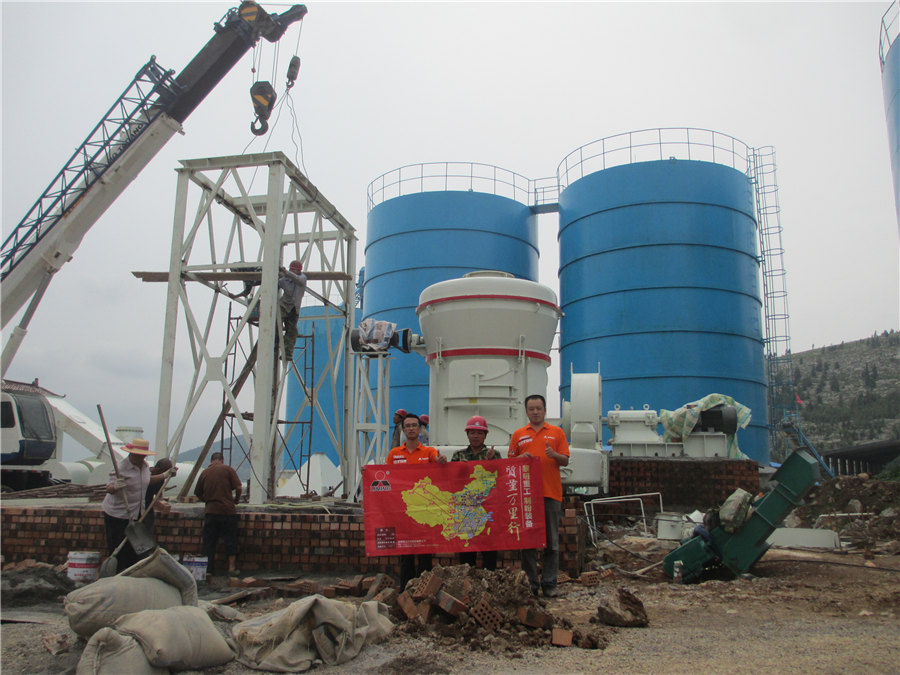

HOME→Calcium carbide mud mill quotation Heng'an mill calcium carbide mud mill quotation Heng'an mill calcium carbide mud mill quotation Heng'an mill

Calcium carbide mud mill quotation Heng'an mill calcium carbide mud mill quotation Heng'an mill calcium carbide mud mill quotation Heng'an mill

43.jpg)

Preparation and curing method of red mudcalcium carbide slag

2023年5月1日 A low carbon geopolymer (RCFG) was developed from the 100% solid wastes including red mud (RM), calcium carbide slag (CS), GGBS and FA in this study The effect of GGBS content and curing conditions on the fresh and harden properties of the binders were Industrial solid wastes red mud and calcium carbide slag are used to prepare View Abstract2024年10月29日 In this study, different dosages of Calcium Carbide Slag (CCS) were used to modify Red Mud (RM), including partially replacing RM with blast furnace slag (GGBS) prior to Preparation and Performance Assessment of Calcium Carbide Slag 2022年5月1日 CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are Recycling and utilization of calcium carbide slag ScienceDirect

Preparation and curing method of red mudcalcium carbide slag

2023年2月1日 Geopolymerization involves a chemical reaction between these source materials and alkaline activators, with curing conditions playing a crucial role in the final properties of the 2018年7月11日 Calcium carbide (CaC 2) is widely used for the production of various acetylene derivatives, accompanying with a huge amount of carbide slag waste To develop a clean Greener Production Process of Acetylene and Calcium 2024年2月26日 In this paper, calcium that can be mineralized by CO 2 in calcium carbide slag is defined as utilizable calcium Instead of the traditional NH 4 Cl extractant, NH 4 Ac solution Research on Utilizable Calcium from Calcium Carbide Slag with 2023年2月1日 Metakaolinbased geopolymers possess excellent corrosion and hightemperature resistance, which are advantageous compared to ordinary Portland cement The Preparation and curing method of red mudcalcium carbide slag

.jpg)

Resource utilization of solid waste carbide slag: a brief review of

Calcium oxide or calcium carbonate prepared from carbide slag is further used in calcium carbide production On the one hand, it can get rid of the dependence of calcium carbide production 2020年5月1日 With an view to providing methodological and data support for the development of policies in the cement industry, this paper quantitatively analyzes the environmental Life Cycle Assessment of Comprehensive Utilization of Calcium The huge production capacity of calcium carbide is accompanied by a large number of solid waste carbide slag Due to the immature treatment technology of carbide slag, a large number of Resource utilization of solid waste carbide slag: a brief review of 2013年4月1日 Lime mud, a kind of industrial waste that produced in paper mill, was proposed as CO2 sorbent in calcium looping process The carbonation performance of the lime mud was investigated in a dual Utilization of lime mud from paper mill as CO2 sorbent in calcium

.jpg)

114 Calcium Carbide Manufacturing US Environmental

114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO2021年6月25日 We are an experienced supplier of quality chemicals and reagents and offer you a wide range of chemical solutions on sale Whatsapp us +8615724766919What is Calcium Carbide and How to Buy Calcium 2020年5月29日 Ball milling of calcium carbide (CaC 2) enables the reaction of its ethynyl moiety with organic electrophilesThis was realized simply by comilling CaC 2 with organic substrates in a sealed jar without the need for an additive or a catalyst Various ketones including those bearing αhydrogens were ethynylated in good yields at short reaction timesDirect Exploitation of the Ethynyl Moiety in Calcium Carbide Calcining the raw materials such as limestone to generate lime (ingredient for calcium oxide); then adding water to digest lime to generate lime milk (ingredient for calcium hydroxide) and then passing into the carbon dioxide carbide lime milk for calcium carbonate precipitation; lastly, the calcium carbonate precipitation by dehydration, drying and crushing system to get light Grinding mill for Calcium carbonate

.jpg)

Preparation and curing method of red mudcalcium carbide slag

Request PDF On Feb 1, 2023, Yuxuan Shi and others published Preparation and curing method of red mudcalcium carbide slag synergistically activated fly ashground granulated blast furnace slag 2023年3月17日 Industrial activity results in tonscale production of calcium carbide and generation of a significant amount of calcium carbide residue (CCR), which is often disposed of in the environment as wasteSustainable application of calcium carbide residue as a filler for Methods Equipment Finished product(D97/ μ m) Features Dry grinding process Raymond roller mill 25150 1Applicable materials: medium and low hardness; 2Product features: medium and lowend products, suitable for the production of coarse powder;How to Choose a Calcium Carbonate Grinding Mill DASWELL2022年11月21日 Calcium carbide residue (CCR) is a high alkaline byproduct generated from acetylene gas factories [23] Given its abundant calcium hydroxide (Ca(OH) 2) content, it has been widely reported as alkali activator combined with pozzolanic materials such as ground granulated blastfurnace slag (GGBS) and fly ash to prepare a cementfree binderStrength development and microstructure of sustainable

.jpg)

Calcium Carbonate Grinding Mill

Carbonation method calcining the raw materials such as limestone to generate lime (ingredient for calcium oxide) and carbon dioxide; then adding water to digest lime to generate lime milk (ingredient for calcium hydroxide)and then passing into the carbon dioxide carbide lime milk for calcium carbonate precipitation; lastly, the calcium carbonate precipitation by dehydration, 2021年11月1日 The reason is that as the desulfurization reaction proceeds, a large amount of Si in sodium aluminosilicate hydrate (108Na 2 OAl 2 O 3 168SiO 2 18H 2 O) and hydrated garnet (CaOAl 2 O 3 A novel process to fully utilize red mud based on lowcalcium The calcium carbide reacts with the mud to form aetylene gas The actylene gas is detected by a gas detector at the shale shaker after pumping 4,500 strokes The drillstring is composed of 9,500 ft of 5in,, 195# drillpipe and 500 ft of drill collars having an ID of 2875 inSolved The mud logger places a sample of calcium carbide in2013年2月1日 After being activated at 650°C, calcium compounds of carbonate and hydroxide in the carbide slag are mainly transformed into calcium oxide The activated carbide slag utilized as the Use of lime mud from paper mill as a heterogeneous

Research on Utilizable Calcium from Calcium Carbide Slag with

2024年2月26日 With the increasing accumulation of alkaline industrial solid waste, the mineralization of CO2 using alkaline industrial solid waste has broad application prospects Carbide slag is highly alkaline and contains a large amount of calcium elements, making it an excellent material for CO2 mineralization Our idea was to acquire qualified products and fast 2017年1月31日 The reaction of hexachlorobenzene (HCB; known as a persistent organic pollutant) and calcium carbide (CaC2; known as an efficient and safe comilling reagent) in a planetary ball mill at room Efficient destruction of hexachlorobenzene by calcium carbide 2024年5月23日 Optimization of proportions and solidification mechanism of allsolid waste cementitious materials based on circulating fluidized bed fly ash, calcium carbide slag, and red mud May 2024 Case Optimization of proportions and solidification mechanism of all 2020年9月21日 A type of calcium coke was developed for use in the oxythermal process of calcium carbide production The calcium coke was prepared by the copyrolysis of coking coal and calcium carbide slag, which is a solid waste generated from the chloralkali industry The characteristics of the calcium cokes under different conditions were analyzed experimentally Development of calcium coke for CaC2 production using calcium carbide

Life Cycle Assessment of Comprehensive Utilization of Calcium Carbide

2020年5月1日 Calcium carbide slag is a special solid waste in China, which can be used for cement production with a great advantage on CO 2 emission reductionThe recyclability of calcium carbide and the availability of largescale industrial production facilities, as well as the future possibility of fossilresourceindependent manufacturing, position this compound as a key chemical platform for sustainable development Expand 82 SaveA rotary kiln process for making calcium carbide2024年8月9日 Utilizing MSC composite materials (MMetakaolin(MK)), SSlag, CCalcium carbide residue (CCR)), the waste engineering mud produced through the drilling and grouting pile construction method was solidifiedThrough the analysis of unconfined compressive strength (UCS), Xray diffraction (XRD), and scanning electron microscope (SEM) on solidified Study on mechanical properties and microstructure of metakaolin The calcium carbide reacts with the mud to form acetylene gas The acetylene is detected by a gas detector at the shale shaker after pumping 4,500 strokes The drillstring is composed of 9,500 ft of 5 in, 195lbm/ft drill pipe and 500 ft of Solved 115 The mud logger places a sample of

.jpg)

Carbide Willson Ruins National Capital Commission

Born in 1860 in Woodstock, Ontario, Thomas Leopold “Carbide” Willson was a pioneer of the North American electrochemical industry, with over 70 patents in his name The inventor’s fame and his nickname “Carbide” come primarily 2022年11月1日 Approaches for coping with the current challenges of energy shortages and environmental pollution are urgently needed (Li et al, 2018, Wang et al, 2019)Particularly, the production of calcium carbide (CaC 2) involves high reaction temperature (2473 K) and high power consumption (approximately 3500 kWh/t CaC 2)In 2020, the CaC 2 production Comparison of new twostep calcium carbide production process This is due to the fact that unlike the other materials, calcium carbide produces CO gas which uniformly distributes and mixes the carbide while foaming the slag; does not require a balancing lime addition as do siliconbased additives (in fact every pound of carbide adds about one pound of lime); reacts exothermically (producing heat) to not chill the slag; and under typical Calcium Carbide Applications Carbide Industries LLCIn this study, a CO2 sequestration material was obtained by all components solid wastes, ie, carbide slag and copper tailing based on red mud (RM) as crystal regulator after a sintering and carbonation process With the increasing dosage of RM, the mineral compositions of generated RMmodified clinkers were mainly γC2S (ie, around 80 %) at low dosage RM (ie, 30 %), An all solid waste CO2 sequestration material consist of multiple

Life cycle assessment of acetylene production from calcium carbide

2021年11月1日 In China, the calcium carbide and methane partial oxidation methods are used to produce acetylene, with the former being predominantly used China is the largest producer and consumer of calcium carbide worldwide, with 2018 output reaching 2608 million tons, 90% of which was used to produce polyvinyl chloride, 1,4butanediol, and vinyl acetate through Silicon Carbide Grinding Mill is a common silicon carbide production process It is mainly produced by silicon carbide Raymond mill machine and its supporting equipment HCMilling(Guilin Hongcheng) is the manufacturer of silicon carbide Raymond mill machine Here is the production process of silicon carbide Raymond mill machineNews How Is Silicon Carbide Powder Produced? Production 2020年8月5日 Lime mud, a kind of industrial waste that produced in paper mill, was proposed as CO 2 sorbent in calcium looping process The carbonation performance of the lime mud was investigated in a dualfixed bed reactor (DFR) and a thermogravimetric analyzer (TGA)Kinetic analysis about the CO2 capture capacity of lime mud 2023年2月11日 The development of calcium carbide industry in China is highly correlated with that of the chloralkali industry, as 80% of the calcium carbide output is used to produce PVC [35, 72]CO2 emissions in calcium carbide industry: An analysis of

Calcium Carbonate Ultrafine Vertical Mill SBM Ultrafine

Processing material: calcium carbonate Product fineness: 2003000 mesh Material output: 300,000 tons/year Equipment configuration: CLUM1425 ultrafine vertical mill, HGM125 ultrafine grinding mill, FJJ secondary powder selection system, finished material conveying system, automatic packaging and palletizing system, centralized control systemWe are an experienced supplier of quality chemicals and reagents and offer you a wide range of chemical solutions on sale Whatsapp us +8615724766919Industrial Chemicals for Sale Calcium CarbideDescription Larger calcium carbide containers were used starting around 1963 These were also used for dry chemical transport DuPont Chemical had 20 special cars built to carry these larger containers, and AHM made the early DuPont Calcium Carbide Container Car (Early) – Steel 2022年5月1日 Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride is produced from coalbased CaC 2CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are generated annually in China, among which only a Recycling and utilization of calcium carbide slag ScienceDirect

Solution Grinding Mill, mineral mill, limestone mill, calcite mill

Request a Quotation Thank you for your interest in Our Industrial Grinding Mill If you want to get help immediately, please chat online now At the same time, you can also fill in your requirements, we will reply you in 24hours *2023年12月1日 lime mud and lime mud calcined at 550, 650, 750, and 850 C were added as activators, and the dosages were 5%, 10%, and 15% according to the weight of the GGBFS(PDF) Calcined paper mill lime mud as an activator in GGBFS In the calcium carbonate superfine powder vertical mill, the contact point between the grinding roller shell and the grinding disc liner adopts electronic limit technology and mechanical limit protection technology, which can avoid the destructive effects caused by machine vibration (such as the direct crushing of the grinding roller and the grinding disc) ( Such as the grinding roller Calcium Carbonate Ultrafine Powder Vertical MillCalcium Carbonate powder can be generally divided into coarse powder processing (03MM), fine powder processing (20 mesh400 mesh), and ultrafine powder deep processing (400 mesh1250 mesh) and micro powder processing (1250 mesh3250)Calcium Carbonate grinding processing, calcium carbonate

Utilization of lime mud from paper mill as CO2 sorbent in calcium

DOI: 101016/JCEJ201301068 Corpus ID: ; Utilization of lime mud from paper mill as CO2 sorbent in calcium looping process @article{Sun2013UtilizationOL, title={Utilization of lime mud from paper mill as CO2 sorbent in calcium looping process}, author={Rongyue Sun and Yingjie Li and Changtian Liu and Xin Xie and Chunmei Lu}, journal={Chemical Engineering 2023年5月1日 Calcium carbide slag (CS) is a byproduct of the hydrolysis of calcium carbide to produce acetylene, containing more than 80% calcium hydroxide and thus presents a high alkalinity [23]Its large production volume challenges the disposal of CS, and currently CS is mainly dealt with by pilling and landfilling, which not only occupies a large amount of land Preparation and curing method of red mudcalcium carbide slag DOI: 101016/jrser2022 Corpus ID: ; Recycling and utilization of calcium carbide slag current status and new opportunities @article{Gong2022RecyclingAU, title={Recycling and utilization of calcium carbide slag current status and new opportunities}, author={Xuzhong Gong and Tong Zhang and Junqiang Zhang and Zhi Wang and Junhao Liu Recycling and utilization of calcium carbide slag Semantic Scholar