Har Driver of Bin kaolinite clay mixing station

Use of kaolinite clays in development of a low carbon MgOclay

2021年6月1日 This study investigates the feasibility of using calcined kaolinitic clay to produce an MgO binder The MgObased binder were prepared using a low kaolinite content clay and 2021年4月15日 Kaolinitic clay, with its high pozzolanic reactivity after activation and abundant resources worldwide, is regarded as a promising supplementary cementitious material (SCM) Recent progress of utilization of activated kaolinitic clay in 2024年5月20日 This paper aims to utilize the waste hydrocarbonated shale (HCS) from the Tazareh Coal Mine in nanoscale particles to enhance the mechanical properties of low Improving Mechanical Properties of LowStrength Kaolin Clay by 2021年3月29日 Highly kaolinitic and composite calcined clays combined with Portland cement and limestone Hydration of clinker enhanced in both binary and ternary binders Lower Calcined clay – Limestone cements: Hydration processes with high

.jpg)

Microstructure and PhysicalMechanical Characteristics of Treated

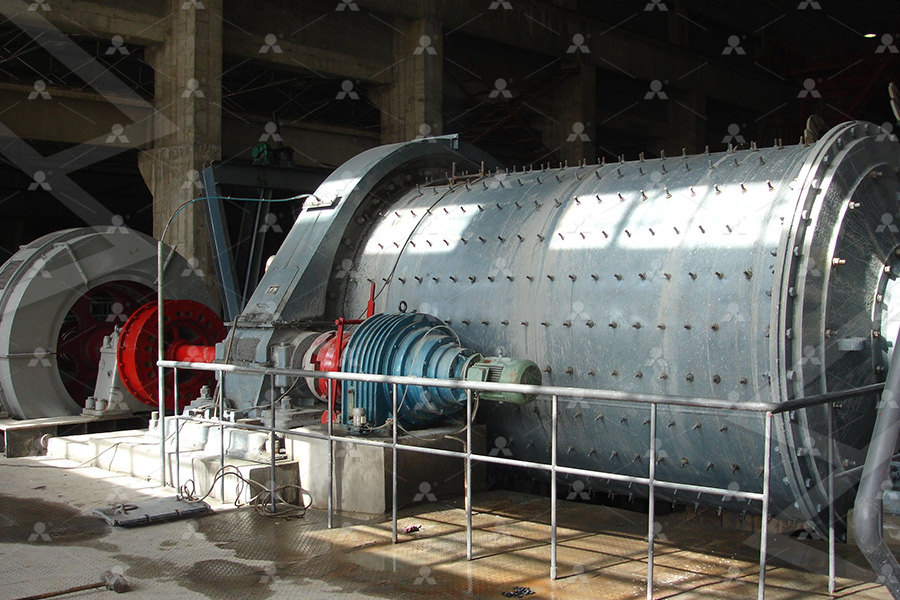

clays were simulated by adding varying proportions of the bentonite to the kaolinite (considered here as the parent soil) and thoroughly mixing the powders to produce five soils of wide 2013年5月1日 The addition of alkaliactivated ESP transformed the soil from highplasticity to lowplasticity clay and significantly increased the overall particle size; the clay fraction Characterization of alkali activated kaolinitic clay ResearchGate2020年2月18日 Researchers have identified numerous techniques to enhance the compatibility of SBS with the asphalt binder such as use of clay, functional groups and crosslinking agents Effect of kaolinite clay/SBS on rheological performance of asphalt Abstract A new largescale suspension calcination process and key equipment suitable for dehydration and calcination of kaolin clay are introducedResearch and Design of Suspension Calcining Technology and

.jpg)

Mechanical behaviour of compacted kaolin clay stabilised via alkali

2022年12月1日 Carbon saving can be achieved by using industrial waste as binder in place of conventional binders Alkaliactivated fly ash from coal combustion has been used as binder 2024年5月14日 This investigation examines the effect of clamshell ash (CSA) and lime additives on the physicomechanical characteristics of kaolinite clay soil stabilized at the optimum silica Experimental investigations on physicomechanical properties of 2017年10月28日 The increase of the calcined kaolinite content of calcined clay leads to a decrease of the clinker hydration degree, more metakaolin is consumed, leading to the formation of higher amount of CASH Significant refinement of porosity is observed for LC 350 systems compared with PC, even for the blend containing only 170% of calcined kaolinite in calcined clayHydration Study of Limestone Calcined Clay Cement (LC2024年2月28日 Changes in surface charge properties with time were measured after mixing times of 1, 3 and 15 h, the latter representing “equilibrium” Timedependent behavior is believed to be caused by mineral dissolution followed by readsorption or Surface Charge Properties of Kaolinite Clays and Clay Minerals

Simple and Reliable Quantification of Kaolinite in Clay Springer

2020年4月14日 21 Clay Characterization In this study, 14 clays from 9 countries were used TGA was used as reference technique for the kaolinite content determination The kaolinite content wt% kaolinite is obtained from the mass loss during kaolinite dehydroxylation wt% kaolOH according to Eq 1, where M kaolinite (25816 g mol −1) and M water (1802 g mol −1) 2019年5月30日 Understanding the adsorption mechanism of CO2/CH4 in kaolinite clay is essential for the carbon dioxide geological sequestration and enhanced gas recovery in shale reservoirsAdsorption mechanism of CO2/CH4 in kaolinite clay: insight from 2019年6月1日 PDF The impact of substitution of cement paste with uncalcined clay (bentonite and kaolinite) Table 1) in the clays Mixing of Series 1 was undertaken in a custommade 2 litres container by Clays as SCM – Reactivity of Uncalcined Kaolinite and Bentonite, and emulsifier for about 72 hours, the clay was sieved with a 7μm sieve and the filtrate was allowed to settle down while continuously decanting the water The concentrated clay was then transferred into centrifuge cups and set to rotate in the centrifuge for 30 minutes The clay was then removed and spread on a panEffect of Kaolinite Clay on Properties of Drilling Mud

Kaolinization of 2:1 type clay minerals with different swelling

2020年5月1日 Furthermore, the edges of the illite particles in P0I8 were sharp (Figure 4b), while those of the intermediate particles of P2I8 were round and had attached precipitates of 2501000 nm (Figure 4c)2024年9月21日 This study investigated the physicochemical effects of kaolinite (CK) and montmorillonite (CM) calcined clays on the sulfate balance, early hydration, and artificial pore solution of limestone calcined clay cement (LC3) The effects of fineness, clay dissolution, and ionadsorption capacity were evaluated by isothermal calorimetry, compressive strength, ICP Effects of kaolinite and montmorillonite calcined clays on the 2024年5月28日 The adsorption behavior of NH 4 + and Mg 2+ at kaolinite surfaces was investigated by using molecular dynamics (MD) simulations, considering the factors such as ion concentration, NH 4 + /Mg 2+ mixing ratio, and layer charge of kaolinite The results showed that the increase in ion concentration did not affect the adsorption modes of NH 4 + and Mg 2+ Adsorption behavior of NH4+ and Mg2+ at kaolinite surfaces: 2015年8月25日 Red ceramics were produced at 750°C by mixing reddish yellow kaolinite clay from Marom (West Region of Cameroon) with waste glass (percentage ranging between 0 and 15% mass) Depending on the nature of the materials, kaolinite clay, waste glass and ceramics were characterized by determination of chemical and mineralogical compositions, linear Red ceramics produced from mixtures of kaolinite clay and

.jpg)

Inducing Hydrophobicity to Improve Long Term Engineering

2018年10月11日 Mixing siloxane in kaolinite results in physical adsorption of siloxane onto the surface of kaolinite, without changing the crystalline structure of the clay, as seen in the XRD results An optimum amount of 75 wt% of siloxane in kaolinite was found which presented a maximum contact angle of 128º2020年9月18日 This paper presents effects of particle size distribution and plasticity on geotechnical properties of sandclay mixtures Two different clay types (kaolinite and bentonite) were mixed with differentsized clean sand at mixture ratios of 0 to 100% with increasing 10% by dry weight An intensive series of standard compaction, Casagrande, fall cone, and plastic limit Observations and findings on mechanical and plasticity behavior 2020年4月1日 This study investigates the feasibility of using an oven and a balance to determine the kaolinite content in clay The mass of 14 clays was recorded after three heating steps at 200 ℃, 400 Simple and Reliable Quantification of Kaolinite in Clay Using an 2005年2月1日 Styrene–butadiene–styrene copolymer (SBS)/kaolinite clay (KC) compounds were prepared using a mixing technique The effects of SBS/KC ratio and mixing temperature on the mechanical properties of the compounds and the Preparation and properties of styrene–butadiene–styrene

Performance of Limestone Calcined Clay Cement (LC3) with

2018年9月10日 Five clays from various sources with different kaolinite content (17–95%) were studied The main factor controlling the diffusivity of LC³ systems was found to be the kaolinite content of the clay2024年9月16日 Limestone calcined clay cement (LC3) is emerging as an alternative to Portland cement, offering economic advantages, reduced CO2 emissions, and mechanical properties on par with Portland cement Central to the effective utilization of LC3 is understanding how the fineness of its components affects its performance The current study investigates limestone Effects of clay type and component fineness on the hydration and Preparation of soft clay A soil bed of 400 mm height was prepared from a kaolinite acquired from a local company (ElBasateen for Industry, CairoEgypt) The soil bed was prepared by mixing the kaolinite with a water content near to its liquid limit using a mechanical mixer for 20 min to reach full saturation and homogeneitySoft clay improved by deep cement mixing column technique2007年8月25日 Particle and crystal unit of kaolinite clay a, Crystal unit and particle (after Carroll 15 ); b, Arrangement of atoms in the crystal unit (Brindley 2 )Variation in geometric arrangement of particles in Kaolinite clay

Identification of Microfabric of Kaolinite Clay Mineral Using X

2007年7月24日 The Xray diffraction data on Kaolinite clay presented by Gurner (), Brindley and Robinson (1946a, b), Martin (), Gillot (), Yoshinaka and Kazama (), and Martin and Ladd indicates that the clay specimens with dispersed microfabric have strong basal peaks (reflections from basal planes such as 001, 002) but show a decrease in intensity for prism peaks (reflections PDF On Jan 1, 2015, Blanca Bauluz Lázaro published HALLOYSITE AND KAOLINITE: TWO CLAY MINERALS WITH GEOLOGICAL AND TECHNOLOGICAL IMPORTANCE Find, read and cite all the research you need on HALLOYSITE AND KAOLINITE: TWO CLAY MINERALS WITH 2024年1月1日 Dry, homoionic systems of two montmorillonites and a kaolinite were treated with NH 3 and then evacuated exhaustively to eliminate any physically adsorbed ammonia It was concluded that the NH 3 retained by the minerals was associated with the exchangeable cations The mechanism of this adsorption process is the same as that which leads to the formation of Mechanism of NH3 Adsorption by Montmorillonite and Kaolinite Clays Request PDF On Dec 1, 2023, Laura Stefanini and others published Characterisation of calcined waste clays from kaolinite extraction in alkaliactivated GGBFS blends Find, read and cite all the Characterisation of calcined waste clays from kaolinite extraction

PREPARATION AND CHARACTERIZATION OF KAOLINITE CLAY

PREPARATION AND CHARACTERIZATION OF KAOLINITE CLAY FOR PRODUCTION OF NATURAL POZZOLAN Zin Mar Aung1, Mar Mar Swe2 Abstract 50x50x50 mm cube specimens, at the end of the mixing period The hand tamping method was used to finish the mortar consolidation in the mold2007年11月23日 Lawal et al (2022) stated that kaolin is a white, soft, and plastichydrated aluminum silicate clay mineral composed of kaolinite, dickite, nacrite, and halloysite that is formed by the Identification of Microfabric of Kaolinite Clay Mineral Using Xray 2009年1月31日 Request PDF Behavior of kaolinite and illitebased clays as landfill barriers The technical requirements for the landfill of municipal wastes in the European Union (EU) are given in the Behavior of kaolinite and illitebased clays as landfill barriersPDF On Apr 10, 2019, MA Abuh and others published Implications and characterization of waste glass cullet – kaolinite clay ceramics Find, read and cite all the research you need on Implications and characterization of waste glass cullet – kaolinite

(PDF) Study of NanoKaolinite, Bentonite Limetreated in Soil

2017年3月1日 This paper reports the outcome of the laboratory investigation conducted on new clay liners modified with kaolinite combined with various content of limetreated, various content of bentonite and 2020年1月16日 The interaction between waste particles and clay is also evident since the structures present in the raw materials are hard to be identified It is clear that this waste has generated significant changes in the microstructure of the pieces, which is a good signal for the replacement of clay for this material, being useful for the industryAdditive Manufacturing via the Direct Ink Writing Technique of 1996年12月1日 A wellcharacterized kaolinite has been hydrated in order to test the hypothesis that platey kaolinite will roll upon hydration Kaolinite hydrates are prepared by repeated intercalation of kaolinite with potassium acetate and subsequent washing with water On hydration, kaolinite plates roll along the major crystallographic directions to form tubes Experimental Transformation of Kaolinite to Halloysite Clays and Clay 2004年2月1日 Raw material for ceramics consists mainly of kaolinite, illite, quartz and feldspar Three representative clays, a high kaolinitic (HB), illitic and quartzrich (KW) and naturally mixed kaolinite The Change of the Phase Composition in Kaolinite and IlliteRich Clay

Correlation of PaperCoating Quality with Degree of Crystal

2024年1月1日 Several kaolinite samples were selected for xray diffraction studies on the basis of their papercoating ability The evaluation of the kaolin clay for paper coating was based on a series of empirical tests including viscosity, resistivity, brightness, and particlesize distribution2024年1月1日 Tropical soils range from nutrientdepleted lateritic soils rich in halloysite or kaolinite to Inceptisols rich in interstratified kaolinitesmectite (KS), smectite, or related 2:1 clays Given the strong influence of clay minerals on tropical soil quality, better understanding of factors influencing their occurrence is important for modeling and managing tropical environmentsKaolinite and Halloysite Derived from Sequential Transformation Clays and Clay Minerals, Vol 49, No 5, 374–380, 2001 BASELINE STUDIES OF THE CLAY MINERALS SOCIETY SOURCE CLAYS: GEOLOGICAL ORIGIN WILLIAM F M OLL,JR 7222 Braemar Circle, Crystal Lake, Illinois 600146604, USA INTRODUCTION History In any clay deposit, the nature of the mineral assemblage and the composition of individual clay mineralsBASELINE STUDIES OF THE CLAY MINERALS SOCIETY SOURCE CLAYS2011年4月6日 The undrained shear strength of clays is an important geotechnical parameter used during construction processes Several laboratory tests were performed on kaolinite and smectite mixed with pore fluids with different pH values Vane shear tests were carried out and it was found that the undrained shear resistance for clays increased considerably if the pore fluid Undrained shear strength of clays as modified by pH variations

Xray diffraction patterns of the clays (K=kaolinite; I=illite

The mixing technology with kaolinite clay (containing Al 2 O 3 ) was used to obtain the granules and to enhance the CO 2 conversion to methanol as a product2011年1月25日 The aggregates are more elongated and appear to include more oriented particles the lower I v is On the whole, though, the microREV fabric seems classifiable as random for the samples of highest The Microstructure of Dispersed and Flocculated Samples of Kaolinite Download scientific diagram Effect of kaolinite clay concentration on viscosity of emulsion measured at a shear rate of 200 s (1 for two emulsifying water pH 47 and 90 from publication: Role Effect of kaolinite clay concentration on viscosity of emulsion 1999年4月1日 Kaolinite [Al2Si20s(OH)4] is defined as a 1:1 dioctahedral clay mineral Its surface layers (or cover layers) along the [001] direction are ideally a 1:1 TO layer on both sides, yielding a layer (PDF) Cation exchange capacity of kaolinite ResearchGate

Molecular Simulation of Adsorption and Diffusion of Methane and

2023年9月28日 Grand Canonical Monte Carlo (GCMC) simulation and Molecular Dynamics (MD) simulations were used to study the effects of temperature (310 K to 400 K), pressure (≤30 MPa) and water content (0 formance of clays Cementitious minerals form upon mixing of clay with lime causing an improvement in strength and durability In the study, the changes in the microfabric of longterm cured limestabilized kaolinite clay using Xray diffraction pattern, scanning electron microscope and unconfined compressive strength (UCS) is presentedLongterm behavior of limestabilized kaolinite clay Springer