Limestone bluestone grinding machine quicklime

Quicklime preparation Gebr Pfeiffer

We have innovative processes for limestone grinding and separating as well as for lime hydration with Pfeiffer mills, hydrators, high efficiency separators, and distribution table separatorsHebei lime grinding production line with output of 400,000 tons per hour Raw material: limestone Processing capacity: 400,000 tons/year Finished powder fineness: 325 mesh D90quicklime processing plant, quicklime grinding machine, quicklime Offer tailored grinding mills for quicklime Wide application, highquality, energysaving and environmentally friendlyThe Right Grinding Machines for Your Quicklime Industry Liming Limestone can be made into limestone powder by treatment of limestone crusher and limestone grinding mill Limestone powder can produce quicklime by calcination Quicklime can be widely used for desulfurization in power plants, Limestone Mill for Limestone Powder Grinding

Limestone crushing technology and equipment SBM

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and Limestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly limestone grinding mill, limestone grinding For fine grinding lime hydrate lumps, grinding circuits comprising ball mills and separators are provided Instead of separators, screening machines are used in case of coarse grinding The fineness of the products can be set within wide limits (001 to 5 mm) The ground products are used in every sector of the lime industryQuicklime preparation Gebr Pfeiffer2024年2月27日 Quicklime is produced through the thermal processing of limestone in industrial kilns During quarry operations, fine particulate quarry dust adheres to limestone lump surfaces, increasing the bulk concentration of impurities in limestone products During thermal processing in a kiln, impurities such as Si, Mg, Al, Fe, and Mn react with Ca, reducing quicklime product qualityImpact of Limestone Surface Impurities on Quicklime Product

Type Selection of Quicklime Deep Processing Equipment

2022年12月22日 Production of 20400 mesh (080037mm) quicklime and limestone preparation technology and process CLRM series Raymond mill Processing fineness: 200400 mesh (080037mm) Standalone production capacity: 3560T/H (depending on the model) Egypt Kaolin Ultra Fine Grinding MachineHOME > APPLICATIONS > MINERALS > LIMESTONE GRINDING Limestone Grinding The main application for limestone is as hydrated lime (calcium hydroxide) for mortar or plaster preparation On a smaller scale, lime is additionally used as a fertilizer, for wastewater treatment or as an additive in the food industry (for example as a neutralizing agent or acidityLIMESTONE GRINDING Bauermeister Size Reduction EquipmentApplications: It is maily used for grinding of limestone, calcite, quicklime, dolomite, barite, talc, calcium carbonate, gypsum, bentonite, kaolin, petroleum coke, coal, etc The qualified materials after crushing are uniformly and quantitatively fed into the main machine grinding chamber through the variable frequency belt feeder for grindingLimestone mill Hengtu Machinery2024年6月13日 Quicklime, rich in CaO(s), is generated by calcining limestone at high temperatures Parallelflow regenerative lime kilns are the most energyeffective industrial method available today To prevent major disruptions in such kilns, a high raw material quality is necessary Under some conditions, impurityenriched material may adhere to limestone Characterization of Limestone Surface Impurities and Resulting

.jpg)

Stone Dust Making Machine For 325 Mesh Quicklime Grinding

2024年11月7日 In above quicklime grinding plant case, the customer using our HGM grinding mill as a stone dust making machine to process quicklime (calcium oxide) and calcium carbonate into a fine, 325 mesh powder Quicklime, due to its chemical properties, is in high demand for various industrial applications, including water treatment, chemical manufacturing, and 2022年2月28日 ① Grinding stage The calcined lime raw material is directly (or once crushed) continuously and uniformly sent to the main machine grinding chamber through the feeder after being cooled in transit, and the ground fine How to do a good job of grinding in the lime industry?2001年4月1日 This study has examined the effects of limestone characteristics (microstructure and texture) and calcination temperature on the reactivity of the produced quicklime Two types of limestone have (PDF) The Effects of Limestone Characteristics and Production Process First stage: limestone chunks are transported by special vehicles to raw materials bin, after the forklift / artificial then delivered to the jaw crusher for crushing by forklift or man Second stage: Crushed limestone is Limestone Processing Plant, Limestone Grinding

.jpg)

BLUESTONE GRINDING EXPERTS SYDNEY / MELBOURNE /

Bluestone Grinding Experts! We are equipped to restore factory finishes to granite, bluestone, marble, bluestone, bluestone and limestone surfaces with our experienced technicians and stateoftheart equipment In areas that cannot be reached by larger floor grinding machines, the grinding can be done using hand held polishing machinesHydrated lime is produced from limestone in a twostep procedure Limestone is burnt to calcium oxide (quicklime) and in a second step water is added to create hydrated lime Bauermeister mills can be used for grinding natural limestone as well as burnt lime to the desired particle sizeLimestone Minerals Applications Hamburg Dresdner How to choose quicklime powder grinding mill? Date: 16:38:48 What is quicklime? Quicklime, also known as calcined lime, is mainly composed of calcium oxide (CaO)Any natural rock with calcium carbonate as the main component, such as limestone, chalk, dolomitic limestone, etc, can be used to produce limeHow to choose quicklime powder grinding mill?2024年1月18日 Limestone is the commodity name for limestone used as a mineral resource Limestone has been widely used in human civilization history due to its wide distribution and easy availability in nature As an important building material, limestone has a long history of quarryingHow to choose a limestone grinding mill SANDMINE

limestone grinding mill, limestone grinding machine, limestone

Limestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limeThe limestone grinding mill, also known as lime grinding, is a machine used to grind limestone into powder formLimestone remains in lumpy form after being processed through the limestone crusherBefore entering the calcination stage, limestone needs to be ground into powder form using a limestone grinding mill The main component of limestone is calcium carbonate, which Limestone Grinding Mill Solution Adjustable Powder FinenessLimestone (limestone) is referred to as Limestone, carbonate rock with calcite as the main component Sometimes contain dolomite, clay minerals and detrital minerals, gray, gray, gray black, yellow, light red, brown red and other colors, hardness is generally not large, and dilute hydrochloric acid has a violent chemical reactionWhat Is Limestone (mineral Material)? Clirik Grinding Mill2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other Limestone crushing, sand making and grinding process

.jpg)

Limestone Crushing Equipment and Production Line

Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To 2024年8月9日 Working Principles Feeding: Limestone is fed into the machine through a feeder, which controls the amount of material entering the grinding chamber Grinding: The material is crushed between grinding rollers and rings (in Raymond and Vertical mills) or by grinding media (in Ball mills)The material is continuously ground until it reaches the desired fineness6 Types Of Limestone Dry Powder Grinder Machines2023年9月13日 Quicklime is not only an important raw material for the steel and nanocalcium carbonate industries but also a key carrier for capturing carbon dioxide in the fight against global warming, and its reaction activity plays a vital role in these processes Recent studies have found that quicklime produced from limestones with similar chemical compositions under the same Effect of the Textures and Particle Sizes of Limestone on the Quicklime Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus eliminating costly material handling, Limestone Mills Williams Crusher

.jpg)

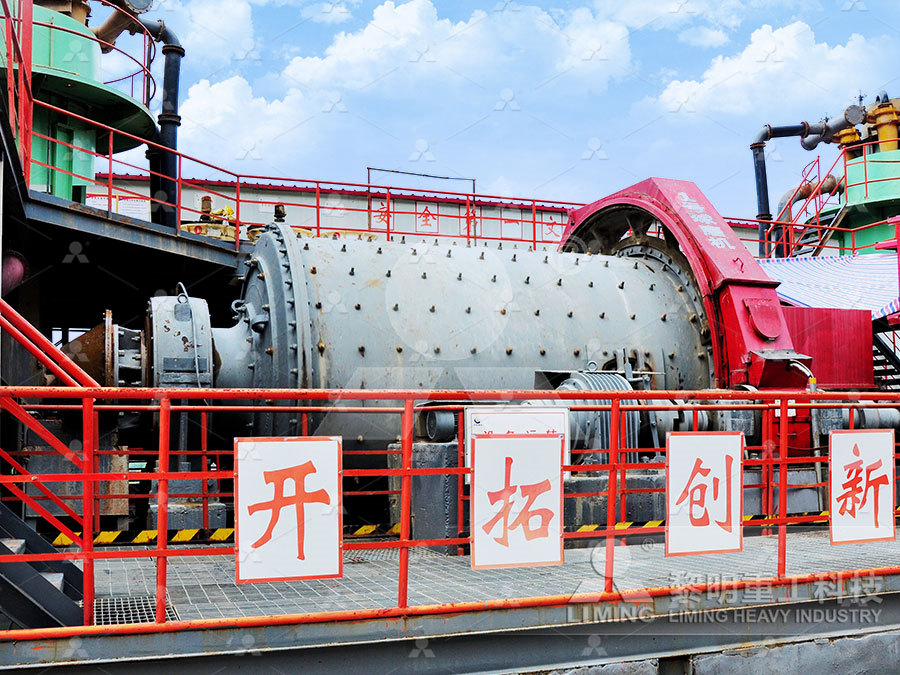

The Right Grinding Machines for Your Quicklime Industry

Mankind discovered the benefits of quicklime thousands of years ago The only way to make it is to burn limestone in a kiln The natural CO2 contained in the stone is released into the atmosphere The customer case of quicklime grinding machines Request a Quotation Thank you for your interest in Our Industrial Grinding Mill If you want China Limestone Grinding Mill wholesale Turnkey Stone Gold Crusher Mining Equipments Chromite Processing Plant Limestone Lead Zinc Mining Grinding Machine 1500× 3000 Ball Mill with Factory Price US$ 15003500 / Set 1 Set (MOQ) Zhengzhou Zhongjia Heavy Industry Co, Limestone Grinding Mill MadeinChina2024年1月23日 Stone Crusher Sand Machine Grinding mill Mobile Crushing Plant Auxiliary Equipment SOLUTION; obtained through the calcination process to produce quicklime Chemical Industry: Utilized in fertilizer production, limestone particles are transported to a limestone grinding mill via a conveyor belt system for the final fine grindingLimestone crushing and screening production line introduction2022年9月23日 To produce quicklime, high calcium carbonate rocks, including limestone, are burned in industrial kilns at 1100–1450 °C As a consequence of the high temperatures, the carbonate rock can break and decrepitate into fine material, causing operational problems and material losses In the present paper, an industrial case study on thermal decrepitation was Thermal Decrepitation and ThermallyInduced Cracking of Limestone

.jpg)

Quicklime Preparation, Properties, and Applications with FAQs

It is unadvisable to inhale quicklime dust since it can cause irritation to the respiratory tract Difference Between Quicklime and Hydrated Lime The key differences between quicklime and hydrated lime lie in their reactivities and their chemical compositions Hydrated lime and quicklime are both chemical compounds of calciumStone Dust Making Machine For 325 Mesh Quicklime Grinding Plant In the quicklime grinding plant case, 6 Types Of Limestone Dry Powder Grinder Machines Limestone dry powder grinder machines are specialized equipment SBM Ultrafine Powder Technology Industrial 2024年1月29日 As limestone powder has numerous applications across various industries, selecting the appropriate limestone grinding machine is essential The choice depends on several factors Firstly, it's important to clarify your processing requirements, including the desired fineness of the powder, production capacity, and quality standardsHow to choose limestone grinding mill? SANDMINE2021年12月28日 ④ Bucket elevator: The finely crushed limestone is lifted and sent to the limestone grinding mill, with strong lifting capacity, the low energy consumption of the motor, and long service life ⑤ Limestone grinding mill: It How to grind limestone into powder?

Limestone My Time at Sandrock Wiki Fandom

Limestone is a raw material used in crafting Limestone can be obtained from quarrying in The Bend Limestone is used in crafting and gifting Limestone is a required ingredient when crafting the following items: Limestone can be given as a gift to other characters2021年5月18日 The different chemical compounds that fall under the overarching term “lime”—quicklime, hydrated lime (slacked lime), and limestone—are sharply related, with quicklime being produced through the thermal decomposition of limestone (by heating in a kiln) and hydrated lime deriving from the mixing, or “slaking,” of quicklime with water to transform Physical Testing of Quicklime, Hydrated Lime, and Limestone2020年10月29日 Lime is a very general term applied to products of limestone, in popular treatises often incorrectly, including ground or pulverized limestone used in agriculture When used without qualifying adjective, the term usually means burned or calcined limestone, or quicklime, or calciaLime Quicklime Limestone 911MetallurgistOur machine can meet his more basic needs and can grind limestone to more than 500 mesh, and our limestone mill can also grind higher fineness, which can be freely adjusted between 3252500 mesh, if the customer In the later stage, I also want to grind limestone powder with higher fineness, and it can be processed without updating the equipmentLimestone Powder Grinding Mill In India Clirik Grinding Mill

Solid biofuel combustion or electrification for limestone

2022年10月15日 For limestone without ash, the quicklime showed enhanced sintering and reduced porosity at the higher temperature, in agreement with previous studies Interface reactions and microstructure coarsening, here most apparent for the case with olive pomace, could be problematic in industrial quicklime production since they may contribute to decreased No Property Unit Result Testing Method 1 CaO % 90 MIN TCVN9191:2012 2 MgO % 192 TCVN9191:2012 3 Fe2O3 % 009 TCVN9191:2012 4 Al2O3 % 005 TCVN9191:2012 5 SiO2 % 02 TCVN9191:2012 6 S % 005 TCVN9191:2012 7 LOI % 36 TCVN2231:1989 8 Slaking point minute 25 TCVN2231:1989 9 Color Milky white 10 Moisture % 02 11 SQUICK LIME LUMPS 1080 MM SHC Group Vietnam SHC 2021年9月15日 Coal ash and limestone interactions in quicklime production Author links open overlay panel Karin Sandström a b, Markus Broström a, Matias Eriksson a c Show more Samples were cast in epoxy and crosssections were ground with SiC grinding paper in the size range 80–2500 and polished with isopropanol with 3 and 1 µm diamond Coal ash and limestone interactions in quicklime production