HOME→Ore powder grinding production process Ore powder grinding production process Ore powder grinding production process

Ore powder grinding production process Ore powder grinding production process Ore powder grinding production process

Ore Grinding SpringerLink

2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding process, rod grinding process, and autogenous grinding process Ore grinding process falls 2021年9月6日 A pulverization method for micronsized ore powder production by highpressure gas propulsion is proposed In this paper, we discuss the methods and pulverizing mechanism Micronsized ore powder production by propulsion and rapid Ore powder production involves the conversion of mined ore into fine particles through a series of crushing, grinding, and classifying processes The equipment used in this process must be Advancements in ore powder production process equipment: ore grinding is divided into dry grinding, wet grinding, and moist grinding Dry grinding relies on pneumatic conveying, in which the classification system and gas supply system of grinding Ore Grinding Methods and Process of Ore Grinding

.jpg)

(PDF) Some features of the grinding process in the production of

2020年1月1日 PDF The article sets out some of the features of the grinding process in the production of powdery materials Analysis of the literature review on the Find, read and cite The use of fossil fuels such as coal, natural gas, and oil is common in cement production, both as a fuel for the kiln and as a source of heat for other parts of the process which leads to CO2 emitted by combustionHowever chemical reactions happening in the kiln (calcination) are also responsible for up to 60% of the total of emissions of the cement production process [PCA]Cement Production Demystified: StepbyStep Process and Powder processing often involves bulk powders, additives, or ingredients being milled for particle size reduction A mill or grinder uses a mechanical action to break the material and reduce it to the required size This may encompass a Grinding Milling Powder ProcessSolutionsJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

Leadzinc ore crushing and grinding process SBM Ultrafine Powder

2022年6月10日 The processing and production process of leadzinc ore mainly includes three processes: crushing, grinding and beneficiation In the crushing process, the threestage closedcircuit crushing is a more modern method suitable for the crushing of highhardness leadzinc ore, which can complete the work of ore crushing and partial dissociation, thereby improving the 2024年8月1日 When producing black powder using a ball mill, the type of grinding media used plays a crucial role in the efficiency and quality of the final product Different types of media have various advantages and disadvantages, affecting the grinding process and the characteristics of the black powder Steel, Ceramic, and Lead Media: Pros and ConsEffective Ball Mill Media for Superior Black Powder ProductionThe barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERY2013年1月1日 This operation is usually associated with spray drying, freezedrying, roller drying, crystallization or intervention on their terminal operation as formatting This chapter highlights the importance of grinding in food powder production The main grinding theories have been described as well as the related mathematical modelsGrinding for food powder production ScienceDirect

From Ore to Finished Product Copper

From its original home buried underground in a mine to its use in a finished product such as wire or pipe, It is found in ore deposits around the world The next step in the process flow is smelting for sulfide ore concentrate and solvent extraction for oxide ore leach solution 62012年6月1日 The feed material is typically composed of the BFRs and the catalyst, both in powder form As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed Grinding in Ball Mills: Modeling and Process Control2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber of the mill 2 Grinding: Inside the grinding chamber, the bauxite ore is subjected to a series of grinding processes The grinding rollers and rings in How does HGM micro powder grinding mill process bauxite?1, Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing But the degree of largescale is relatively lower compared to vertical grinding mill 2, HLM vertical mill: largescale equipment, high capacity, to meet the largescale production Iron ore grinding mill Grinding plants for Iron Ore

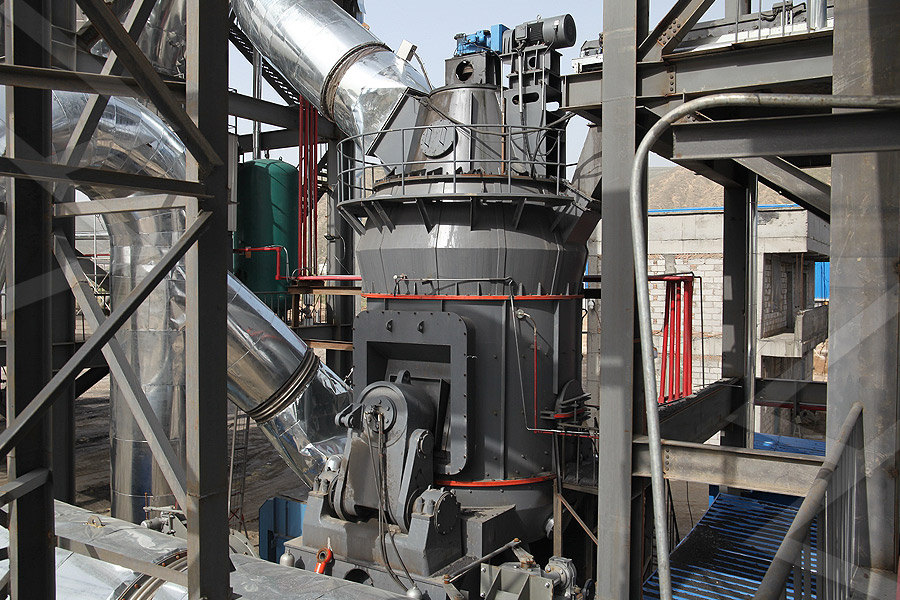

Advancements in ore powder production process equipment:

Ore powder production involves the conversion of mined ore into fine particles through a series of crushing, grinding, and classifying processes The equipment used in this process must be robust, efficient, and capable of handling the diverse characteristics of different ore types2023年9月5日 2 The Process of Powder Metallurgy (1) Powder production This process includes the creation and mixing of the powder To enhance the moldability and plasticity of the powder, plasticizers such as gasoline, rubber, Powder Metallurgy: A Comprehensive Guide for 2020年3月28日 The grinding product t10 is negatively correlated with the feed sizes of ore when the grinding force is applied to the ore At the same time, it has a simple positive linear relationship with the Development of a Novel Grinding Process to Iron Ore Pelletizing SOME FEATURES OF THE GRINDING PROCESS IN THE PRODUCTION OF POWDER MATERIALS Yunusov Bakhtiar1, Normuminov Jakhongir1 1The Tashkent state technical university, after I Karimov, Tashkent city, Uzbekistan Annotation The article sets out some of the features of the grinding process in the production of powdery materialsSome features of the grinding process in the production of powder

Powder Metallurgy Processes and Making Metal Powder

2020年10月26日 This research includes a review of powder metallurgy processes, advantages and disadvantages, applications, and production methods of metal powder Powder metallurgy process steps consist of The article sets out some of the features of the grinding process in the production of powdery materials RSES 2020 SOME FEATURES OF THE GRINDING PROCESS IN THE PRODUCTION OF POWDER MATERIALS Yunusov Bakhtiar1, Normuminov Jakhongir1 1The Tashkent state technical university, after I Karimov, Tashkent city, Uzbekistan Annotation(PDF) Some features of the grinding process in the production of powder Iron Oxide Grinding Production Line With HGM80 Ultrafine Mill In the Iron Oxide Grinding Production Line, HGM80 ultrafine mill is used to process 1250 mesh iron oxide powder, with an hourly output of 12 tonsSBM Ultrafine Powder Technology Industrial Grinding Mill, 2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing Su XD, et al A Grinding Wheel of SelfLubrication with Solid Powder Lubricant and Centrifugal Impeller Lopes JC, Rodriguez RL, et al Novel comparison concept between CBN and Al2O3 grinding process for ecofriendly production J Clean Prod 2022 A comprehensive review on the grinding process: Advancements

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 AG/SAG mills are typically used for coarse grinding, where large pieces of ore are efficiently broken down The grinding process reduces the ore size, which enhances the efficiency of subsequent beneficiation processes by increasing the surface area available for chemical reactions and physical separations 2 BeneficiationMedia Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using 82: Mining and Ore Processing Geosciences LibreTexts2022年4月1日 In this work, we explore an alternative route for producing metal powders by the use of surface grinding We demonstrate the production of nearly monodisperse AISI 52100 steel powders for AM applications The formation of these powder particles is analyzed using material characterization techniquesProduction of powders for metal additive manufacturing 2022年5月24日 The copper ore processing and production process mainly includes three processes: crushing, grinding and beneficiation Email: sales@clirik Call Us: +86 HOME; >>Stage 2: Grinding Copper ore crushing processNEWSCLIRIK ultrafine

Cocoa Powder Manufacturing Process: From Bean to Powder

What are some FAQs about cocoa powder production? Cocoa powder is an essential ingredient in many products and recipes, from chocolate bars to hot cocoa But how is it made? Here are some frequently asked questions about the cocoa powder manufacturing process What role does temperature play in the process? Temperature plays a crucial role in 2023年5月6日 In the crushing process of copper ore processing, the twostageclosedcircuit crushingsinglestage ball milling process is more common in small copper ore concentrators whose production scale is below 500t/d Threestage crushing is currently the most crushing and grinding process used by large and mediumsized copper ore concentratorsCopper Ore Production Process JXSC Mineral2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s energy budget Overall Energy Use of Fine Grinding in Mineral Processing2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of Iron Ore Processing, General SpringerLink

Quartz Processing Mastering the Art of Stone to Powder

2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to below 25 mm Quartz Grinding The finely crushed quartz particles are conveyed by bucket elevators to storage bins, then fed into quartz ball 2017年3月4日 It is a process of ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue mineralsSIZE REDUCTION BY GRINDING METHODS ResearchGate2023年9月6日 4 Milling: The dried talc ore is then milled into a fine powder Milling involves grinding the talc particles to achieve the desired particle size distribution Different types of grinding mills, such as ball mills, Raymond mills, or ultrafine vertical mills, Talcum Powder Production Process2021年11月3日 Phosphate Rock Processing Process Phosphate ore processing and production processes mainly include three processes: crushing, grinding, and beneficiation In the crushing process, the threestage closed Phosphate Mineral Powder Grinding Mill SBM

Machining 101: What is Grinding? Modern Machine

2021年7月3日 Grinding process control balances these three interactions to achieve the desired parameters These interactions feed into three major commercial grinding processes: rough grinding, precision grinding and ultra HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM SBM Ore Ultrafine Grinding Mill2017年2月16日 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents and solid fuel (coke)(PDF) Iron Ore Sintering: Process ResearchGate2024年2月26日 In this work, the grinding, settling and filtering behaviour of Brazilian and Australian iron ore fines are studied and compared, with the aim of discovering the internal relationship between the (PDF) Grinding of Australian and Brazilian Iron Ore Fines for Low

Magnesite Grinding Equipment Production Line

2021年10月29日 Highpressure mill: can produce 50325mesh magnesite ore powder HGM ultrafine grinding mill: can produce 1503000mesh magnesite powder, the powder quality is medium and high CLUM vertical roller mill: can produce 1503000mesh magnesite ore powder, the powder quality is superior, the fine powder content is higher, and the powder shape is betterGrinding, the first operation in the process, is a crucial step for the subsequent operations Three iron ore mixtures with different grindability index (low, medium, and high) were used in order to verify the influence in the operational parameters such as production rate, discharge density, and pump pressureStudy of Iron Ore Mixtures Behavior in the Grinding Pelletizing ProcessA brief introduction to powder grinding production line Powder grinding production line is widely applied for grinding materials into the size of 80 to 3,000 meshes in various industries of building materials, chemical engineering, chemicals, mining, medical research, construction, and other industries Composition of powder grinding linePowder Grinding Plant with High Capacity and Reasonable Price 2019年1月15日 Autogenous grinding is the process in which, the ore is grounded itself without any grinding media As the grinding media is harder than the ore, there is always high impact force applied to the ore, which leads to the breakage throughout the materials but not through the interfaces between the materials present in ore [21]For the present study, two different run of Generation of low ash fine clean coal powder by autogenous grinding