Analytical pure atomized iron oxide purity

Effect of atomization on surface oxide composition in

2020年6月30日 The results showed that the surface oxides consisted of a thin (~4 nm) iron oxide (Fe 2 O 3) layer with particulate oxide phases rich in Cr, Mn, and Si, with a varying composition XPS analysis combined with depth In regard to purity, sponge iron is reduced from iron ore and even after the reduction process can still contain significant levels of unreduced iron oxide and impurities such as SiO2 and V2O5 PROPERTIES AND APPLICATIONS FOR IRON POWDER MADE BY Iron oxide powders (αFe2O3) were obtained via a chemical process A homogenous mixture prepared from iron (II) chloride tetrahydrate and urea of analytical purity and water was heated SYNTHESIS AND CHARACTERIZATION OF IRON OXIDE POWDERS2015年1月1日 Iron and Iron oxide are widely used in catalytic, magnetic and biomedical application including contrast agents, drug delivery and hyperthermia Recently, laser ablation Structural and Optical Properties of Pure Iron and Iron Oxide

Understanding atom probe's analytical performance for iron

We systematically varied analysis parameters to study oxygen deficiencies, and to improve the understanding of the formation and dissociation of molecular ions We complemented 2011年10月25日 According to the Applicant, Iron oxide (black minimum content of total iron of 60 % [24] The A pplicant states that the purity criteria set in feed additive [57] The three IronEvaluation on the analytical method Iron oxide2020年6月25日 In this study, the surface chemistry of iron and steel powder was investigated by combined surface and thermal analysis The progressive reduction of oxides was studied using model sintering cycles in hydrogen Evolution of surface chemistry during sintering of 2020年6月30日 This study aims at understanding the reaction kinetics for reduction of the aforementioned oxide scale on the iron nanopowder when heated in pure hydrogen Investigation on the reduction kinetics of the micron meter Analysis of Iron Oxide Reduction Kinetics in the

Synthesis, Properties, and Applications of Iron Oxides: Versatility

2021年5月18日 Iron oxides nanoparticles with magnetic properties are good candidates for biomedical applications as they improve the quality of magnetic resonance imaging (MRI), cell 2023年11月4日 In this study, firstly, an ultrapure magnetite concentrate with 7212% Fe and 009% Si was obtained by reverse flotation from superior magnetite concentrate with 6838% Fe and 233% Si Then, using the ultrapure magnetite concentrate as raw material, highpurity reduced iron powder with Fe grade of 9906% was prepared by Höganäs process, of which Preparation of highpurity reduced iron powder by Höganäs 2020年6月25日 Wateratomized iron and steel powder is commonly used as the base material for powder metallurgy (PM) of ferrous components The powder surface chemistry is characterized by a thin surface oxide layer and more Evolution of surface chemistry during sintering of 12011 (Steel for determination of C, C: 5µgg−1), AIron (Highpurity electrolytic iron, RRRH = 1570 Toho Zinc Co Ltd) and LECO 501078 (Low sulfur iron powder LECO Corp) 23 Analytical procedure 231 Determination of C and S by combustion/infrared absorption method Analytical procedures21,22) were previously described in detailDetermination of Trace Element Quantities in Ultra HighPurity Iron

Iron powder for pressing sintering Höganäs

Our pure iron powder grades are produced by atomization or reduction Carbide powders Iron based powders MCrAlY based powders Molybdenum based powders Nickel based powders Oxide based powders Pure metals, alloys other Powders for cold spraying Outstanding compressibility and chemical purityShowing 130 of 43 results for "iron powder" within Products Products Building Blocks Explorer Genes Papers Technical Documents Site Content Chromatograms Filter SortIron powder SigmaAldrich MilliporeSigma2020年6月30日 From the powder metallurgical field, it is known that wateratomized prealloyed iron powders with strong oxide forming elements like, Cr and Mn form, besides the dominant Ferich thin oxide film, minor amounts of oxide particles 13 If not reduced, these more stable oxsides remain within the consolidated sample 46 Similar correlations have been drawn Effect of atomization on surface oxide composition in 316L 2018年1月1日 A very high purity (9999+%) high temperature cofired ceramic (HTCC) alumina has recently become commercially available The raw material of this HTCC alumina is very different from conventional (PDF) Determination of trace impurities in high purity aluminium oxide

Characteristics and Sintering of Fine Wateratomized and Carbonyl Iron

I Surface analysis of fine wateratomized iron powder and sintered material J Wendel, R Shvab, E Hryha, L Nyborg Accepted for publication in Surface and Interface Analysis, ECASIA 2017 special issue II Sintering behaviour of fine wateratomized iron powder – effect of initial green state J Wendel, S Manchili, E Hryha, L Nyborg2020年4月14日 iron with 999% purity is about $1000 US dollars / tonne, and the price of pure iron with 9995% purity has climbed to $4000 US dollars / tonne, while the price of ultrahighpurity iron with 99 The Preparation of HighPurity Iron (99987%) Employing a AA59179 Iron Oxide, purity, functionalities, etc) is available upon request NOTE: Images, pictures, colors, particle sizes, purity, packing, descriptions, and specifications for the real and actual goods may differ Gas Atomized is generally immediately available in most volumesAA59179 Iron Oxide, black, technical Low Price $12020年6月1日 atomized using high purity Ar gas However, A 9999% pure Fe strip was cleaned using 4 kV ion sputtering until no oxide or The complex iron oxides were found in the austenitic steel powder (PDF) Effect of atomization on surface oxide

.jpg)

Tailoring green and sintered density of pure iron parts using

2018年12月1日 Typically, spherical powders allow for a higher packing density in the powder bed, thereby increasing the attainable density of a printed sample [9]Inaekyan et al [7] have utilized BJAM with wateratomized iron powder and examined the densities and mechanical properties that can be obtainedThe authors reported a green density nearing 40%, a sintered 2015年12月31日 Various magnetic nanoparticles like iron carbide (Fe3C), magnetic iron oxide (magnetite/maghemite), metal iron (αFe), and iron@iron oxide are obtained by varying the solvent and keeping Structural and Optical Properties of Pure Iron and Iron 2024年6月11日 Sustainable and highly efficient production of highpurity iron from oxide ores by acidic electrowinning in anionrich electrolytes June 2024 DOI: 1026434/chemrxiv2024stwdnSustainable and highly efficient production of highpurity iron 6 Formula for percentage purity percentage purity = mass of pure substance ÷ mass of impure sample × 100% To find the mass of pure substance, we can react a sample and leave the impurities behind From the amount of product formed, we can back calculate to find out the amount of the pure substance that actually reactedStoichiometry: Percentage yield percentage purity

.jpg)

Iron Powder Material Additive Manufacturing Material

2023年12月11日 Carbonyl iron: Ultrafine high purity powder produced via iron pentacarbonyl decomposition: Water atomized: Made by atomization of molten iron pumped through nozzle; irregular shapes: Electrolytic: Deposited from aqueous iron salt solutions onto cathodes: Reduced iron: Produced from mill scale via H2/CO reduction at 400700°C: Annealed2018年11月12日 Most iron oxide nanoparticles applications, and in special biomedical applications, require the accurate determination of iron content as the determination of particle properties from measurements in dispersions is strongly dependent on it Inductively coupled plasma (ICP) and spectrophotometry are two typical worldwide used analytical methods for Improving the reliability of the iron concentration quantification 2020年6月30日 TG graphs for the reduction of oxide layer on Fe nanopowder in pure hydrogen up to 1000 K, showing results for size ranges (a) 4060 and (b) 6080 nm, respectively(PDF) Analysis of Iron Oxide Reduction Kinetics in the2013年3月1日 Characterization of oxide products on the surface of wateratomized steel powder is essential in order to determine the reducing conditions required for their removal during the sintering stage Characterization of Surface Oxides on WaterAtomized

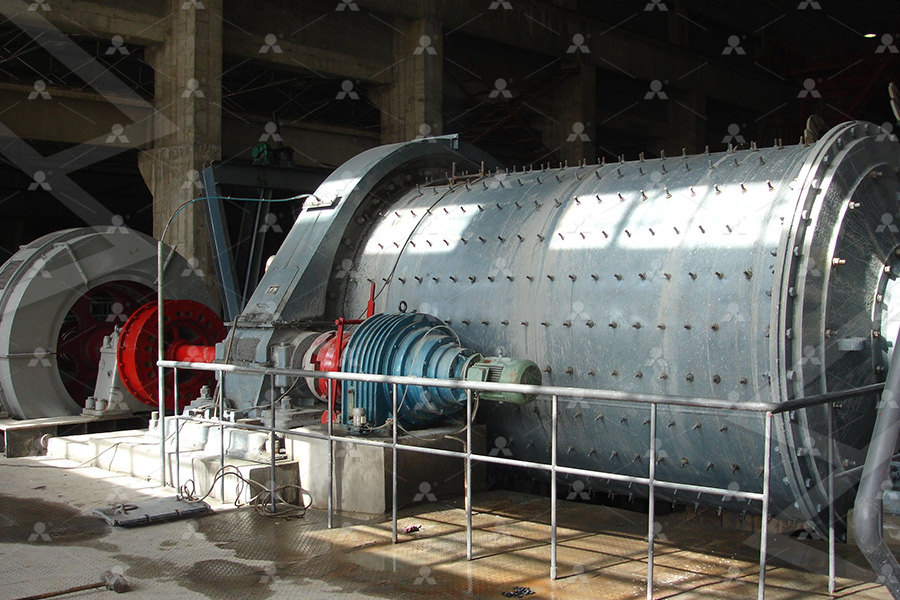

Atomized Pure Iron Powder LWPM

LAP10029 is a kind of ultrapure water atomized iron powder With apparent density 295310g/cm3, good compressive performance, wide range of application, and it is widely used in the production of high strength and high density sintered structural parts2019年3月1日 Preparation of HighPurity Aluminum Oxide via Mechanochemical Oxidation of Aluminum in a 01 M KOH Solution, Followed by Chemical and Heat Treatments(PDF) Preparation of HighPurity Aluminum Oxide via FE10029 is a high purity water atomized iron powder with irregularly shaped and high density particles The high compressibility of FE10029 makes it a perfect choice for manufacturing pure iron or iron alloy parts with high tensile strength Iron Powder Manufacturers and Distributors – Find 2023年7月7日 Similarly, Iron Oxide NPs showed excellent antimicrobial potential against bacterial species “Salmonella typhi” “Xanthomonas Oryzae” and “Lactobacillus” at low concentrations (150 µg/mL)(PDF) Synthesis, characterization, and applications of

High Purity Iron Powder Additive Manufacturing Material

2024年11月15日 Introduction High purity iron powder is a critical material used in various industries, from metallurgy to electronics But what exactly makes it so special? How does it differ from regular iron powder? In this guide, we’ll dive deep into the world of high purity iron powder, exploring its composition, characteristics, applications, and much more2020年4月14日 In this study, highpurity iron with purity of 99987 wt% was prepared employing a process of direct reduction–melting separation–slag refining The iron ore after pelletizing and roasting was reduced by hydrogen to obtain direct reduced iron (DRI) Carbon and sulfur were removed in this step and other impurities such as silicon, manganese, titanium and aluminum The Preparation of HighPurity Iron (99987%) Employing a2020年6月26日 Water‐atomized iron and steel powder is commonly used as the base material for powder metallurgy (PM) of ferrous components The powder surface chemistry is characterized by a thin surface oxide Evolution of surface chemistry during sintering of water atomized iron Atomized Copper Powder available in all sizes ranges for research and Industrial application (pure copper powder) or gas atomized (spherical copper powder) methods TitanateLithium Titanium Oxide Nanopowder: Colour: White: Purity: ≥ 9999%: Particle size: 110 µM(customizable) Ingredient/MF: Li4Ti5O12:Atomized Copper Powder Low Price $30 Highly pure

.jpg)

Preparation and formation mechanism of monodisperse micaceous iron

2018年4月15日 1 Introduction Iron oxide is an important inorganic nonmetallic material, which is widely used in pigments [1, 2], catalyzer [3, 4], biomedical engineering [5] and other fields [6]Micaceous iron oxide (MIO), a type of hematite (Fe 2 O 3), has attracted much attention due to its good durability, excellent chemical stability and low cost [[7], [8], [9]]2020年10月1日 The surface oxide layers covering wateratomized iron and steel powder have been studied using thermogravimetric and surface analysis methods The oxide layer on the nominally pure iron powder ASC10029 was shown to be reduced at just below 400 °C under dynamic conditions at 10 °C/min in highpurity hydrogenReduction of surface oxide layers on wateratomized iron and 2023年11月4日 In this study, firstly, an ultrapure magnetite concentrate with 7212% Fe and 009% Si was obtained by reverse flotation from superior magnetite concentrate with 6838% Fe and 233% SiPreparation of highpurity reduced iron powder by Höganäs Atomized Iron Powder is relatively pure with irregular particles that are produced by the atomization method We also can supply spherical iron powder CNPC Atomized iron powder is the best material that can be used for suppressing Purity: 995%997: Certification: ISO9001,SGS,RoHS:Atomized Iron Powder Pure Iron Powder Metal Powder

.jpg)

Pure Analytical Laboratories Your High Purity Metals Specialists

Certified high purity inorganic materials precious metals including over 70 elements and their compounds; We Offer: Custom synthesis of new material for fuel cells, renewable energy sources other industrial applications; We Offer: Certified custom powder standards for X RF;2013年9月1日 Water atomized steel powder particles are covered by heterogeneous surface oxide, formed by thin (~ 6 to 8 nm) iron oxide layer covering most of the powder surface, and particulate features formed Oxide Transformation in CrMnPrealloyed Sintered Steels2022年10月25日 The iron nanopowder is covered by a 3–4 nm thick iron oxide layer, while the carboncoated iron nanopowder is encapsulated with several nanometric carbon layersCarboncoated iron nanopowder as a sintering aid for wateratomized Analytical and Pure Reagents indicated for general analytical applications that need high purity levels and very low Aluminium Nitrate 9hydrate pure, 9801020% b G Aluminium Oxide Basic (Reag Ph Eur) for analysis for chromatography in column 4 bAnalytical and Pure Reagents Tecora

Analysis of pure copper A comparison of analytical methods

2008年9月1日 The reliability and performance of various analytical methods for the determination of 22 trace elements in pure copper is compared and discussed2020年6月30日 Iron nanopowder is hence used in the present research as an additive to improve the density of wateratomized iron powder compacts The purity of the metal powder was higher than 995 wt % The reference Fe 2 O 3 nanopowder was also obtained from the same 998% pure iron oxide αFe 2 O 3 → Fe 3 O 4, 76: Hydrogen reduction Analysis of Iron Oxide Reduction Kinetics in the NanometricBrowse a full range of High Purity Grade Analytical Water products from leading Molecular Weight (g/mol): 18015 MDL Number: MFCD InChI Key: XLYOFNOQVPJJNPUHFFFAOYSAN Synonym: dihydrogen oxide,dihydrogen monoxide PubChem CID: 962 ChEBI: CHEBI:15377 IUPAC Name: oxidane SMILES: O Promotions NC IMPAK ULTRA High Purity Grade Analytical Water Fisher Scientificized iron powder in which molten iron is atomized using pressurized jet of fluid (gas/water) to produce pure, spherical/irregular and coarse iron powder; and reduced iron powder in which oxides of iron are subjected to carbothermic or hydrogen reduction to produce pure, irregular and coarse iron powder2) Iron powder with diverse sizes, shapes,Physicochemical Properties of Mill Scale Iron Powders JSTAGE

Calculate the percentage of pure iron in 10 Kg of iron (III) oxide

2022年8月19日 VIDEO ANSWER: So to solve for this, you're going to right here the equation per percent mass of iron It will be equivalent to the mass of iron divided by the mass of iron oxide of p2 03 multiply by 100% Okay, so using this equation, let's solve