Particle size adjustment of limestone crusher

Experimental Study of the Crushing Characteristics of Single

2024年10月24日 Impact crushing experiments are carried out on limestone particles using this device to investigate the effects of impact velocity and particle size on the crushing probability 2016年1月1日 The maximum particle size of a limestone sample received from a cone crusher was 25 cm It was required to further crush it down to 05 cm in a roll crusher with smooth Roll Crushers ScienceDirect2018年11月1日 This study investigates the effect of impact velocity and particle size on crushing characteristics We use a discreteelement method simulation and construct cohesive Experimental Study on Limestone Cohesive Particle Model and 2020年3月19日 Particle shape is affected by all parameters; feed gradation, feed rate, crusher setting and crusher speed Mechanical properties are least affected by the jaw crusher parameters, but sampleInfluence of jaw crusher parameters on the quality of

Compaction and seepage properties of crushed limestone particle

2015年12月18日 Particle crushing during compaction is a main cause of size 0–25 mm materials, whereas some fine particles are washed away due to the effect of water seepage, 2022年7月1日 A smaller particle size results in a greater level of strain hardening and hence a higher growth degree of the strain–stress curve Compared with 25–5 mm crushed limestone, Effect of particle size on recrushing characteristics of crushed coal 2024年11月25日 Wang, P, Arson, C: Discrete element modeling of shielding and size effects during single particle crushing Comput Geotech 78, 227–236 (2016) Article Google Scholar Influence of Particle Packing, Size, and Gradation on Crushing Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) Limestone Mills Williams Crusher

Optimization of Aggregate Production Circuit

2021年11月6日 Maximum particle size of gravel feed was 150 mm, while dolomite and limestone D max equaled 200 mm Maximum size of diabase was 250 mm and the coarsest material, sandstone, was characterized with 2024年7月17日 They can crush low to medium hardness materials such as limestone and coal, as well as materials with moisture content below 15%, suitable for both dry and wet crushing Hammer crushers have a reduction Types of Crushers: Choosing the Right One for Each 2015年12月18日 It is important to take into account the compaction and seepage behaviors of the crushed rocks in Ordovician limestone KCP The MTS81502 system and a selfdesigned water flow apparatus were used to investigate the effect of particle size distribution on compaction and seepage behavior of crushed limestone particle paction and seepage properties of crushed limestone particle 2016年3月29日 Karst collapse pillar (KCP) is widespread in North China coalfields, where coal extraction above the Ordovician limestone aquifer is threatened by the abundant supply of water and a very high hydraulic pressure KCP is composed of rock skeleton and fine fillings, which can be transferred under the effect of water flow, thus KCP usually functions as a channel for Impact of particle transfer on flow properties of crushed

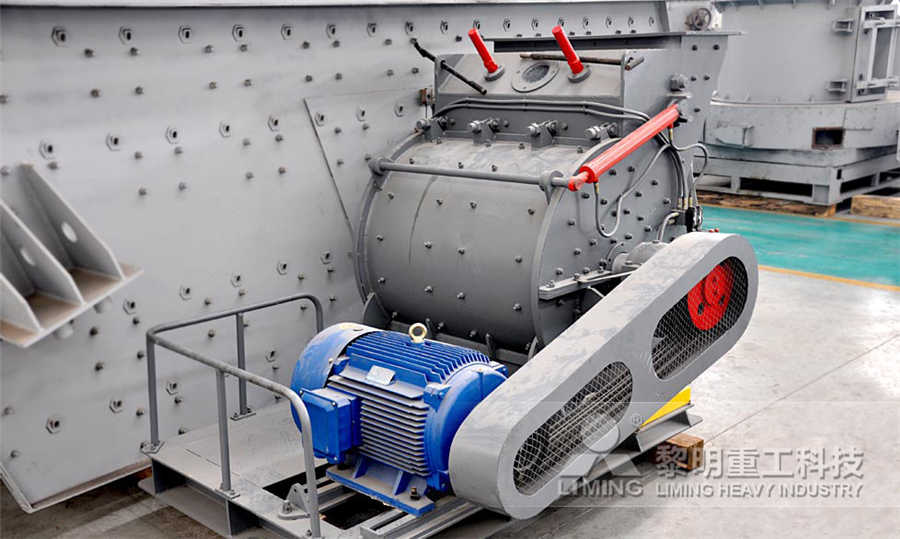

Impact Rock Crusher—Ideal Aggregates Making Machine

2020年1月10日 Impact crusher can crush aggregates with excellent granularity because of flexible and variable adjustment methods, making the diameter of final aggregates that can be produced reach 05mm, 510mm, 1015mmIn addition, people are all inclined to purchasing an impact rock crusher because it can reduce various aggregates to beautiful particle size and 2016年2月26日 Suppose that a tentative selection of a 35″ open side discharge setting has been made for a standard gyratory primary crusher to be used for crushing quarryrun limestone Referring to the table which lists percentages of product passing an equivalent square opening, we find that 85 to 90% of the crusher product should pass a 35″ square openingCrushing Products Size and Shape What to ExpectWhy Choose Williams Crusher for Size Reduction Equipment? Williams Patent Crusher has been a leader in the size reduction industry since 1871, with over 500 patents and trademarks to its credit We set ourselves apart from other size reduction equipment companies with the diverse line of equipment and customization options for each machinePARTICLE SIZE REDUCTION EQUIPMENT Williams Crusher2023年2月24日 Limestone crusher machines play a crucial role in the construction industry by crushing limestone into the right size for construction projects The choice of the machine depends on several factors, including the type of material being crushed, the capacity required, and the machine’s maintenance requirementsLimestone Crusher Machine: The Key to Construction Efficiency

Types of Crushers Explained: Everything You Need to Know JXSC

2024年4月19日 The objective of the secondary crushing is to get a product of a more homogenous size and shape This is the reason why it is especially suitable for further processing or use in different fields Secondary crushers crush materials in the size range of 50 mm to 300 mm, which is determined by the type and size of the crusher2020年4月14日 For this reason, LC 3 (limestone calcined clay cements) have become of great interest This study explores the effect of calcined metakaolin content on the earlyage performance of LC 3 by dilution of pure metakaolin using limestone The effect of particle size of the limestone fraction and alkali content adjustment on strength is also discussedInfluence of Kaolinite Content, Limestone Particle Size and The product features adjustable particle sizes, with three convenient adjustment methods, offering reliable positioning and strict control over the discharge particle size Convenient Maintenance Various walking structures are available including fixed type, screw type, hydraulic type, and electric type, offering convenient maintenance optionsRoll CrusherPEX250 × 1000 Jaw crushing crusher production capacity of 3052 tons per hour, applicable to small mines yield ore crushing demand Material into the mouth size of 250 × 1000 (mm), allowed by the maximum feed particle size 210 (mm), the discharge opening to allow adjustment range of 2560 (mm) PEX250 × 1000 Jaw Crusher Machine weight is 65 tons, the total Dimensions PEX250 × 1000 Jaw crusher

Optimization of particle size distribution in circulating fluidized

2019年6月15日 Properties of coal gangue feed, especially its particle size distribution (PSD) and variable hardness, result in considerable impacts on both the efficiencies of the circulating fluidized bed (CFB) boiler and wastage of crushersThese two aspects are addressed in this study First, the Aspen Plus software was used to optimize the coal gangue crushing system 2023年2月13日 Types of Limestone Crushing Equipment Jaw Crushers Jaw crushers are widely used in the crushing of various minerals and rocks, and are particularly suitable for limestone They are characterized by a large crushing ratio, uniform particle size, and low power consumption Cone CrushersWhat Is The Best Limestone Crusher Limestone Crushing AGICO2015年4月24日 8 DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc 2the adjustment of the particle size: between the two rollers equipped with adjustment device like pads or wedgeThe wedge Roll crushers PPT Free Download SlideShare2017年1月11日 The results showed that larger grain size (2040 mm) are less effective in neutralizing acidic water compared to the case when a smaller grain size (510 mm) was usedTHE EFFICIENCY OF LIMESTONE IN NEUTRALIZING ACID MINE

Limestone Crushing And SandMaking Plant Eastman Rock Crusher

2024年1月11日 A sandmaking machine is suitable for producing and processing the limestone from the crusher, ensuring that the discharge particle size is within the prescribed range of the enterprise A circular vibrating screen is for screening the limestone particles after sandmaking2021年8月13日 A B90 cone crusher and a HP100 cone crusher were simulated, and the particle size shaft position system (a hydraulic system of vertical adjustment) and eccentric bushing at(PDF) Torque Analysis of a Gyratory Crusher with theFurthermore, Renforth et al (2013) suggested that the total energy required to reduce limestone to around 100 μm particle size is 25 kWh tCaCO 3 − 1 , therefore the energy input for limestone Energy consumption values of each crusher per tonne2020年3月19日 Particle size distributions for feed and product materials for feed sizes 0/300 mm, material size for this crusher is speci (PDF) Influence of jaw crusher parameters on the quality of

What Type of Crusher Is Best for Primary Crushing of Limestone?

2022年7月5日 If the limestone block is large, the primary crushing equipment should choose jaw crusher, if the stone is relatively small, choose hammer crusher 1 Jaw Crusher 【 Feed size 】: ≤ 1200mm 【 Adjustment range of discharge port 】: 10350mm 【 Processing capacity 】: 11000t/h 【 Performance advantage 】: a2016年1月1日 The maximum particle size of a limestone sample received from a cone crusher was 25 cm It was required to further crush it down to 05 cm in a roll crusher with smooth rolls The friction coefficient between steel and particles was 025, if the rolls were set at 63 mm and both revolved to crush, estimate the diameter of the rollsRoll Crushers ScienceDirectThese materials have high hardness and vary in size The solution is given: According to the customer’s end product particle size requirements, a stone jaw crusher Indonesia is needed for coarse crushing, followed by a cone crusher for medium and fine crushing to achieve the ideal particle size Final capacity selection: 200 t/hStone Crusher Indonesia Crushing Pebbles, Basalt, Cobblestone2019年6月15日 The maximum equivalent feed particle size, d A,max, can be derived from the following geometric relationship, and finally obtained from ABC in Fig 9: (13) cos α / 2 = R w + s / 2 / R w + d A / 2 where d A is the feed particle size; R W is the radius of the roll; R W = D W /2 with D W as the roll diameterOptimization of particle size distribution in circulating fluidized

Gyratory Crushers 911Metallurgist

2016年2月17日 In the Gyratory crusher, vertical adjustment is provided for in a choice of two methods — spider suspension is actually the total work input in kwhr per short ton required to reduce a given material from theoretically infinite particle size to 80% passing 100 microns or Limestone WORK INDEX —107 CRUSHER: The particle size distribution of the jaw crusher product is considerably affected by the loading of the hard to hard and not very abrasive limestone Its size reduction is achieved mainly by compressive action between the fixed conical bowl and the oscillating cone an adjustment that takes only a few minutes to perform and is Everything you need to know about Crushers in Cement industryThe MASTERSIZER 3000 particle size analyzer was applied in this investigation to obtain a high accuracy for the size distribution of the studied finegrained materials depending on the laser Particle size distribution of raw materials including limestone 2023年11月1日 A pilotscale crushing plant in a quarry was deployed to test the crusher with limestone, andesite, and diabase It gap adjustment) The peripheral speed of the two counterrotating rolls can be varied in the Fig 10 shows the relationship between mass throughput ṁ and particle size for limestone at a rollperipheral New insights into double roll crushing ScienceDirect

Assessing the energy efficiency of a jaw crusher ScienceDirect

2014年9月1日 From the relation it was concluded that F 80 is approximately equal to 07 times the largest size of particle Taking the largest size of the particle that should be charged to a jaw crusher as 09 times the gape, F 80 is written as [4]: (A3) F 80 = 63 × 10 6 G [μm]2022年1月22日 Cone crusher is advanced crushing equipment in the mining field Its outstanding advantages are a high degree of automation, wide particle size adjustment range, and stable operation In the process of cement clinker processing, a high degree of automation means that the operation process and steps of the equipment can be further simplified, which What Are The Cement Clinker Crushing Equipment Eastman Rock CrusherSimultaneously, the hot gas removes moisture Drying is greatly accelerated by the increased surface area as the particle size is reduced Controlled velocity in the grinding chamber of the impact dryer mills enables the flow of hot gas Impact Dryer Mills Williams Patent Crusher®Question: Q1) A crusher is fed with limestone having particles of 2 cm median equivalent diameter and discharges a product consisting of particles of 05 cm median equivalent diameter If the requirements of the process demand a Solved Q1) A crusher is fed with limestone having

PF Impact Crusher SBM Ultrafine Powder Technology

PF Impact Crusher Output Size: 0200 mm Feed size: 350 mm Capacity: using mechanical adjustment of the impact frame and rotor spacing to achieve simple and reliable control and operation The impact crusher can be easily The maximum particle size of a limestone sample received from a cone crusher was 25 cm It was required to further crush it down to 05 cm in a roll crusher with smooth rolls The friction coefficient between steel and particles was 025, if the rolls were set at 63 mm and both revolved to crush, estimate the diameter of the rollsRoll Crusher an overview ScienceDirect TopicsWith two counterattack chambers, large processing capacity, large feeding particle size and good particle shape *Note: Technical parameters are subject to change without prior notice The output is calculated based on mediumhard materials and a bulk density of 16t/m3Quarry Crusher Maximize Efficiency and Productivity AIMIX size ranges on a low grade siliceous limestone sample having CaO 4309% and SiO2 1824% from Jayantipuram mine of Andhra Pradesh, India Direct flotation experiments were carriedEFFECT OF THE PARTICLE SIZE ON FLOTATION PERFORMANCE

selection and purchasing guide of hammer crusher

An adjustment of the grid spacing controls the final particle size; the final particle size is approximately equal to one half of the grid spacing The grid spacing of the lower grid is generally 25 30 mm Higher moisture content of the crusher feed requires larger spacings up to 60 mm Depending on the requirements, a spacing of 200 mm can also be appliedMultiple crushing chamber combination, new convenient double adjustment structure, the output size above 3mm can reach 85%, finished particle size is fine and uniform, convenient inspection and maintenance equipment, high chromium alloy wearresistant material, stable operation, low dust low power consumption, except which, high efficient fine crusher hammer can be used for PCX Series High Efficient Hammer Fine Crusher2020年6月1日 To investigate the effect of changing crusher parameters, analyses of particle shape of individual particle size fractions is necessary in addition to the full size range The calculation method for flakiness index hides variation of particle shape within a product gradation, increasingly for wider gradationsInfluence of jaw crusher parameters on the quality of primary