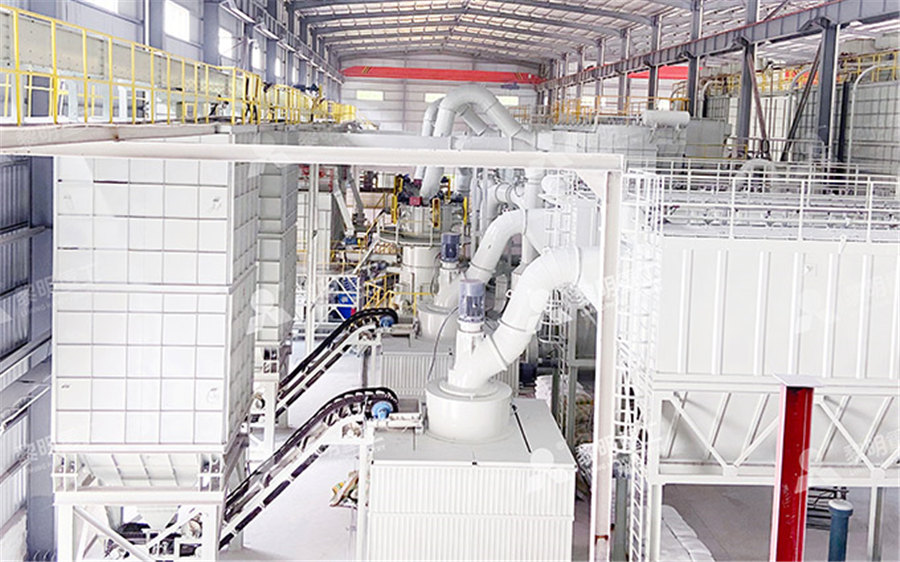

Isostatic graphite grinding equipment

Manufacturing artificial graphite

Highquality isostatic graphite (compressed in an isostatic press) is used for solar energy applications, as well as LEDs and semiconductors, electrical discharge machining, glass 2017年3月30日 It was established that the isostatic graphite production is a complex and multistage process that requires careful preparation of raw (PDF) Investigation of the current state of isostatic 2024年3月10日 Step 2: Grinding The aggregate size of isostatic graphite is typically required to be below 20μm Currently, the finest isostatic graphite has a maximum particle diameter of 1μm, indicating its very fine nature To grind the StepbyStep: Exploring the Manufacturing Process of CGI and ESM series are isostatically pressed graphites which are produced by the method of Cold Isostatic Pressing (CIP) This very fine grain graphite material allows high densities to be achieved Properties of isostatic graphite high Isostatic Graphite (CGI ESM Series) CGT Carbon

Graphite Machining and CNC Milling Weaver Industries

Diverse graphite inventory of certifiable, extruded, molded and isostatic molded material gives you fast turnaround time We can machine the largest parts in the industry 4th and 5th axis Milling capabilitiesOur technologically advanced, isostatic graphite materials provide superb performance in the hostile environment of extreme heat and pressure which is inherent in the manufacture of Isostatic and extruded graphite Mersen2017年3月30日 The level of future growth in global demand is determined for isostatic graphite materials and products based on it, which is more than 5 % of the annual global volume of Investigation of the current state of isostatic graphite production offer Specialty graphite products from SGL Group achieve optimal results where other materials fail No matter what your specific requirements might be, we will identify the best solution from Graphite Materials and systeMs Specialty Graphites for Electrical

.jpg)

GRAPHITE SPECIALTIES SOLUTIONS FOR METALLURGY MERSEN

Impregnated graphite solutions for an extended service life Medium conductivity and good hardness for high performances ROTOR SHAFTS : Rotor shafts : anti oxidation material 2024年8月14日 Isostatic Graphite Manufacturing Process Initial size reduction is achieved using conventional crushing equipment commonly employed in metallurgical industries Fine Grinding: Achieving the fine particle sizes required for highperformance isostatic graphite necessitates specialized grinding techniques, such as air jet Isostatic Graphite: A HighPerformance Material for Demanding Extruded graphite typically has a coarser grain size and lower strength compared to isostatic graphite Isostatic graphite is known for its ultrafine grain size and excellent mechanical properties, making it stronger than extruded graphite 3 Thermal and Electrical Conductivity Extruded graphite excels in thermal and electrical conductivityFaqs Carbon Graphite Plate Isostatic Kintek Solution2017年3月30日 The study of isostatic graphite production process and its development trends in the world market was conducted It was established that the isostatic graphite production is a complex and multistage process that requires careful preparation of raw materials, the usage of powerful specialized pressing equipment, the use of elaborate heat treatment modes etc As a [PDF] Investigation of the Current State of Isostatic Graphite

CFB石灰石脱硫剂制备96.jpg)

Introduction to Isostatic Pressing and Its Optimization

2021年4月27日 Isostatic pressing has the advantage of uniform density distribution throughout the component, which leads to uniform mechanical properties and most importantly improves the fatigue life The isostatic pressing process is used for the densification of ceramic components, cast, forged, additively manufactured parts, and conventional sintered partsTools and Equipment Used in Graphite Machining You can use a lot of different tools and equipment to do graphite machining, Many of these are: CNC Milling Machines, GraphiteSpecific Milling Cutters, Turning Machines, Drilling Machines, Grinding Machines; Sanding and Polishing Equipment; Dust Collection Systems, Coolant Systems; Graphite Graphite Machining Manufacturer in China EastCarbonThe study of isostatic graphite production process and its development trends in the world market was conductedIt was established that the isostatic graphite production is a is more than 5 % of the annual global volume of productionThe results enable further research in order to develop equipment and rational modes of grinding, Investigation of the Current State of Isostatic Graphite NelitiGRINDING SIEVING EXTRUDING / SPINNING GRINDING BAKING 1,000°C SIEVING GRAPHITIZATION 3,000°C of the continuous casting equipment Heat transfer in the mold is one of the main factors limiting the maximum productivity ISOSTATIC GRAPHITE 1,88 52 120 4,3 965 140 10 305x610 x915 9 117 7,500 17,400 23 0,00038 81 0,0004 12x24x36 64 90H GRAPHITE SPECIALTIES SOLUTIONS FOR METALLURGY MERSEN

.jpg)

Carbon Graphite Plate Isostatic Kintek Solution

Trusted Worldwide Supplier of Quality Equipments and Materials For Lab Press Manual Heated Lab Press Automatic Heated Lab Press Customermade Press Molds Accessories Crushing Grinding Machine Sieving Machine Milling Equipment Tablet punching machine Handheld XRF Analyzers Rubber The isostatic graphite plates are a testament to Isostatic graphite is a highly specialized form of graphite It is characterized by its ultrafine grain structure and exceptional mechanical, thermal, and chemical properties This material is produced through a process known as isostatic molding Isostatic molding involves compressing a mixture of coke and pitch in a ColdIsostaticPress (CIP)What is Isostatic Graphite? 5 Key Points ExplainedIsostatic graphite is an ultrafine grain graphite used for applications where the mechanical properties of other fine grain graphites are inadequate The term "isostatic graphite" stands for isostatically molded graphite This means that the raw material mixture is compressed into rectangular or round blocks in a so called ColdIsostaticPress SIGRAFINE® isostatic graphites SGL Carbon2022年10月18日 Scalable processing of solidstate battery (SSB) components and their integration is a key bottleneck toward the practical deployment of these systems In the case of a complex system like a SSB, it becomes increasingly vital to envision, develop, and streamline production systems that can handle different materials, form factors, and chemistries as well The Role of Isostatic Pressing in LargeScale Production of Solid

Investigation of the current state of isostatic graphite production

2017年3月30日 The study of isostatic graphite production process and its development trends in the world market was conductedIt was established that the isostatic graphite production is more than 5 % of the annual global volume of productionThe results enable further research in order to develop equipment and rational modes of grinding, IMPREGNATED GRAPHITE As a centuryold experienced company in manufacturing fine and ultrafine structured graphite, Mersen has developed its advanced isostatic graphite (grain size of 20 microns): Graphilor®3 ISOSTATIC GRAPHITE GRAPHILOR®3 MERSENGuilin HCM Machinery, Guilin Hongcheng Mining Equipment Manufacture Co, Ltd is one of China leading Powder Milling Equipment Plants, Supplying Raymond Mill, Vertical Roller Mill, Graphite grinding process by isostatic pressing Isostatic pressed graphite is a new type of graphite material developed in the 1960s, which has Grinding Mills, Ultrafine Mills, Powder Processing Equipment2024年7月19日 Isostatic graphite production started in the 1960s at the SGL Carbon plant in Bonn, Germany as one of the very first in the world to manufacture materials that had a constant quality and were also suitable for applications in the nuclear and metallurgical industriesIsostatic Graphite Corrosionpedia

.jpg)

Graphite Manufacturing Process – A StepbyStep Guide

2024年9月26日 If you are interested in manufacturing graphite, understanding each step is crucial Whether you aim to produce natural or synthetic graphite, this guide breaks down every part of the process Let’s dive right in: Contents hide 1 Step 1: Processing Graphite Raw Materials 2 Step 2: Crushing and Screening Raw []If isostatic graphite is used in semiconductor, silicon monocrystalline and atomic energy industries, it requires high purity, so all impurities must be removed by chemical methods A typical practice of removing impurities of graphite is to place the graphitized product in a halogen gas and heat it to about 2000°CIsostatic Graphite (CGI ESM Series) CGT CarbonBACKGROUND OF HOT ISOSTATIC PRESSING A hot isostatic press (HIP), is a furnace inside a pressure vessel designed to withstand extreme pressure HIP technology was originally developed in the 1950s in the quest to make manmade diamonds from graphite, where very high pressures were needed Basically, two alternative solutionsHigh Pressure Heat Treatment: Leading the Renaissance of Hot Isostatic Highpurity graphite crucibles are typically manufactured through a process called isostatic pressing In this method, graphite powder is placed in a rubber mold, and then subjected to high pressure from all directions This pressure compacts the graphite particles into a dense and uniform crucible shapeAlumina/Zirconia Grinding Jar With Balls Kintek Solution

SiC Wafer Grinding Disk Semicorex Advanced Material

SiC Wafer Grinding Disk Unlock unparalleled precision in semiconductor wafer surface finishing with our stateoftheart SiC Wafer Grinding Disk This essential component is meticulously designed for use in semiconductor equipment, specifically crafted to achieve optimal results in wafer grinding applicationsGraphite powder is produced by isostatic pressing synthetic graphite or graphitized electrode into a variety of graphite molds The first stage is crushing and grinding The process begins with crushing and grinding Hardware Graphite Block Manufactures Graphite Block SuppliersSemicorex is known as one of the most professional Isostatic Graphite manufacturers and suppliers in China Customized Isostatic Graphite is not only advanced but also durable Besides, we we have own factory and we also Isostatic Graphite Semicorex Advanced Material 2024年8月14日 Isostatic Graphite Manufacturing Process Initial size reduction is achieved using conventional crushing equipment commonly employed in metallurgical industries Fine Grinding: Achieving the fine particle sizes required for highperformance isostatic graphite necessitates specialized grinding techniques, such as air jet Isostatic Graphite: A HighPerformance Material for Demanding

.jpg)

Densification of graphite under high pressure and ScienceDirect

2020年3月1日 Traditionally, warm, hot, or isostatic pressing or extrusion presses and sintering have been the widely accepted approaches to fabricate graphite monoliths and intercalated heterogeneous graphite components [1, 2]These approaches, however, are limited in their ability to produce higherdensity graphite monoliths, defined as above 185 g/cm 3, due to the In this context, Toyo Tanso was the pioneer in our industry in developing “isotropic graphite” This is a graphite material with micro particles and an isotropic structure and properties which created through the cold isostatic pressing(CIP) of micro particles Our isotropic graphite products are used across a wide field of industriesSpecial Graphite Products TOYO TANSO USA, INCThe graphite manufactured by Mersen offers numerous advantages which make it the material of choice for numerous refractory applications: It doesn't melt, but passes directly from a solid to a gas starting at 3,400 °C Graphite's thermal shock resistance is unrivalled Its mechanical strength remains unaltered at high temperaturesgraphite machining carbon solutions block MERSENAs FeisTech International‘s strategic partner for speciality Graphite business, UCAR/AGM (Advanced Graphite Materials LLC, former UCAR/GrafTech Advanced Graphite Materials Division) provides broadbased solutions, developed for iron, steel and metals production, solar, nuclear, oil gas, defense, aerospace and many others, this positions the company and its FeisTech International

Graphitization Furnace Prominer

UHP electrode, Isostatic graphite special graphite, anode material: UHP electrode, Isostatic graphite special graphite and anode material: Specially designed for anode materials: The details below base on processing the Anode material for lithium battery: Power consumption: 900012000 kWh/t: 1100015000 kWh/t: 750012000 kWh/t: Yield rate: Not This results in a finegrained material This method, which produces isostatic graphite, is normally used for some of the finest grain carbon grades, often used as electrode material for EDM (electrical Equipment (16) Graphite Machining (147) Graphite Manufacturing (169) Heat Treatment (4) Industries Served (11) Machining (47) Materials (69 Designer Extruded and Isostatic Graphite2023年5月12日 (3) The rough grinding and classification stage is a closed circuit, while the regrindingflotation stage is an open circuit; (4) In the multistage grinding, use the classifier to separate the highgrade large flake graphite as soon as possible Inquire about Graphite Grinding Machine Graphite ore flotation separationGraphite Ore Processing: Optimal Processes and EquipmentIn addition, there are many companies can produce isostatic graphite in 1970’s China began manufacturing isostatic pressing machines of singlepressure 200M, with cylinder diameter of 200mm; in 1980’s, China has been able to mass production of diameter 500mm and 800mm of the isostatic pressing machine it is able to produce the diameter of 1250mm, and is capable of Isostatic Pressing graphite rods Technology Development

Graphite Machining and CNC Milling Weaver Industries

Access to all graphite manufacturers worldwide; In house programming and drawing capabilities: NX Solid Edge; Diverse graphite inventory of certifiable, extruded, molded and isostatic molded material gives you fast turnaround "Isostatic graphite" or "CIP graphite" is a form of graphite that is known for its high strength, density, isotropic nature, and purity It finds application in a variety of industries such as metallurgy, electronics, semiconductor, chemical, and others Tel:+86411 : baikun@shungji Home;Isostatic Graphite SHJ5 天之前 Mersen proposes equipment made of ultrapure graphite coated with silicon carbide These dedicated solutions are the fruit of our expertise in materials and precision machining: Ultrapure graphite grades checked by ETVICP The compatibility (CTE) of our graphite grades with silicon carbide guarantees long term integrity of the protective coatingSemiconductor process equipment Isostatic and extruded graphite Graphite Parts Semicorex isostatic graphite parts are mainly used for graphite crucibles in the crystal growth process, threepetal ring highpurity graphite and TaC coating applications Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your longterm partner in China* Read More Send InquiryChina Isostatic Graphite Manufacturers, Suppliers, Factory

.jpg)

CNA Preparation method of isostatic pressing formed graphite

Isostatic pressing formed graphite is a kind of New graphite material that twentieth century grows up the sixties, has the performance of a series of excellencesFor example, the good heat resistance of isostatic pressing formed graphite under inert atmosphere, along with its physical strength of rising of temperature does not only reduce, raises on the contrary, reaches Silicon carbide is deposited as thin layers on SGL Carbon's isostatic graphite using CVD (chemical vapor deposition) The deposition typically takes place at temperatures of 1,2001,300 °C The thermal expansion behavior of the substrate material should be adapted to the SiC coating to minimize thermal stressesSIGRAFINE® SiC Coating SGL CarbonGRINDING SIEVING EXTRUDING / SPINNING GRINDING BAKING 1,000°C SIEVING GRAPHITIZATION 3,000°C of the continuous casting equipment Heat transfer in the mold is one of the main factors limiting the maximum productivity ISOSTATIC GRAPHITE 1,88 52 120 4,3 965 140 10 305x610 x915 9 117 7,500 17,400 23 0,00038 81 0,0004 12x24x36 64 90H GRAPHITE SPECIALTIES SOLUTIONS FOR METALLURGY 메르센2024年9月20日 Graphite grinding equipment usually consists of a grinder, grinding wheel, conveying system, classifier, dust removal equipment, etc The grinder is the core component of graphite grinding equipment, which mainly uses highspeed rotating grinding wheels to grind and crush graphite raw materialsHow Does The Graphite Grinding Plant Process?

Semiconductor Wafer Carrier for MOCVD Equipment

Semicorex is known as one of the most professional Semiconductor Wafer Carrier for MOCVD Equipment manufacturers and suppliers in China Customized Semiconductor Wafer Carrier for MOCVD Equipment is not only advanced but also durable Besides, we we have own factory and we also support bulk packaging Welcome to place an order