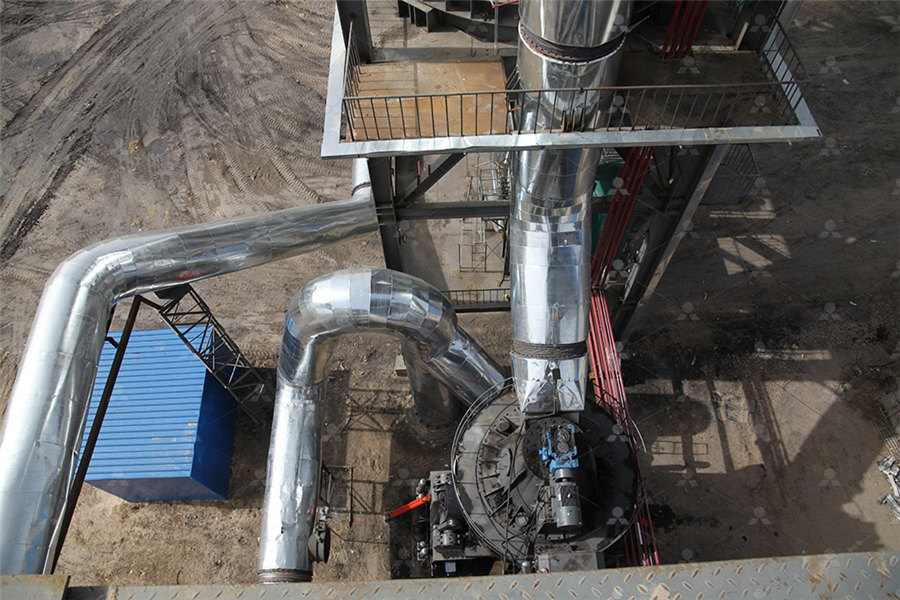

Gypsum production line cooling

Calcining Technology Claudius Peters

For fine raw materials such as synthetic gypsum sources the Horizontal Impact Calciner allows direct calcining without grinding The Claudius Peters Homogenizer, provides better plaster quality whilst the Claudius Peters Rotary Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, 1116 Gypsum Manufacturing US EPA2024年4月3日 The invention relates to a cooling device for an industrial byproduct II type anhydrous gypsum powder production line, which is particularly suitable for primary cooling ofCNU Cooling device for industrial byproduct II type Gypsum Powder Making Machine is also called Gypsum Powder Production Line Equipment ,Natural gypsum powder is dihydrate gypsum (CaSO42H2O) after crushing, grinding, calcination, cooling homogenization, aging, packaging and made; gypsum powder production is the core technology of calcination (dehydration) system, the two gypsum crystal Structure, various Gypsum Powder Making Machine,Gypsum Powder Production Line

.jpg)

Gypsum: production solutions Grenzebach

Design, construction, and commissioning of a new gypsum production line are only the first steps in a good customer relationship Professional service in daytoday operation is just as important: we want your investment to be consistently Gypsum Powder Production Line Processing capacity 50,000300,000 tons/year Processing materials phosphogypsum, desulfurized gypsum, industrial byproduct gypsum The calcined products are sent to the cooling bin for Gypsum Powder Production LineDesign, construction, and commissioning of a new gypsum production line are only the first steps in a good customer relationship Professional service in daytoday operation is just as important: we want your investment to be consistently profitable – that's why our engineers are there to help and advise you throughout the entire lifecycle of the plantProduction lines for gypsum blocks GrenzebachGYPSUM POWDER PRODUCTION LINE Processing capacity: 50,000300,000 tons/year Processing Highgrade gypsum is mostly used as raw material for the production of special gypsum products, such as food, medical The calcined products are sent to the cooling bin for cooling through conveying equipment such as screw conveyor and plate Gypsum Disposal Gypsum Grinding Gypsum Calcination Gypsum

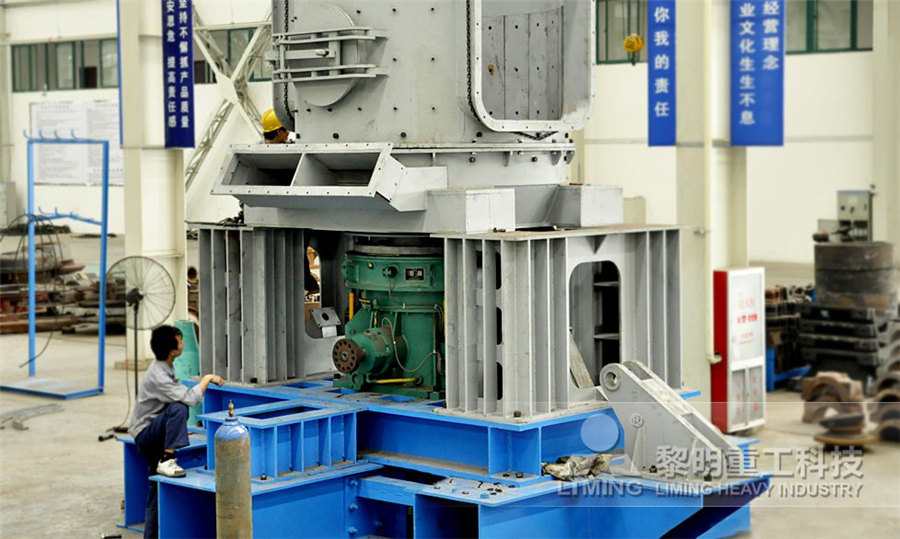

Gypsum Powder Production Line

Manufacturer of Gypsum Powder Production Line Gypsum Powder Production offered by Vinayak Gypsum Interiors Pvt Ltd, Mumbai, Maharashtra The main principle of drying system: the boiling furnace body is consist of delicate and intensive cooling coil pipe Put the heat conductive oil in the pipe, China Gypsum Board Production Equipment wholesale Select 2024 high quality Gypsum Board Production Equipment products in best price from certified Chinese Production Equipment Cooling manufacturers, Plastic Board Production Line suppliers, Gypsum Board Production Equipment MadeinChinaShijiazhuang Wuxing Mechanical Co, Ltd Was founded in 2004, the former stateowned enterprises We are a focus on gypsum board production line, gypsum powder production line, calcium silicate board production line, mineral wool board production line and cellulose equipments, RD, manufacturing, sales, installation, debugging and training in the integration Gypsum Board Making Machine Manufacturer, Light Mineral Natural gypsum powder is made of dihydrate gypsum (CaSO42H2O) after crushing, grinding, calcining, cooling and homogenizing, aging and packagingThe core technology of gypsum powder production is calcination (dehydration) system 300,000 tons per year Desulfurization gypsum production line in Anhui Province, ChinaNatural dihydrate gypsum (CaSO42H2O) powder production line

Gypsum: Production solutions for gypsum plaster Grenzebach

Gypsum plaster is one of the oldest building materials Over the years, it has been increasingly optimized for its intended applications, so users today benefit from a wide range of products To do justice to the complexity of this product, we provide our customers with full support in the production of gypsum plaster2012年11月16日 Moreover the production line must work in the most energy and materialefficient way available at each production site Each admixture has its own specific role, but it necessarily interacts with all others and with the technological process since the crystallisation of gypsum is influenced by any product added to the slurryInteractions between admixtures in wallboard production Global GypsumNatural Gypsum Powder Plant We offer a complete natural gypsum plant solution according to the location of your factory, plant area and market conditions Production power of our plant is 20,000/ Year 500,000 / year Synthetic Home Gypsum Processing Equipment ManufacturerMultiple processes are taken in production of the plant First, gypsum ores are being crushed, conveyed and stored into raw material bin, and then the crushed gypsum ores get grinded into powder with fineness required by the raymond Gypsum Powder Machinery Gypsum Powder

Wallboard Production Lines Gyptech

No matter if roller, belt or modular chain type conveyors – we will supply the matching solution for your production line Stacking, feeding, palletizing – all steps required to get your products ready for transport are within the range of our services You set your requirements – we transform these into sustainable technical solutionsDesign, construction, and commissioning of a new gypsum production line are only the first steps in a good customer relationship Professional service in daytoday operation is just as important: we want your investment to be consistently profitable – that's why our engineers are there to help and advise you throughout the entire lifecycle of the plantGypsum: production solutions GrenzebachProduction support Design and development of product recipe according to local conditions, training of your laboratory and production staff, laboratory procedures and production documentations (instructions, methods, forms etc), the most optimal chemical additives suitable for your gypsum and local conditions,production support for 3/6/12 months, training of your Gypsum plasterboard production plants and equipmentCheck out the comprehensive video that showcases the fascinating manufacturing process of gypsum boards Step into the world of a creative factory where the adventure of board production unfolds In this article, we will dive deep into the efficient gypsum board manufacturing process, highlighting the machines and production line involvedMastering Gypsum Board Manufacturing: Unveiling Machines Production Line

Gypsum powder fertilizer production line granulation effect

Experimental purpose: To explore the best granulation conditions and methods by studying the granulation process of gypsum powder, and to provide reference for the production of gypsum fertilizer Raw material: Calcined Gypsum powder Raw material Moisture:23% Raw material form: powder Raw material Powder Mesh:80100mdesulfurization gypsum powder production line,Gypsum Plaster Powder Production Line China,find quality Gypsum Plaster Powder Production Line Manufacturer and supplier at Hengshui Decheng Machinery raw gypsum powder becomes calcined gypsum powder After cooling or aging, the finished product is packed into different bags by packing machine China Gypsum Plaster Powder Production Line Manufacturers2013年5月21日 The gypsum calcining systems are designed to process natural gypsum from the local underground gypsum quarries A greenfield project To take over production from the old three calcining kettles, the new calcining line was designed for a plaster capacity of 14t/hr, utilising a Claudius Peters EM 47568 Gypsum Calcining MillInnovative gypsum processing at GIPS ADGypsum Board production flow "Tiger Board" is produced in the factory automated production line Let's see the manufacturing process How Tiger Boards are made [Tiger Board manufadtacturing process] Calcination process Gypsum Board production flow

.jpg)

Gypsum Block Production Line

The gypsum block production line is composed of conveyor, weighing machine for water, weighing machine for gypsum, mixer, moulding, hydraulic system, grip, and control panels Features of Gypsum Block Machine Fully automatic 2020年1月25日 The article by Azimi et al [] was made using a solution with slightly lower concentration of zinc , 120 g/l, but still close to the actual process conditions and can be utilized as a referenceThe internal Outotec values have been measured on site to give reference for the calcium solubility The neutral solution comes in a temperature of about 70–75 ℃ to the Outotec Gypsum Removal Circuit and Outotec Cooling Tower Performance Gypsum, or hydrous calcium sulfate, is a crucial mineral in the production of everything from wallboard to cement and even many consumer products, surrounding us throughout our daily lives United States gypsum production was at an estimated 20 million metric tons (Mt) of crude gypsum and 16 Mt of synthetic gypsum in 2019, allowing the US to maintain the title of world’s A Look at US Gypsum Production FEECO International IncBenk PVC ceiling production line can make 150600mm width PVC ceiling with your requirements, and it is also very easy to operate the machines Benk also supply aftersale service for PVC ceiling production line for every clients, and benk also supply 1 year guarantee for PVC ceiling machinePVC Ceiling Production Line KM Benk Machine

.jpg)

Process for producing alphahemihydrate gypsum Google

alphahemihydrate gypsum involves placing calcium sulfate dihydrate in an autoclave in the presence of saturated steam at elevated pressure over an extended period of time This method can be used for autoclaving of lump or ground gypsum Typical pressures for the autoclave can be from atmospheric to about 15 psiConstruction and commissioning of a new gypsum production line is only the first stage in a good customer relationship Professional service in daily operation is just as important: We want your investment to be profitable without any interruption – that’s why our engineers are there for you with guidance and support over the entire lifecycle of the plantThe reliable partner during the entire life cycle of a gypsum The November 2024 issue of Global Gypsum Magazine includes a report on gypsum in Thailand to tie in with the location of the Global Gypsum Conference Exhibition, plus its regional neighbours Malaysia, Indonesia, the Philippines and Vietnam This issue also includes the latest technological acquisition of Grenzebach, an indepth discussion with New West Gypsum Global GypsumThere are many decisions for construction and setting up a gypsum board factory depending on the location of the factory, Also the production line layout and technology of the equipment (paper rewinding, mixing, rolls, dryer), the product types and their formulation are the options that clear path to your goalGypsum board factory requirements Gyps Board

.jpg)

Gypsum processing and use Humanitarian Library

Gypsum rock is converted into gypsum plaster by driving off some of the chemically combined water Heating gypsum at 120°C for one hour results in a hemihydrate (CaSO 41⁄2H 2O) – with three quarters of the water removed Gypsum hemihydrate is also known as Plaster of Paris Prolonged heating over several hours results in the formation ofGypsum Powder Production Line Capacity : 20100t/h Applicable Materials : Gypsum ore Applications: Industrial and building materials, medicine, food processing, literature and art and other fields Case Description: Introduce the establishment of gypsum grinding production line and related productsGypsum Powder Production Line Hongji Mining MachineryChina Gypsum Line wholesale Select 2024 high quality Gypsum Line products in best price from certified Chinese Gypsum Board Production Line manufacturers, Gypsum Machine suppliers, wholesalers and factory on MadeinChinaGypsum Line MadeinChina2011年1月1日 Download Citation Gypsum: Properties, production and applications Gypsum is a very soft mineral composed of calcium sulfate dihydrate and often occurs in nature as flattened and often twinned Gypsum: Properties, production and applications ResearchGate

Desulfurization Gypsum Production Line

Shandong Jinxin Corporation In 2004, the first Phosphogypsum Production Line with capacity of 15 million tons was launched and in 2005, it succeeded in producing materials for the company’s15 million square meters gypsum board production line After the year of 2005, we provided phosphogypsum production lines inFor high gypsum board line speed and thus high production capacity utilization the use of high concentrations of gypsumbased ball mill accelerator (BMA) are common practice Very low concentration of retarder, such as amino acid based Retardan200 Multifunctional polymers for increased gypsum board production 2019年5月21日 2 2 Brief Introduction Gypsum is a white to gray mineral found in the earth’s crust Its properties and products of gypsum to be used as building material in construction works are discussed such as the plaster of paris, gypsum board, wallboard, cement etcThe boiling furnace for gypsum industry, gypsum powder production line 2018年7月31日 Cooling processes may be evaluated as one of the energy input of sustainability In this regard, clinker cooling department which is one of the most important parts of cement production line plays a significant 12% C 3 A, 8% C 4 AF, and 5% gypsum This is the typical composition of ASTM Type I cement There Development of Cooling Performance of Clinker Cooler Process

.jpg)

China Customized Gypsum Board Production Line Manufacturers

XIANGYI is one of the most professional gypsum board production line manufacturers and suppliers in China Please feel free to wholesale cheap gypsum board production line for sale here and get quotation from our factory All customized products are with high quality and low price 58 you in the industry of gypsum board production, and searching for a measurement system for the production line? LIMAB offers a high qualityrange of noncontact measurement systems for the gypsum board production processGypsum board production LimabGYPSUM PRODUCTION LINE Gypsum Production Process has become an important study in terms of the product development and improvement of gypsum plant Gypsum has many types with usages in industrial areas After waiting and cooling, the calcined gypsum is GYPSUM PRODUCTION PLANT Chemical Process Plants