 Proper machine location can help make the most out of the available space By strategically positioning machines, you can ensure enough space for workers to move around safely and enough room for storage and Machine Location And Safe Working Distances Around

Powder mill, Powder grinding mill All industrial

Final grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L BioStoneMill is a manufacturer of Industrial Electric Stone Flour Grinding Mills that can be easily integrated into an existing milling plant +39 0541 info@paglierani germ, bran and various nutritional contents) is sieved and the excess Industrial Electric Stone Grinding Mill Manufacturer BioStoneMillThe industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc The average achievable particle size range of the pin mill is around a d50 of 80 micronsGrinding mill Palamatic Process2013年1月1日 manufacturers of aeroengines and missile guidance system s, that grinding was the meters and shoulders could be produced with a single machine setup p0310 Many grinding machine companies Principles of Modern Grinding Technology ResearchGate

.jpg)

Rod Mills: Efficient Grinding Solutions for Mining

2016年6月1日 Dry ROD MILL Grinding No other type of mill is so well adapted to dry grinding materials to 4 or 8 mesh in single pass with the production of a minimum amount of fines A major factor in dry grinding is the rapid removal of finished material to prevent cushioning of the rods This is accomplished in the End Peripheral Discharge Rod Mill2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding lengths of drum ranging from about 15 in to 55 inGrinding Mills Common Types 911Metallurgist2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013)Grinding in Ball Mills: Modeling and Process Control2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap between the bowl liner How it Works: Crushers, Grinding Mills and Pulverizers

Mill, Grinding mill All industrial manufacturers

Final grain size: 74 µm 400 µm Rotational speed: 21 rpm Output: 16 t/h 50 t/h Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which is widely used June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Energy Use of Fine Grinding in Mineral Processing2018年8月17日 Marty wants you to go back in time and take a look at the major player Metso whose roots can be traced as far back as the 1930’s when the first Hardinge Cascade Mills were builtGrinding Mills — Types, Working Principle Applications

.jpg)

Barite Industrial Ultrafine Grinding Mill SBM Ultrafine Powder

2021年9月23日 Recommended barite grinding mill: In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest fineness can reach 3000 mesh SBM is a professional manufacturer of milling equipment for the ore industry2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding2021年1月16日 Now, let us dive into the world of Surface Grinding Machines Surface Grinding Machines You can do surface grinding of the components in any of the following types of machines Why we use Surface Grinding Machine You use Surface Grinding Machine for producing accurate flat surfaces with geometrical accuracy and good surface finishSurface Grinder Types of Grinders How They Work Fine 2017年3月4日 A stamp mill (or stamp battery or stamping mill) is a type of mill machine that cru shes material by pounding rather than grinding, either for furthe r processing or for extraction of metallic oresSIZE REDUCTION BY GRINDING METHODS ResearchGate

.jpg)

Understanding the operation of grinding mills in the mining and

Optimizing these parameters can improve the mill's performance and reduce energy consumption 4 Feed Size and Distribution: The feed size distribution affects the capacity and efficiency of the grinding mill Properly sized feed particles can improve the mill's throughput and reduce energy requirements 52020年6月3日 The design of such grinding mills is extremely critical, requiring sophisticated software tools, proprietary calculation worksheets, and experienced technical engineers and drafters This blog will review how the mill design process has changed over the last 30 years While most of the changes have been positive, new issues and problems have risen in the How grinding mill design changed over the last 30 yearsthe gypsum calcining mill GPSE Gypsum kettle GK Vertical roller mill MPS GC Feed size [mm] 20 Calcining indirect direct Hot gas temperature [°C] 750 600 Exhaust gas temperature [°C] > 220 ˜ 160 Dwell time [min] 60–200 2–4 Heat consumption [%] ˜ 120 100 Initial setting [min] > 12–20 > 5–8 6 The crystal water content is reduced byGrinding and calcining of gypsum with Pfeiffer grinding plantsMILL SELECTION Dry grind processing is ideal for products with particle size specifications of 2–3 microns average or larger Dry grinding offers many potential cost savings It can cut transportation costs because materials can be shipped Solids Choose the Right Grinding Mill Chemical

.jpg)

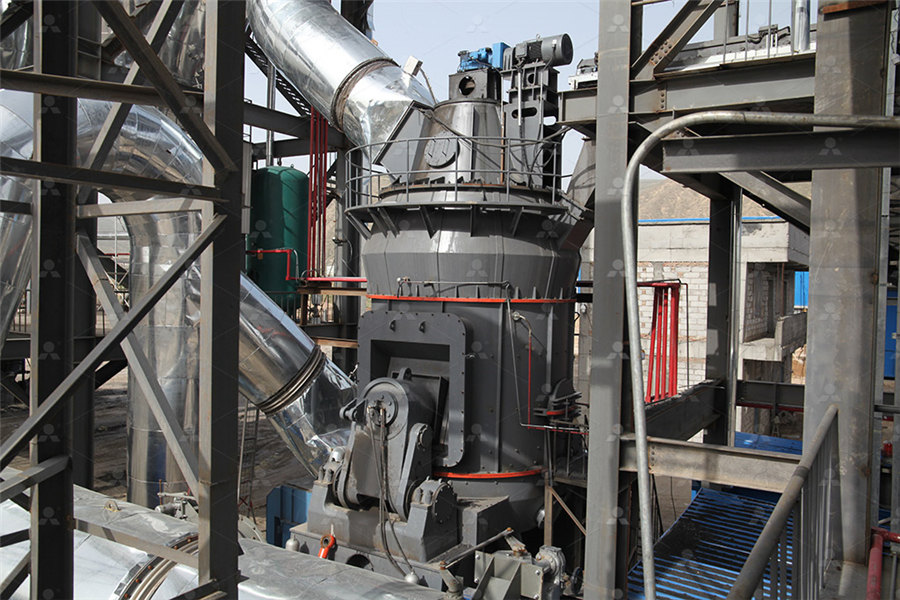

Grinding MillIndustrial Grinding Mill, Ultrafine Grinding Mill

Grinding mill is an industrial grinding mill used to grind solid stones into fine powder Stable performance, high efficiency and low consumption, easy use +年1月1日 A Panalytical (Epsilon1; 50 kV; Ag anode Xray tube) XRF spectrometer was used to analyze the elemental composition of pulverized rock samples at Sepro Mineral Systems (Langley, BC)Measurement of electrical energy consumption in a Bond ball mill2021年6月29日 PDF Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to on Performance of an Industrial Ball Mill June 2021; cycle grinding mill are 200, 400 Effects of Mill Speed and Air Classifier Speed on Performance of 2022年7月2日 where, v = it is the speed of the cutter in m per min d = cutter diameter in mm n = Speed of the cutter in rpm #2 Effective Cutting Speed It indicates the surface speed over the effective diameter (DC ap)This is necessary in order to determine the correct cutting data at the actual depth of cut (a p) It is used when you are working with round cutters, ball nose end Milling Formulas Definitions [Explained with Example] PDF

.jpg)

Ball Mill Maintenance Installation Procedure 911Metallurgist

2016年10月20日 Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Ball Mill Maintenance 2021年1月5日 These factors significantly reduce the grinding efficiency and increase the cost of grinding 1 ton of material In order to avoid such a situation, Energosteel’s specialists recommend: Determine the minimum internal volume of the mill If the mill manufacturer recommends filling the mill at 30%, the calculation of the loading tonnage shall be THE MILL FILLING RATE IS THE FOUNDATION OF EFFICIENT GRINDINGOutput: 6 t/h 350 t/h Motor power: 75 kW 3,300 kW Machine length: 2,400 mm 7,200 mm WTM intelligent vertical mill is dedicated to the highefficiency dissociation of minerals, providing users with energysaving, consumptionreducing, qualityenhancing and efficiencyenhancing solutions, realizing maximum Stone mill, Stone grinding mill All industrial manufacturersThe gypsum powder ultrafine grinding mill can grind gypsum ore into gypsum powder, which is widely used in industry, construction, medicine, The industrial ultrafine grinding mill produced by SBM runs stably, is energysaving and environmentally friendly, can produce 1503000 mesh gypsum powder, and its fineness can be adjusted freelyGypsum Powder Ultrafine Grinding Mill