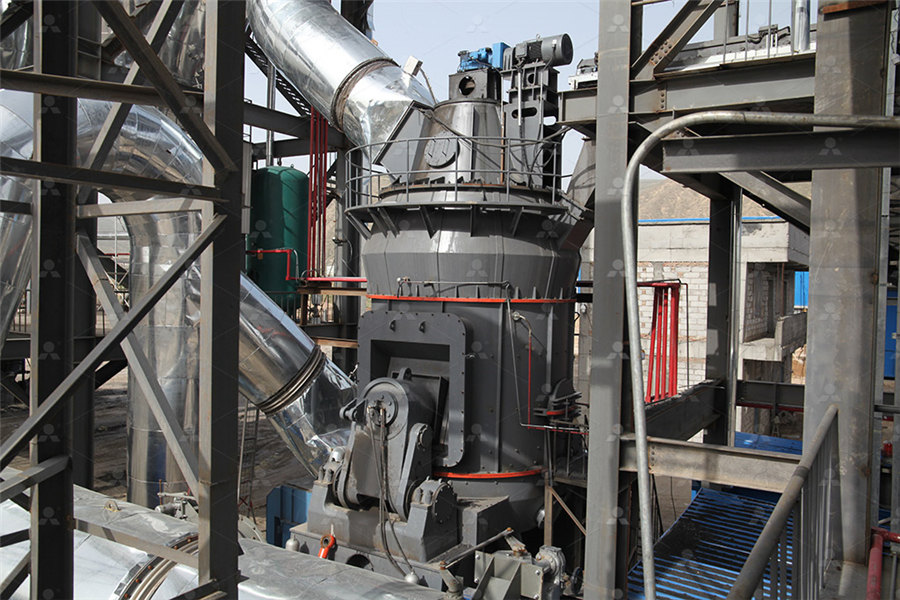

Slag vertical mill

.jpg)

2 µm 5 µm Loesche

slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiencyOK™ Raw and Cement MillOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It Vertical roller mills FLSmidth CementThe MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

.jpg)

Energysaving and Efficient Vertical Roller Mill Fote

A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, LM Vertical slag mill integrates drying, grinding, powder selection and conveying together, simple system, compact layout, the area is about 50% of the ball milling system Reduce the cost of investment, low energy consumption, compared LM Vertical slag millVertical Roller Mill Vertical roller mills are mainly engaged in three major fields of coal powder, slag and nonmetallic ore Divided into: vertical coal mill, vertical slag mill, vertical roller mill, and ultrafine vertical mill (ultrafine powder processing) One machine is multipurpose, it can be used for grinding, grading, crushing, drying, etcvertical roller mill, vertical slag mill, vertical coal mill, Superfine 2007年11月1日 The first industrialscale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3) The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of 3600cm²/g and 4300cm²/gMPS vertical roller mills for slag and slag cements

OK™ Raw and Cement Mill

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeOur vertical roller mills are able to pulverise steel slag into powder Cement Pulverisation Steel Slag Vertical Roller Mill Technology 01403 223 101 enquiriesUK@loescheCement Pulverisation Steel Slag Vertical Roller Mill TechnologyVertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill vertical coal mill, and ultrafine vertical mill (ultrafine powder processing)vertical roller mill, vertical coal mill, vertical slag mill, superfine The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3roller system and classifier to 2006 Slag Grinding With MPS Vertical Roller Mills PDF Mill

.jpg)

Slag Mill Vertical Slag Mill Provider SINOMALY

This vertical slag mill can be installed in a slag powder production line with an output range from 45t/h to 300t/h The structure of the slag grinding mill is similar to the cement mill and raw mill, except that the feeding method is different2007年2月1日 The aeration of this magnetic drum separator is so designed that practically pure iron with no granulated slag is removed from the stream of material After the magnetic drum, the recirculated material finally returns to the grinding table The picture in Figure 6 shows typical iron contents found in a slag grinding plant with vertical roller millSlag grinding with the Polysius Roller Mill in ChinaAlmost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process The concept of M and Srollers was established in 1992, which is one of the most Cement Blast Furnace Slag Loeschevertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock • Mill motor speed • Mill air flow/mill differential pressurePROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

Slag vertical mill

Slag vertical mill is mainly applied in metallurgical and cement industries and is the highend equipment for treatment of slag and crushed coal The slag vertical mill developed and manufactured by DHHI includes slag mill, coal, etcVertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsCement grinding Vertical roller mills VS ball mills4 Considerations for Choosing a Vertical Roller Mill for Slag Processing When selecting a vertical roller mill for slag processing, the following factors should be taken into account: Slag Composition The chemical and physical properties of the The utilization of vertical roller mills in mineral slag processingtrm型矿渣辊磨的型谱 type spectrum of trm slag mill 4 trm型矿渣立式辊磨 ag r mill 磨机规格 trm32 trm43 trm45 trm50 trm53 trm56 磨盘直do,mm 3200 4300 4500 5000 5300 5600TRM SERIES SLAG VERTICAL ROLLER MILL TRM SERIES SLAG

.jpg)

VRM In Cement Plant Maximize Energy Saving CNBMSINOMA

Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder Integrating crushing, transporting, grinding and drying, the steel slag vertical mill is a kind of ideal equipment for grinding steel slag The models of CHAENG’s GRMS steel slag vertical mill are complete, include GRMSS33 31 Steel Slag Vertical MillThe slag grinding process is introduced The basic control forms of vertical mill are presented by analyzing the dynamic characteristics of material layer in slag vertical mill Simulation results show that, in steady conditions, selftuned scaling factors fuzzy controller performs better than basic fuzzy controller in material layer control Selftuned scaling factors fuzzy controller was Material layer control based on slag vertical mill's steady PRODUCT OVERVIEW LM series vertical mill is a new type of milling equipment with advanced technology, excellent performance and drying functionIt integrates the functions of drying, grinding and powder classifying,used in LM series vertical mill

cement plant,ball mill,vertical mill,rotary kiln,slag

As a professional ball mill manufacturer, we can provide different types of ball mills used for grinding cement, coal, slag, etc The production capacity is 20180 t/h More>>HLM series slag vertical roller mill produced by HCMilling(Guilin Hongcheng) can be widely used in slag grinding treatment The whole set of slag grinding treatment process includes crushing, drying, grinding, grading, transportation, collection, storage and other steps, which can realize the complete production and processing of slag from large particles to finished fine powderNews Application Of Slag Grinding Mill Introduction To Vertical mills are generally used for grinding slag powder A vertical cement mill is also called a vertical slag mill It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grinding The vertical cement mill of AGICO CEMENT is inseparable from the following points:Slag Grinding Plant GGBS Plant Slag Mill, Slag Grinding MillFor slag vertical mills, targeted and planned maintenance should not omit hidden dangers in key wearresistant parts of the vertical mill, so as to achieve advance prediction and control, and eliminate hidden dangers in advance, which can prevent major accidents and improve the operation of the equipment efficiency and unithour output, providing guarantee for efficient How to properly maintain cement and slag vertical mills?

GGBS Production Line Slag Mill for Slag Powder Grinding AGICO

Since the late 1980s, vertical mill manufacturers all over the world have done a lot of research work on vertical mill slag grinding technology and achieved fruitful results The application in recent ten years shows that the vertical roller mill grinding system has been a mature and advanced grinding system in the field of slag powder grindingSlag Vertical Roller Mill CHAENG GRMS slag vertical roller mill integrates the functions of fine crushing, grinding, drying, powder selecting and conveying, with the advantages of high grinding Capacity : 15260 t/h Diameter of grinding table : 26005600 mm Specific surface area : Slag Vertical Roller Mill Xinxiang Great Wall Machinery Co, Ltd Vertical Slag Mill; Ball Mill; Coalwater Slurry Ball Mill; Raw Material Ball Mill; Cement Ball Mill; Coal Ball Mill; Slag Mill; Rod Mill for fertilizer, ferrous metal, nonferrous metal and glass ceramics In addition, the slag mill can also be used in dry and wet grinding for all kinds of ores and other materials Features 1 Low Slag Mill2023年6月6日 Slag vertical mill selection requires rigorous numerical analysis, equipment price, scale of slag vertical mill manufacturer and aftersales capabilities are all factors that need to be considered As a slag vertical mill manufacturer with nearly 30 years of production experience, Guilin Hongcheng has rich experience in slag vertical mill parison and Analysis of Slag Vertical Mill Selection

GGBS Vertical Roller Mill

vertical slag mill is typically designed to deal with industrial waste residues generated by the blastfurnace ironmaking Due to its high physical and chemical activity, and potential hydraulicity, the slag has been widely as admixture matters in the cement industry And the slag can replace the cement in the concrete to improve the quality and durability of the concreteCurrent systems for steel slag grinding that include ball mill systems, vertical mill systems and roller press systems on the market The ball mill system has high energy consumption, high noise and small singleunit capability, but the ball How is the steel slag vertical mill grinding process?Slag Cements are wellrecognized in many countries with traditional and powerful steel production High chemical resistance, low heat of hydration and sustainability are strong arguments for Slag Cements The main disadvantage of Slag Cement is the slow strength development Slag (ASTM C 989 and EN 15167) or Slag cement (ASTM C 595 and EN 1971)SikaGrind® for vertical roller millsCHAENG steel slag vertical mill uses many external circulation and effectively removes iron in the external circulation, which can make the iron content in the tailings less than 2% And the steel slag powder has high fineness that the finished specific Steel Slag Vertical Mill CHAENG

.jpg)

LM Series Vertical Mill LIMING(Shanghai)

LM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, chemical indus : English French(français) Russian(русский) Spanish(español) HOME LM Slag vertical mill; Model LM 192N LM 222N LM 242N LM 272N LM 273N LM 342N LM 343N LM 353N LM 393N LMSteel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller mill The produced steel slag powder has a specific surface area of 400500㎡/kg, which is widely used in cement and concrete admixture, realizing the highvalue resource utilization of steel slagSteel Slag Grinding Plant CHAENGLM vertical mill adopts new milling devic and automatic electric control system, integrating drying, grinding, powder selection and conveying together Language English РусскийLM Vertical Roller Mill, slag vertical mill, coal vertical mill Application of vertical roller mill: Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etcVertical Roller Mill for Cement, Clinker, Slag, etc

.jpg)

What is a vertical roller mill (VRM)? A Comprehensive Guide to

2023年10月3日 Unveiling the Vertical Roller Mill In the everevolving world of industrial machinery, vertical roller mills (VRMs) have gained immense popularity for their efficiency and versatility This powerful milling machine is used across various industries, including cement, mining, and chemicals, to grind raw materials and achieve finely ground products