Silicon micro powder making process

.jpg)

Silicon Powder Properties Produced in a Planetary Ball Mill as a

2020年1月15日 In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, grinding bead size (20 mm, 2 mm, 025 mm) and rotational speed based on the concepts presented in 2020年4月11日 SEM images show that the produced silicon powder is composed of macro and microporous silicon crystallites having an average size dimension of about 47 nm The High Purity Porous Silicon Powder Synthesis by Magnesiothermic 2023年11月23日 In this review, we aim to provide a brief overview of the distinct and representative fabrication methods of silicon nanoparticles, including topdown, bottomup, and reduction approaches Then, we look into various Silicon nanoparticles: fabrication, characterization, 2018年9月1日 In this study, a powder technology manufacturing route as a pioneering, low cost, simple and safe method is used for the fabrication of nanoporous silicon (NPS) powder It is a Production of high throughput nanoporous silicon (NPS) powder

Inexpensive method for producing macroporous

2012年11月8日 A multistep liftoff process is used to fabricate freestanding macroporous silicon films that are on the order of 50–100 microns thick with pore diameters greater than 50 nm 252020年9月16日 A facile procedure for the synthesis of ultrafine silicon nanoparticles without the need for a Schlenk vacuum line is presented The process consists of the production of a (HSiO 15) n sol–gel precursor based Facile production of ultrafine silicon nanoparticles2014年1月1日 The most basic way of creating powder is to manually grind the membranes using a mortar and pestle (eg, of the agate or quartz type) Handmilling relies upon forced contact Milling of Porous Silicon Microparticles SpringerLink2024年2月1日 Silicate microspheres are fabricated via a facile and lowcost strategy Microsphere crystallization is prevented by employing a twostage heating process or a two Lowcost fabrication of multicomponent silicate microspheres with

.jpg)

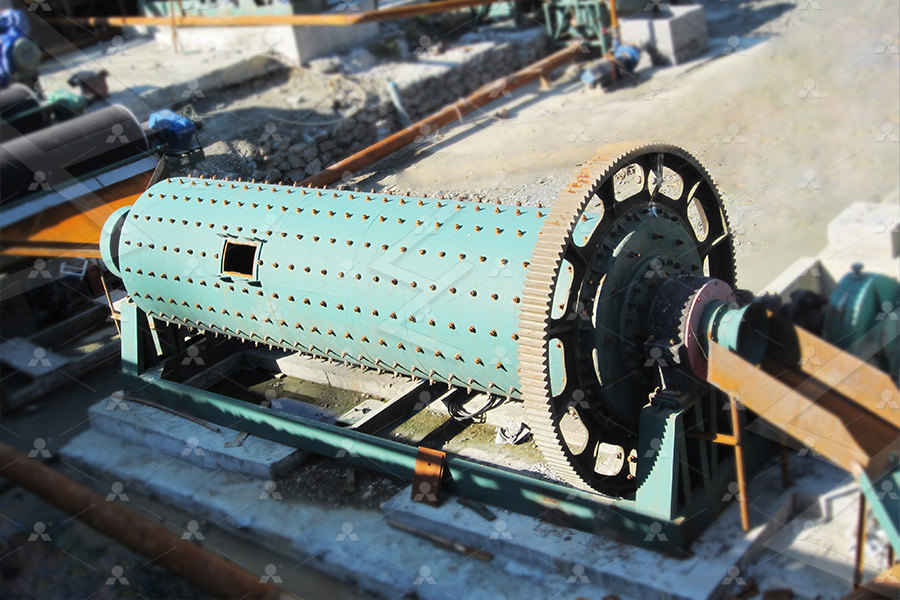

The Impact of Ball Milling Process Parameters on the Preparation

2021年7月21日 In order to explore the impact of different ball milling technical parameters on the grain size of nano silicon powder, this paper adopted the orthogonal experimental design in 2020年3月18日 At the onset, the silicon powders are synthesised by CO 2 laserinduced heating of silane followed by H 2 and a photosensitiser (eg sulphur hexafluoride) to a degree that can be effectively dissociatedFull article: Methods of extracting silica and silicon from A diagram of the semiconductor oxide transistors made by Frosch and Derick in 1957 [24] In 1955, Carl Frosch and Lincoln Derick, working at Bell Telephone Laboratories, accidentally grew a layer of silicon dioxide over the silicon wafer, Semiconductor device fabrication Wikipedia3、Screening of fine powder, through the wet sorting process, screening, microscope realtime monitoring, drying, production of white corundum micropowder 4、Packed with 25kg per bag, one tonne as a unit for tonnage White corundum micro powder Corundum Silicon

Creating Silicone The Process Explained United

In order to produce silicone, silicon must first be isolated from silica In order to accomplish this, a large volume of quartz sand is heated up to 1800 degrees Celsius As a result, pure, isolated silicon is obtained In order to make fine The invention discloses a process for preparing powder by atomizing molten metal silicon, which relates to the field of industrial silicon production and comprises the following steps: firstly, transferring molten metal silicon liquid to a heatinsulating bag, opening a discharge port of the heatinsulating bag, introducing highpressure airflow to an airflow outlet so that the molten Atomization powder making process for molten metal silicon2023年11月15日 Overview Silicon alloy powders are materials composed primarily of silicon with added alloying elements like iron, aluminum, magnesium, copper, and nickel Silicon has valuable semiconducting properties but in its pure form is brittle When combined with other metals in powder form, silicon alloys gain improved strength, hardness, wear resistance, high understanding Silicon Alloy Powder Additive Manufacturing Micro silica is an amorphous polymorph of silica (SiO 2 / silicon dioxide) It is also known as silica fume or condensed silica fume It is an ultrafine powder collected as a byproduct during the production of the silicon and ferrosilicon alloys It consists of spherical particles having an average diameter of 150nmMicro Silica (Silica Fume): Production Applications GharPedia

.jpg)

Silicon carbide manufacturing process GAB Neumann

The simplest manufacturing process for producing silicon carbide is to combine silica sand and carbon in an Acheson graphite electric resistance furnace at a high temperature, between 1600°C (2910°F) and 2500°C (4530°F) Fine silicon particles can be converted to silicon carbide (SiC) by heating in the excess carbon from the organic material2019年10月15日 Silicon and composite characterization The elemental analysis of Silgrain® as a starting material is shown in Table 1As Silgrain® is a metallurgical grade of Si, some impurities are expected SiliconCarbon composite anodes from industrial battery grade silicon Powder microdosing system Pharmaceutical powders in metered doses demand maximum filling precision This is particularly cha The process of making dishwasher tablets that have more than one layer is very delic Powder Manufacturing Equipment Making2021年9月20日 For further questions, please us at the below given ID If you need to buy the powder, you can also go to the powder page to buy it We (AEM) provide tantalum powder, niobium powder, hafnium powder, Comparison of Six Methods for Making Silicon Nitride

Silicon Wafers: Production, Properties and Application

2024年1月11日 Silicon wafers are thin slices of highly pure crystalline Silicon, used in the production of integrated circuits This article delves into the fascinating world of silicon wafers, unraveling their production process, unique properties, A pattern—sometimes referred to as a master—is the part you use to create a precise negative in your silicone mold If you are simply trying to replicate an existing object, it might make sense to use that object as your pattern You’ll How to Make Silicone Molds: A Practical GuideSilica fume particles viewed in a transmission electron microscope Silica fume, also known as microsilica, (CAS number 6, EINECS number 2737611) is an amorphous (noncrystalline) polymorph of silicon dioxide, silicaIt is an ultrafine powder collected as a byproduct of the silicon and ferrosilicon alloy production and consists of spherical particles with an average Silica fume WikipediaSilicon powder, also known as micronized silicon, is used for many different applications Silicon powder improves the performance of your product Skip to main content Language English English the latter produced using a proprietary hydrometallurgical processWhat is silicon powder? Elkem

Micro Injection Molding: Principle, Benefits, and Applications

2023年7月7日 The process involves using micro molds typically made from aluminum, which enables faster and more costeffective machining The use of compact barrels, fewer mold cavities, and smaller runners also contribute to cost reduction These factors collectively contribute to the overall costeffectiveness of the micro molding process2005年1月1日 In this study, micro powder blasting techniques are applied to micropattern making process using developed Si3N4hBN composites Material properties of the developed machinable ceramics according Application of powder blasting techniques to micropattern making SiO2 Nano powder, Properties Applications Silicon dioxide (SiO 2) is a compound of Silicon and Oxygen, commonly called silica and the elements are linked by the covalent bondIt is one of the components of the sand and can be found naturally in Quartz It is usually white or colorless and is not soluble in water or ethanolSiO2 Nano powder: Properties Applications MOLCHEMHowever, the purity of silicon micro powder is very high, usually above 99% and silicon micro powder contains little impurities 3From the perspective of quality stability, microsilica powder is a byproduct of the production process of ferro alloys And the quality is unstable due to many factors in production But the quality of the silicon the differences between silica fume and silicon micro powder

.jpg)

Silicon nanoparticles: fabrication, characterization, application and

2023年11月23日 Silicon nanoparticles have emerged as pivotal components in nanoscience and nanoengineering due to their inherent characteristics such as high energy capacity and outstanding optical properties2023年8月4日 Silica fume, also known as micro silica powder, Silica fume is a byproduct of silicon and ferrosilicon alloy production making it an ideal choice for large concrete structures subjected to temperature fluctuations 4 Know The Silica Fume Production Process2023年12月28日 Silicon powder is a fine granular form of silicon that has widespread use across many industries due to its unique properties and Metallurgical process: Metallurgicalgrade: 9899% : 1500 μm: Metallurgical Silicon Powder: A Versatile Engineering Material2020年5月10日 Micro vs Nano: Impact of Particle Size on the Flow Characteristics of Silicon Anode Slurries(PDF) Micro vs Nano: Impact of Particle Size on the

.jpg)

Micro Silicon Powder MadeinChina

China Micro Silicon Powder wholesale Select 2024 high quality Micro Silicon Powder products in best price from certified Chinese Powder Can manufacturers, diamond tool Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Micro Silicon Powder2018年8月7日 Making those chips is a fiendishly complicated process They require essentially pure silicon The slightest impurity can throw their tiny systems out of whackThe UltraPure, SuperSecret Sand That Makes Your Phone Possible2019年12月1日 S Tripathy, DK Tripathy, Investigated the process variable's effect on microhardness using chromium powder mixed EDM for H11 die steel workpiece Process parameters like a pulse on time, peak current, powder concentration, duty cycle were varied to analyze the effect on microhardnessA systematic review on powder mixed electrical discharge 2017年10月1日 MicroRaman spectroscopy has been used to investigate the acceptor distribution in highly pdoped silicon As an example, the dopant distribution in crystalline thinfilm layers, as developed for (PDF) Doping of nanocrystalline silicon powders by

.jpg)

Silicon Derived from Glass Bottles as Anode Materials for Nature

2017年4月19日 Compared with reported routes for the preparation of SiO 2 (Fig 1a), quartz powder derived from glass bottles can be directly used for the reduction process without preleaching in toxic acid and Silicon Carbide Micro Grits are produced by milling of selected and cleaned macro grain feedstock The milling and classification is done in CUMI’s state of the art milling and classifying facilities which yields powders of tight distribution, consistent shape, high purity and low dust levels A safety screening of the powders is carried out to Continue reading "Silicon Carbide Silicon Carbide Powder Manufacturers Suppliers CUMI MineralsThe inclusion of metal silicon powder in the manufacturing process of these cells is imperative, as it endows them with the necessary conductivity and lightabsorbing properties By efficiently converting sunlight into electrical energy, metal silicon powder contributes significantly to the global shift towards renewable energy sourcesMetal Silicon Powder: Definition, Properties, and Applications2016年9月20日 Over 40% of highpurity silicon (Si) is consumed as sludge waste consisting of Si, silicon carbide (SiC) particles and metal impurities from the fragments of cutting wire mixed in ethylene glycol OneStep Formation of SiliconGraphene Composites from Silicon Sludge

Process Parameters Used in Macro/Micro Powder Injection Molding

2020年6月3日 Abstract Powder injection molding (PIM) is a wellknown manufacturing technique for the production of complex, netshaped macroparts using a broad range of materials and alloys Eventually, the PIM method has been modified into micropowder injection molding (μPIM) because of the increasing demand of microparts in global market Nowadays PIM and μPIM 2021年3月1日 Silica sand was first transformed into silica powder via a specific chemical process The produced silica powder was reduced by magnesium granules at a temperature range of 500–800 °CHigh Purity Porous Silicon Powder Synthesis by 2020年5月20日 Properties of Si–C, Si–O, and Si–F bonds In most organosilicon compounds, Si is tetravalent with tetrahedral molecular geometryCarbon–Silicon bonds compared to Carbon–Carbon bonds are longer (186 pm vs 154 pm) and weaker with bond dissociation energy 451 kJ/mol vs 607 kJ/mol The C–Si bond is somewhat polarised towards carbon due to Fundamentals of Silicone and their uses in Textile2020年7月31日 Electrical discharge machining (EDM) is an advanced machining method which removes metal by a series of recurring electrical discharges between an electrode and a conductive workpiece, submerged in a dielectric fluid Even though EDM techniques are widely used to cut hard materials, low efficiency and high tool wear remain remarkable challenges in Recent Advances and Perceptive Insights into PowderMixed Dielectric

Silicon powder, 325mesh, 99 trace metals

Bulk and Prepack available Aldrich; Silicon powder, ?325 mesh, 99% trace metals basis; CAS No ; Explore related products, MSDS, application guides, procedures and protocols at Sigma Aldrich a one stop solution for all your research industrial needsWhat are the basic characteristics of Silica micro powder? Ultrafine crystalline silica particles have a total purity content of +9997% SiO2 Typical Silica powder characteristics are: High purity, fewer ionic impurities and low alpha ray emission; Particle size adjustable to customer requirements in the range of 7 µm (D50) up to 75 µm (D50)High Purity Silica Fine Specialty Chemicals CaplinqActivated Silicon Oxide SiO2 Powder Description: Activated Silicon Oxide (SiO2) Powder Features: Made by Coupling process – particle surface with a functional group, make micro silica work better crosslinking with the resin, greatly Improve adhesion between resin and silicon powder and interfacial hydrophobicity, significantly improve casting body impact strength, Activated Silicon Oxide SiO2 Powder low Price $40The micropowder (F1200, d50 μm = 30 ± 05 μm) was prepared, and the organic coated modified SiC fine powder was The thermal decomposition process of the precursor and the preparation process were analyzed Silicon Carbide Nanopowder has more applications due to its smaller It is used in the making of pencils, sandpaper, Silicon Carbide (SiC) Micron and Nano Powder Nanografi

.jpg)

Powder metallurgy – basics applications IIT Guwahati

Powder metallurgy – basics applications Powder metallurgy – science of producing metal powders and making finished /semifinished objects from mixed or alloyed powders with or without the addition of nonmetallic constituents Steps in powder metallurgy:Powder production, Compaction, Sintering, Secondary operations Powder production: