Main parameters of roller mill

.jpg)

Optimization of working parameters of highpressure roller mill

2024年11月15日 In order to improve the crushing efficiency of highpressure roller mill and reduce energy consumption, the optimal parameter combination of highpressure roller mill is sought, GM160140The main performance parameters of the highpressure Roller Mill are production rate, power consumption and percentage of discharge size, which can be predicted based on materialOptimization of working parameters of highpressure roller mill 2017年4月1日 The main parameter related with the product rate and product particle size is the classifier rotor speed The cut size of classification can be controlled by adjusting the speed of Operational parameters affecting the vertical roller mill 2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such Analysis of vertical roller mill performance with changes in material

.jpg)

Optimize the Rolling Process Parameters for Material AA1100

In this paper, Taguchi optimization technique is used to predict the best results for the given inputs such as roller diameter, friction value, velocity of the rollers and percentage reduction to 2017年4月1日 In this study, the analyses of energy and exergy were implemented for an industrialscale vertical roller mill (VRM) of Kerman Momtazan Cement Company (KMCC) of Operational parameters affecting the vertical roller mill 2019年2月21日 The paper analyzes the interrelation of: motion, particle size of ground rice grains, displacement, and grinding in a roller–plate mill The purpose of the study was to A study of operating parameters of a roller mill with a new design2022年10月26日 This paper is focused on the inherent characteristics of the main drive system of the F5 coldrolling mill in a steel plant First, the main transmission mechanical structure Influence Factors of Inherent Characteristics of F5 Cold‐Rolling Mill

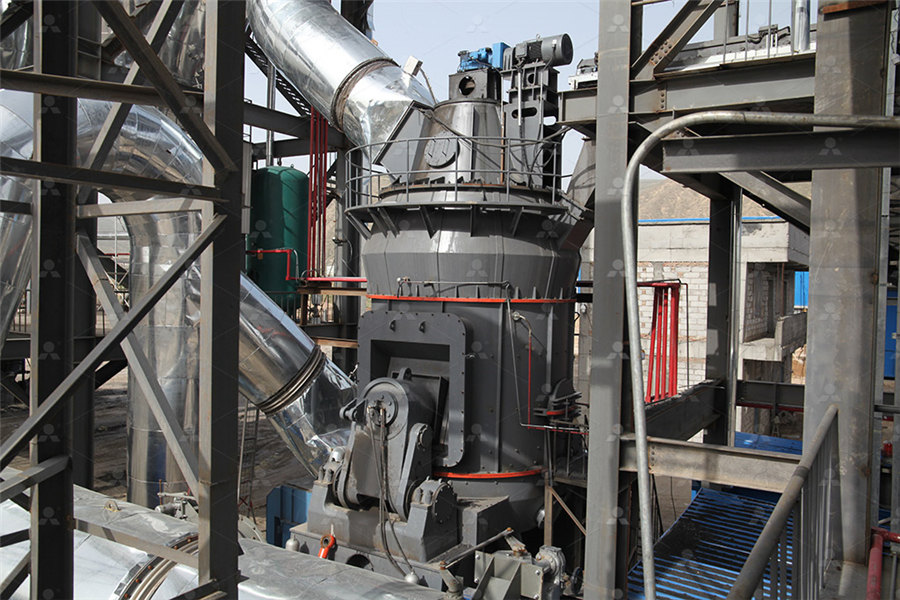

Roller Mill Springer

Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and 2014年11月1日 Various rolling models and optimization methods are applied in each step The procedure starts from the customer product mix and the annual production A pass schedule program is applied toOn the Optimization Procedure of Rolling Mill DesignDownload Table Design parameters of vertical roller mill from publication: Performance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement Plant In this study, an Design parameters of vertical roller mill Download Table2021年1月1日 In the study the advantages of vertical roller mill are discussed over ball mills With proper optimization of these parameters, This paper reviews the main relevant technologies that are already available in the construction industry and explains how to consider them for alkaliactivated cement and concrete productionReview on vertical roller mill in cement industry its

.jpg)

Unstable vibration of roller mills Semantic Scholar

2006年10月24日 The working principle and structure of lowvibration vertical roller mills and forces of key component were analyzed intelligently and based on the intelligent numeral calculations, the maximum stresses of three key components were much lower than the yield strength of materials and the rocker armroller system of the proposed lowVibration Vertical 2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling (a fixed roller and a movable roller), the driving system (main motor, reducer, belt pulley, and gear shaft), the hydraulic system, the stand, the transverse leakproof device, the Roller Mill SpringerLink2017年4月6日 A 20high Sendzimir mill is widely used in cold rolling The deformation of rolls within the roll system as a whole is analyzed without pinpointing upon each roll and impact on the rolling process The mechanical model of the work roll, first intermediate roll, second intermediate driven roll, and second intermediate idler roll was proposed and the contact force of each roll Force Model and Elastic Deformation Analysis of 20High Sendzimir Mill 2023年12月1日 The vibration of the rolling mill has been a persistent issue affecting its safe and stable operation To address the vibration problem in the F2 stand of a continuous rolling mill, this paper establishes a digital twin model of the rolling mill Based on the digital twin model, a rolling mill virtual commissioning framework has been proposed to enhance the accuracy of realtime Virtual commissioning and process parameter optimization of

.jpg)

Analysis and Optimization of Grinding Performance of Vertical Roller

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersDownload scientific diagram Technical specifications of vertical roller coal mill from publication: An investigation of performance characteristics and energetic efficiency of vertical roller Technical specifications of vertical roller coal millbe used, which are: a ball mill or a VRM vertical roller mill The ball mill makes use of grinding bodies and they have been the main tool for more than 100 years, although they have a low efficiency, while the vertical mills are much more modern tools that are capable of saving between 45 to 70% of the power consumed [4]Parameters for the Grinding Process in Vertical Mills Using GobA vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote Machinery

.jpg)

Design and analysis of sand casting process of mill roller

2019年10月24日 The quality characteristics of the mill roller in sand casting has been affected by casting defects caused by in proper process parameter usage and intern affects its proper function that lead to large number of shop floor trials, high rate of rejection, and low casting yield The objective of this research is to design and analyze sand casting process of mill roller In 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Their main advantages include good energy efficiency, Operational parameters affecting the vertical roller mill 2021年1月6日 Download Citation Review on vertical roller mill in cement industry its performance parameters India is the world's second largest producer of cement and produces more than 8 per cent of Review on vertical roller mill in cement industry its

Analysis of vertical roller mill performance with changes in

2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical Compression crushing is also the main crushing mechanism in the VRM, but there is also shear force between grinding roller and particles2011年3月1日 In order to reduce the larger pressure resistance (pressure difference between inlet and outlet) of a vertical roller mill, the flow field in the vertical roller mill is numerically simulated by CFD technology Based on the simulation results, the reasons that led to the larger pressure resistance of the vertical roller mill is studied, offering the theory guide for the Numerical Study of the Flow Field in a Vertical Roller MillDownload scientific diagram Drawing of the basic structure of a roller mill with two rotating/counterrotating rollers (crosssection) from publication: A study of operating parameters of a Drawing of the basic structure of a roller mill with two rotating 2019年2月21日 The paper analyzes the interrelation of: motion, particle size of ground rice grains, displacement, and grinding in a roller–plate mill The purpose of the study was to analyze and evaluate A study of operating parameters of a roller mill with a new

Calculating Power Parameters of Rolling Mill ProQuest

Therefore, the number of rolling stands in the mill line is almost halved in comparison with twohigh rolling and drawing in roller dies [6] The threeroll milling process in twogroove stands (Figure 1b) is a vital technology for the production of round bars and hexagonal sections used in Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsCement grinding Vertical roller mills VS ball millsOperational parameters affecting the vertical roller mill performance × Close Log In Log in with Facebook Log in with Google or Password Remember me on this computer or reset The main parameter related with the product rate and (PDF) Operational parameters affecting the vertical roller mill 2015年1月1日 Mill gap of 2roller mill type was the main parameters for this preliminary study An adjustable 2roller mill had been specially built for the studyPreliminary study of the effect of mill gap of 2milling rollers on

Calculating Power Parameters of Rolling Mill Based

Making “digital twins” for rolling processes and mill equipment should begin with the development of mathematical models of the deformation zone The deformation zone of twohigh flat mill rolling have been studied in detail, @inproceedings{Flizikowski2019ASO, title={A study of operating parameters of a roller mill with a new design}, author={J{\'o}zef Flizikowski and Weronika Kruszelnicka and Andrzej Tomporowski and Adam Mroziński}, year={2019}, url= {https The A study of operating parameters of a roller mill with a new designMill differential pressure [mbar] Grinding bed thickness with span [mm] Amount of external material recirculation [t/h, or BE current A] Gas flow through mill [act m³/h] Vibration velocity at mill gearbox [mm/s] Power consumption of mill motor with span [kW or alternatively A] Power consumption of system fan [kW] Mill outlet temperature [°C]Important operation parameters in Vertical mill2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on the energy Analysis and Optimization of Grinding Performance of Vertical Roller

Selected Aspects of Modelling and Design Calculations of Roller Mills

Impact of the roller’s mass m made of cast iron and its angular speed ω 1 on the dynamic ω reaction’s value κ 𝜅 From the obtained simulation calculation results (Figures 3 and 4), it unambiguously shows that together with the increase of the roller’s weight m and its angular speed ω 1 , ω the reaction value κ increases approximately in the quadratic function, where Roller Mill November 30, 2022 Pin Mill November 30, 2022 Fluidized Energy Mill November 30, 2022 EdgeRunner Mills and EndRunner Mills November 30, 2022 Cutter Mill November 30, 2022 Comments 4 Christopher Ajiduah says: 3 years ago The article is very clear and concise Thank you very muchHammer Mill: components, operating principles, types, uses, 2007年1月1日 This chapter describes how the flour milling process interacts with the wheat kernel structure to separate it into its functional components It traces briefly the historical development of flour milling technology leading to the introduction of roller mills a century ago, introducing the themes of wheat hardness, bread quality and the international grain trade that Chapter 7 Roller Milling of Wheat ScienceDirect2021年1月29日 design parameters It was a Vertical Roller Mill is designed for rated capacity 215 TPH but its Such fluctuating loads include arc furnaces, rolling mill drives, and main winderIncrease productivity of vertical roller mill using seven QC tools

.jpg)

Calculating Power Parameters of Rolling Mill ProQuest

Therefore, the number of rolling stands in the mill line is almost halved in comparison with twohigh rolling and drawing in roller dies [6] The threeroll milling process in twogroove stands (Figure 1b) is a vital technology for the production of round bars and hexagonal sections used in 2013年8月1日 This article reviews the principle and structure features of high pressure roller mill Moreover, the major progress in structure and technology parameters is summarized For the effect of application in nonferrous and ferrous ores, the high pressure roller mill will be widely applied in the futureA Review on the Development of High Pressure Roller MillLimestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Limestone Powder Ultrafine Vertical Roller MillThe scope of this paper is to analyse the strength and hardness of the sugarcane roller shaft, which has the main contribution in the sugarcane industries For designing the shafts of two roller mills, To Study and Optimize the Process Parameter Throw Roller Burnishing Process on EN19 Material by Response Surface Methodology, (PDF) DESIGN AND ANALYSIS OF ROLLER SHAFTS FOR SUGAR CANE MILLS

.jpg)

Operational parameters affecting the vertical roller mill

2017年4月1日 In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The identification and quantification of the grinding parameter relationships was carried out to implement these relationships into a computational verticalrollermill performance model2023年6月16日 Rolling mill rolls overview The position and structure of the roll in the Roll main parameter design The basic parameters of the roll Roll nominal diameter (or nominal Cast iron rolls are mostly used Reason: The hardness of the roll surface is the main requirement Support roller: Forged steel with chromium alloy is Classification of rolling mill rolls and selection of materialsPDF On Jan 1, 2017, J Harder published Drives for large vertical roller mills generated by the main standalone verity the surface roughness and to find the process parameters for best (PDF) Drives for large vertical roller mills ResearchGate2012年12月31日 Report system used to show our main work pa ram eters roller mill, limestone, pul verized coal and accumulativ e total parameters, the time of history and can be used for roller mill work Design and Realization Of Roller Mill Control System

.jpg)

Static Structural Analysis of Crushing Rollers of Three Roller Sugar Mill

Sugarcane roller mill is the vital part of sugar industry DESIGN AND ANALYSIS OF ROLLER SHAFTS FOR SUGAR CANE MILLS BY USING FEA TECHNIQUE WITH DIFFERENT PARAMETERS TJPRC Publication The scope of this paper is to analyse the strength and hardness of the sugarcane roller shaft, which has the main contribution in the sugarcane International Journal of Engineering Research Technology (IJERT), 2015 Sugarcane roller mill is the vital part of sugar industry The main objective of milling is to separate the sucrosecontaining juice from the caneIJERTStatic Structural Analysis of Crushing Rollers of Three Roller