Granite vertical ore grinding machine working principle

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE

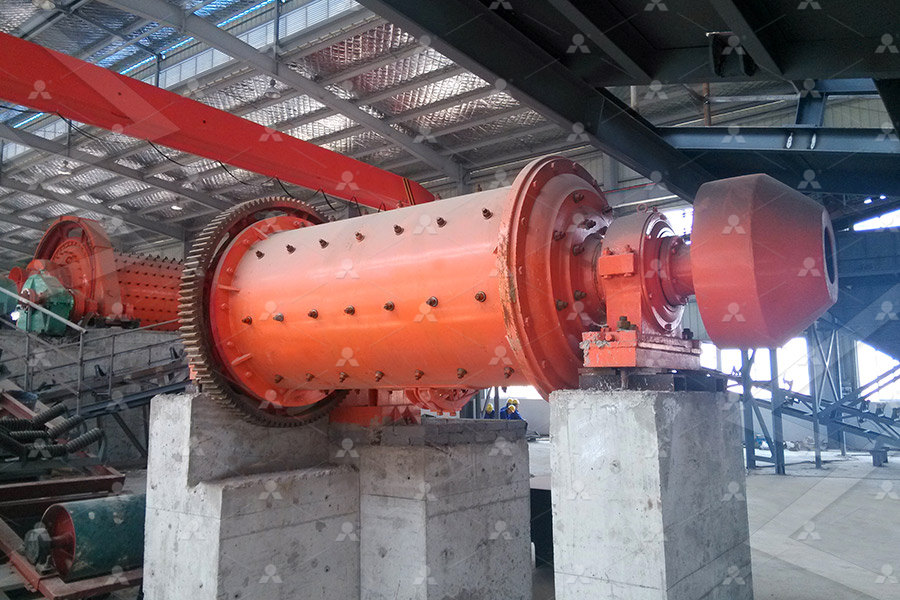

2019年4月16日 The paper demonstrates why the Loesche VerticalRollerMill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system are VRM's are state ofvertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS2015年1月29日 An investigation was reported of a new attempt in the fabrication of an ultrafine abrasive tool for vertical spindle grinding The principle of solgel was applied to granulate ultra Vertical Spindle Grinding of Si and Granite with a New Abrasive Disk2023年7月20日 According to the grinding medium features, ore grinding is mainly classified into ball grinding process, rod grinding process, and autogenous grinding process Ore grinding Ore Grinding SpringerLink

.jpg)

Roller Mill SpringerLink

2024年1月1日 Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding table from the feed inlet through the 2024年10月12日 This article will explain the working principle, application scenarios, main classifications, and advantages of stone grinding machines I Working Principle of Stone Grinding Mill Machines Stone grinding machines mainly rely on the squeezing and grinding action between the grinding roller and the grinding ring to achieve the crushing of stonesClassification and application of stone grinding mill machine2020年8月12日 This document discusses grinding machines It provides an overview of the working principle, specifications, purposes and types of grinding The main types are surface grinding, cylindrical grinding, centerless grinding, Grinding machine PPT Free Download SlideShareWorking principle of surface grinding machine English Arabic; English; French; Portuguese; Russian; Spanish; info@makemachinetools Products Pipe cutting and VMC1600 Vertical Machine Center VMC1570 CNC Milling Machine/CNC Machine Center VMC400 CNC Vertical Machine Center VMC1060 Vertical Machine Center VMC1270 3 Axis Vertical Machine Working principle of surface grinding machine

.jpg)

Cylindrical Grinding Machine: Types, Process Working Principle

In the plunge grinding machine the grinding wheel moves radially towards the substance 4 Creep Feed Grinding Machine The creep feed grinding machine eliminates a full chunk of the substance through the grinding wheel all at once This machine greatly reduces the manufacturing time 5 Centerless Grinding Machine The centerless grinding Introduction The LM Vertical Grinding Mill , launched by SMMVIK Machinery, integrates five functions of crushing, grinding, powder selection, drying and material conveyingIt is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionLM Vertical Grinding Mill SMMVIK MachineryBall Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powdersBall Mill Grinding Machines: Working Principle, Types, Parts Grinding Machine A grinding is metal cutting operation which is performed by means of a rotating abrasive wheel that acts as a tool; These are mostly used to finish workpieces which must show a high surface quality, accuracy of shape and dimension Mostly, it is finishing operation because it removes material in very small size of chips 025 – 05 mmGrinding Machine Definition,Working,Parts,OperationTypes

.jpg)

Surface grinding machine PPT SlideShare

2014年10月25日 12 • This grinding machine with all working motions is shown in Fig a The grinding operation is similar to that of face milling on a vertical milling machine In this machine a cup shaped wheel grinds the work piece over its full Grinding Machine: Working Principle, Parts, Types and Applications Last Updated on Mar 6, 2023 Download as PDF The column acts as a vertical support for the rest of the machine It is in this portion upon which the wheel head, wheel guard, and abrasive wheel are mountedGrinding Machine: Learn its working, types, and applications2021年8月27日 The grinding wheel is the most important and unique part of the electrochemical grinding machine Before understanding the working we must go through the principle of working of electrochemical grinding The working principle of electrochemical grinding is When a metal surface is acted upon with an electrolyte under a high Electrochemical Grinding: Definition, Parts or Construction, Working 2023年8月23日 A Surface Grinding Machine is a versatile and essential tool used in the manufacturing and metalworking industries to achieve precise and smooth surfaces on workpieces It is capable of removing material from the Surface Grinding Machine: Diagram, Parts, Working,

.jpg)

Working principle and characteristics of vertical mill

To sum up, vertical mills have become a popular choice in various industries due to their efficiency and versatility They are capable of handling different types of materials and producing highly uniform products The working principle of these machines involves force grinding, which ensures consistent results while minimizing energy consumptionThe grinding disc is not confined to a cylindrical form and is able to come up with a multitude of possibilities That will be useful for moving various geometries in accordance with the objects Read More :Types of Grinding Machine Types Surface Grinding Machine: Types, Parts Working Bench Grinding Machine: Parts, Working What is Bench Grinding Machine? It is the most common type of grinding machine found in tool rooms and workshops It is used to sharpen the tools, grind the workpiece surface and remove roughness Small items in the labs are machined using a bench grinder Parts of Bench Grinding Machine MotorGrinding Machine: Definition, Types, Parts, Working Operations2022年7月4日 Vertical Shaper is widely used for cutting slots, key holes, grooves etc Horizontal Shaper: The ram holding the tool in a horizontal axis and the ram is reciprocating This type machine is also used for the production of flat surfaces, keyways, external grooves, and more Geared Shaper: Very less industry using this type of machine nowadaysShaper Machine: Definition, Parts, Working Principle, Types,

.jpg)

Grinding Machine: Types, Parts, Working Operations (With PDF)

2018年10月1日 Grinding Machine Definition A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the materialIt is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece Generally, the grinding is a type of finishing operation to make sure that there is high surface quality, CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying +17CLUM Ultrafine Vertical Grinding Mill2022年7月4日 Milling Machine Definition: The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutterThe metal removal rate is higher very high as the cutter has a high speed and many cutting edges It is the most important machine in the tool room as nearly all the operations can be performed on Milling Machine: Definition, Parts, Operation, Working Principle 2023年5月5日 A grinding machine consists of the following parts: 1 Base – The base of the grinding machine supports the other parts of the machine It is made of cast iron and rests on a flat foundation 2 Column – The column is a vertical structure that supports the grinding wheel and the grinding head It is made of cast iron and has a dovetail slide on which the grinding Grinder Machine – Working, Types, Applications, Pros Cons

Drilling Machine: Working Principles, Types, Operations, Tools

2024年11月7日 Working Principle of Drilling Machines The working principle of any drilling machine remains almost similar When power is supplied to the motor, the spindle rotates, causing the attached stepped pulley to also rotate as shown in the image below Fig 1: Working of a Drilling MachineBasic Principle of Grinding Machine (1) Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free This document provides information about grinding machines and grinding processes It Basic Principle of Grinding Machine PDF Grinding grinding operation may be used for removing thick layer (05mm) of material in general class of work Abrasive belt grinding is a common finishing process in the metal and wood industryBelt grinding can be used for both coarse and fine grinding The principle parts of this attachment areFabrication of Mini Abrasive Vertical Belt Grinding Machineprinciple of dual wheel marble machine zdrowieinatura principle of dual wheel marble machine Portable machine for cutting marble, ceramics, etc vision of a dual table machine which can be easily adjusted for marble cutting machine having an upper gen eral purpose saw structed in accordance with the principles of the The platform 23 is supported upon three wheels 25, marble processing machines working principle

Granite Surface Processing Machines StoneContact

This machine is suitable for continuous grinding and polishing of granite and marble slabs The working speeds of the plate conveyor belt and the grinding plate traverse beam are all controlled by frequency converters; the grinding plate working pressure and plate grinding width are adjustable within the set value rangeWorking Principle Ultrafine vertical roller mill is mainly composed of motor, reducer, grinding wheel device, Largest mining machine showroom in the world 1000 square meters of exhibition hall, covering 200+ mining equipment SBM’s ore grinding equipment sells well all over the world with high quality and highcost performanceUltrafine vertical roller mill SBM Ultrafine Powder TechnologyRaymond Mill Working Principle In the Raymond mill, a Raymond mill spring with a pressure of 10001500 kg is fastened to the grinding roll hanger After starting work, the grinding roller rotates around the main shaft and rolls close to the grinding ring under the action of the Raymond mill spring and centrifugal forceRaymond Roller Grinding Mill Vertical Roller Grinding Mill Machine2024年1月5日 Granite powder grinding mill machines are industrial tools used to break down granite rock into fine powder Granite, renowned for its durability and aesthetic appeal, has transcended its traditional role in construction to become a valuable resource in various industries The utilization of granite powder, a byproduct of the stonecutting process, has Granite Powder Grinding Mill Machines

Surface Grinding Machine: Types, Parts Working Procedure

2021年6月4日 Surface Grinding Machine: Types, Parts Working Procedure What is Surface Grinder? Surface Grinding Machine: Types, Parts Working Process : A surface grinder consists of an abrasive wheel, a chuck (a workplace holding device) and a rotary table The surface grinder is generally used for finishing the workpiece or the objectKnow about the working of drilling machines +91 inquiry@bhavyamachinetools Now in UAE For Local Support Service Home; Profile; Products; Infrastructure; Network; Shop; Site Map; Contact; Post navigation ← Previous Next → Understanding the Working Principle of Drilling Machines Radial drilling machine, Multi Drilling Machine Working Principle ApplicationsThe ball mill machine is known as a ball grinding machine It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since 1985, supply globally service includes flow design, manufacturing, installation, and free operation training in mining, grinding, screening, crushing plantBall Mill JXSC Mineral2024年9月25日 Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plantsWe can offer you a free design and completed solutions according to your project Baichy Heavy Industry has grown into a hightech mining equipment comprehensive enterprise, integrating RD, manufacturing, sales, Working Principle And Application Exploration Of Vertical Shaft

Lathe MachineIntroduction,Working, 9 Parts,Types,

INTRODUCTION: In the Mechanical Engineering field Lathe machine plays an important role in Manufacturing In this article, I am going to discuss the Lathe machine in detail A lathe is a machine tool used to remove unwanted metals 2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel 14 Types of Grinding Machines [Working, Diagram The carding machine opens raw fibers into individual strands through a series of roller and cylinder surfaces with teeth or wire points that comb, strip, and card the fibers Key actions include combing to open tufts, stripping to separate fibers, carding to isolate individual fibers and remove neps, and doffing to form a continuous web Regular maintenance like grinding the wire points Working Principle of Carding Machine PDF Grinding At Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes Whether it's efficiently crushing ores, Horizontal ball mill and vertical Raymond mill can be used for milling of 200+ ores, with a fineness of 1002500 meshOre Crushing, Sand Making, Grinding Machinery Bellian Mining

HAWEMAT Präzisa Granite 5AxisCNC Tool grinding machine

HAWEMAT Präzisa Granite 5AxisCNC Tool grinding machine Complete machine base body made of granite; All axes mounted on granite base plate, with direct measuring system; Vertical (Yaxis, Granite) 280 mm Resolution XYZaxis of the drives 00001 mm Speed X 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM2023年2月23日 They use the principle of impact crushing to produce highquality cubical aggregates from various materials, including hard rock, soft rock, and recycled materials Understanding the working principle, components, and types of impact crushers can help you select the right machine for your application and achieve efficient crushingUnderstanding the Impact Crusher Working Principle for AGICO

Shaping Machine: Learn the working principle, operations types

2023年7月19日 Working Principle of Shaping Machine The working principle of a shaping machine is based on a quick return mechanism like Whitworth Fig 1: Quick Return Mechanism of Shaping Machine A rigid table on the machine supports the workpiece Over the workpiece, the ram moves back and forth as shown in the animation above