Grinding limestone glass production method

.jpg)

Glass Manufacturing Process How is Glass made

2019年1月29日 The float glass production process can be divided into five universal steps: 1Batching of raw materials: The main components, comprising silica sand, calcium oxide, soda magnesium are weighed and mixed into Sodalime glass consists of sand, limestone, soda ash, and cullet (broken glass) The manufacture of such glass is in four phases: (1) preparation of raw material, (2) melting in a 1115 Glass Manufacturing US EPA1993年7月1日 The progress of grinding was evaluated by the increasing rate of fine particles The effect of properties of samples on the grinding rate was studied As a result, It was found Production of Fine Particles of Silica Glass and Limestone by 1993年7月1日 A production of fine particles by autogenous grinding with a stirred mill is based on frictional action of feed particles Then, it could be considered that the mechanical propertiesOriginal Production of Fine Particles of Silica Glass and Limestone

.jpg)

Manufacturing Process for Float Glass

Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite These materials are mixed in huge agitators Guidance is ofered for soda–lime–silica glass making with the intention of providing a basis for the assessment of both the continued supply of established limestones and dolomites and the Practical guide for the assessment of glass making limestones and 2023年8月20日 Join us on an illuminating exploration of the intricate steps that bring glass from sand to spectacle , the manufacturing of glass involves blending carefully selected raw materials, including sand, soda ash, and limestone, The Journey of Glass: Unveiling the Manufacturing 2022年5月22日 Therefore, the first aim of this research work was the examination of main grinding parameters of the limestone particles to determine an empiric energymodel Dry and EnergyModel and Life CycleModel for Grinding Processes of

Influence of recycled concrete, marble, glass, and limestone

2024年1月2日 In particular, this study undertakes the grinding of recycled concrete powder (RCP), glass powder (GP), limestone powder (LP), and marble powder (MP) into particles smaller than 0075 mm These finely ground materials are then employed as substitutes for cement at varying rates of 25%, 30%, and 35%, thereby composing mortar mixtures2023年8月20日 Fritting, a method where crushed glass is fused onto a glass surface, imparts texture and depth, transforming plain glass into a threedimensional canvas Enameling, a technique of applying powdered glass that The Journey of Glass: Unveiling the Manufacturing 2013年12月20日 The benefits of using limestone as a partial replacement of Portland cement (PC) are well established in the literature Economic and environmental advantages by reducing CO2 emissions are well known This paper describes the influence of the producing method (intergrinding or separate grinding) and particle size distribution on properties of Portland Influence of grinding method and particle size distribution on the The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY

Assessing the effect of alkanolamine grinding aids in limestone

2020年10月26日 Surfactanttype grinding aids such as propylene glycol, triethanolamine, triethanolamine acetate, and polyglycol phenol ether are also commercially available (Prziwara and Kwade, 2020)2020年11月26日 In this study, a patented dry production method of glass foam was explained that consists of crushing and grinding waste window glasses, mixing natural foaming agents, placing the mixtures into (PDF) A Production Method for Glass Foam InsulationAssessing the effect of alkanolamine grinding aids in limestone calcined clay cements hydration Franco Zunino⇑, Karen Scrivener Laboratory of Construction Materials, EPFL STI IMX LMC, École Assessing the effect of alkanolamine grinding aids in limestone 2024年1月29日 As limestone powder has numerous applications across various industries, selecting the appropriate limestone grinding machine is essential The choice depends on several factors Firstly, it's important to clarify your processing requirements, including the desired fineness of the powder, production capacity, and quality standardsHow to choose limestone grinding mill? SANDMINE

.jpg)

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Understanding material characteristics and defining production needs can help you choose the right crushing method, saving costs throughout the production process Types of crushers Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing2024年7月12日 Step 2: Grinding limestone rocks The crushed limestone needs to be sent to a mill for further fine grinding FTM Machinery offers various options, including Raymond mills, ultrafine mills, and vertical roller mills The grinding process requires precise control over fineness, typically requiring the powder to reach 200 mesh (74 μm) or finerPelletized Lime Production: A Detailed Howto Guidesofter particles to either the grinding media or the harder particles [5] Although these differences in resistance to grinding of clinker blends have been reported, Du¨ndar and Benzer [12] found no difference between the breakage rates of intergrinding and individual grinding blends of clinker, limestone, gypsum and pozzolanResistance to Grinding and Cement Paste Performance of Blends 2021年4月1日 Samples of all raw materials used in this study are shown in Fig 1Clinker, gypsum and limestone were obtained from a cement plant [54]The two types of waste glass, ie, LCDG and SLG, were gathered from a plant that manufactures display glass [55] and a waste glasscollecting company [56], respectivelyThe LCDG fragments consisted of two layers; a Performance of glassblended cement produced by intergrinding

How to Produce Graded Glass Sand by Grinding and Classification

2020年11月8日 The problem of producing a uniform, mediumfine sand for glassfurnace feed has been of interest to the glasscontainer industry for many years In the 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise How to Produce Graded Glass By blending PVC with additives like calcium carbonate, produced by grinding limestone, he finds a way to plasticise it, greatly increasing its commercial use 1957 – Float glass method Sodalime glass is made by heating silica, sodium carbonate and lime to a very high temperatureHistory of limestone uses – timeline — Science Learning Hub2021年2月9日 1 Collection of raw materials The raw materials such as silica (in the form of sand or quartz SiO2), soda ash (Na3CO3), limestone (CaCO3), and cullet (broken glass) are collected separately and mixed in a proper proportion The fusion of cullet (broken glass) is added to bring down the melting point of the chargeManufacture of Glass: Step by Step Process Sciencedoze2022年10月11日 It is also a very efficient and costeffective method of production A float glass window is typically used for smaller windows in The process begins by melting raw materials, such as sand, soda ash, and limestone, in a furnace at temperatures exceeding 2,000 degrees Fahrenheit The molten mixture is then poured onto a Float Glass Process: The Most Common Method Of Manufacturing Flat Glass

.jpg)

Limestone Quarrying and Processing: A LifeCycle Inventory

Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in origin as is the case with travertine2013年11月1日 In addition to the benefit of reducing CO 2 production, the use of cement/limestone or fly ash blends can improve performance [27] the intergrinding method may provide an approach to overcome this delay in set and slow strength gain 4 Glass Ceram, 63 (7–8) (2006), pp 274276 CrossRef View in Scopus Google ScholarJet mill grinding of portland cement, limestone, and fly ash: 2020年2月18日 Event openpit mining methods in the exploitation of limestone by PT Semen Baturaja (Persero) Tbk cause depletion of water, air, and soil At the end of mining activities will leave exmine land (PDF) Environmental Hazards of Limestone Mining and2023年6月29日 The objective of this study is to describe primary lithium production and to summarize the methods for combined mechanical and hydrometallurgical recycling of lithiumion batteries (LIBs)Lithium Production and Recovery Methods: Overview of Lithium

.jpg)

Calcium Carbonate Grinding Mill Powder Modify

2022年5月5日 According to different production methods, calcium carbonate can be divided into heavy calcium carbonate, light calcium carbonate, colloidal calcium carbonate, and crystalline calcium carbonate Heavy calcium 2021年1月10日 Limestone calcined clay cements (LC 3) are a family of blended cements that incorporate limestone and calcined clays replacing part of the clinker [4], [5]Among all the materials that are commonly used as SCM, limestone and calcined clay are the only available in the quantities required for a reduction of the clinker factor on a globalscale [1]Assessing the effect of alkanolamine grinding aids in limestone 2021年4月19日 Herein, we evaluate experimentally the interactions among clinker, limestone and gypsum during the final grinding stage in Portland cement production We present a simple, yet rigorous, method that enables the determination of the individual grinding contributions to the intergrinding processResistance to Grinding and Cement Paste Performance of Blends Blown Glass Casting: In this method, a molten glass gather is blown into the mold, taking on its shape Pâte de Verre: This technique involves creating a pastelike mixture of crushed glass and a binder The paste is carefully placed into the mold, and the mold is fired to melt the glass, leaving behind a solid glass objectOur Glassmaking Processes — The Glass Foundry

.jpg)

How Is Glass Made ? The Magical Transformation Behind The

2024年7月12日 The primary raw materials for glass production include:The primary raw materials for glass production include: Silica (SiO2): Sulphur; as sand or as the salt dendrite for filaments Soda Ash (Na2CO3): It reduces the melting temperature of the silica Limestone (CaCO3): Gives strength to the final format of the product2022年5月22日 Fine and ultrafine grinding of limestone are frequently used in the pharmaceutical, chemical, construction, food, and cosmetic industries, however, research investigations have not yet been published on the combination of energy and life cycle modeling Therefore, the first aim of this research work was the examination of main grinding parameters EnergyModel and Life CycleModel for Grinding Processes of Limestone 2021年7月15日 Ripping and dozing is an alternate method of excavation that has to be integrated with conventional loading, crushing, and transportation arrangements This method has limitations because it is not suited to achieve higher levels of production (ie, >1000 TPD) for many operationsLimestone Mining, Industry, and Society SpringerLinkProduction of glass: limestone is crushed, ground, mixed with sand and other raw materials, and melted The following are some specific processing methods: Limestone grinding: Commonly used methods for limestone grinding include ball mill, vertical mill, Raymond mill, etcHow to process limestone? clirik ultrafine grinding mill

.jpg)

EnergyModel and Life CycleModel for Grinding Processes of Limestone

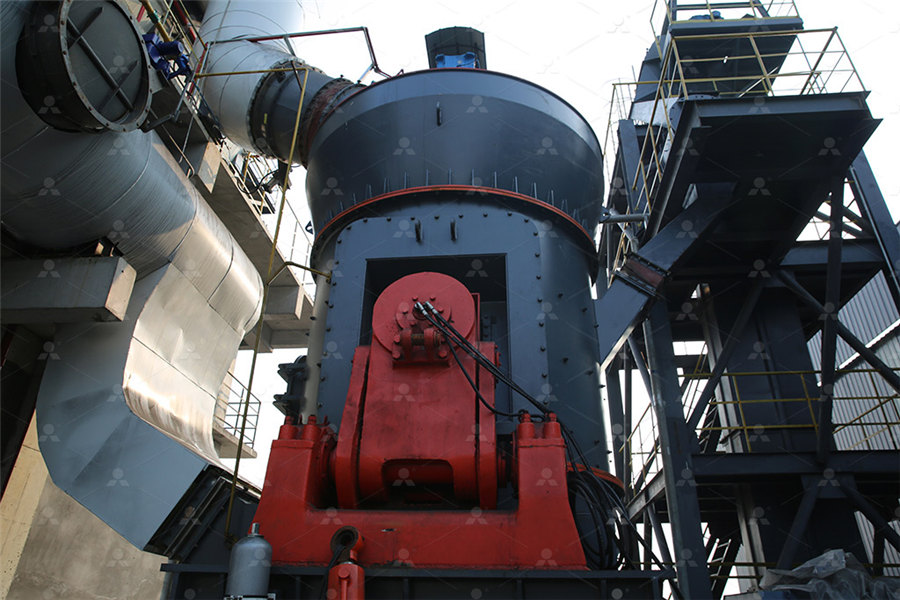

The production of fine and ultrafine limestone particles in grinding mills has an impor tant role for the development of future products Limestone as grinding material is used in2022年5月22日 Normalized and weighted values in the wet grinding process in nanograms (Functional unit: 1 kg of limestone product Impact assessment method: CML 2001/Aug 2016EnergyModel and Life CycleModel for Grinding Processes of Limestone 22*70m Limestone Grinding Mill Machine, Grinding Method SemiDry Grind Certification ISO, CE, ISO9001: ISO14000 Condition New Model 900*1800 Factory Established glass ceramics, etc As well as for ore dressing of both ferrous nonferrous metals The ball mill can grind various ores and other materials either wet or dry22*70m Limestone Grinding Mill Machine2022年8月1日 Preparation of waste glass powder by different grinding methods and its utilization in cement Recycling of calcined lowgrade limestone slurry in producing low carbon cementitious binder towards 2023, Environmental Development Show abstract Conventional cement production is a significant contributor to greenhouse Preparation of waste glass powder by different grinding methods

.jpg)

GLASS PRODUCTION METHOD AND INDUSTRIAL GLASS

2019年10月29日 In a stabilized industrial production trial over several days, in a glassmaking furnace, the limestone being replaced at 100% by calcium oxide, the partial substitution of the sodium carbonate by sodium silicate at 20% of the sodium supplied allowed an increase by 15% of the daily production of the furnace without said production having been pushed to the 2021年4月19日 The production of blended cements involves grinding raw materials such as cement clinker, pozzolan, blast furnace slag, limestone and gypsum, within the same mill This is known as intergrindingResistance to Grinding and Cement Paste Performance of Blends 2021年9月1日 Glass is unique among the archaeological materials of the Late Bronze Age, in its production, use and social meaning Emerging as a regularly produced substance in the midsecond millennium BCE almost simultaneously in both Mesopotamia and Egypt, we still know surprisingly little about its origin and the organization of production and distribution to the elite The Origin of Glass and the First Glass Industries2016年5月1日 The second pilot production of Limestone Calcined Clay Cement (LC3) was carried out in India A survey of several clay mines in Gujarat was carried out and a suitable clay was selected based on (PDF) Second pilot production of limestone calcined clay

(PDF) CEMENT PRODUCTION PROCESS REPORT A SINOYA 1

PDF On Apr 7, 2022, Alick Sinoya published CEMENT PRODUCTION PROCESS REPORT A SINOYA 1 Find, read and cite all the research you need on ResearchGateMelt Processes Lorraine F Francis, in Materials Processing, 2016 343 Float Glass Process The float glass process was invented in the 1950s in response to a pressing need for an economical method to create flat glass for automotive as well as architectural applications Existing flat glass production methods created glass with irregular surfaces; extensive grinding Float Glass Process an overview ScienceDirect Topics2008年4月1日 Through the new method, highenergy grinding was performed using a commercially available planetary mill on silicate materials such as limestone, feldspar, corundum, and quartzFast test method for the determination of the grindability of 2021年4月1日 This study aims to investigate the grindability and performance of glassblended cements depending on the grinding method and glass type Two grinding methods, intergrinding and separate grinding, and two types of waste glass, liquid crystal display glass (LCDG) and sodalime glass (SLG), were considered To study grindability, the milling characteristics of the Performance of glassblended cement produced by intergrinding