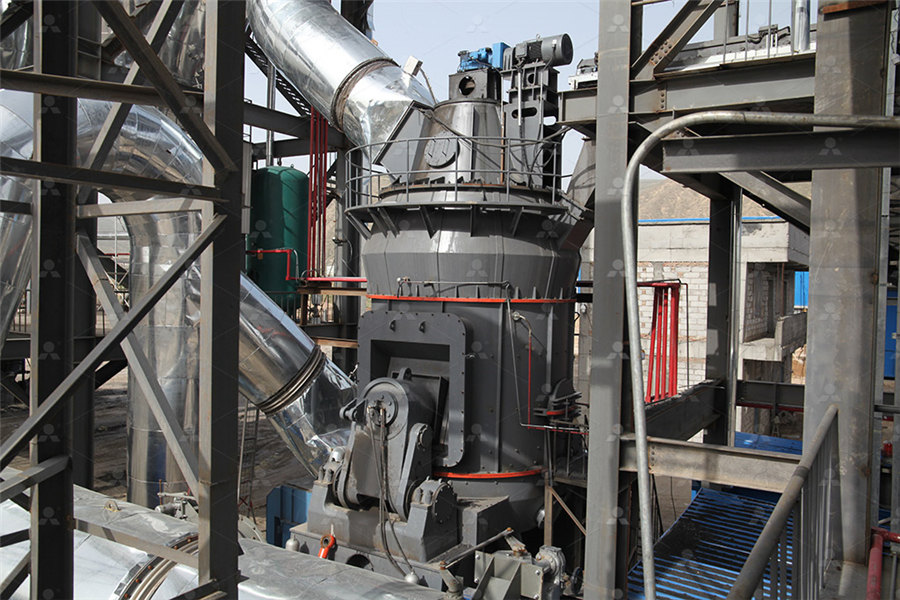

Jiangxi Zhenglian Aluminum's Electrolyte Waste Slag Grinding Machinery

.jpg)

从废弃含锂铝电解渣中选择性回收碳酸锂的清洁工艺

2023年9月1日 本研究采用湿法冶金工艺,使用碳酸钠溶液作为浸出剂,从含锂铝电解渣中选择性浸出锂。 锂的浸出效率高达 9912%,而钙 (Ca) 和铝 (Al) 等其他元素的浸出率极低。 此外, 2024年7月24日 The lithium was selectively recovered and enriched from spent aluminum electrolyte slag by using calcium salt roasting transformation followed by HBL121solvent Cleaner Process for the Selective Extraction of Lithium from Spent Wu et al (2021) developed a new way to recover Li from waste electrolytes by saturated sodium carbonate roasting at 650 °C for 2 h and then leaching with HNO 3 Roasting with saturated Efficient lithium recovery from electrolytic aluminum slag via an 2023年9月1日 This study employed hydrometallurgical processes to selectively leach lithium from Licontaining aluminum electrolyte slag, using sodium carbonate solution as the leaching Clean Process for Selective Recovery of Lithium Carbonate from

.jpg)

Research Progress of Electrolytic Aluminum Overhaul Slag Disposal

2023年4月25日 This article analyzes and summarizes the composition and hazards of the overhaul slag and the current development status of domestic and international electrolytic 2023年8月1日 The main components of overhaul slag are aluminum and silicon oxides These components could be dissolved in the molten cryolitebased salt system (ie, electrolyte) in the Dissolution behavior of overhaul slag from aluminum reduction 2024年2月1日 The electrolytic aluminum industry generates a large amount lithium (Li)containing electrolytic aluminum slag (EAS) annually, and this can result in severe Efficient lithium recovery from electrolytic aluminum slag via an 2024年4月13日 Aiming at the disadvantages of the existing treatment method, such as the long process flow, environmental pollution, poor working environment, etc, we propose a new Study on Recovery of Lithium from LithiumContaining Aluminum

.jpg)

Efficient lithium recovery from electrolytic aluminum slag via an

The electrolytic aluminum industry generates a large amount lithium (Li)containing electrolytic aluminum slag (EAS) annually, and this can result in severe environmental pollution and 2022年10月10日 In this work, electrolytic aluminum carbon anode slag was separated by flotation Using the selectivity index ( SI) as an indicator, the influencing factors of the carbon Recovery of carbon and cryolite from spent carbon anode slag of 2014年2月19日 Slags are byproducts of the metallurgical industry It is of importance to recycle materials and recover heat from metallurgical slags to reduce the energy consumption and environmental impact of steel industry China is the largest iron and steelmaking slag producer in the world, and intensive efforts have been made during last decades for slag valorisation, Current Development of Slag Valorisation in China Waste2024年7月24日 Spent aluminum electrolyte slag is a byproduct produced during the electrolysis of aluminum and contains elements such as F, Al, Na, and Li It is a toxic and harmful substance with a stable and complex structure As a Cleaner Process for the Selective Extraction of Lithium

.jpg)

Copper Slag Beneficiation Process Equipment JXSC

2024年1月3日 The gravity separation method can be used in slag containing a certain amount of coarser particle size of single metallic copper The monomer can be well dissociated during the grinding process, but this part of the 2024年1月31日 Slag grinding exhibits complex nonlinear dynamics that challenge control Sun W, Chen J, Li J Decision tree and PCAbased fault diagnosis of rotating machinery Mechanical Systems and Signal Processing 2007; 21: 1300–1317 Crossref Intelligent process control system for predicting operating 2023年6月2日 The effects of LiF, MgF2 and KF additions to the electrolyte on current efficiency were investigated during aluminium electrolysis using base NaF−AlF3−Al2O3 system with a cryolite ratio of 25 Efficient extraction and recovery of lithium from waste aluminum 2023年4月25日 As the main solid waste of the electrolytic aluminum industry, overhaul slag contains a large amount of hazardous 2013(5):2327 LI N, LI R X, XIE G, et al Separation of carbon and electrolyte in waste cathodes of aluminum electrolysis by flotation method[J] Light Metals, 2013(5):2327 doi: 103969/jissn10021752201305 Research Progress of Electrolytic Aluminum Overhaul Slag Disposal

Efficient lithium recovery from electrolytic aluminum slag via an

2024年2月1日 Aluminum metal was produced using the cryolitealumina molten salt electrolysis method (Ishak et al, 2017)A large amount electrolytic aluminum slag (EAS) is generated during the electrolysis process, as the falling of carbon particles on the anode into the electrolysis cells and the accumulation of lithium fluorine result in energy consumption and electrolyte scrapping 2024年4月17日 Recycling plays an important role in today's world due to its considerable contributions to mitigating energy concerns and environmental challenges One of them is dross recycling from aluminum (Al) cast houses Unlike other recyclable materials, dross has an abundance of components, including rare earth elements, heavy metals, ferrous, and recycled Aluminum dross: aluminum metal recovery and emerging 2023年3月12日 The aluminum electrolysis industry continually and unavoidably produces hazardous solid waste in the form of carbon anode slag Carbon anode slag poses a serious environmental pollution risk, and it must be disposed of in a harmless manner On the other hand, it contains a few valuable resources, as well In order for the aluminum electrolysis industry to Recovery of Carbon and Cryolite from Spent Carbon Anode Slag2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating huge amounts of steel slag as waste through the blast furnace and Linz–Donawitz (LD) process Presently, these wastes are disposed by dumping in Sustainable Approaches for LD Slag Waste Management in Steel

.jpg)

Recovery and purification of metallic silicon from waste silicon slag

2019年5月1日 The recovery of silicon from the waste industrial silicon slag is urgent for the cleaner production of silicon industry The feasibility and optimization of recovering and purifying the metallic Kaolin (china clay) is a hydrated aluminum silicate crystalline mineral (kaolinite) Steel slag is a solid waste discharged by steel mills during smelting of crude steel Powder Grinding; Waste Recycling; Tel:+86 ; Fax: +86 371 HengYang Machinery2021年10月1日 To recover valuable elements such as lithium from waste aluminum electrolyte, Wu et al (2021) mixed Na 2 CO 3 with waste aluminum electrolyte and roasted them at 650 • C for 25 h, and Na 2 A novel approach for lithium recovery from waste lithium 2024年6月29日 Aluminum electrolyte is a necessity for aluminum reduction cells; however, its stock is rising every year due to several factors, resulting in the accumulation of solid waste Currently, it has become a favorable material for the resources of lithium, potassium, and fluoride In this study, the calcification roasting–twostage leaching process was introduced to extract Stepwise extraction of lithium and potassium and recovery of

Cleaner Process for the Selective Extraction of Lithium from Spent

Spent aluminum electrolyte slag is a byproduct produced during the electrolysis of aluminum and contains elements such as F, Al, Na, and Li It is a toxic and harmful substance with a stable and complex structure As a consequence of fluorine pollution and low lithium recovery efficiency in the traditional hydro metallurgy process, a novel cleaner production technology was developed 2022年10月10日 One of the main electrolytic aluminum production costs is the consumption of carbon anodes, and carbon anode slag is a common hazardous waste in the aluminum industryRecovery of carbon and cryolite from spent carbon anode slag of 2024年2月1日 Aluminum metal was produced using the cryolitealumina molten salt electrolysis method (Ishak et al, 2017) A large amount electrolytic aluminum slag (EAS) is generated during the electrolysis process, as the falling of carbon particles on the anode into the electrolysis cells and the accumulation of lithium fluorine result in energy consumption and electrolyte scrapping Efficient lithium recovery from electrolytic aluminum slag via an 2min After which terpenic oil was added and the slurry was stirred for 05min Following this, the air was introduced, and after 05min of aeration, scraping of froth was startedRecovery of carbon and cryolite from spent carbon anode slag of

Sustainable Recovery of Fluorine from Waste Aluminum Electrolyte

2023年8月2日 Request PDF Sustainable Recovery of Fluorine from Waste Aluminum Electrolyte by Sulfuric Acid Baking The highvalue, green and harmless purification of aluminum electrolysis comprehensive 2023年8月2日 The highvalue, green and harmless purification of aluminum electrolysis comprehensive solid waste can not only reduce its harm to the environment and soil but also separate and recover the highvalue rare elements This study aims to develop a process for recovering and treating waste aluminum electrolytes by sulfuric acid roasting The results of Sustainable Recovery of Fluorine from Waste Aluminum Electrolyte The carbon anode slag from the electrolytic aluminum production process is classified as toxic hazardous waste by China's National Hazardous Waste List (2021 Edition) (code: 32102548; hazard China’s primary aluminum output from 2010 to 2020DOI: 101016/jresconrec2023 Corpus ID: ; Efficient extraction and recovery of lithium from waste aluminum cryolite electrolyte @article{Tang2023EfficientEA, title={Efficient extraction and recovery of lithium from waste aluminum cryolite electrolyte}, author={Chaobo Tang and Jiahui Wang and Shenghai Yang and Xianpan Zhang and Shuai Li and Yanqing Lai Efficient extraction and recovery of lithium from waste aluminum

Selective comminution and grinding mechanisms of

2022年1月10日 The recovery of spent carbon anode (SCA) materials plays important roles in environment protection and resources recycling, while this cannot be efficiently achieved without liberation2024年5月23日 This work was supported by the Key Research and Development Program of Yunnan Province, Joint Disposal and Comprehensive Utilization of Typical Hazardous Waste of Electrolytic Aluminum (No AA), Demonstration of Industrialization of Spent Anode Carbon Recovery Electrolyte Treatment and Conversion to Aluminum Fluoride and Alumina The recycling of carbonrich solid wastes from aluminum 2023年10月19日 In late July 2023, Guangxi Guigang Hengyao steel Co, Ltd successfully completed the production and acceptance inspection of their annual 300,000ton ultrafine highperformance cementitiousWhat is a ultrafine slag grinding plant? ultrafine slag grinding 2024年3月26日 Metallurgicalgrade siliconrefined waste slag (MGSRS) was produced during the MGSi refining production process, which occupies huge amounts of land resources, caused the loss of nearly 110,000 tons of MGSi every year Therefore, it is of great significance to recover the elemental silicon from MGSRS However, because silicon is tightly wrapped by Effect of Grinding Liberation on Recovery of Silicon from MGSi Waste

Jiangxi Hengchang Mining Machinery Manufacturing Co, Ltd

Jiangxi Hengchang Mining Machinery Manufacturing Co, Ltd is the leading company in mining gravity separator machine designing manufacturing in China Up to now, we have developed four major product lines; they are mining milling machine, mining classifying separator, mining flotation machine and the mining gravity separator2023年3月2日 Discover the benefits, types, and applications of Slag Crusher Machines in the steel industry Learn how these machines work, the types of slag they can crush, and the maintenance required for optimal performance Maximize the benefits of steel recycling and contribute to a more sustainable future with this comprehensive guideWhat is a Slag Crusher Machine and How Does it Work?2023年10月1日 The main components of waste aluminum cryolite electrolyte are cryolite (Na 3 AlF 6), potassium cryolite (K 2 NaAlF 6), lithium cryolite (Na 2 LiAlF 6), fluorite (CaF 2), and approximately 2% carbon black (Wang et al, 2019)The main treatment methods of waste aluminum cryolite electrolyte can be divided into two categories: combined thermalwet Efficient extraction and recovery of lithium from waste aluminum 2022年4月1日 Circular economy is an emerging subject area which has widely been recognised to have immense potential for resource circularity and sustainable development (Velenturf et al, 2019, Lanau and Liu, 2020)It comprises sustainable resource processing strategies that focus on a ‘produce, use and recycle’ paradigm (Nikoloski, 2020)The concept integrates economic The potential for copper slag waste as a resource for a circular

.jpg)

Fluorineretaining agent for overhaul slag of aluminum

2020年1月2日 The invention discloses a fluorineretaining agent for overhaul slag of an aluminum electrolytic cell The fluorineretaining agent comprises the following components of, by mass, 80100 parts of calcium sulfate, 6080 parts of calcium oxide, 5070 parts of calcium hydroxide and 3060 parts of calcium chloride The invention further discloses a method for 2021年8月1日 For an aluminum smelter producing one million tonnes of aluminum per year, the annual savings could be as much as US $045 million for every kg reduction in net carbon consumption View Show abstract(PDF) Occurrence State of Carbon and Electrolyte in 2024年1月1日 Semantic Scholar extracted view of "Efficient lithium recovery from electrolytic aluminum slag via an environmentally friendly A novel approach for lithium recovery from waste lithiumcontaining aluminum electrolyte by a roastingleaching process Shaohua Wu W Tao +4 authors Zhaowen Wang Environmental Science, Materials ScienceEfficient lithium recovery from electrolytic aluminum slag via an 2019年5月23日 Compared with the grinding of other materials, steel slag grinding is poorer, and it is difficult to guarantee the granularity of steel slag cement Hence, to enhance the application of steel slag in cement, more research and exploration have been made on the grinding of steel slag in recent years 641 Grinding of Steel Slag 1 Grinding Comprehensive Utilization Technology of Steel Slag

Environmental impacts of utilizing waste steel slag aggregates as

2016年10月1日 Slag is an industrial waste generated during the steelmaking process Electric arc furnace slag (EAFS) and ladle furnace slag (LFS) are both produced at different stages of steelmaking process, respectively, in electric arc furnaces and refining ladle furnaces As part of this research, an extensive suite of engineering and environmental tests were undertaken on China is the largest producer and consumer of calcium carbide in the world The calcium carbide industry is an indispensable industry to support the basic life of people The huge production capacity of calcium carbide is accompanied by a large number of solid waste carbide slag Due to the immature treatment technology of carbide slag, a large number of carbide slag are stacked Resource utilization of solid waste carbide slag: a brief review of number of waste electrolytes At present, there are few studies on the recycling of waste aluminum electrolytes (WAE), and only a few similar research is related to the waste lining or furnace bottom waste generated when the electrolytic cell is o [10] How ever, it must be noted that an electrolytic cell in normalSustainable Recovery of Fluorine from Waste Aluminum Electrolyte 2019年4月17日 Aluminium is produced by electrolysis using alumina (Al2O3) as raw material and cryolite (Na3AlF6) as electrolyte In this HallHéroult process, the energy consumption is relatively large, and Sustainable wastetreatment procedure for the spent potlining

Clean Process for Selective Recovery of Lithium Carbonate from Waste

Lithium (Li)bearing aluminum electrolyte slag is an inevitable byproduct of the aluminum industry, and improper disposal or stacking it may lead to potential environmental hazards This study employed hydrometallurgical processes to selectively leach lithium from Licontaining aluminum electrolyte slag, using sodium carbonate solution as the leaching agent2023年1月1日 Although considerable effort has been done over a long period of time in the exploitation of industrial waste, ferrochrome slag has received surprisingly less investigationUtilization of steel slag waste as construction material: A review