What are the phosphate ore powder making equipment

Phosphate Rock Processing: 6 Useful Ways and 4 Stages

Commercial phosphorus is obtained from phosphate rock, which is beneficiated after mining There are eight main ways for phosphate processing, which are suitable for different types of phosphate rock, to improve the grade and quality of phosphate rock 展开2021年11月3日 Phosphate mineral powder grinding mills are processing equipment for phosphate rock powders Choosing a highefficiency, intelligent, energysaving, and environmentally friendly phosphate rock powder mill can Phosphate Mineral Powder Grinding Mill SBM Optimize the extraction processes with equipment that ensures precise crushing, controlled grinding, efficient separation, and effective flotation, resulting in improved phosphate recovery rates, reduced waste, and enhanced overall Phosphate Mining Arroyo Process EquipmentThe Phosphate Mining Process Our solutions provide scrubbing, attrition, cyclone and dewatering equipment to help process the phosphate ore into the final mineral which is stockpiled and Phosphate Mining Equipment Phosphate Processing Solutions

How Phosphate Rock Grinding Can Help You Succeed

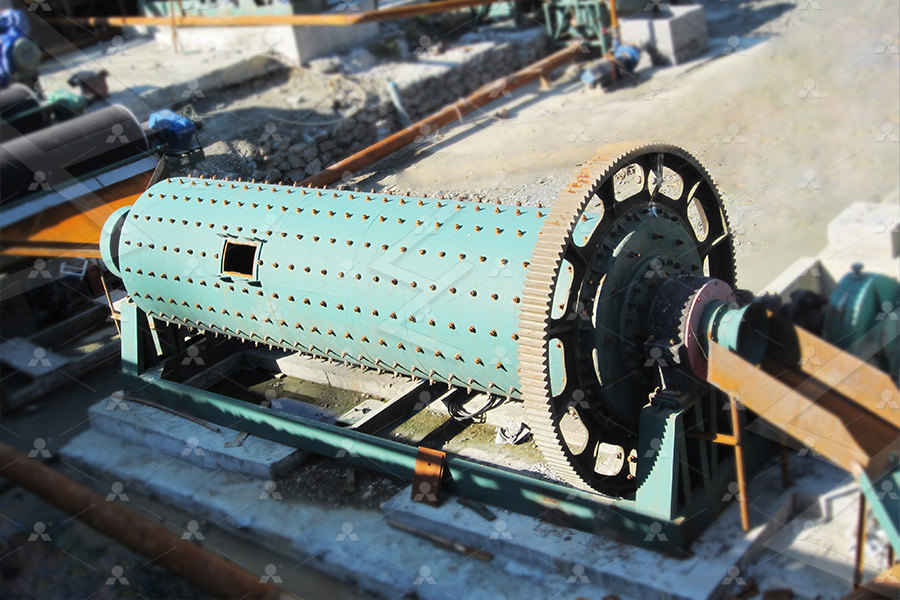

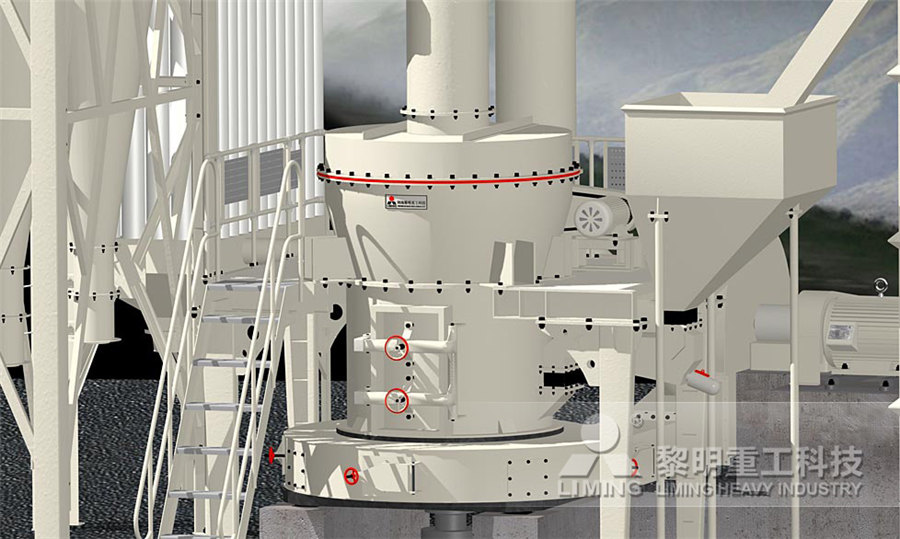

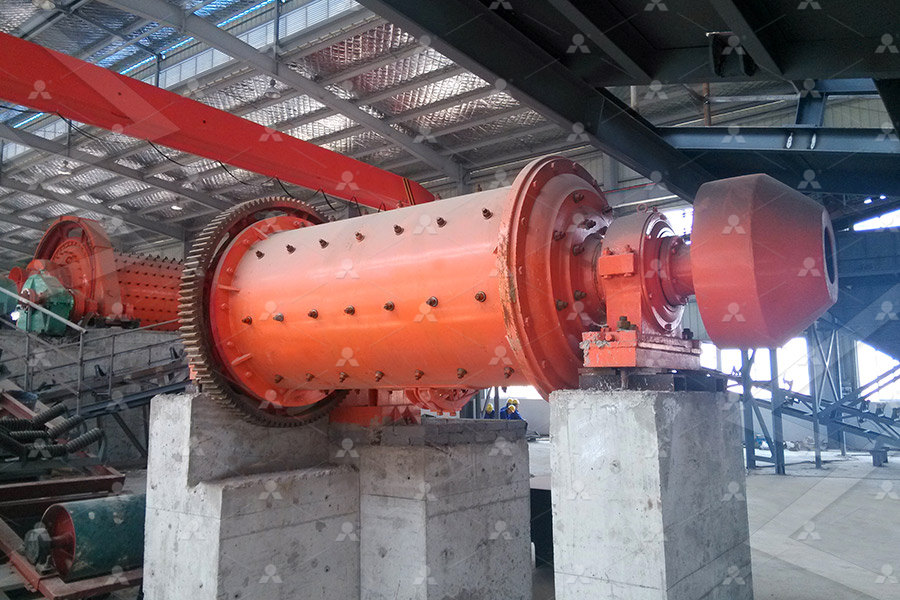

2023年8月30日 Phosphate rock mills are types of grinding equipment used to process phosphate rock into powder, such as Raymond mill, HGM ultrafine mill, and vertical mill Each mill has its unique features and advantages for grinding The three main mill options for phosphate ore are: l Ringroller mills: Vertical rollers rotate inside a fixed horizontal ring (Figure 1) Material fed between the rollers and the ring is ground to The importance of phosphate milling Bradley Pulverizerphosphate (GTSP) is beneficiated, dried, and ground before being transferred to the GTSP production processes Dried or calcined rock is ground in roll or ball mills to a fine powder, 1121 Phosphate Rock Processing US EPA2023年1月2日 The review discusses the geological aspects of phosphate rocks, their availability, and methodologies to convert them to phosphoric acid and ultimately to phosphogypsum A Comprehensive Review on Occurrence and Processing of

How Phosphate Rock Grinding Can Help You Succeed

2023年8月30日 Want to improve the purity of rock phosphate powder? You can learn about phosphate ore beneficiation methods Phosphate rock mill is the key to success Phosphate rock mills are types of grinding equipment used to 2011年9月29日 To understand the powder coating process you should start with the fundamentals Powder coating is a dry finishing process used to apply a dry coating material The coating material is made up of finely ground particles of The Powder Coating Process Products Finishing2024年3月27日 Trisodium phosphate, commonly called TSP, is a packaged, blended cleaning product consisting of 75 to 80 percent trisodium phosphate and 20 to 25 percent sodium carbonate TSP is typically inexpensive and comes in What Is Trisodium Phosphate (TSP)? The Spruce2020年12月15日 The way to successfully upgrade a phosphate ore is based on the full understanding of its mineralogy, minerals surface properties, minerals distribution and liberationReview of the Main Factors Affecting the Flotation of Phosphate Ores

What Are Iron Ore Pellets and How to Make Them?

2023年5月29日 98% of iron ore is used as raw material for steel and iron Iron ore pellets are preferred instead of raw ore when smelting steel because pelletization can maximize the use of iron ore and improve the blast furnace performance What are iron ore pellets? Iron ore pellets are spheres of typically 816 mm to be used as feedstock for blast furnaces2023年7月10日 This Egyptian client’s solid materials are phosphate rocks, for better SSP fertilizer pellet making, you must turn them into powder For this, you can use jaw crusher to break rocks into small particles first and adopt Raymond mill How To Make Super phosphate Into SSP Granule In Egyptyou treat it If you can clean it, you can phosphate Th e simplest of commercial treatment processes is a twostage iron phosphate cleaner/coater Depending on the specifications and performance requirements, this simple twostage system can in crease in complexity and detail to a fifteenstage zinc phosphate processThe Pretreatment System: Chemistry Controls2020年3月19日 Phosphate ore or phosphate rack is an essential nutrient with abundant phosphate minerals, and is the major resource mined for the production of phosphate fertilizers It is also used for anti Phosphate Rock Grinding Mill Manufacturer

Powder Coating: Why A Phosphate PreTreatment Is Essential

2016年3月15日 For many industries, lengthening the lifespan of essential machinery is a critical concern Logically, powder coating is a time and costeffective way of doing so Of course, this process has to be done right to be worthwhile, which is why a phosphate pretreatment process is considered a key element of any preservation policyBased on the P 2 O 5 content, three phosphate grades can be distinguished: lowgrade ores (12–16% P 2 O 5), mediumgrade ores (17–25% P 2 O 5), and highgrade ores (26–35% P 2 O 5) The phosphate ore enrichment processes allow the gangue minerals to be separated from the economical phosphate value Quality of Phosphate Rocks from Various Deposits Used in Wet 2023年3月9日 Seashell powder use and powder making equipment 09/03/2023 admin Seashell Powder Introduction Seashell powder refers to the powder made of oysters, clams, and scallops 95%of them are calcium carbonate, chitin, Seashell powder use and powder making equipment 2024年6月26日 Compared to other phosphate coatings, manganese phosphate offers a variety of valuable benefits that can improve the overall performance and reliability of metal parts These include: Maximum Hardness – Manganese What Is Manganese Phosphate and What Is It Used For?

Phosphate wash before Powder Coating Surface

Phosphate wash before powder coating is essential step for better finishing and higher quality The phosphate layer not only enhances adhesion but also improves the durability of the powder coating itself, making it more resistant to 2021年11月3日 Phosphate Rock Ore Grinding Equipment Only by selecting the right equipment can we produce phosphate powder that meets the requirements, and can maximize efficiency and reduce energy consumption, so as to obtain ideal profits Stone Crusher >> Jaw Crusher – Coarse CrushingPhosphate Mineral Powder Grinding Mill SBM Ultrafine Powder 2024年4月1日 Since Padhi et al reported the electrochemical performance of lithium iron phosphate (LiFePO 4, LFP) in 1997 [30], it has received significant attention, research, and application as a promising energy storage cathode material for pared with others, LFP has the advantages of environmental friendliness, rational theoretical capacity, suitable An overview on the life cycle of lithium iron phosphate: synthesis 2024年10月4日 If you need a heavyduty cleaner to tackle tough messes, trisodium phosphate (TSP) might be the solution Whether you need to prep a longneglected exterior surface for painting or remove years of cakedon grime behind your oven, TSP’s powerful cleaning action can help you get the job doneHowever, this potent, inexpensive cleaning product also has its Using Trisodium Phosphate to Clean Tough Messes This Old

(PDF) Fundamentals of the WetProcess Phosphoric Acid

1996年11月7日 During the digestion process, as shown by the overall reaction below, sulfuric acid is dissociated into H + and S O 2− 4 ions The H + ions are involved in the extraction of the phosphate Phosphate Beneficiation Background Definition of “Beneficiation”: This is the second step in the mining process, after removal of the ore from the ground Beneficiation is the technical term describing the industrial process of mechanically separating minerals from each otherPhosphate Beneficiation Florida Polytechnic UniversityPhosphate binders are a medication that removes excess phosphate from your body If you don’t take them, you’re at a greater risk for more serious conditions Locations: Mix a powder with water or another liquid and drink within the first two to three bites of foodPhosphate Binders: Purpose, Risks Results Cleveland Clinic2019年1月30日 Phosphate ore is an important raw material for manufacturing fertilizers and phosphorous chemical products While most of the phosphate resources cannot be directly treated as feed stock due to the low grade of P2O5 and high content of impurities In order to obtain a qualified phosphate concentrate, the beneficiation of the lowgrade phosphate ore is, Review on Beneficiation Techniques and Reagents Used for Phosphate Ores

.jpg)

Iron Phosphate Pre Treatment Great Dane Powder

2019年8月19日 Powder coating —the kind industrial and parts manufacturers demand— can be extremely durable and protect metal parts from corrosion and rust At Great Dane Powder Coating, our process includes an Iron Phosphate 2022年5月4日 Pelletizing, not to be confused with pelleting (extrusion), continues to see increasing use across industries for the many benefits it can offer to previously difficulttohandle bulk solids and Pelletizing: The Process, The Equipment, and the 2017年1月1日 World phosphate rock production capacity in 2015 according to US Geological Survey, Mineral Commodity Summaries, January 2017 (USGS, 2017) (PDF) WORLD PHOSPHATE INDUSTRY ResearchGateThe Phosphate Mining Process Our solutions provide scrubbing, attrition, cyclone and dewatering equipment to help process the phosphate ore into the final mineral which is stockpiled and ready for use The freedigging phosphate ore is typically Phosphate Mining Equipment Phosphate Processing Solutions

Phosphate Processing Equipment Overview FEECO

Basic Requirements for Phosphate Processing Equipment Phosphate processing equipment must be designed with the specific characteristics of phosphates in mind to reach an effective solution that will stand up to the rigors of processing phosphates while making the most out of this available resource2021年2月17日 Open pit mining method is one of the surface mining methods that has a traditional coneshaped excavation and is usually employed to exploit a nearsurface, nonselective and lowgrade zones deposits It often results in high productivity and requires large capital investments, low operating costs, and good safety conditions The main topics that will Open Pit Mining IntechOpenIron ore must go through a lengthy preprocessing stage before it can be pelletized – a series of steps that work to beneficiate and concentrate lowgrade ores This process varies depending on the ore source, but typically involves various stages of crushing and grinding to Iron Ore Pelletization FEECO International IncStep 1: Extracting The Phosphate Rock for Mineral Fertilizers The first step in the process of making phosphorus fertilizers is mining the natural sources of phosphate This mining is done by extracting rock phosphate ore from raw material deposits worldwide These deposits are typically found near bodies of water, such as oceans, lakes, and Mineral Fertilizer Production Process Kemper Equipment

Reagents used in the flotation of phosphate ores: A critical review

2003年7月1日 The performance of the collector in phosphate ore flotation was investigated by means of Xray diffraction (XRD), Xray fluorescence (XRF), scanning electron microscope (SEM) and Fourier transform 2023年6月1日 Phosphating is the process of depositing, by conversion, a layer of insoluble phosphate compounds, on the metal’s surface Although phosphate coatings have been studied since the early (PDF) Phosphate Conversion Coating – A Short Review2023年9月11日 The use of phosphorus by mankind is long established From use in agriculture, foods, high tech electronics, and more recently in EV battery cathode production, one cannot escape its impact on today’s society This paper will review and describe the circular journey of phosphorus through its value chain from the mining operation of phosphate ore through Phosphorus — a Circular Journey from the Ground to the2023年10月9日 Iron ore powder can be reduced quickly through fast mass transfer and high temperature, making it possible for HIsmelt to process inexpensive highphosphate iron ore Due to the high secondary combustion rate, the utilization value of hightemperature exhaust gas is very low, which can only be used to preheat fine oreDevelopment and Problems of Fluidized Bed Ironmaking Process:

.jpg)

Iron Ore Pelletizing Process: An Overview

PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate2021年11月2日 Raw Materials and Equipment In this study, phosphate ore was acquired from an enterprise in Yunnan, and coke was used as the reductant Table 1 and Fig 1 show the chemical composition analysis and XRD patterns of the phosphate ore and coke powder Overall, the main phase was Ca 5 (PO 4) 3 F and SiO 2, the content of P 2 O 5 was 29%, and there Experimental Approach for the Characterization of LowGrade Phosphate 3D Model of a FEECO Pin Mixer for Pelletizing (Pelletising) Phosphate Ore Disc Pelletizer (Pelletiser), Pelletizing (Pelletising) Phosphate Ore Pipe Reactor for Phosphatic Fertilizer (Fertiliser) Production Rotary Kiln for Upgrading Phosphate Ores Hammer Mill for Phosphates Rotary Cooler for Phosphates Granulation Drum for PhosphatesPhosphate Processing Equipment FEECO International Inc5 天之前 Copper industrial minerals include: natural copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite, etc Chalcopyrite (a compound of copper, sulfur, and iron) is mined mainly, followed by chalcocite and bornite If copper ore wants to be fully utilized, it must be processed by flotation Flotation separation is an important copper ore beneficiation process in Copper Ore Processing Plants, Flow And Equipment

Review of the Main Factors Affecting the Flotation of Phosphate Ores

Phosphate ores can also be classified based on their major gangue minerals as: (i) Siliceous ores if associated with silica, (ii) clayey ores if containing aluminum silicates, (iii) calcareous ores of sedimentary origin if containing carbonates as the major impurities, (iv) phosphate ores rich in organic matter, (v) phosphate ores with multiple gangue minerals, and finally, (vi) igneous and 2022年12月7日 Phosphate ores upgraded by flotation are widely used as vital raw materials for the sustainable production of phosphate fertilizers to maintain the food supply Highgrade phosphate reserves become more and more depleted Lowgrade phosphate mining and processing are in the spotlight of the fertilizer industries to cope with the exponential growth in Optimization of the Flotation of LowGrade Phosphate OreThis process is suitable for low grade phosphate ores including magnetite type apatite and sedimentary metamorphic type phosphorite ore 2 Reverse Flotation Process Mainly used for the separation of phosphate and dolomite; dolomite is collected with fatty acid collector in weak alkaline medium, and the phosphorus mineral is enriched in the groovePhosphate Mining Production Line TAYMACHINERYMetal ores contain sufficient minerals with important elements including metals that can be economically extracted from the rock The ores must be processed to extract the metals of interest from the waste rock and from the ore minerals Alloys are mixtures of materials, at least one of which is a metal Bronze alloys were widely used in weapons123: Metals and Ores Chemistry LibreTexts