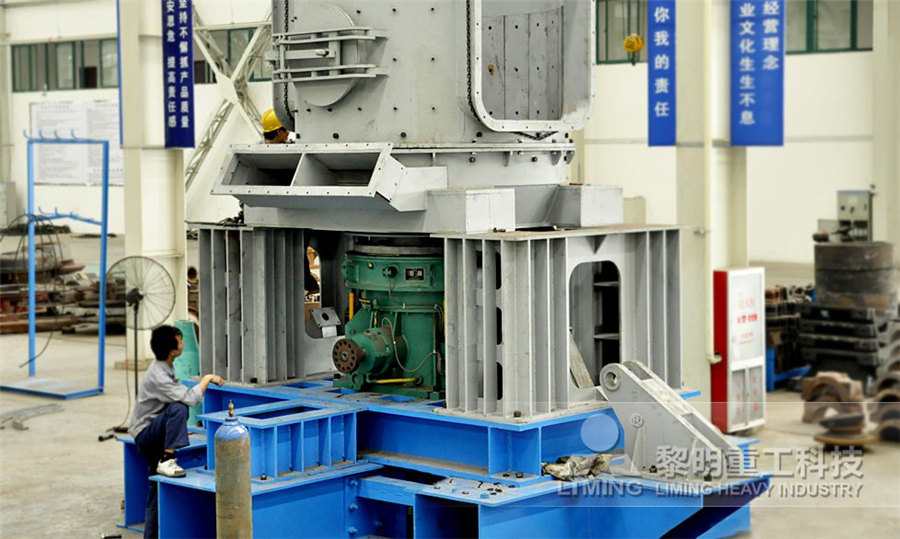

Cone crusher structure and working principle

.jpg)

Cone Crushers (Parts of a Cone Crusher) Explained

The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism (mechanically or hydraulically actuated)The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber The mantle is a moving part that gyrates in an eccentric motion That is, it doesn’t remain completely centred – it swings Cone crusher basics in 4 minutes SRPThe working principle of cone crushers offers several advantages: Efficiency: Cone crushers enhance productivity by providing high crushing and screening efficiency Various Product Sizes: Cone crushers can be adapted to produce Working Principle of Cone CrushersInformation about crushing technology, construction, working and maintenance of crushers for bulk materials is given in this article There are four basic ways to reduce size of a material: by Construction, Working and Maintenance of Crushers for Crushing

.jpg)

Cone Crusher SpringerLink

2023年5月3日 Cone crusher is a type of crushing equipment whose crushing cone rotates in the conical cavity within the shell to realize intermediate crushing or fine crushing of material The cone crusher is a compression type of machine that crushes material by squeezing or compressing the feed material In addition, these spindles are completely covered with a sturdy mantle and a concave cover the hopperCone crusher working principle HAMAC2012年8月15日 Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel Cone Crusher Engineering IntroCone crusher is a type of crushing equipment whose crushing cone rotates in the conical cavity within the shell to realize intermediate crushing or fine crushing of material through squeezing, Cone Crusher Spring Cone Crusher

.jpg)

Cone Crusher Working Principle: Crushing Rocks and

2023年2月23日 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces But how does it work? In this article, we'll explore the cone crusher working principle, including 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary working of the crusher is as under The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing assemblyConstruction, Working and Maintenance of Crushers for Crushing 2024年3月19日 Understand cone crusher diagram basics with our comprehensive blog post Learn about the structure and operation of cone crusher models Equipment Processing Plants Solutions Example Analysis: Cone Crusher Diagram: Simplified Guide JXSCThe basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber The Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any Cone crusher basics in 4 minutes SRP

.jpg)

Working Principle of Cone Crushers

Essentially, cone crushers have a cylindrical body with a conical head designed to compress and crush materials within This head rotates thanks to an eccentric shaft, allowing for the crushing of stones Working principle of cone crushers Working Principle of Cone Crushers Feeding Stage: Stones are fed into the cone crusherThe video shows how does a hydraulic cone crusher works, and its structureThe cone crusher mainly has 4 kinds of types:Spring cone crusherhttps: How does a cone crusher work ? working principle and structure2023年11月30日 This article presents a comprehensive comparison between jaw crusher, impact crusher, and cone crusher, highlighting their differences in terms of structure, working principles, crushing capabilities, and applications 1 Structure and Working Principle Jaw Crusher: Jaw crushers have a fixedComparative Analysis: Jaw Crusher vs Impact Crusher vs Cone CrusherThe cone crusher is a modified gyratory crusher, and accordingly many of the same terms including gape, set, and throw, apply The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 68)Major suppliers of cone crushers include Metso Cone Crusher an overview ScienceDirect Topics

Hydraulic Cone Crusher Working Principle Animation YouTube

Types of cone crushers used in aggregates production, mining operations, and recycling applications how to select the right one https://bitly/3d509vR =====Difference in structure of cone crushers Difference in working principle of cone crushers When the compound cone crusher is working, the motor drives the eccentric sleeve to rotate by the Vbelt, transmission shaft and bevel gearsThe Models And Parameters Of Cone Crusher HXJQ2024年3月15日 Cone Crusher Working Principle Starting with the motor, a welltuned system powers the cone crusher Through a sequence of components including the Vbelt, a huge pulley, the transmission shaft, a small bevel gear, and ultimately a large bevel gear, this motor drives the eccentric sleeveHow Does a Cone Crusher Work and What is It? JXSC2024年10月18日 The fine cone crusher, also called the shorthead cone crusher, or “round mill” Its structure is basically the same as that of the mediumfine cone crusher The difference lies only in the different shapes of the movable cone and the immovable coneKnowledge!The Basic Structure Of a Cone Crusher And Its Working Principle

How Does A Cone Crusher Work: Understanding The

2023年7月31日 A cone crusher is crucial, especially in aggregates and mining industries It plays a role in crushing hard rocks into smaller rocks for further processing Understanding how a cone crusher operates is essential to 2021年3月15日 (a) Structure diagram and (b) functional principle diagram of cone crusher Traditional productivity calculation model Mathematical model of the ore arch areaChamber Optimization for Comprehensive 2020年6月3日 In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics belowWe will be exploring in more detail the A Detailed Overview of Cone Crushers and What You Need to 2023年2月15日 Discover the most popular types of cone crushers on the market and their unique features, advantages, and disadvantages This comprehensive guide will help you make an informed decision when choosing the right cone crusher for your specific needs in the mining and quarrying industriesA Comprehensive Guide to Cone Crusher Types

.jpg)

Jaw Crusher Working Principle StudiousGuy

2 Both the structure and working of a jaw crusher are quite simple 3 The product size is quite small and can range up to millimetres 4 Repair and maintenance of a jaw crusher are convenient and easy 5 The reliability of a jaw crusher is significantly high 6 The broken parts of the jaw crusher are easy to replace Disadvantages of a Jaw WORKING PRINCIPLE The working principle of Conmix Cone Crusher is to be useful for primary crushing, secondary crushing and final crushing as well With the higher production and higher quality, it is becoming more and more popular among SHREE CONMIX ENGINEERS PVT LTD CONE CRUSHERThe following article covers the basics of cone crushing, including chamber structure, openside, and closedside settings, eccentric throw, and more INSIDE YOUR CONE CRUSHER The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber The mantle is a moving part that gyrates in an Porter Group News Cone Crusher Basics2024年6月17日 Jaw crusher structure, and working principle Jaw crusher is a commonly used crushing equipment in gravel plant, which is composed of frame, jaw plate and side guard plate, transmission parts Jaw crusher structure, and working principle Medium

.jpg)

Horizontal Shaft Impactor Working And Design Crusher Mills, Cone

CS Series Cone Crusher Jaw Crusher Impact Crusher Cone Crusher Hammer Crusher Sand Making Series Advanced portable mobile crusher structure and design technology; horizontal shaft impact crusher – Crusher South Africa Vertical Shaft Impact Crusher Working Principle,VSI5X Structures Working Principle Cone Crusher Structure The main parts of a cone crusher are Rack, horizontal axis, moving cone, balance wheel, eccentric sleeve, upper broken wall (fixed cone), lower broken wall (moving cone), Cone Crusher JXSC MineralWORKING PRINCIPLE OF BAG FILTER Figure 1 depicts the working principle of bag filter See Figure No1 The dustladen air enters the bag filter bustle Bag Filter In The Basic Principles, Structure And Control Bag Filter Working Principle Crusher Mills, Cone Crusher, Jaw So, this blog encompasses the working principle involved in cone crusher machinery How Does A Cone Crusher Work the basic working principle Before jumping to its working technology, you shall first understand what a cone How Does A Cone Crusher Work?

.jpg)

Understanding the Impact Crusher Working Principle for

2023年2月23日 Impact Crusher Working Principle The impact crusher working principle involves a highspeed rotor that rotates around a horizontal axis The rotor is equipped with a series of hammers that strike the material as it enters the crushing chamber The material is then shattered against the hardened steel plates that line the crushing chamber5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by a scrubbing action (shearConstruction, Working and Maintenance of Crushers for Crushing 2015年6月23日 Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between themImpact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill)Impact Crusher Working Principle 911Metallurgist2022年9月15日 Difference between Gyratory Crusher and Jaw Crusher; Difference between Gyratory and Cone Crusher; Gyratory Crusher Advantages and Disadvantages; Principle : It works on the principle of compression Construction : • It consists of a funnel shaped casing, open at the top A conical crushing head, in the form of a truncated cone, gyrates Principle, Construction, Working, and Features Chemico World

.jpg)

Crushing Principles of Mechanical Crushing 911 Metallurgist

• Cone Crusher Operating Principle • Crusher Capacity • Crusher Operation • Optimization and Crusher Performance Map • Conclusions NCC, Borås, Sweden Crusher Selection Feed size • In a cone crusher the stones are crushed with both SPB and IPB as the material moves down through the chamber2021年5月6日 A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge point The motion is, however, a more complex one than the Dodge motion, being Jaw Crusher Working Principle 911Metallurgist2023年2月28日 The working principle of primary crushers varies depending on the type of crusher, but generally, they work by reducing the size of the material through compression or impact In jaw crushers, the material is fed into the crushing chamber and is crushed between a fixed jaw and a movable jawThe Complete Guide to Primary Crushing, Secondary Crushing, Working Principle of Spring Cone Crusher The spring cone crusher works by using an eccentric rotating drive shaft that causes the cones to move in a circularSpring Cone Crusher Working Principle YouTube

-2.jpg)

Crusher Working Principle YouTube

Describes the basic principle as to how a Gyratory or Jaw Crusher work at crushing rocks More at https://911metallurgist/equipment/crushing/2016年2月18日 Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took place in an orderly, and Working Principle of Crushers 911Metallurgist2023年3月11日 The basic working principle of an impact crusher The fundamental working principle of an impact crusher is fairly straightforward, yet its impact force can be substantial The machine crushes materials by applying a highspeed impact force, causing them to What is an impact crusher? AGICO2021年5月25日 When the spring cone crusher is working, the motor drives the eccentric bearing bushing via spring coupling, transmission shaft and a couple of cone gear wheCone crusher working principle, how does cone crusher works?

(a) Structure diagram and (b) functional principle diagram of cone crusher

Download scientific diagram (a) Structure diagram and (b) functional principle diagram of cone crusher from publication: Chamber Optimization for Comprehensive Improvement of Cone Crusher Cone crusher working principle and type Cone Crusher Cone Crusher broken parts are expected to block the work of two truncated cone One is the dynamic cone , fixed on the spindle; the other, said fixed cone Cone Crusher Basic Structure and Working PrincipleLordz Cone Crusher Working Principle2023年3月10日 Cone Crusher Menu Toggle Full Hydraulic Cone Crusher; Sand Making Machine This is the structure that supports the screen cloth and the By understanding the working principles and applications of vibrating screens, you can make informed decisions about which type of vibrating screen is best suited for your needs FAQs What Vibrating Screen Working Principle: Understanding How It Works {Cone Crusher vs Gyratory Crusher}Both cone and gyratory crushers have a cone, and their outline that looks have a little resemblance The two crushers can continuous working, and their working principle in the same way But the cone crusher vs gyratory crusher, their structure and performances are different Structure Different 1 ConeCone Crusher VS Gyratory Crusher JXSC Mine

CONE CRUSHER MODELLING AND SIMULATION Chalmers

mining industry The cone crusher concept was developed in the early 20th century and the basic layout of the machine has not changed dramatically since then Efforts aimed at developing the cone crusher concept further involve building expensive prototypes hence the changes made so far are incremental by nature