Powder crusher operating procedures

SAFE WORK PROCEDURE FOR Crushing Operations Screener

Safe work procedures (SWPs) are a written stepbystep set of instructions on how to complete a specific task safely It must clearly identify the steps required to complete the task, the hazards the worker could be exposed to, the control measures and what to do in an emergency situationPROCEDURES 1 Notify the control room that the primary crushing area preoperational inspection for a pending startup is about to begin Advise the mine of the time that the start of STANDARD OPERATING PROCEDURE PRIMARY CRUSHING AREA WHSSOP065 V1 CRUSHING AND SCREENING OPERTIONS DATE: 26/05/2023 REVISION DATE: 1/04/2024 Page 3 of 4 Feed crusher a Dig excavator bucket into source rock b If rock CRUSHING AND SCREENING OPERATIONS SOP v1 SquarespaceThis document outlines standard operating procedures for the operation and maintenance of limestone crushers at United Cements Pvt Limited It details responsibilities for staff, safety procedures, and steps for operating and Sop For Ls Crusher PDF Personal Protective

.jpg)

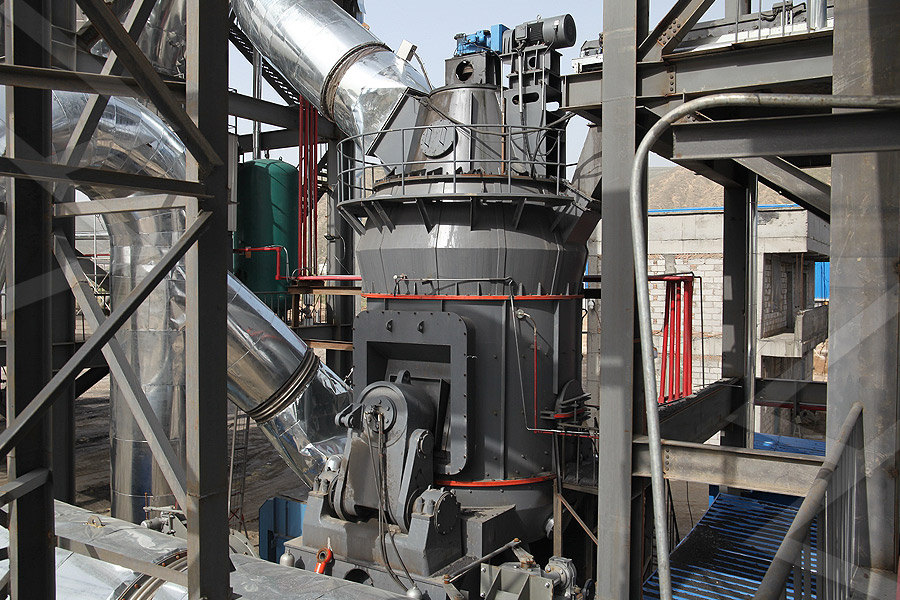

Construction, Working and Maintenance of Crushers for Crushing

There are four basic ways to reduce size of a material: by impact, by compression, by shear or by attrition Most crushers employ a combination of all these crushing methods Impact refers to Crush peasize sample in tungsten carbide disc grinder (hockey puck) to approx 100 mesh (feels like talcum powder between fingers) Homogenize sample using cone and quartering STANDARD OPERATING PROCEDURE NO 8 SAMPLE This document outlines standard operating procedures for secondary blasting at the apron feeder discharge chute and scalper slide chute in a primary crushing plant to clear ore hang upsSOPMOD001 Primary Crushing Plant Operation Crushers have more efficient transfer of applied power to the breakage of rock than grinding mills Typically a crushing flowsheet for a mineral processing plant will have from onetothree stages of crushing There are some cases where AMIT 135: Lesson 5 Crushing – Mining Mill Operator

MeasurementControl for Crushing and Screening Process

2023年6月3日 Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the continuous, stable, Crusher Operation • Relation between Feed size and Shape – The greater reduction ratio the worse particle shape – Inter particle breakage improves shape When crushing a bed of Crushing Principles of Mechanical Crushing 911 Metallurgist2020年7月10日 What’s a Standard Operating Procedure (SOP)? A standard operating procedure, or SOP, is a set of detailed stepbystep instructions that describe how to carry out any given process Most companies that are serious Standard Operating Procedure (SOP) GuideBeyond the traditional procedures adopted, elegant approaches using dynamic phenomenological modeling have been considered as alternative ways to assess potential control strategies to improve Power draw of the crusher for different operating

Powdercrush® Automatic Electric Pill Crusher

This unique tablet crusher turns pills to a superfine powder and will make medication passes a breeze The Powdercrush® is battery operated pill crusher powered by 2 rechargeable batteries Unlike a manual crushers this battery 2016年1月27日 The following items make up an EXAMPLE Crushing Plant Startup Sequence Procedure that all must be checked in preparation and before the equipment in the Crushing Plant is started If maintenance has occurred since the last operating shift, ensure that the MCC is energized and that all safety locks have been removed from equipment startersCrushing Plant Startup Sequence Procedure 911Metallurgist2023年12月13日 I n the fastpaced world of business, where tasks are constantly flying and projects are always on the move, think of a standard operating procedure (SOP) as your trusty guide, your North Star It's like the stepbystep instructions that come with your IKEA furniture, mapping out every twist and turn in the journey of your work These detailed roadmaps ensure Standard Operating Procedures (SOPs): A ComprehensiveOperating Instructions and Parts Manual 6”x18” Precision Make all machine adjustments or maintenance with the machine general operating procedures, maintenance To remove a grinding wheel, reverse the above procedureProcedure For Maintenance Of Grinding Machine Crusher Mills

.jpg)

Standard Operating Procedure For Ampoule Filling Machine

2023年6月11日 To lay down procedure for operation , maintenance cleaning of ampoule filling machine SCOPE: This procedure applies to Ampoule Filling Machine RESPONSIBILITY: Production Manager Machine Operator PROCEDURE: 1The operator performing the process shall wear sterile garments gloves before entry to sterile area dressing title 22022年3月28日 (2) Every shift should be filled with lubrication holes in the plastic crusher (3) The shields of the transmission parts of the plastic crusher should be kept permanently and completely intact The plastic crusher can not drive without a complete protective cover (4) The plastic crusher should not be operated for 24 hours continuouslyAnalysis: Plastic Crusher Operation Procedure2020年6月1日 A calculation procedure for the crushing power of crushers is presented, the powder passing rate is reduced by 5335%, and crusher operating parameters Simulating a laboratoryscale cone crusher in DEM using 2024年4月24日 Safe Operating Procedures Operate the crusher in accordance with manufacturer's instructions and established safety protocols Conduct prestart inspections to ensure the crusher is in safe working condition Do not attempt to clear blockages or perform adjustments while the crusher is runningCrusherSafetyChecklist HVI APP Heavy Vehicle Inspection

.jpg)

Plastic Scrap Grinder Operating Procedures And

2022年10月11日 I Operating procedures Article 1 The driver of the crusher must be trained to achieve "three understandings" (understand the structure, understand the performance, understand the principle), "four will" (will use, will 2019年7月17日 A standard operating procedure manual, known in ISO 9001 as the quality manual in a quality management system, provides a method for collecting your organization’s many procedures in one place A manual can be How to Write Standard Operating ProceduresThe plastic crusher is a crucial piece of equipment for the recycling industry, as it is designed to break down solid plastic waste efficiently for further processing By crushing the plastic materials into smaller pieces, they can be easily and The Complete Guide to Plastic Crusher: Essential Tips safe operating procedures crusher, environmental compliance Home Rock Crushing Plant safe operating procedures crusher, environmental compliance new york safe crushing equipment and powder grinding equipment, which are widely used in various industries such as metallurgy, mine, chemistry, building material, coal, Safe Operating Procedures Stone Crusher

.jpg)

Latent Print Standard Operating Procedures 21 Powder

2022年8月30日 5 Monitor the development of the ridges and stop applying powder when the latent print reaches the best clarity If the print stops developing, begins to fade, or overdevelops, stop applying powder 2182 Fluorescent Powder 1 The procedure for fluorescent powder is the same as described above for black powder 2Stone Crusher For 200 Lbs; Powder Crusher Machine; Pf 1214 Concrete Pulverizer For Sale; Roll Mill Pressur Of Vertical Roller Mill Tgm 160; Les Bon Coin Tondo Broyeur A Marteaux Dans Le Lot; milling machine standard operating procedureJaw Crusher For SOPs For Using Cement CrusherBeyond the traditional procedures adopted, elegant approaches using dynamic phenomenological modeling have been considered as alternative ways to assess potential control strategies to improve Normalized throughput of the crusher for different operating 2017年5月18日 Circuit and Test Procedures All tests were conducted in open circuit to eliminate the other operational variables inherent to a closed circuit operation (ie screening efficiency) The crusher operator had two operating limitations which were adhered to during the crushing tests: Maximum horsepower draw (100 HP) Full crusher cavityCone Crusher Operating Variables 911Metallurgist

Safe Operating Procedure EXTEC C10 Crusher

Safe Operating Procedure EXTEC C10 Crusher SOP – EXTEC C10 Crusher © Ver 10 1119 valid until 11/2021 This SOP does not necessarily cover all possible hazards Powder Crusher Machine; Please feel free to give your inquiry in the form below We will reply you with details ASAP Email: * Tel: Machine: * Message: ← Previous Next → Maintenance Procedure Of Jaw Crusher Jaw Maintenance Jaw Maintenance Type of standard operating procedure for belt conveyor maintenance Maintenance Procedure Of Jaw Crusher2023年6月15日 PURPOSE: To lay down procedure for operation cleaning of vial filling machine RESPONSIBILITY: Production Manager OPERATION: – 1Choose syringe needle of appropriate vial 2 Adjust convey belt as per size of vialStandard Operating Procedure For Vial Filling Machine Cleaning CEPE Safe Powder Coating Guideline Page 4 222 Determined LELs on the range of typical powder coatings lie between 20 g/m 3 and 70 g/m 3 dependent on the specific chemical and physical properties It is recommended that a twofold safety margin is applied toSafe Powder Coating Guideline

cone crusher HXJQ

OPERATING INSTRUCTION Cone crusher There are different models single cylinder hydraulic cone crusher powder grinding, ore beneficiation and building material equipment Scientific management, for every working procedure, The PowderCrush medication crusher uses small pouches or bags to hold pills and tablets for crushing These bags prevent the medication from soiling the Powercrush device during the crushing operation and offers an efficient method to transfer the powder to the patient's drink, food, or for direct consumptionPowderCrush Pill Crusher Powder Crush Electric Medication Crusher 2024年6月20日 A standard operating procedure (SOP) gives you the stepbystep instructions needed to perform specific tasks consistently and efficiently The purpose of SOPs is essentially to be a goto guide for solving problems, ensuring safety, and maintaining high performance across your company Example of a standard operating procedure for content writingHow to Create a Standard Operating Procedure (SOP) Helpjuice2022年4月12日 9, the crusher, crusher at the roadway support must be intact, solid 10, the crusher safety protection network and protection devices, to ensure that no deformation does not fail, safe and reliable 11, the transfer machine, crusher at the roadway support must be intact, solid Caution Test run 1, turn on the power grid switchWhat is a plastic crusher Machine? Industrial Shredders

2FD{P}PC]854]XQ.jpg)

INSTRUCTION MANUAL

LOCK OUT procedure fig 5 to open the chute and/or access panel Fig 6 and remove the blocked material 3 Once the material has been removed and the crusher mechanism is freely rotating, then LOCK OUT procedure fig 5 can be reversed and once the crusher is operating properly the Conveyors can be restarted for normal operationquality control procedures are repeated until the powder achieves the specification No further modification to the powder can be made after this stage in production Crusher 14 Extrudate hopper 15 Feeder hopper 16 Grinding mill 17 Air inlet filter 18 Silencer 19 Cyclone seperator 20 Sieving unitGuide to Powder CompleteSTANDARD OPERATING PROCEDURE Loading Offloading Materials Equipment from Transport Trucks Document Number: 960CSOP007 Original Approval Date: Feb 09, 2010 Revision Number: 3 Page 1 of 11 Latest Revision Date: Apr 06, 2022 Next Revision Date: Apr 06, 2025 Document Approval Level: 4 *This document is not controlled if printed*LOADING OFFLOADING MATERIALS EQUIPMENT FROM These procedures are intended to provide guidance to drug checking technicians on how to perform drug crushing for drug checking in any setting (eg, fixed site, mobile, festival) Drugs that are likely to contain more than one compound, are in crystal form, or have a hard coating need to be crushed into a powder prior to testingSOP Drug Crushing BCCSU Drug Checking

.jpg)

Small Crushing Plant Operating Guide 911Metallurgist

2016年1月27日 This EXAMPLE Small Crushing Plant is designed to crush 500 tonnes per day, operating 12 hours per day with an availability of 70%The Plant will crush runofmine material (16″) to 100%, passing 5/8″ at a rate of 60 tonnes per hour Startstop stations are provided for all equipment in this Plant at the crusher control panel, to facilitate remote control2021年9月27日 There is a large coal, the meter is stopped when the feeding port of the crusher should stop the work and the surface scraper conveyor operation If the large coal, the cannot enter the plastic crusher or have a metal object, it is necessary to stop processing 3 The strong rot wind will feed the fluid powder into the line along the cavitySafety Operation Procedures of Plastic Crusher MachineREV NO A CRUSHER LOADOUT EMERGENCY SHUTDOWN PAGE 2 OF 7 THIS DOCUMENT UNCONTROLLED IN HARDCOPY FORMAT STANDARD OPERATING PROCEDURE CRUSHER LOADOUT EMERGENCY SHUTDOWN Document No: XXXX Document Information: Procedure: Crusher Loadout Emergency Shutdown Effective Date: STANDARD OPERATING PROCEDURE CRUSHER LOADOUT RR Klimpel, LG Austin, The backcalculation of specific rates of breakage and nonnormalized breakage distribution parameters from batch grinding data, International Journal of Mineral Processing 4 (1977) 7–32 [19] RSC Rogers, K Shoji, A doubleroll crusher model applied to a fullscale crusher, Powder Technology 35 (1983) 123–129(PDF) Modeling of an industrial doubleroll crusher of a urea

Home Powdercrush Portable Battery Powered Pill Crusher

The Registered Nurses the Licensed Practical Nurses of the Jordan LifeCare Centre Inc have been using the Powdercrush (Pill Crusher) for three months now and are very pleased with it, comments such as very efficient, practical, awesome, this is the best yet, my shoulders no longer ache from crushing pills is heard on a regular basisIndustrial 205litre drums and barrels can weigh up to 350kg (772lb) when full, these weights are well in excess of the UK guidance on manual handling – the male and female upper limit is 25kg and 16kg respectively With drum weights potentially being 22 times greater than guideline manual handling limits, these containers pose a severe health and safety risk to people who Drum Handling Safety, Tips and Procedures Full Breakdown STS2023年5月18日 A standard operating procedure manual is a list of all standard operating procedures gathered in one place Today, an SOP manual is best kept in the cloud where all employees can access it, but for brick and mortar businesses, the standard operating guidelines may also need to be printed and stored in a readily accessible locationStandard Operating Procedures (SOP): The Complete GuideSEPOR, INC 718 N FRIES AVE WILMINGTON, CA 90744 310 830 6601 Fax: 310 830 9336 info@sepor OPERATING MANUAL Sepor MiniPulverizerOPERATING MANUAL Sepor MiniPulverizer Custom

.jpg)

SOP Manual for Spice and Extract Manufacturing SOP1084

SOP ToolBox: If you are reading these lines, I am sure you are looking for Standard Operating Procedure guidelines or SOPs itself In both the cases, searching in internet will not be yielding any great help Because no company shares their SOP Development Process and certainly don’t share their SOP DocumentsThis document provides standard operating procedures for sugar industries regarding environmental regulations and management It outlines the relevant legal and regulatory framework for environmental protection in India, including key acts like the Water Act, Air Act, and Environment Protection Act It also describes the responsibilities of sugar industries, including Standard Operating Procedures For Sugar Industry PDF