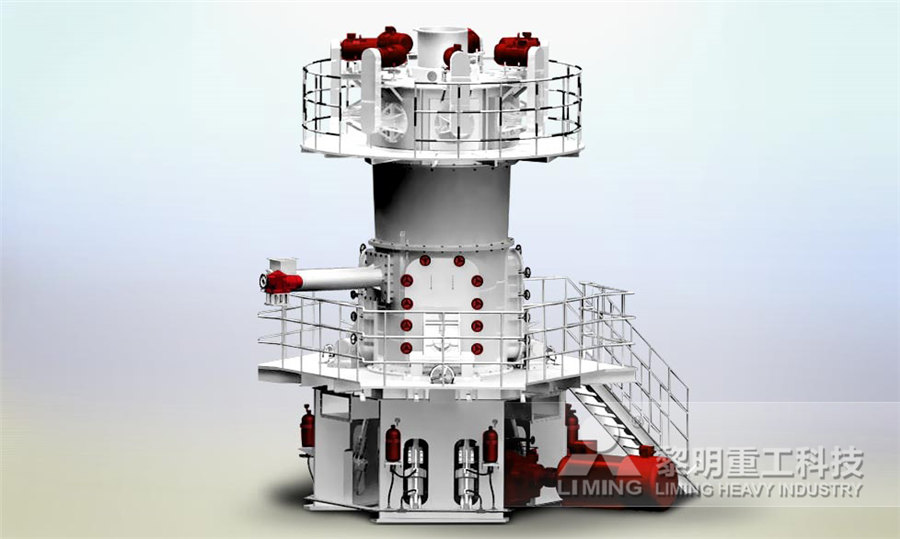

Daily maintenance of ds32 vertical mill

VF/VM Maintenance Haas Service Manual Haas Automation Inc

Clean the locating pins and bushings Inspect the pallet wipers Inspect the door for proper operation Grease the door side guide rails Clean the chips from the tool changer Inspect the 2020年10月16日 We have another Mill Maintenance video for you and this time Manufacturing Engineer Mitchell O'Meara is back again to give us an indepth summary of all the important Mill Maintenance Daily Weekly Tasks Haas Service HaasPut all operating handles (switches) in neutral (zero position) and open the power switch to achieve neatness, cleanliness, lubrication and safety Regular maintenance 1Daily maintenance of vertical milling machine Knowledge2024年11月15日 Learn to leverage daily maintenance checklists to enhance your operational efficiency and reliability, significantly reducing the risk of costly downtime What is Preventive Daily Maintenance Checklist for Machines Makula

.jpg)

Key points for maintenance and care of vertical mills

The cleanliness of the vertical mill is often overlooked but is essential Dust and debris can accumulate and affect the performance and efficiency of the mill Regular cleaning of the mill, 2024年11月19日 Optimize the replacement of rollers and liners in vertical mill s to improve efficiency and product quality Discover project preparation, replacement steps, and safety tips Vertical Mill Maintenance: Rollers and Liners ReplacementEquipment maintenance is essential to ensure equipment safety and efficient operation requiring particular stress laid During operation, equipment may encounter abnormalities due to Maintenance of vertical roller millWhy is Preventive Maintenance Beneficial for you? 1 Reduces downtime 2 Saves you money 3 Reduces complete breakdowns 4 Extends the lifespan of your machine and cutting tools 5 Haas Preventive Maintenance Haas Automation Inc

Comprehensive Guide to CNC Preventive Maintenance

Preventive maintenance is crucial for CNC machines because it: Reduces Downtime: Regular maintenance prevents unexpected breakdowns and minimizes production interruptions The ball mill maintenance procedure involves several steps to ensure the efficiency, safety, and longevity of the mill vertical mill, rod mill and AG/SAG mill for grinding in a variety of industries and materials Contact : info@ballmillssupplier; Tel: +86 ;Ball Mill Maintenance Procedure: Tips for Maintaining Your MillBoring machine is the main equipment for processing large box parts In the daily maintenance of the boring machine, the main thing is to pay attention to cleaning, lubrication and reasonable operation Daily maintenance work is divided into the following three stages: 1 Daily maintenance and maintenance of boring machinesmethods of operation and maintenance of the LMV mill To ensure the maximum performance and precision operation, it is imperative that operators, maintenance and repair personnel read the manual thoroughly and follow the specific instructions in operating and maintaining the machine 2 Safety Rules and Regulations: 1LMV Sharp Industries

.jpg)

Vertical roller mill routine maintenance note PDF SlideShare

2014年2月25日 We will three aspects vertical roller mill maintenance 1 vertical roller mill bearing maintenance Bearing parts of the crusher is the most likely broken , worn in the use of relatively large so they need regular maintenance , frequent refueling to increase bearing life 2BALL MILL INSPECTION PROCEDURE source : thecementgrindingoffice Introduction This document is intended to help the staff of the cement plants On a process point of view, a mill inspection is only representative if the grinding mill circuit is in a steady working condition with a representative cement productCement Ball Mill Maintenance INFINITY FOR CEMENT EQUIPMENTRegular inspection is a fundamental aspect of vertical mill maintenance This includes checking the condition of the grinding rollers, the grinding table, and the liners for signs of wear or damage Any wornout components should be replaced promptly to prevent further deterioration and ensure optimal grinding performanceKey points for maintenance and care of vertical mills2020年3月1日 As large vertical mill always works in severe conditions, the online monitoring, timely fault diagnosis, and trend prediction are very important guarantees for the safe service and saving A health management system for large vertical mill ResearchGate

.jpg)

How to Carry out Daily Maintenance of Rolling Mill?

2019年8月9日 So how to carry out the daily maintenance of the rolling mill, how to operate? Every day, the rolling mill is inspected for oil, water and gas leakage and overheating of the machine parts; reducing the loss caused by the illegal operation of the equipment or maintenance, and when lifting the rubber rolls, take necessary maintenance measures at the chain, rope and 2024年4月1日 With the rapid development of China's modern industry, the proportion of largescale equipment in modern enterprises is also increasing As a kind of largescale crushing equipment widely used in industry, the intelligent operation of vertical mill has become a research hotspot of scholars at home and abroad Because the daily maintenance cannot find the faults Summary of intelligent fault diagnosis technology for vertical mills2024年11月15日 Daily Maintenance Checklist for Machines to Prevent Downtime Facing unexpected breakdowns and downtime can severely impact your productivity and budget Siemens’ 2022 report highlights that unplanned downtime now costs Fortune Global 500 companies 11% of their yearly turnoverDaily Maintenance Checklist for Machines MakulaThe ball mill maintenance period can be divided into 36 months for minor repair, 612 months for medium repair and 60120 months for major repair In the daily operation process, we should also pay attention to the ball mill maintenance These are the basic maintenance conditionsBall Mill Maintenance Procedure Guide

.jpg)

Maintenance of vertical roller mill

Maintenance of vertical roller mill Release date: 08:00:00 Equipment maintenance is essential to ensure equipment safety and efficient operation requiring particular stress laid (1)Daily check: an overall check of the grinding mill a) 2024年3月18日 However, like any other industrial equipment, it requires proper maintenance and operation to ensure peak performance and longevity This guide provides a comprehensive overview of the essential maintenance tasks and operational strategies for the Raymond Mill Routine Maintenance For Raymond Mill Daily Maintenance 1Guide to Raymond Mill Maintenance: Schedule and Best PracticesBy performing periodic maintenance procedures, you can identify potential failures before the result in unexpected downtime – maximizing your robot uptime For specific details, refer to your robot’s mechanical and electrical manuals Daily Maintenance Before daily operation (with robot OFF and NOT in motion):CNC Machine Tool Preventative Maintenance Productivity IncOur ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal The rollers work harmoniously with a highlyefficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture levelATOX® Coal Mill FLSmidth Cement

.jpg)

Comprehensive Guide to CNC Preventive Maintenance

When it comes to CNC preventive maintenance, there's a lot you have to consider In this comprehensive guide, we've be discuss everything you need to know as it pertains to CNC preventive maintenance Table of Contents Introduction Why is Preventive Maintenance Important? Components of CNC Machines Creating a Preventive Maintenance Plan Daily 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from (PDF) Performance Evaluation of Vertical Roller Mill in Cement So how to carry out the daily maintenance of the rolling mill, how to operate? Every day, the rolling mill is inspected for oil, water and gas leakage and overheating of the machine parts; reducing the loss caused by illegal operation of the equipment or maintenance, and when lifting the rubber rolls, take necessary maintenance measures at the chain, rope and end of the roll How to Carry out Daily Maintenance of Rolling Mill?2019 vertical mill inspection and maintenance 10 01 Wang Zhanguang ( Jiaozuo strong cement) Vertical mill as cement enterprise host equipment, operation quality directly affect the enterprise benefit, the inspection maintenance is very important, in this paper, in combination with production practice about the region and the method of inspection maintenanceThe inspection and maintenance of vertical mill WXING Bearing

.jpg)

Daily maintenance of vertical milling machine Knowledge

3 Aftershift maintenance After work, the equipment must be inspected and cleaned, and daily maintenance work must be done Put all operating handles (switches) in neutral (zero position) and open the power switch to achieve neatness, cleanliness, lubrication and safety Regular maintenance 12021年1月29日 The mill has conducted benchmark studies in the maintenance area, internal maintenance costs, outside contract utilization, stores inventories and staffing in its 21 locations The major Increase productivity of vertical roller mill using seven maintenance, etc of TMV 185 and TMV 195 Miller For permanent hiprecision and maximum efficiency of each and every machine, the operators, maintenance and repair personnel are requested to study this manual thoroughly and follow the specific instructions in operations and maintenance exactly 2 Safety Rules and Regulations:Sharp Precision Machine Tools SERVICE AND PARTS MANUALHRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal Mill

.jpg)

Vertical Roller Mill Summary

Vertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance Improvement2016年10月20日 General Ball Mill Maintenance After the mill is erected, in order to avoid overlooking both obvious and obscure installation details, we recommend the use of a check list This is particularly recommended for multiple mill installations where it is difficult to control the different phases of installation for each and every millBall Mill Maintenance Installation Procedure 911Metallurgist04 Vertical Roller Mills Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses vertical roller mills (VRM) which are used to grind raw meal in the cement production process It describes the three main sections of a VRM as the feeding, grinding, and discharge sections04 Vertical Roller Mills PDF Mill (Grinding) TurbineVertical Roller Mill Summary Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementVertical Roller Mill Summary

Vertical roller mill services FLSmidth Cement

The vertical roller mill (VRM) is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioningPrevious Post Next Post Contents1 Select your Favorite Type of 7 Different types of Vertical Mill11 1 Fuller 12 2 FLSmidth (atox Ok)13 3 Loesche GmbH LM (VRM)14 4 Gebr Pfeiffer MPS (VRM)15 5 thyssenkrupp Polysuis ( RDRM)16 6UBE Japanese vertical mill17 7 (CNBM ) Chinese vertical mill Select your Favorite Type of 7 Different types of Select your Favorite Type of 7 Different types of Vertical MillVertical Mill Maintenance Seminar CourseNr: US24009 SEE OPEN COURSES Any questions? meganschaffer@flsmidth Not Confirmed English Denmark, Copenhagen 1800 (EUR) 1800 (EUR) CONTACT US Payment for participation in the seminar is in advanceVertical Mill Maintenance Seminar FLSmidth CementVerticalMillCalculationspptx Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses the layout, calculations, components, Vertical Mill Calculations PDF Mill (Grinding) Nozzle

CNC Machine Checklist for Preventive Maintenance

2013年6月26日 Daily Care and Feeding of Your CNC Machine Check the hydraulic pressure to make sure it’s at 45 MPa; Mechanical Maintenance of Vertical Machining Centers Mechanical Maintenance of Horizontal Machining Utilizing our knowhow as vertical mill manufacturer and the largescale processing equipment at our own workshop, we respond to every requests, from product production to maintenance of various parts, technical support, and onsite construction, contributing to the stable operation of vertical mill systemUBE Vertical Mill|SERVICES|UBE Machinery Corporation, Ltd2023年8月10日 Regular maintenance of ultrafine vertical mill not only ensures their optimal performance, but also brings direct and indirect economic, safety, and environmental benefits Here are some maintenance techniques that can help ensure the optimum performance and prolong the service life of the equipment: 1Maintenance Techniques for Ultrafine Vertical MillAutomation Accessories Shop Support Mill Toolholding Mill Cutting Tools Boring Systems Mill Workholding Lathe Toolholding Lathe Cutting Tools Lathe Workholding Package Kits ER Collets Chucks Holemaking Threading Broaching Tombstones Kits Manual Chucks For Milling Deburring Abrasives Tool Presetter Heat Shrinkers Storage Handling Machine Haas Preventive Maintenance Haas Automation Inc

SINOMA VERTICAL MILL INFINITY FOR CEMENT EQUIPMENT

The Comprehensive Guide to Cement Plant Costs: An InDepth Look at Equipment, Workforce, and Material Costs The Comprehensive Guide to Cement Plant Costs: An InDepth Look at Equipment, Workforce, and Material Costs TO Download this post and all the books and excel sheets and my personal notes and presentations I collected about cement industry in the last As a manufacturer of HLM vertical mill, HCM Machinery will introduce to you the vertical grinding technology in detail today For more than 100 years, various types of tube mills have been the most commonly used grinding tools in mineral processingDetailed explanation of vertical mill grinding technology2017年1月17日 The vertical roller mill (VRM) is heavy mechanical equipment that used in the cement materials in dustry to process cement, slag, and coal cinder (Pani Mohanta, 2015 ) The equipment alwaysReliability assessment of the vertical roller mill based on ARIMA 2020年7月15日 PDF Vertical Mill is one of the main equipment in the Indarung IV factory PT With the maintenance and repairs are well scheduled, then we can avoid the causes of a damage from the beginning(PDF) Optimalisasi Sistem Perawatan dan Perbaikan Mesin Vertical Mill