Pulping process

Pulping Process an overview ScienceDirect Topics

Pulping is the process where fibers are separated and treated to produce pulp The wet pulp is then converted into paper at an integrated pulp and paper mill or is dried and transported from the pulp mill to a paper mill Different pulping processes are used depending on the fiber material Kraft Pulping Globally, kraft process is the dominant technology of paper and pulp Kraft ProcessThe Kraft pulping process is the dominant manufacturing process by which wood chips are transformed into pulp, the intermediate material from which a very broad spectrum of finished Kraft Pulping Process an overview ScienceDirect TopicsThe pulping process is aimed at removing as much lignin as possible without sacrificing fiber strength, thereby freeing the fibers and removing impurities that cause discoloration and The Pulp and Paper Making Processes Princeton University

Pulping an overview ScienceDirect Topics

The pulping process is the step in which the components of the lignocellullosic material are separated from each other The focus is on recovering cellulose, with lignin and 2021年1月3日 Learn about the history, types, and challenges of pulping processes for making paper and pulp from wood and nonwood biomass Explore the recent developments and A review of the traditional pulping methods and the recent 2021年1月3日 A comparison of different pulping techniques has shown that the mechanical pulping process produces high pulp yields per unit volume of wood of poor quality (low A review of the traditional pulping methods and the recent 2024年4月27日 Learn about the basic processes for obtaining pulp from wood, including mechanical and chemical pulping Compare the advantages and disadvantages of each The Wood Pulping Processes SpringerLink

(PDF) Pulp and paper industry: An overview on pulping

2020年6月18日 In this paper, we present a review of pulping technologies to convert logs or wood chips and nonwoody materials into pulp for use in papermaking which consist of mechanical, chemical andkraft process, (from German kraft, “strong”), chemical method for the production of wood pulp that employs a solution of caustic soda and sodium sulfide as the liquor in which the pulpwood is Kraft process Chemical Pulping, Pulp Bleaching PapermakingPapermaking Pulping, Refining, Bleaching: Mechanical or groundwood pulp is made by subjecting wood to an abrading action, either by pressing the wood against a revolving grinding stone or by passing chips through a mill The Papermaking Pulping, Refining, Bleaching BritannicaPulping and papermaking of kenaf Latifah Jasmani, ZMA Ainun, in Pulping and Papermaking of Nonwood Plant Fibers, 2023 8211 Pulping processes Pulping is a process of liberating the fiber from its structure by subjecting wood or cellulosic fibers to cooking process using chemicals to convert wood to pulp for papermaking purpose There are different types of pulping Pulping an overview ScienceDirect Topics

(PDF) Pulp and paper production: A review ResearchGate

2021年1月25日 Pulp and paper production are extremely complex and incorporate a wide variety of process fields, including wood preparation, pulping, chemical recovery, bleaching and paper production, to Kraft pulping process is the most dominant lignocellulose pulping process producing about 130 million tons of pulp annually (228) Lignin obtained from kraft pulping process has a complex and recalcitrant structure The success of kraft pulping is attributed to Kraft Pulping Process an overview ScienceDirect TopicsMechanical pulping is the process in which wood is separated or defibrated mechanically into pulp for the paper industry The mechanical pulping processes use wood in the form of logs or chips that are mechanically processes, by grinding stones (from logs) or in refiners (from chips), to separate the fibersMechanical pulping WikipediaThe introduction of the Fourdrinier machine in the early 1800s made it possible to produce paper at a faster rate, and the mechanical pulping process was an important part of this development The mechanical pulping process is an important method of producing pulp for papermaking, particularly for newsprint and other lowcost papersUnderstanding the Mechanical Pulping Process A

.jpg)

Basic Overview of Pulp and Paper Manufacturing Process

Kraft pulping is by far the most common pulping process used by plants in the United States for virgin fibre, accounting for more than 80 % of total United States pulp production 2211 Kraft Pulping Process Kraft process produces a variety of pulps These pulps are used mainly for packaging and highstrength papers and boardremoved during the pulping process The fiber from nearly any plant or tree can be used for paper However, the strength and quality of fiber, and other factors that can complicate the pulping process, varies among tree species In general, the softwoods (eg, pines, firs, and spruces) yield long and strong fibers that impart strength to paper andThe Pulp and Paper Making Processes Princeton UniversityThis process is most often used on cotton and paper materials Neutral sulfite semichemical (NSSC) process The neutral sulfite semichemical (NSSC) process is the dominant semichemical pulping process, and it typically involves cooking in Na2SO3buffered solution at a neutral PH, followed by mechanical refining to liberate fibersChemical Pulping Methods Pulp and Paper Technologyafter the pulping process Shives Shives are small fiber bundles of fibers that have not been separated into individual fibers durin g the pulpin process They appear as "splinters" that ar darker n th pulp Yield Yiel d is a general term use n any phase of pulping , papermaking chip screening bleaching,PULPING FUNDAMENTALS University of Cincinnati

.jpg)

The Wood Pulping Processes SpringerLink

2024年4月27日 The mechanical pulping processes per refiner currently in use are: thermomechanical pulping (TMP), chemothermomechanical pulping (CTMP), and hightemperature thermomechanical pulping, more commonly referred to as the medium density fiber (MDF) process []For the TMP and CTMP processes, fiber separation is mainly achieved at 2020年6月18日 Soda and alkaline pulping processes (eg, the Kraft process) are used in the paper industry to remove lignin from wood to produce pulp(PDF) Pulp and paper industry: An overview on The recovery process for kraft pulping involves: concentration of black liquor by evaporation; combustion of strong black liquor to give the recovered inorganic chemicals in the form of smelt The smelt, Na 2 S and Na 2 CO 3 dissolved in water, gives green liquor; preparation of the white cooking liquor from green liquorHandbook of Pulping and Papermaking ScienceDirectHolmen's paper is produced in a thermomechanical pulping process, (TMP) Learn more about paper production in this stepbystep guide with infographics and videos Making highquality, sustainable paper in an efficient TMP processHow paper is made in a TMP process Holmen

.jpg)

Pulp and Paper Making Processes SpringerLink

2023年2月6日 The semichemical pulping process in current operating mills use the sulfurfree or neutral sulfite semichemical (NSSC) process Sodiumbased sulphite cooking liquor is used in the NSSC process whereas in the nonsulfur process sodium carbonate is used alone or combination of sodium carbonate and sodium hydroxide is used (EPA 2001a)The pulping process can be divided into two main types: mechanical pulping and chemical pulping Mechanical pulping involves grinding the wood chips or other raw materials using mechanical force to separate the fibers This method is fast and efficient but produces a lowerquality pulp that is not suitable for all paper typesPaper Manufacturing Process: How Paper is Made? Deskera2017年11月14日 Chemical process dapat dibagi menjadi tiga macam yaitu, soda pulping, kraft pulping dan sulfite pulping Soda pulping menggunakan Na 2 CO 3 sebagai zat aktif untuk mendegradasi lignin Metode ini sangat boros dengan bahan kimia terutama soda oleh karena itu, recovery Na 2 CO 3 dilakukan dengan evaporasi untuk mendapatkan kembali Na 2 CO 3 dari Macammacam Proses Pulping Warung Sains TeknologiThe kraft pulping process has potential environmental impacts, including the release of pollutants and the depletion of natural resources The white liquor used in the process contains sulfides, which can react with air and water to produce harmful byproducts such as The Kraft Pulping Process: A Comprehensive Overview CNBM

102 Chemical Wood Pulping US EPA

The kraft pulping process (see Figure 1021) involves the digesting of wood chips at elevated temperature and pressure in "white liquor", which is a water solution of sodium sulfide and sodium hydroxide The white liquor chemically dissolves the lignin that binds the cellulose fibers togetherAt present, the chemical pulping industry uses primarily sulfate pulping (Kraft pulping), sulfite pulping, or soda pulping processes for separating lignin on an industrial scale from wood and from some annual plants, such as bagasse, different straw species, flax, hemp, and bamboo During the respective process, the different lignin types are recovered from the cooking liquors and Pulping an overview ScienceDirect TopicsIn the mechanical pulping process, there are two major mechanical pulps that we have to take into account – thermomechanical pulp (TMP) and groundwood pulp (GW) For the TMP process, wood is chipped and then processed in steam Understanding the Pulping and Papermaking ProcessThe sulfite process was for a time the most important chemical pulping process, but has been largely replaced by alkaline pulping In the 1850s, the soda process was devised, which used lye (a caustic soda) to remove lignin from wood chips Two decades later, sodium sulfate wasPulping PrintWiki

.jpg)

Kraft Paper Manufacturing Process, Types and

2024年2月20日 This chemical solution effectively breaks down the bonds between lignin, hemicellulose, and cellulose Notably, approximately 90% of the pulping chemicals can be recovered and reused economically, rendering the KRAFT PULPING PROCESS The kraft process, sometimes called “Kraft Pulping” or the “Sulfate Process,” is the process by which wood is turned into wood pulp, the main component of the paper Wood chips are treated with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S) in large pressure vessels called digestersKraft Paper Primer: Kraft Paper Manufacturing Process Types of Pulping is the first step in the papermaking process, with the purpose of producing a clean fiber suspension that can be pumped forward in the process Fibers from virgin pulp, recovered paper or paper machine broke are mixed, ie, pulped, with water to form a suspension inside the pulperPulping Voithkraft process, (from German kraft, “strong”), chemical method for the production of wood pulp that employs a solution of caustic soda and sodium sulfide as the liquor in which the pulpwood is cooked in order to loosen the fibres The kraft process differs from the sulfite process in that (1) the cooking liquor is alkaline and therefore is less corrosive to iron and steel, so that the Kraft process Chemical Pulping, Pulp Bleaching Papermaking

.jpg)

The Wood Pulping Process: A Comprehensive Guide

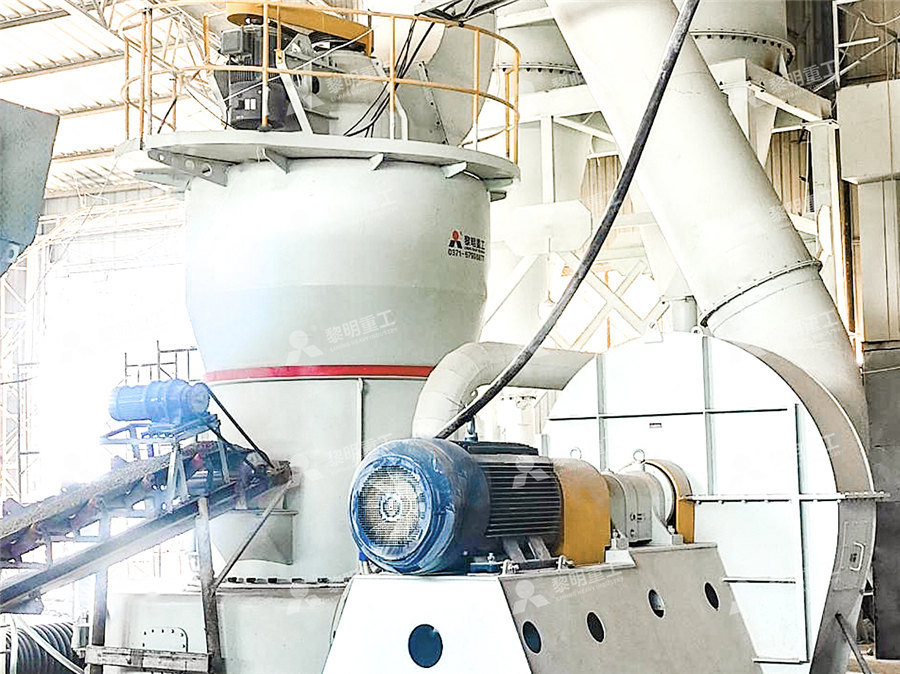

2024年11月14日 Key Machinery in the Wood Pulping Process The wood pulping process involves various specialized machinery to ensure efficient highquality pulp production Let’s see the machinery used in wood pulping process one by one Debarkers Debarkers, such as drum or ring debarkers, are designed to remove bark from logsA variety of pulps are produced by the kraft process and are primarily used for producing packaging, high strength paper, and board Sodium hydroxide and sodium sulphide are the active cooking agents (white liquor) used in the kraft pulping processPulp and Paper Making ProcessesThe pulping process is aimed at removing lignin without loosing fiber strength, thereby freeing the fibers and removing impurities that cause discoloration and possible future disintegration of the paper Hemicellulose plays a key role in fibertofiber bonding in papermakingPaper Pulp Manufacturing Papermaking Process in the Paper 2024年9月23日 Pulping is the process of using chemical or mechanical methods, or a combination of both, to dissociate plant fiber raw materials into natural pulp (unbleached pulp) or bleached pulp The main function of pulping is to provide highquality pulp for papermaking and other fiber processing industriesWhat is paper pulping? Younge Group: Paper industry process

Kraft Pulp Mill Process Encyclopedia MDPI

2020年10月29日 Kraft pulp mills produce a fibrous material composed of wood cellulose fibers, constituting the main raw material for papermaking The kraft process is the dominant technology in the world to produce pulp, allowing the At the start of the papermaking process, the solution comprises of roughly 1% fibre and 99% water Diluting the paper fibres this way allows us to make thin, uniform paper Step 3: Wire section At the wet end of the paper machine sits How is Paper Made? A StepByStep Guide to Our 2020年6月24日 This work introduces a phenomenabased model for delignification in the kraft pulping process The solubilization of lignin is described as a set of chemical reactions representing the entire chemistry of lignin degradation as well as dissolution of the degraded lignin For modeling, reaction mechanisms and reactions kinetics derived mainly from the Detailed Modeling of Kraft Pulping Chemistry DelignificationThe sulfite process produces wood pulp that is almost pure cellulose fibers by treating wood chips with solutions of sulfite and bisulfite ions These chemicals cleave the bonds between the cellulose and lignin components of the lignocellulose A variety of sulfite/bisulfite salts are used, including sodium (Na +), calcium (Ca 2+), potassium (K +), magnesium (Mg 2+), and Sulfite process Wikipedia

The Science Behind Our Kraft Pulp Process Paper Excellence

THERMOMECHANICAL PULP Paper Excellence sells its kraft pulp externally to customers around the world Some of Paper Excellence’s Canadian mills also produce a type of mechanical pulp, referred to as thermomechanical pulp or TMP, for use in making their own paper products (see How We Make Paper)Our Meadow Lake mill makes Bleached Chemi Thermal 2023年1月1日 In this chapter, we considered chemical, mechanical, and hybrid as the pulping strategies for nonwoody fibers (Fig 21)Statistical report showed that chemical pulping techniques produce 741% of the world pulp, while 214% of pulp is attained by mechanical pulping process, and 45% of the pulp is produced by using other techniques (Sabharwal et Pulping process for nonwoody plants ScienceDirect2018年11月5日 4122 Alkaline sulfite pulping In alkaline sulfite pulping process, the raw materials are cooked in the cooking liquid consisting of NaOH and Na 2 SO 3 at pH 10–135 Compared with kraft pulping process, one of the advantages of alkaline sulfite process is that the gas produced is odorlessPulping and Papermaking of NonWood Fibers IntechOpen2018年2月15日 The major advantage of mechanical pulping is its high yield of fibers up to 90% Chemical pulping yields approximately 50% but offers higher strength properties and the fibers are more easily breached because the mechanical pulping process does not remove lignin Even with subsequent bleaching , these fibers are susceptible to yellowingBrief Description of the Pulp and Papermaking Process

.jpg)

PULP MAKING PROCESSpptx SlideShare

2022年9月21日 The document summarizes the pulp making process There are two main types of pulping processes mechanical and chemical Mechanical pulping uses grinding or refining to separate fibers but retains lignin, producing weaker paper Chemical pulping uses chemicals to remove lignin and produce stronger paper suitable for highquality uses2023年11月20日 Paper is one of the most significant inventions in human civilization, which considerably advanced global cultural development Pulping is a key step in the conversion of fiber raw materials into paper Since its inception, pulping has rapidly evolved, continually adapting to technological advancements Researchers are constantly investigating various Development of Raw Materials and Technology for Pulping—A