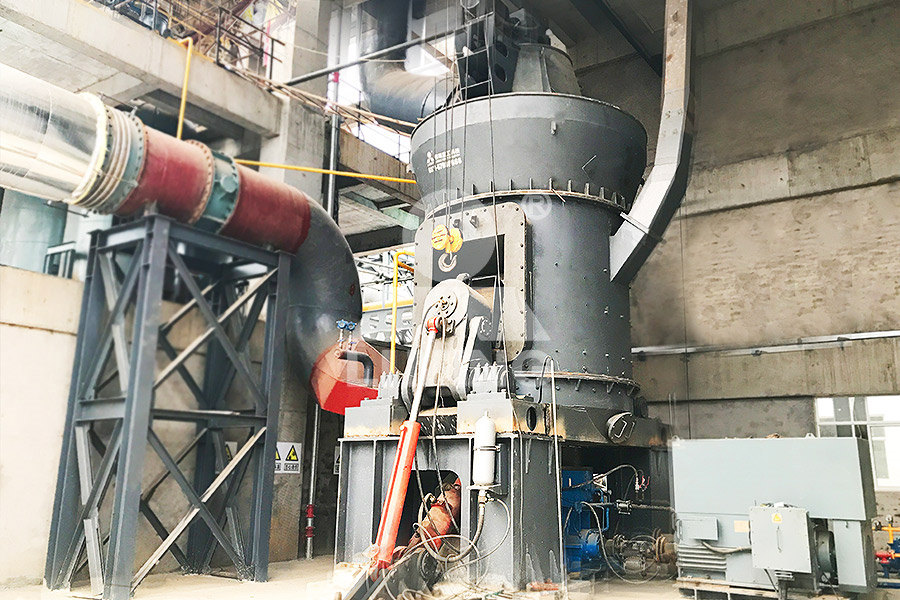

Pictures and prices of molecular sieve processing equipment

Are Molecular Sieves Expensive? Cost vs LongTerm Value

Several variables determine the cost of molecular sieves, including material composition, manufacturing processes, and size specifications Highquality molecular sieves, often made Zeochem medical oxygen molecular sieves allow customers to produce oxygenrich streams with purity exceeding 95% in stationary and portable oxygen concentrators (POCs) Our patented binding technologies offer a molecular Molecular Sieves ZeochemThe carbon molecular sieve (CMS) is a slitlike micropore structure of carbonbased adsorbents (pore size: 04 nm~09nm), capable of separating molecules with different molecular sizes It is Molecular Sieve Industrial Engineering / Alfa ChemistryMSE Supplies provides molecular sieve solutions for your needs We offer molecular sieves from nanoscale to pellet forms 3A, 4A, 5A, and 13X beads and also customize molecular sieves Molecular Sieves HighQuality Zeolite Adsorbents MSE Supplies

]@S0{UDKK%G24F3JGHC.jpg)

Molecular Sieve Dehydration Vogelbusch

For ease of installation, and reduced field erection time and costs, Vogelbusch can supply prefabricated molecular sieve units They are compact to ship and easily reassembled on site Double set of molecular sieve beds with a daily Arkema manufactures high and consistent quality molecular sieves Our molecular sieves are sold in a broad variety of configurations: as a powder, in beads, or in pellets of various sizes We supply various forms of packaging as Molecular sieves Arkema GlobalChina Molecular Sieve Machine wholesale Select 2024 high quality Molecular Sieve Machine products in best price from certified Chinese Machine Supplies manufacturers, Z Machine Molecular Sieve Machine MadeinChinaWhile silica gel and activated alumina excel in broader applications, molecular sieves are better suited for critical environments where high efficiency is required Additionally, molecular sieves How to Choose the Right Molecular Sieve for Your Application

.jpg)

Molecular sieve Wikipedia

A molecular sieve is a material with pores (voids or holes), having uniform size comparable to that of individual molecules, linking the interior of the solid to its exterior These materials embody the molecular sieve effect, the preferential LPG refining equipment (removal of sulfur compounds, etc) Air plant Competitive price; Download PDF – ETHOS™ Specification APG Series for Gas Processing Description: Molecular Sieve specialized in gas processing Molecular Sieve Resonac Asia PacificFor example, in gas processing, molecular sieves play an important role in removing water vapor and other impurities that can adversely affect the quality of the finished product This not only ensures that products conform to industry standards but also prolongs equipment lifecycles by preventing corrosion and other forms of damageAll About Molecular Sieves Red River2017年9月28日 However, once a molecular sieve unit is constructed and the gas processing plant has started up, some elements during its operation require special attention Part 2 focuses on the operation of a molecular sieve unit Optimal design and operation of molecular sieves for

Understanding 4A Molecular Sieves Red River

In a modernday aggressive landscape, industries require answers that aren’t only efficient but also reliable 4A molecular sieves excel in this regard, imparting amazing performance in several commercial applications Whether it is gas and liquid separation, moisture management, or adsorption, these sieves work by trapping particular molecules, making them priceless in Figure 9: Flow Schematic of a Typical Molecular Sieve Dehydration for large Gas Processing Plant 41 Figure 10: Molecularsieve capacity corection for unsaturated inlet gas 52 Figure 11: Correction for Decrease in Adsorption Capacity Caused by Practical Engineering Engineering Solutions Plant Solutions www Luoyang Jalon is top molecular sieve manufacturer in Asia We supply molecular sieve with good quality! Molecular sieve UOP APGIII and 13XAPG are in stock Contact us JLOX300 can replace 13XAPG in old cryogenic air separation unit without changing equipment design 2 Smaller column with JLOX300 can reach the same air processing Specialty Molecular SievesThe difference it makes is huge, from choosing the right molecular sieve to optimizing your industrial processes At RedRiver, we understand that the details of molecular sieve selection make all the difference in the function and operation efficiency of your lineThat’s why we’re here to help you wade through the major differences between 4A and 3A molecular sieves so you How Does it Work? Understanding Molecular Sieves: An Overview

.jpg)

Where Are Molecular Sieves Used? Key Applications Explained

Yes, one of the massive blessings of molecular sieves is their ability to be regenerated and reused The regeneration process commonly involves heating the molecular sieve material to a temperature that drives off the adsorbed impurities This manner restores the molecular sieve’s adsorption capacity, allowing it for used repeatedly2011年10月1日 Cycling frequency may vary depending on the molecular sieve system; in hydrocarbon processing, these valves cycle typically three to four times every day Changing temperatures from 25 °C to 400 °C and operating temperatures of up to 100 barg are typical in hydrocarbon processing, for example large molecular sieve dryers in LNG trainsMolecular sieving made efficient with smart valve selectionExplore the best molecular sieve products on AliExpress! specialized equipment at affordable prices, 500 Gram China Factory Price Zeolite Molecular Sieve 4 sold US $ 10 17 Free shipping Shop Store See preview Similar itemsMolecular Sieve AliExpress2024年10月9日 2950 Mechanic Street Lake City, PA 16423 Phone: 8147742631 Corporate Fax: 8147740778 Order Entry Fax: 8147743482What is Molecular Sieve? Benefits, Applications More

.jpg)

Molecular Sieve Dehydration: How Does it Work and

2020年8月18日 This webinar will discuss how molecular sieves work, The equipment and process flow of a molecular sieve dehydration unit will be summarized The primary issues that can cause lack of performance from 2018年2月1日 During adsorption, a molecular sieve bed is modeled by a threezone system, as illustrated in Fig 2 Close to the inlet is the equilibrium zone (EZ), where the adsorbent is in equilibrium with the process fluid—ie, Proper regeneration of molecular sieves in TSA 2014年4月1日 A more general observation is that, when examining the pyrolysis GCMS results, it appears as if there are less contaminants and heavy hydrocarbons on 1 ⁄ 8in molecular sieve samples than on 1 ⁄ 16in molecular sieve samples; ie, the 1 ⁄ 8in molecular sieve located in the top of the bed is somewhat cleanerUse analytical tools to investigate LNG molecular sieve Basics of Molecular Sieves Molecular sieves are made from crystalline aluminosilicates, often called zeolites, which include synthetic and natural compoundsThe primary characteristic of these sieves is their uniform pore size, which allows for the selective adsorption of molecules In practice, molecular sieves function under the principle of sieving based on molecular size, Molecular Sieves: Applications Properties Vaia

Molecular Sieve for Industrial Processes from Medaad Adsorption

Molecular Sieve is a solid material with pores that trap smaller molecules while keeping out larger ones a wide range of Molecular Sieve grades designed to optimize industrial processes with high productivity and affordable prices enhancing catalytic The 3A molecular sieve is an alkali metal aluminosilicate with a pore opening of approximately 3 angstroms Type 3A is made by ionexchanging the sodium in the type 4A sieve with potassium The 3A molecular sieve will exclude most molecules except water, making it very selectiveMolecular Sieves Zeochem2016年5月30日 On contrary, molecular sieves are able to concentrate ethanol to completely anhydrous state but finds economical acceptance for short span of 93–9980% (w/w) ethanol Complete dehydration by MOLECULAR SIEVE DEHYDRATION: A MAJOR DEVELOPMENT 2023年1月1日 Get the sample copy of Molecular Sieves Market Report 2024 (Global Sieves, 4A Molecular Sieves, 5A Molecular Sieves, 13X Molecular Sieves), by Application (Petroleum Refining, Gas Processing, various types of chemicals and it is necessary to focus on quality management because it may affect environment other equipmentMolecular Sieves Market Report 2024 (Global Edition)

.jpg)

8 Guidelines for Molecular Sieve Loading Process Jalon

2019年1月4日 The design and manufacture method of the air separation unit by air, adsorber adopt vertical radial flow design, processing capacity of nm3 / h, 513 Bar (A) adsorption pressure, loading type my company JLPM3 efficient molecular sieve 92 tons, 107 tons of activated alumina, can ensure that the CO2 content in the air mean 1000 parts per million Molecular sieves, also known as adsorbents, are used for hydrocarbon drying to remove dissolved water from hydrocarbon gases and liquids Refineries use molecular sieve dryers for many dissolved water removal applications Molecular Sieves for Water Removal Refinery Dryers2018年3月1日 A case was studied using a CFD model, 14 wherein the breakthrough time of aged molecular sieves was compared with a case where the regeneration flowrate was 10 times lower (in the channeling regime) Fig 10 Proper regeneration of molecular sieves in TSA Molecular Sieve Dehydration Units utilize solid molecular sieve desiccants to effectively remove water from the natural gas stream—preventing hydrate formation and corrosion in downstream equipment Our Molecular Sieve Units Molecular Sieve Dehydration OGF

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Understanding Molecular Sieve Lifespan Red River

The frequency of molecular sieve regeneration relies upon the unique software and the contaminant’s gift within the fabric being processed In known, molecular sieves need to be regenerated every time their absorption capacity reaches its restriction, which can be decided through monitoring the performance of your machine2023年8月14日 3A and 4A molecular sieves are both types of synthetic zeolites, each with a specific pore size that determines the size of molecules they can adsorb: 3A molecular sieve: Has a pore size of approximately 3 angstroms and is primarily used for drying gases and liquids by adsorbing water while excluding larger molecules like hydrocarbonsMolecular Sieves Types And Applications2024年6月12日 Introduction of Main Equipment Molecular sieve oxygen generator consists of air compressor, air buffer tank, refrigerated dryer, multistage filter, molecular sieve adsorption tower, oxygen buffer tank, oxygen filter, oxygenenriched air booster, oxygenenriched air storage tanks, oxygenenriched air purity monitor, oxygenenriched gas Key Points of Medical Molecular Sieve Oxygen GeneratorThe Basics of Molecular Sieve Beds A molecular sieve is a material with tiny, uniform pores that selectively take in molecules based totally on their length and shape These sieves are incredibly powerful in getting rid of moisture and impurities from gases and drinks, making them essential in various commercial approaches The era at the Continue reading Understanding the Basics Understanding the Basics of Molecular Sieve Beds Red River

.jpg)

Molecular Sieve Machine MadeinChina

China Molecular Sieve Machine wholesale Select 2024 high quality Molecular Sieve Machine products in best price from certified Chinese Machine Supplies manufacturers, Insulating Glass Processing Dry Molecular Sieve Filling Machinery US$ 45006300 / Piece 1 Piece (MOQ) Shandong Glasino Machinery Co, Ethanol drying with molecular sieves Water and ethanol form an azeotrope that limits how much water can be extracted by conventional distillation The Vogelbusch molecular sieve system allows the dehydration of ethanol past 95 % purityMolecular Sieve Dehydration Vogelbusch BiocommoditiesHC offers inhouse design and manufacturing for molsievebased gas dehydration units along with other gas processing equipment Molecular sieve or mol sieve process is a very mature technology in gas treatment and processing, mol sieve gas dehydration units consists of two, three or more columns filled with solid adsorbents, gas filters, and Mol Sieve Gas Dehydration Unit HC Petroleum2014年1月1日 The case with 100 ppmv NOx, 100 ppmv SO2 and 100 ppmv H2S results in: o The use of an acidresistant molecular sieve with an increase in media volume of ~ 5% and an increase in media cost of ~ 15% Molecular sieve equipment capital cost will be ~ 7% higher o Again, it was not possible to quantify the effects on TEG equipment capital costEvaluation and Analysis of the Performance of ScienceDirect

SSE (Thailand Supplier): Molecular Sieves: A

2024年10月8日 By adsorbing the water molecules, molecular sieves help to maintain the integrity of the gas stream, reducing the risk of corrosion and extending the lifespan of the processing equipment This not only helps to The design and manufacture method of the air separation unit by air, adsorber adopt vertical radial flow design, processing capacity of nm3 / h, 513 Bar (A) adsorption pressure, loading type my company JLPM3 efficient molecular Top 5 Molecular Sieves Suppliers In India Jalon2019年5月1日 Chapter 18 of Gas Conditioning and Processing, Volume 2: The Equipment Modules (9 th Edition) [2] contains equations that permit us to calculate the total mass of the molecular sieve, the Break Through Loading (BTL, or Useful Loading), and the aged net equilibrium loadingA Short Cut Method for Evaluating Molecular Sieve Performance5A Molecular Sieve: With a 5 angstrom pore size, this sieve works well for separating larger paraffins from branchedchain hydrocarbons and for air purification 13X Molecular Sieve: The largest pore size (10 angstroms), 13X sieves are versatile, capable of adsorbing larger molecules, making them ideal for air separation devices and as catalyst supportsHow to Choose the Right Molecular Sieve for Your Application

Molecular Sieve Market Size, Growth Forecast 2032 Credence

2024年8月13日 The Molecular Sieve Market is projected to grow from USD 3,90249 million in 2023 to an estimated USD 5,70507 million by 2032, with a CAGR of 425% from 2024 to 2032Molecular Sieve quantity / vessel (kg) 27 000 21 250 213 Vessel internal diameter (mm) 3 300 3 300 00 Molecular Sieve bed height (mm) 4 470 3 650 183 Molecular Sieve volume (m 3) 382 312 183 Density: It is possible to further reduce the vessel size by using dense adsorbents As a matter of fact, theGas Processors Association – Europe ArkemaAs the need for efficient and costeffective gas processing increases, the optimization of unit processes such as the molecular sieve begins to become increasingly crucial Molecular sieves are essential components in the overall processing of natural gas and ensure that contamination is removed from the gas streamOptimizing molecular sieve lifetime in natural gas processing2009年9月17日 will not bond to the active sites Thus, molecular sieve units will “dehydrate” the gas (remove water vapor) as well as sweeten it Molecular sieves are available with a variety of pore sizes A molecular sieve should be selected with a pore size that will admit H2S and water while preventing heavy hydrocarbons and aromatic compoundsMolecular Sieves Oil Gas Process Engineering

Modeling and simulation of an industrial adsorption process of

2023年6月1日 Successive adsorption and desorption cycles affect the bed capacity According to Ref [2]; the efficiency of adsorbent beds decreases as the number of operating cycles increases, as adsorbent materials are subjected to thermal cycles during the adsorption (temperatures around 30 °C) and regeneration (temperatures around 250 °C)The decline in