Why can't the highpressure oil of the coal mill stand up to pressure

.jpg)

Derivation and validation of a coal mill model for control

2012年5月1日 During normal operation, the mill pressure drop is predominately proportional to the primary air differential pressure and a small change in coal mass does not affect the pressure drop significantly Also, when the coal mass becomes zero, the pressure drop also becomes 2020年8月12日 Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coalAn investigation of performance characteristics and 2024年2月1日 The improvement of operational flexibility is limited by the deaerator water level control The discussion in this article showed that the throttling extraction steam of high Enhancing the flexibility and stability of coalfired power plants by A number of different faults can occur in the coal mill, and if the fault leads to a decrease in the output coal flow from the coal mill, this can lead to drop out of the entire power plant unit In Coal Mill an overview ScienceDirect Topics

Thermodynamic analysis of a coalfired power plant

With the justified concern of their rapid depletion and the environmental impacts associated with their largescale use, there is a quest for advanced coalfired power generation technologies Abstract Increasingly, the variable electricity in terms of possessing supply c oalfired power plants are required to balance power resilience to renewable frequent startups, energy Increasing the flexibility of coalfired power plantsPulverization is currently the favored method of preparing coal for burning Mechanically pulverizing coal into a fine powder enables it to be burned like a gas, thus allowing more Improving Coal Pulverizer Performance and Reliability Pall This paper presents a comparison of the Riley Vertical Roller Mill with Riley's two other pulverizer designs— a lowspeed ball tube mill and a highspeed attrition pulverizer Specific topics A Comparison of Three Types of Coal Pulverizers Babcock Power

.jpg)

Coal mill pulverizer in thermal power plants PPT

2012年11月17日 The document discusses coal mill/pulverizers used in thermal power plants It describes how pulverized coal is dried, ground, circulated, and classified within the mill to produce a fine powder that is then transported to 2019年4月18日 This chapter describes the process of coalification, which gradually turns plant debris into coal, involving heat, pressure and the effects of time Chemical changes during The Origin and Classification of Coal SpringerLink2024年11月15日 Coal is a black or brownishblack sedimentary rock that can be burned for fuel and used to generate electricityIt is composed mostly of carbon and hydrocarbons, which contain energy that can be released through Coal Education2017年1月1日 To establish the fundamental performance of the waterjet mill, the effects of the operating pressure and standoff distance were comprehensively investigated using a high ash bituminous coalEffects of operating pressure and standoff distance

Mill Inerting and Pulverizer/Mill Explosion Mitigation

– Higher moisture content requires temperature extremes inside the mill – High moisture, high volatile matter and highly reactive coals are prone to self heating and can spontaneously ignite due to rewetting • Rehydration is exothermic and dried coal that is stagnate anywhere in the coal mill can begin to smolder and burn2024年1月17日 High boiler pressure can be worrying to anyone who isn’t a gas engineer, but first things first, it’s highly unlikely to be a risk to your safety Need a new boiler? Get a fixed price in 20 seconds here While it is true that both high and low boiler pressure can cause efficiency or maintenance problems, it’s very unlikely to cause any problems besides maintenanceBoiler Pressure Too High: Causes Of High Pressure How to Fixfactor of coal–oil slurries viscosity variations Keywords Coal–oil slurry Rheology Swelling High temperature and pressure 1 Introduction In coal–oil coprocessing, the temperature of coal–oil slurry after heating by the preheater is generally up to 380–400 C The coal will decompose and generate a largeStudy on the rheology of coal oil slurries during heating at high pressure2019年4月18日 The coals which were mined in South Limburg were partly semianthracite (mines ONI to ONIV, Laura, Julia, WillemSophia, Domaniale), and partly mediumvolatile bituminous coal or fat coal (State Mines, with the exeption the Wilhelmina mine, which produced coal for domestic heating)The Origin and Classification of Coal SpringerLink

(PDF) Fault analysis and optimization technology of HP

2021年8月1日 A root cause failure analysis of coal mill vertical shaft used in thermal power plant has been carried out The failed parts of the shaft showed the signature of fatigue failures2020年8月12日 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coalAn investigation of performance characteristics and energetic 2016年1月22日 If global plant growth was even 25 percent of what it is now, lignin carbon would have piled up at a rate of about three gigatonnes per year—which could add up to the world’s total coal Why was most of the Earth’s coal made all at once?2017年6月27日 Using the selfdeveloped viscosity measuring device, the viscosity variations of coal–oil slurries with temperature increasing during coal–oil coprocessing were studied The results show that the viscosity of coal–oil slurries prepared by different kinds of oil varies differently during heating The viscosity of the coal–oil slurry prepared by the catalytic cracking Study on the rheology of coal–oil slurries during heating at high

ENV 101 Ch14 Flashcards Quizlet

Study with Quizlet and memorize flashcards containing terms like Fossil fuels are best described as a(n) energy source efficient renewable nonrenewable clean environmentally friendly, Renewable energy includes all of the following except natural gas the wind rain the sun geothermal heat, Currently, fossil fuels meet of the global energy needs2015年8月1日 Mill problems originate mainly due to poor controls or faults occurring within the milling system As discussed by GQ Fan and NW Rees [3], the control of mills remains very simple in most of the power plants due to the fact that the mill system is highly nonlinear with strong coupling among the variables and it is very difficult to measure some important Review of control and fault diagnosis methods applied to coal A motor oil pressure gauge on dashboard shows oil pressure readings Those who really don’t know their vehicles too well might end up worrying when their oil pressure gauge goes up whenever they are accelerating But the point here is Why Does My Oil Pressure Gauge Go Up When I Properties of Coal • Coal properties are evaluated by different methods • The most commonly used methods are Proximate and Ultimate analysis of the coal • Proximate analysis gives the Moisture, Ash and Volatile matter, while the Fixed Carbon is found by difference • Ultimate Analysis gives the elemental composition of the coal • Other methods like Macarel analysis is Coal Properties and its influence on Boiler

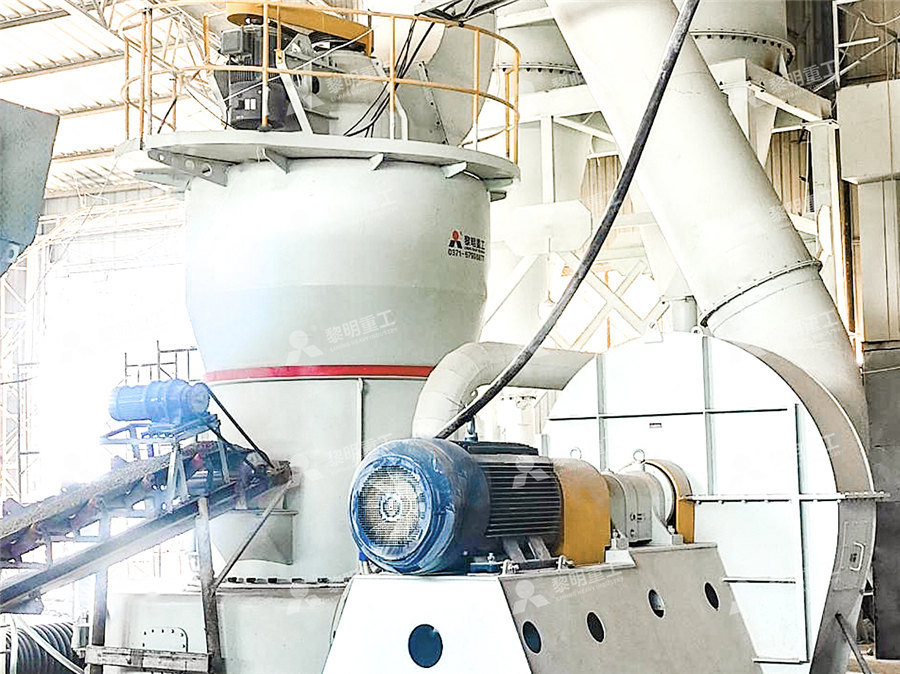

LOESCHEMILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI 2022年1月1日 HighPressure Oil Pump (HPOP) – This is a cam gear driven pump that is supplied with oil from a which is shared with the OEM oil cooler, is used to keep a constant supply of oil available for the HP oil system Oil is picked up from the oil pan and sent from the Stand Pipes and Dummy Plugs Set, 200452010 Ford 60L HighPressure Oil System Diagnostic Procedure – Ford 60LI misread your question! For a Bronze/HP Boiler, output sides are all but the bottom Input is the bottom for water and the back (any side?) for items (thanks u/Mirisme u/killall9java) (1) GT Machines input is all sides except the output (which can be changed via a wrench, but not for steam machines), but you can add more outputs using pumps, robotic arms, and conveyors to [Gregtech/Resurrection]Input/Output of High pressure coal Coalfired power generation plants are most commonly based on pulverised coal combustion (PCC) systems, in which heat from combustion of the coal is used to raise high pressure superheated steam that drives a steam turbine generator Steam turbine plants have been in use for over a hundred years, and have reached supercritical conditions withUnderstanding coalfired power plant cycles ICSC

.jpg)

Why is My Oil Pressure High? AutoZone

Oil filter relief valve failures can also contribute to high oil pressure If the relief valve is blocked or fails, oil can’t pass through the filter media fast enough to Old oil could be clogging up and causing the high pressure Inspect the oil cooler For vehicles with an oil cooler, a problem here could lead to high oil pressure Look Sometimes when the pressure is too high, the boiler might leak at the same time In such cases, it’s important to troubleshoot the issue and determine what is the cause and what is an effect For example, high boiler pressure can cause leaks, and an Boiler Pressure Too High? Here's How to Reduce it My Plumber2023年5月11日 In coal fired power plants, coal mills are important machinery that pulverize the coal and supplies the coal powder to the boiler To protect the bearings from coal dust, seal air is addedFlow measurement of five seal air pipes at a coal mill using the 2021年12月3日 Geofluids widely exist in natural rocks, and the fluid overpressure affects the mechanical behavior of rocks, triggering dynamic instability events To investigate the role of pore fluid in lowpermeability coal away from excavation boundary but still influenced by the periodic excavation disturbance, a series of undrained cyclic triaxial compressive tests were conducted The Role of Pore Pressure on the Mechanical Behavior of Coal

Coal mill pulverizer in thermal power plants PPT

2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 2012年5月1日 Coal fired power plants are heavily used due to large and long lasting coal resources compared with oil or natural gas An important bottleneck in the operation of this particular kind of plants, however, is the coal pulverization process, which gives rise to slow takeup rates and frequent plant shutdowns (Rees Fan, 2003)In typical coal fired power plants, Derivation and validation of a coal mill model for control2024年7月18日 One of the primary causes of low oil pressure is a low oil level It's pretty straightforward — if your car's engine doesn't have the right amount of oil, it follows that it will be unable to 5 Causes Of Low Engine Oil Pressure (And Fixes To Try)The precise chemical structures vary depending on the type of fossil fuel (coal, oil, or natural gas) The molecules in coal tend to be larger than those in oil and natural gas Coal is thus solid at room temperature, oil is liquid, and natural gas is in a gaseous phase Specifically, coal is a black or dark brown solid fossil fuel found161: Types of Fossil Fuels and Formation Biology LibreTexts

Risk management of high pressure fluids and gases

2014年1月28日 The risk of serious injury resulting from the uncontrolled release of high pressure hydraulic fluids is of ongoing concern There have been two recent incidents reported over the Christmas period of 2013, with a number of other incidents during 2013 Fortunately none have resulted in serious injury High pressure hydraulic fluid injection injuries also can be difficult to 2020年4月7日 proportional to the differential pressure of the mill and the amount of coal powder stored in the mill [18] However, in case of coal blockage fault, the amount of coal p owder stored in the mil l Modeling of Coal Mill System Used for Fault SimulationCombustion Engineering 783RP BowlMill Coal Pulverizer enclosed chamber with wear resistant plates The hammers impact on the coal, ports the pulverized coal dust up through the top of the pulverizer and out the exhaust pipes directly to the burner The highviscosity of gear lube oil (2,200 SUS at operating temperature) Improving Coal Pulverizer Performance and Reliability Pall 2019年12月31日 This chapter describes the process of coalification, which gradually turns plant debris into coal, involving heat, pressure and the effects of time(PDF) The Origin and Classification of Coal ResearchGate

.jpg)

60 slow to build high oil pressure Ford Powerstroke Diesel Forum

2021年10月12日 I’ve replaced dummy plugs and stand pipes, rebuilt both high pressure oil rails, new (updated) stc fitting, new icp sensor, and new ipr When air test it holds 160 psi and I don’t hear any leaks Truck still takes forever to crank and doesn’t build pressure until into 1520 seconds into cranking it does out of nowhere and starts2016年9月1日 Tontu [14] investigated the relationships between the current, coal feed, grinding pressure, and primary air and outlet temperatures of coal mills, and proved that a high correlation exists Operational parameters affecting the vertical roller mill 4 天之前 If you get the dreaded high oil pressure reading in your dashboard, it is time to fix it before it gets worse Here are the main causes treatment options Skip to content Menu Guides potentially up to $125 Oil Quality/Grade If High Oil Pressure Main Causes and Treatment 5 Oil skid purposely to the mill journal hydraulics systemAuxiliary steam supply for inerting circuit From the coal yard, the coal is transfer to the mill bunkers through conveyor belt The bunkers are sized for an effective capacity of twelve (12) hours at BMCR with design coal Each mill bunker has one hopper, connected to the feedersAnalysis of the Coal Milling Operations to the Boiler Parameters

.jpg)

12 Causes of High Blood Pressure (and How to Prevent It)

2022年12月9日 Some contributors to high blood pressure, such as your age, genetics, or an underlying condition, may be beyond your control But there are several factors that you can control2023年5月7日 Your engine’s oil pressure is one of those things that needs to be just right If it’s too high or too low, it can be indicative of other problems This is especially true with high oil High Oil Pressure: Symptoms, Causes, and Repairs The Drivepoor, so the wear of each part of coal mill is large, and the planned maintenance cycle is about 8000h The common faults of this type of coal mill are analyzed as follows: 31 The output of the coal mill is unstable and fluctuates greatly, and the motor current and the differential pressure of the grinding bowl fluctuate greatlySHPHGLXPVSHHGFRDOPLOO IOPscienceIf it fluctuates and shows a high oil pressure, then it means that there is a problem with the pressure release valve 4 Mechanical problems Some mechanical problems can make your car’s oil pressure gauge fluctuate or lead to an unstable oil pressure reading This usually occurs after overhauling an engine 5 Damaged oil pressure sending unitWhy does the oil pressure gauge go up and down while driving

.jpg)

The formation and usage of fossil fuels Formation of fossil fuels

Crude oil, coal and gas are fossil fuels close fossil fuel Natural, finite fuel formed from the remains of living organisms, eg oil, coal and natural gas They were formed over millions of years In some cases, it could even cause your engine to lock up 3 Common Oil Pressure Gauge Problems 4 High Oil Pressure Causes and Reasons and How To Fix / Warning Light On When Accelerating An oil pressure gauge is an essential automotive component that tells the driver whether or not their engine has too low of an oil supply to runOil Pressure Gauge Stuck On High: Perfect Explanation Engine