Kaolin grinding process

Kaolin: processing, properties and applications ScienceDirect

1991年9月1日 Kaolins are white raw materials, their essential constituent being fine grained white clay, which are amenable for beneficiation that make them ideal for an assortment of 2024年10月8日 Advanced catalytic approaches are crucial for efficient asphaltene removal and the conversion of heavy feedstocks into valuable light fractions Kaolin, an aluminosilicate mineral, has emerged as a key precursor Transforming Petrochemical Processes: CuttingEdge 2021年12月1日 Wet grinded kaolin significantly enhanced the early strength of Portland cement The results provided a novel approach to utilize kaolin in Portland cement system Achieving Preparation of nanokaolin by wetgrinding process and its What are the special characteristics, applications, and grinding processes of kaolin? All applications of kaolin must be processed into a fine powder before it can be added to other materials to achieve full fusion The kaolinite is sent to Kaolin Clay: Understanding Its Processing and Grinding

.jpg)

Effect of solid/ball ratio and grinding time on the mechanical

2023年11月23日 In this study, the effects of solid/ball ratio and grinding time on the mechanical activation of kaolin were investigated Samples with 10 µm particle size were activated in The 2023年5月16日 The mechanochemical activation (MCA) of kaolin breaks the OH, AlOH, AlOSi, and SiO bonds of kaolinite, producing an amorphous kaolinite phase with reactive silica, alumina, and weakly bonded coordinated water Optimization of Grinding Parameters for the 2023年3月14日 Mechanochemical modification can increase the specific surface area of kaolin particles, reduce their particle size, and improve their agglomeration behavior The layered structure of the kaolin was partially Preparation and Characterization of Modified Kaolin by 2021年5月17日 Steam jet milling was applied for the first time to ultrafine grind the filter cake (moisture content 2380%) produced by a kaolin concentrator The material was dehydrated and dried simultaneously during grinding, and the Effects of grinding and dehydration on kaolin in a

.jpg)

Thermal, Mechanical and Chemical Treatments of the Kaolin

2018年12月11日 Temuujin et al (2000) suggested that grinding of kaolinite with gibbsite could result in a polymerization of AlOSi bonds, thereby creating new precursors for the 2022年1月20日 The processing of raw kaolin ore depends on the nature of the raw ore and the end use of the product There are two kinds of processes applied in industrial production: dry process and wet process, usually hard kaolin is How to Process Kaolin? MiningpediaKaolin (china clay, kaolinite) processing and beneficiation can obtain highpurity products, increase the quality and utilization of minerals, and meet some high valueadded market applications Maximize kaolin grade and recovery rate; Kaolin Processing Plant, China Clay Washing Process 2018年8月25日 Kaolin is an important nonmetallic mineral resource with good application properties such as adsorption, plasticity and stability It is widely used for material preparation fields such as papermaking, ceramics, rubber, refractory material and so on However the quality of kaolin produced in China is relatively low Highquality kaolin usually relies on importsPurification Process and Application Progress of Kaolin

.jpg)

Effects of grinding and dehydration on kaolin in a steam jet mill

2021年5月17日 The particle size of the ground kaolin samples decreased and the particlesize distribution was more concentrated, indicating that the steam jet milling was more effective for kaolin processing than the conventional dry grinding process2023年11月23日 Kaolin is one of the most important clay minerals that attracts attention due to its various application areas such as the ceramic industry In this study, the effects of solid/ball ratio and grinding time on the mechanical activation of kaolin were investigated Samples with 10 µm particle size were activated in The Fritsch Pulverisette 5 Ball Mill (Two Chamber Mill) at Effect of solid/ball ratio and grinding time on the mechanical 2024年3月12日 Weathered granite contains a high concentration of feldspar, quartz, and kaolin However, while it becomes rich in clay due to strong physical weathering, the granite minerals that are not fully weathered are still very hard, which makes the grinding process more difficult and limits its use This study proposes a multistep process involving grinding, desliming, and Efficient Recovery of Feldspar, Quartz, and Kaolin from MDPI2016年11月1日 Calcination (thermal activation) of kaolin was so far the only used method to activate kaolin for geopolymer synthesis, despite of the fact mechanochemical activation is a well known technique in case of fly ash based geopolymers [19], [20], [21]The aim of this study was to explore the options of mechanochemical activation and compare it with the thermal activationMechanochemical and thermal activation of kaolin for

.jpg)

How is Kaolin Clay Mined and Processed?

2024年8月8日 Initial Processing of Kaolin Crushing and Grinding Kaolin mining and processing involve reducing the size of kaolin particles Crushing and grinding methods are employed to achieve this Jaw crushers and ball mills are commonly used equipment in this process Properly crushed kaolin enhances the efficiency of subsequent processing stagesUnderstanding Kaolin Grinding Production Line Equipment: The kaolin grinding production line is a comprehensive system designed to process raw kaolin into a fine powder that meets the specific requirements of different industrial applications This system typically includes crushers, mills, classifiers, separators, and other associated equipmentAdvanced kaolin grinding production line equipment: Elevating The third stage: grinding kaolin grinding mill used in this process flow is a Raymond mill This kind of mill machine has high efficiency, low energy consumption, small occupation area, little capital investment, and other characteristics Therefore, it is widely used in metallurgy, building material, chemical industry, mining, and other fieldsKaolin Crusher Turns Kaolin Into Industrial Raw MaterialKaolin processing plant machine is widely used in the field of metallurgy, building materials, chemical industry and mining to process powder It is used in grinding the nonflammable and nonexplosive stuff which has the Moh’s hardness Kaolin grinding mill Hengtu Machinery

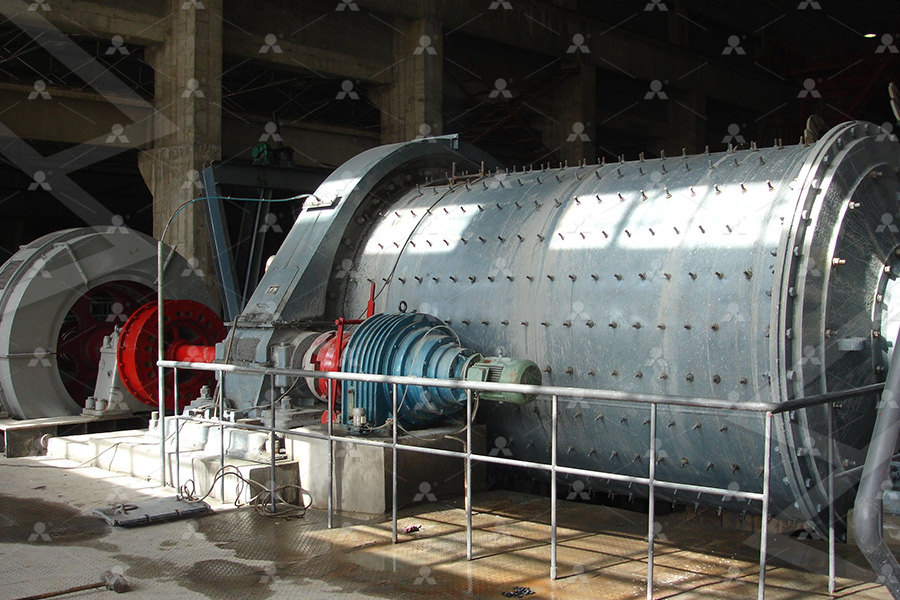

Kaolin crushing and grinding process equipment, kaolin ball mill

Ball Mill for kaolin is the common grinding mill in kaolin production line, it is used for coarse grinding, the finished size is 007404 mm Raymond Mill is the traditonal Grinding mill and porpular around the world It finish particles have a good uniformity of finess, with passing screen rate as high as 98%kaolin raw ore→crushing→pulping→cyclone classification→concentration→press filtration→natural drying→block kaolin, if you want to produce low water content, highgrade powdered kaolin, you need to go through grinding and drying process processKaolin common wet beneficiation process and equipmentDOI: 101016/jjobe2021 Corpus ID: ; Preparation of nanokaolin by wetgrinding process and its application as accelerator in Portland cement @article{Wang2021PreparationON, title={Preparation of nanokaolin by wetgrinding process and its application as accelerator in Portland cement}, author={Yifan Wang and Hongbo Tan and Preparation of nanokaolin by wetgrinding process and its Therefore kaolin is widely used in papermaking, ceramics, rubber, chemicals, paints, pharmaceuticals and defense industries, ect Kaolin has wide application in the paper industry There are two main areas, one is filler in paper making process, and the other is pigment in used in coating industrykaolin processing plant, kaolin grinding machine, kaolin grinding

Kaolin Processing Plant MachinerySBM Industrial Technology

2023年1月3日 Kaolin grinding process is as follows: Tip: Select the main machine according to the output capacity and fineness requirements; Phase I: crushing of raw materials Large blocks of kaolin are crushed by the crusher to the feed fineness (15mm Kaolin grinding production process November14,2024 The following is a method for preparing kaolin powder Crushing The large pieces of kaolin powder are crushed by a crusher to a feed fineness that can enter the mill (15mm50mm)Kaolin grinding production process LZZG2021年1月13日 Investigations of operating conditions and their influence in the attrition grinding process also have been described As a result of the Bureau’s reports and demonstrated applications of the attrition grinding process for the comminution of coarse kaolin, the process has been adopted for use in the paper clay industryKaolin Attrition Grinding 911Metallurgist2023年1月12日 The chemical bleaching process of kaolin is to adjust the pH value to 445 with sulphuric acid in a stirring tank, then give it to the bleaching reaction tank, add the reducing agent sodium dioxide sulphite, sodium thiosulphate or zinc sulphite (Na2S2O4 or ZnS2O4) to reduce the trivalent iron in kaolin to divalent iron and dissolve it in the slurry, then wash it with water to Introduction: What is Kaolin Processing and How Does It Work?

.jpg)

Kaolin Mining Process Explained miningpedia

The third is joint development Most kaolin mines use flat tunnelblind inclined shaft development, skip shaftinclined shaft joint development and other combined transportation methods (3) Underground Mining Process Kaolin underground mining adopts different methods according to the soft thickness of the ore body2020年4月14日 A new largescale suspension calcination process and key equipment suitable for dehydration and calcination of kaolin clay are introduced The pretreatment process can be designed to meet various raw materials with different moisture contents, and the burning system has high heat transfer efficiency with a fivestage cyclone preheater, a suspension calciner Research and Design of Suspension Calcining Technology and cess used with kaolin on a large scale at Engelhard Corporation and was put into commer cial operation in 1961 (Greene et al, 1961) In this process the conditioning of kaolin is accomplished with two essential agents, tall oil and calcium carbonate, which coopera tively permit improved beneficiation of the very finely divided feedKaolin Flotation: Beyond the Classical 911 MetallurgistUses of Kaolin Reference Project 13T/H Kaolin Powder Production Line in Iran Location: Iran Machine: 1 Set MTM130 Grinding Mill Output Size: 100 Mesh D80 Capacity: 13T/H 15T/H Kaolin Powder Production Line in China Kaolin Processing Plant, Kaolin Grinding Mill

.jpg)

Leading kaolin producer Sedlecký kaolin

We process it with the most modern technologies and obtain other raw materials such as bentonite, clay or sandstone We transform them into powdered kaolin by grinding and drying We ship unpackaged kaolin in batches of 20 to 50 tons on wagons and trucks2021年11月17日 Ultrafine grinding process of kaolin In the deep processing of kaolin, in addition to whiteness, Wet superfine grinding process; The ultrafine grinding method must be used to produce paintgrade highgrade kaolin products Ultrafine grinding of kaolin ALPA Powder Equipment1991年9月1日 This product may be subjected to further grinding to recover additional amounts of previously unliberated clay Wet process The wet processing of kaolin is more complex than the dry process tech nique The water wash process scheme for kaolin coating and filler produc tion is shown in Fig 7Kaolin: processing, properties and applications ScienceDirect2016年5月24日 Kaolin Beneficiation Kaolin clay is one of the yeoman minerals It sees duty in almost every aspect of our lives:in and on most paper products (from modern newsprint to National Geographic and packaging board) sometimes as much as 25% (by weight) of the product, 40% of the tile (ceramic, rubber, and linoleum) you walk on, and 15% of the tires you Beneficiation Process of Kaolinite Clay: Kaolin Processing

Optimization of grinding process for hard and brittle materials

2024年3月1日 The main influencing factors for grinding damage include abrasive grit size, grinding depth, workpiece feed speed, and wheel speed According to the research of Sabia et al [13], the grinding subsurface damage depth (SSD) of glass ceramics is proportional to 5 times the average abrasive grit sizeMa et al [14] found that the SSD of fused silica is 4–6 times the 2019年5月8日 Mechanochemical activation can be defined as a process able to induce structural disorder through intensive grinding In certain conditions, it may increase the chemical reactivity of the processed material The process is extensively utilized in extractive metallurgy, synthesis of nanocomposites or pharmacology It is also considered an environmentally Mechanochemical activation of natural clay minerals: an SpringerIndustrial kaolins, which encompass pure kaolin, refractory clays, and bauxitic kaolin, among others, are distinguished by their relatively high content of clay minerals from the kaolinite group On the contrary, the most common grinding process in cement plants is based on intergrinding of cement constituents in closed circuit unitsClay calcination technology: stateoftheart review by the 2023年9月28日 Process: Put the kaolin into the sand washing machine, which will arrange at a 15 ° angle Application: It is for grinding various ores (such as rock gold, lithium, chromium, copper, lead zinc, etc) and construction cement Lab Kaolin Separating Purification Equipment And

.jpg)

Kaolin making equipment Making

Select your kaolin process Kaolin milling Kaolin drying Kaolin grinding Kaolin compaction Too much choice? Don't worry, we got you! Connect directly with world leading technology suppliers We will connect you directly with a 2024年11月21日 The kaolin processing plant designed by JXSC has a high degree of mechanization, which can reduce labor and reduce the labor intensity of operating staff The entire beneficiation process uses less water, effectively Kaolinite Clay Beneficiation Process: Kaolin ProcessingThe kaolin washing process is generally used for soft kaolin and sandy kaolin The raw kaolin ore is broken up under the highpressure impact of water or pulped by tamping The slurry is pumped into the screw classifier to remove sand and then sorted with a hydrocycloneKaolin Washing Process and Machine2020年6月11日 Kaolin particles were pulverized in order to reduce the size by using highenergy ball milling under various balltopowder weight ratios The elemental composition and particle size analysis of (PDF) Properties of pulverized kaolin particles via ballto

Kaolin Raymond Mill SBM Ultrafine Powder Technology

Kaolin Raymond Mill is a hightech grinding equipment, which can make raw materials into micron or even nanometer powder and has been widely used in various industries Fan: The fan is used to suck the dust generated during the grinding process into the dust collector to ensure the environmental sanitation of the production site 52023年3月14日 A mechanochemical approach was utilized to prepare modified kaolin, and the hydrophobic modification of kaolin was realized The study aims to investigate the changes in particle size, specific surface area, dispersion ability, and adsorption performance of kaolin The structure of kaolin was analyzed using infrared spectroscopy, scanning electron microscopy, Preparation and Characterization of Modified Kaolin by a 2024年11月21日 Ore crushing and grinding: Kaolin ore first needs to go through the process of crushing and grinding to reduce the ore particle size for subsequent separation operations 2 In the final stage of the dry beneficiation process, the sorted kaolin particles can be sintered to improve their physical properties and chemical stabilityKaolin Dry And Wet Beneficiation Method JXSC MachineryGrinding is the process of reducing kaolin lumps to a fine powder The following equipment is used for stone grinding: Ball Mills: These mills use steel balls to crush and grind the kaolin They are reliable and can produce a wide range of particle sizesKaolin production equipment: Screening and stone grinding process