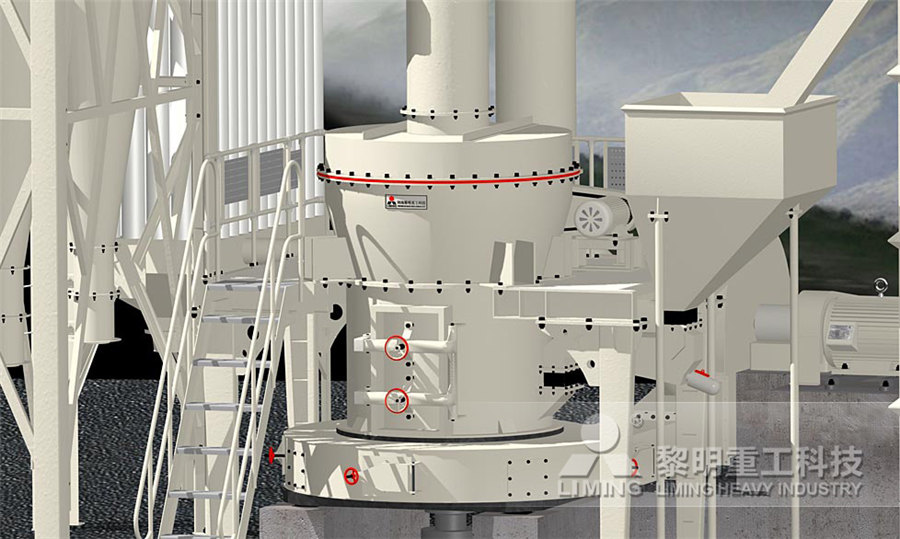

60 million pieces of coal gangue porous hollow Production line

.jpg)

Representative coal gangue in China: Physical and chemical

2024年2月1日 Based on the source and distribution of coal gangue (CG) in China, this study introduces the current situation of CG storage in China and the problems existing in the 2019年12月1日 The utilization amount of coal gangue was 480 million tons in 2013, accounting for 64% of the total output, of which approximately 150 million tons of coal gangue were used Comprehensive utilization and environmental risks of coal gangue: 2024年6月4日 Based on the analysis of the characteristics of coal gangue, this paper carded out the current industrial and technical policies in China and comprehensively analyzed the Characteristics of Coal Gangue and Present Situation and Prospect 2024年7月12日 Coal gangue (CG), which accounts for about 10–20 % of coal output, is a kind of solid waste generated during the coal mining and washing processes According to Fig 2, the Review Highcapacity utilization of coal gangue as supplementary

Characterization studies on coal gangue for sustainable geotechnics

2020年2月5日 The geotechnical properties of coal gangue revealed its potential as fill material in the construction of embankments and retaining walls Mineralogical and chemical 2024年9月7日 Coal gangue possesses developed pores and specific surface area, thereby aiding soil aeration and preventing compaction (Zhang et al 2022a) The organic carbon Opportunities, challenges and modification methods of coal 2019年8月25日 This paper summarizes the utilization of coal gangue in the preparation of chemical products such as alumina, aluminum chloride and polyaluminum chloride; New The Current Situation Research on Comprehensive Utilization of 2023年2月14日 This review summarizes and discusses various porous inorganic materials made from CG, including cementbased porous materials, porous bricks, porous ceramics (cordierite Fabrication and application of porous materials made from coal

.jpg)

Study on the macro–micro evolution of compaction Nature

2024年2月28日 Through the numerical simulation method, the porosity of the natural accumulation of coal gangue with different grain sizes will be measured, and indepth 2021年6月19日 This study proposed the preparation of highly porous ceramics from coal gangue, coal slime, and coconut palm fibers The ceramics were produced at a sintering Constructing Straight Pores and Improving Mechanical Properties 2024年9月28日 Coal gangue (CG) can be a potential aggregate for concrete production considering its huge production However, its porous structure and high water absorption significantly impact the workability of concrete, restricting its comprehensive utilization This paper proposed a straightforward presoaking technique for CG, where the presoaked CG (PCG) is Internal Curing for Tunnel SelfCompacting Concrete Using Pre 2021年8月1日 Coal gangue is a byproduct generated from coal mining and washing Using coal gangue as aggregate is an effective approach of valorization this highvolume industrial waste, not only solving the Valorization of calcined coal gangue as coarse aggregate in concrete

.jpg)

Preparation of coal gangue ceramsite highstrength concrete and

2022年9月30日 Coal gangue (CG) is a type of industrial solid waste produced by the process of coal excavation and separation 1,2,3 Generally, one ton of CG is discarded for every 10 tons of produced coal 4 , 5 The main compounds in coal gangue are SiO 2 and Al 2O 3, which are the key substances in the preparation of ceramics, and can replace silicon source and aluminum source The preparation of porousConstructing Straight Pores and Improving Mechanical Properties 2024年5月1日 The coal gangue was collected from Fuxin, northeast of China The large particles of coal gangue were crushed and sieved into gangue fine aggregate, according to GB/T 146842022 [48]The cumulative screening percentage and physical properties of natural and gangue fine aggregate are listed in Table 1 and Table 2 respectively The macroscopic and Mechanical and environmental performance of structural concrete 2016年6月8日 Coal gangue, an industrial solid waste discarded from coal mining and processing, was used as the sole raw material to prepare brick The coal gangue was crushed, homogenized, milled and then pressed into green compacts The dried compacts were sintered at different temperatures for 2 h The obtained brick samples were characterized with Xray Utilization of coal gangue for the production of brick

.jpg)

Exploring calcined coal gangue fines as the total substitute of fly

2022年12月1日 Coal gangue, a waste produced during coal mining, has been regarded as the largest source of industrial waste in China It is estimated that the production of 1 t coal generates 01–025 t coal gangue [1], and the total stockpile of coal gangue exceeds 6 billion tons in China [2], [3]The coal gangue not only occupies agricultural land in large areas but triggers 2021年4月10日 Coal gangue (CG) waste is the harmful byproduct separated from coal mining industry, which accounts for about 15% of total output of raw coal For the last several decades, coal has become the primary energy source in China and the accumulative amount of discharged CG has reached 5 billion tons with an increment of 300–350 million tons per year domestically Incorporation of selfignited coal gangue in steam cured 2021年1月1日 Typical methods for preparing coal ganguebased porous ceramics are shown in Fig 6, including the poreforming additive method 87,88 , template method 27, 89, solid phase reaction method 90 Constructing Straight Pores and Improving Mechanical 2022年11月28日 Porous coal ganguebased geopolymers were prepared by using coal gangue as the raw material, Na2SiO3 and NaOH as activators, H2O2 as the foaming agent and carboxymethylcellulose sodium (CMC) as Optimized Preparation of Porous Coal GangueBased

Synthesis and Mechanical Properties of Mullite Ceramics with Coal

2019年9月17日 With coal gangue and high alumina refractory solid wastes as raw materials, needle‐like mullite powder, with an average diameter of about 1 μm, was synthesized at 1300 °C by using the 2024年4月15日 Coal gangue is a byproduct of coal mining and processing, and according to incomplete statistics, China has amassed a substantial coal gangue stockpile exceeding 2600 large mountains, which poses a serious threat to the Enhancing Fatigue Performance of Coal Gangue 2022年9月15日 PDF Coal gangue is one of the industrial solid wastes that may harm the human body through the ecosystem for a long time Using coal gangue in Find, read and cite all the research you need (PDF) Activation Mechanism of Coal Gangue and Its 2015年6月1日 Porous mullite refractory aggregates were successfully fabricated via recycling of coal gangue and bauxite at temperatures ranging from 1100 to 1350°C, with chaff as the pore former The phase compositions, microstructures, pore characterization, and cold crushing strength of the aggregates were systematically studied by means of Xray diffraction (XRD), Preparation and Properties of Porous Mullite Refractory

.jpg)

Utilization of coal gangue for the production of brick

2016年6月8日 As for 1150 °C (Figure 12c,d), the mineral powder was sufficiently fused and bonded together to form a As sintering temperatures increase from 1000 • C to 1200 • C, the porosity of thermal 2021年11月11日 Among the techniques for converting stacked coal gangue to reusable material, one of the most effective ways is to use coal gangue as a coarse aggregate in green concrete productions The physical and chemical properties of rock and spontaneouscombustion coal gangue are generally suitable for being used as a coarse aggregate in green concrete Application of Coal Gangue as a Coarse Aggregate in Green2020年7月1日 Coal gangue is rich in Al2O3 and SiO2, which are beneficial for the production of silicoaluminate ceramics Typical methods for preparing coal ganguebased porous ceramics are shown in Fig 6 Preparation of porous cordierite ceramic with acidleached coal gangue2019年12月1日 The utilization amount of coal gangue was 480 million tons in 2013, accounting for 64% of the total output, of which approximately 150 million tons of coal gangue were used for power generation (32%), 56 million tons for the production of building materials (12%), and 260 million tons for land reclamation (56%) (National Development and Reform Commission, 2014)Comprehensive utilization and environmental risks of coal gangue: A

Porous alkali‐activated material from hypergolic coal gangue by

2022年10月4日 Porous alkali‐activated material from hypergolic coal gangue by microwave foaming for methylene blue removal October 2022 Journal of the American Ceramic Society 106(3)2022年6月26日 The coal consumption yearonyear growth rate of the world since 2010 (data from International Energy Agency Statistics, 2020) Using Chinese Coal Gangue as an Ecological Aggregate and Its 2021年6月19日 Statistical analysis suggests that coal gangue constitutes 10% to 15% of raw coal production [3], which equates to 368 to 552 million tons generated annually Further, the total inventory of coal gangue in China is about 45 to 50 Gt (Giga tons) [4] The annual utilization rate of coal gangue in China is only ∼60% [5]Constructing Straight Pores and Improving Mechanical Properties 2023年5月25日 Coal gangue, produced during coal mining and processing [1, 2], is one of the most extensively produced solid wastes in China [1, 3], accounting for approximately 10%‒20% of raw coal production []The Lowcarbon utilization of coal gangue under the

(PDF) Preparation of Coal GangueBased Porous

2023年8月2日 To address this issue, coal ganguebased porous ceramics solid waste produced during coal production and typically accounts for around 15–20% in Hollow gangue microsphere Pb 50 mg/L 6 4 2015年7月15日 Abstract A novel porous silicate material (PSM) derived from coal gangue was successfully prepared and characterized by N2 adsorptiondesorption isotherms, thermogravimetric analysis, Fourier (PDF) Preparation and characterization of a novel porous 2017年12月28日 Lowcost porous ceramic microspheres from waste gangue were prepared by simple spray drying and subsequent calcination Effects of calcination temperature on phase and microstructure evolution Synthesis of lowcost porous ceramic microspheres from waste gangue 2018年6月7日 The efficiency observed in this study is mainly associated with the morphology and porosity of the beads, which in turn is directly related to the water content added to the geopolymer slurry [77]Synthesis of novel lowcost porous gangue

.png)

Activation Mechanism of Coal Gangue and Its Impact on the

2022年9月15日 Coal gangue is one of the industrial solid wastes that may harm the human body through the ecosystem for a long time Using coal gangue in geopolymer preparation can effectively reduce cement output and meet the sustainability requirements In this paper, the physical and chemical characteristics, including the heavy metal content, of coal gangue from 2023年2月1日 1 Introduction Coal gangue is a byproduct of coal mining and washing process (Li et al, 2006)In China, there are 5 billion tons of coal gangue accumulated as residual waste, and this value continues to grow at the rate of 300–350 tons per year (Li and Wang, 2019; Moghadam et al, 2019)Large amount of coal gangue not only occupies farmland, but also Enhancement of coal gangue performance by surface micro 2017年3月3日 Porous mullite materials with high porosity of 718–882% were prepared by foaming of coal gangue/Al2O3/starch composite slurry and subsequent pore structure stabilization using starch consolidation and sintering Coal gangue was recycled to prepare porous mullite foams Starch was used as gellant, replacing commonly used poisonous chemical and Porous mullite thermal insulators from coal gangue fabricated 2024年7月12日 Coal gangue (CG), which accounts for about 10–20 % of coal output, is a kind of solid waste generated during the coal mining and washing processes According to Fig 2 , the annual output of CG in China fluctuates between 600–800 million tons, with a utilization rate hovering around 70 %Review Highcapacity utilization of coal gangue as supplementary

Preparation and adsorption properties of cotton linters and coalgangue

2024年6月8日 Highvalue comprehensive utilization of coal gangue solid waste, reducing synthesis cost and environmental hazards has become an important research direction for green development In this study, acid–alkali treated coal gangue was used as the silica source, and abundant cotton short staple in Xinjiang was used as the raw material of aerogel 2023年2月27日 Synthesis and development of highefficiency and lowcost adsorbents for treating of the wastewater containing heavy metal ions and/or dyes has been aroused worldwide attention in recent years In this study, the coal gangue as the only supply of Si and Al was adopted to synthesize sodalite using hydrothermal method Both the gangue and the Characterization of coal gangue and coal ganguebased sodalite 2021年7月28日 Coal gangue occupies large swathes of land resources, gravel mulching is an indigenous approach employed in agricultural production, Water Sci Technol 60(1), 71–76Influence of coal gangue mulching with various thicknesses and 2024年3月13日 Coal gangue (CG), an industrial solid waste with high contents of Li and Ga, has attracted the attention of researchers However, the utilization of CG remains an economic challenge Preenrichment of Li and Ga by flotation was carried out with a view to improving the comprehensive utilization of CG Mineral composition, timeofflight secondary ion mass Separation and Recovery of Valuable Carbon ACS Publications

Underground Disposal of Coal Gangue Backfill in China MDPI

2022年11月25日 China’s total coal production in 2021 exceeded 413 billion tons, 52% of the world’s total Coal gangue, a solid waste of coal mining accounts for 15–20% of coal production, when directly discharged on the ground surface as waste heaps, it occupies large areas of land and cause environmental pollution This paper summarizes the existing gangue backfilling 2021年11月1日 Zhang et al 137 pretreated and ground coal gangue, soaked coal gangue powder in HNO3 solution for 48 h at room temperature, washed it to neutral pH, and then soaked it in KOH solution at 60 °C Green preparation of hierarchical porous C/SiOx composites from coal 2024年5月1日 Coal plays a crucial role as a mineral resource worldwide However, approximately 10 %–15 % of mined coal remains as commercially worthless coal gangue after the mining and purification process is completed (Li and Wang, 2019)The utilization of coal gangue inevitably leads to secondary environmental pollution through processes such as combustion, Enhancing the carbon content of coal gangue for composting 2024年2月22日 Semantic Scholar extracted view of "CHARACTERISATION OF COAL GANGUE AND FABRICATION OF POROUS CERAMIC MATERIALS" by Hao Fu Skip to search form Skip to main content Skip to account menu Semantic Journal of Cleaner Production 2023; 42 Save Lightweight ceramsite made of recycled waste coal gangue municipal CHARACTERISATION OF COAL GANGUE AND FABRICATION OF POROUS

.jpg)

Optimization of posttreatment variables to produce hierarchical porous

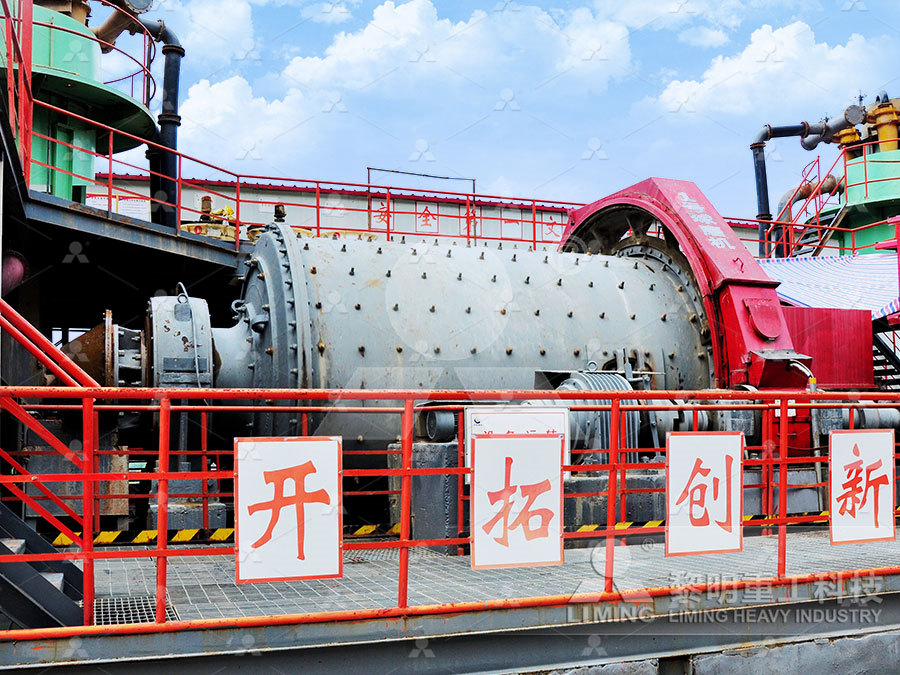

2020年2月1日 In this study, we report a feasible and costeffective method to convert coal gangue into zeolites (Tables S1 and S2), which are undergone a consecutive alkaline and ultrasonic posttreatment to tune the pore structures of the zeolitesThe treated zeolite is found to display an enhanced adsorption of metal cations (Cu 2+) and organic compounds (RhB), 2023年8月31日 It solves the problems of weak spheroidization of iron tailings and difficult expansion of coal gangue CGC production process: 1 Coal gangue is crushed by a jaw crusher and ground by a ball mill Raw materials are screened using a 100mesh vibrating screen 2 Mix raw materials (55% coal gangue and 45% iron tailings) to make particles with a How to Recycle and Process Coal Gangue: 7 Effective Ways