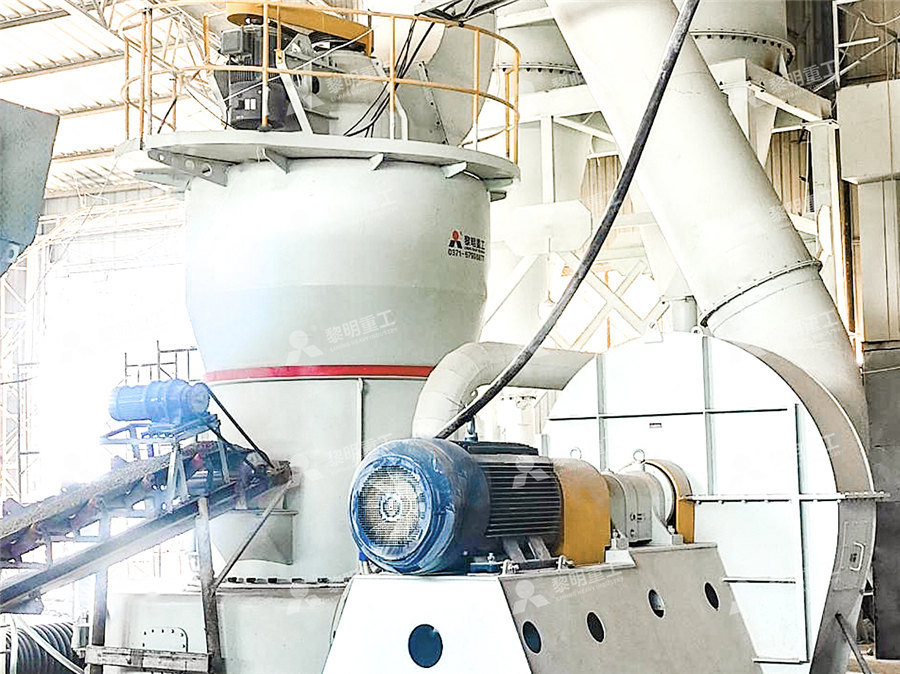

Ore powder mill Yuhui high efficiency

.jpg)

Ore Grinder Machine MadeinChina

China Ore Grinder Machine wholesale Select 2024 high quality Ore Grinder Machine products in best price from certified Chinese Machine Supplies manufacturers, Z Machine suppliers, Ore powder production involves the conversion of mined ore into fine particles through a series of crushing, grinding, and classifying processes The equipment used in this process must be Advancements in ore powder production process equipment: 2023年11月1日 Excessively high material ball ratio would not only impact the ore circulation in the mill and the grinding media movement, but also affect the mill capacity On the other hand, Powder Technology6 天之前 The grinding efficiency was calculated when the particle size of iron ore powder decreased to −45, −38, and −28 μm at different speeds It can be seen that the growth rate of Experimental Study on the Influence of Rotational Speed on

A process mineralogy approach to study the efficiency of milling

2020年12月3日 This study is conducted with the aim of investigating the efficiency of open and closedcircuit molybdenite ore comminution processes (primary and secondary mill, Product features: Safe and reliable, high efficiency and energy saving, low carbon and environmental protection, stable operation, wide range of fineness adjustment, long service life, etcSBM Ore Ultrafine Grinding MillOn the basis of the traditional coarse powder vertical mill, HCMilling (Guilin Hongcheng) has successfully developed the ultrafine vertical grinding equipment for nonmetallic ores by Application of HLMX Ultrafine Vertical Roller Mill for Nonmetallic 2022年1月1日 The results suggested that the highefficiency liberation of ore was obtained using the ceramicmedium stirred mill grinding technology, thus the efficient separation of iron and Highefficiency and energyconservation grinding technology

.jpg)

Micronsized ore powder production by propulsion and rapid

2021年9月6日 We describe a micronsized ore powder production by propulsion and rapid unloading of highpressure gas The research consists of three parts Firstly, we obtain the Henan Yuhui Mining Machinery Co, Ltd is a enterprise that mainly produces large and medium sized beneficiation gravel equipment, crushers, sand making machines and Raymond ball Ball Mill Manufacturer, Jaw Crusher, Rotary Dryer Supplier Henan 2022年4月28日 News/Industry News/Kalium ore powder grinding mill machine Kalium ore powder grinding mill machine 28/04/2022 admin Introduction to Potash Mine High Efficiency Long lifecycle of spare parts High safety and Kalium ore powder grinding mill machine2021年10月11日 Quartz industrial powder grinder machine can be used to further grind quartz sand into quartz powder, and its fineness can be adjusted freely between 1503000 mesh The industrial grinding mills independently Quartz Industrial Powder Grinder Machine SBM

.jpg)

Application of HLMX Ultrafine Vertical Roller Mill for Nonmetallic Ore

At present, the market demand for nonmineral powder is increasingly strong, and the annual average growth rate of consumption of heavy calcium is nearly 95% It is predicted that the annual demand for nonmetallic mineral powder will still maintain a high growth rate in the next 10 years In the pursuit of stable product quality and uniform particle size distribution, the market 2024年9月26日 2 Ultrafine mill Get the Latest Price As an advanced grinding mill combining crushing, grading, and static pressure, the ultrafine mill excels in both fineness and environmental performance It is mainly used to produce ultrafine gypsum powder or micronlevel particles, and is widely used in industries requiring highfineness powders, such as chemicals, coatings, and Upgrade Your Process: 3 Best Gypsum Powder MillsThe gypsum powder ultrafine grinding mill can grind gypsum ore into gypsum powder, which is widely used in industry, construction, medicine, and other fields +17 [ protected] language ① High grinding efficiency, high output, low energy consumptionGypsum Powder Ultrafine Grinding Mill2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber of the mill 2 Grinding: Inside the grinding chamber, the bauxite ore is subjected to a series of grinding processes The grinding rollers and rings in How does HGM micro powder grinding mill process bauxite?

.jpg)

Factors affecting ores grinding performance in ball mills

The parts of a ball mill Ball mills are used to grind various ores and other materials into a fine powder In order for the mill to function properly, it requires accurate and consistent grinding There are a number of factors that affect the grinding performance of ball mills, some of which are discussed belowEnergies 2021, 14, 1786 2 of 14 size [11] The cost of the energy used in comminution represents 50 ÷ 60% of the entire ore processing costs [12]Energy Efficiency Analysis of Copper Ore Ball Mill Drive SystemsType: Ball Mill Motor Type: AC Motor Motor Power: 110kw Rotationl Speed: 2325r/min Application: Mine Materials: Gold, Cooper, Iron, Lead, SlilverHigh Efficiency Low Price Copper Gold Ore Ball Mill Grinding 2022年1月1日 The size of grinding media is the primary factor that affects the overall milling efficiency of a ball mill (eg power consumption and particle size breakage)Effect of grinding media on the milling efficiency of a ball mill

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

2021年3月23日 PDF Milling is among the most energyconsuming technological stages of copper ore processing It is performed in mills, which are machines of high Find, read and cite all the research you China Ore Grinder Machine wholesale Select 2024 high quality Ore Grinder Machine products in best price from certified Chinese Machine Supplies manufacturers, Ore Powder Ultrafine Grinding Machine for Wet Grinding, Vertical Grinder, Mill US$ 66000 / PieceOre Grinder Machine MadeinChina2018年2月1日 In another study to investigate ball size distribution on ball mill efficiency by Hlabangana et al [50] using the attainable region technique on a silica ore by dry milling, a threeball mix of Effect of ball and feed particle size distribution on 2021年9月29日 Sepiolite superfine powder grinding mill is a highefficiency, energysaving, lowconsumption, and environmentally friendly industrial nonmetallic ore mill The equipment is independently developed and produced by SBM, and mainly includes HGM series ultrafine grinding mills and CLUM series vertical millsSepiolite Superfine Powder Grinding Mill SBM Ultrafine Powder

Contact Us

Henan Yuhui Mining Machinery Co, Ltd Zip: Tel: 0086371 Fax: 0086371 Web: Http://cnorecrushers Automation: Modern ore powder production equipment is equipped with advanced automation systems, which improve operational efficiency and reduce labor costs Energy Efficiency: Innovations in mill design and technology have led to more energyefficient equipment, reducing the overall energy consumption of the processAdvancements in ore powder production process equipment: 911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911MetallurgistHigh Efficiency Mining Equipment Ore Wet Grinding Ball Mill HZE manufacture standard wet ball mills with high efficiency, low energy consumption, stability and reliability for grinding minerals of precious metals, base metals and nonmetal It can also be specially designed and customized according to the special requirements of the customersHigh Efficiency Mining Equipment Ore Wet Grinding Ball Mill

(PDF) Grinding Media in Ball MillsA Review ResearchGate

2023年4月23日 high speeds of about 90%, causing breakage o f large ore particles wh ilst reducing the mill’s energy efficiency The num ber of cataracting media increases as mill speed increases [ 62 ] Raymond Mill Raymond mill is a highefficiency pulverizing mill that replaces ball mill to process ore powderIt has outstanding advantages such as strong systematicness, high screening rate, stable transmission, high wear resistance and convenient maintenance Grinding Mill;CLRM series Raymond mill SBM Ultrafine Powder TechnologyThe fineness of the calcium carbonate powder produced can reach 3000 meshes The finished powder has high whiteness, good powder ball shape, high 2um fine powder content, and more fine powder content It is a highend powder Vertical Roller Mill SBM Ultrafine Powder Technology2014年5月1日 In the cement clinker grinding circuit, the residence time distribution in a VRM was measured by applying the dispersion model, the tankinseries model, and the perfect mixer with a bypass [21]Matrix Model Simulation of a Vertical Roller Mill with

.jpg)

Highend calcium oxide ultrafine powder making

2023年11月8日 The HGM125L highend calcium oxide ultrafine powder grinding production line equipped with SBM micro powder technology has been put into use, bringing customers unexpected high energy efficiency and high profits! 2023年4月10日 Ball mill can grind ore to relatively fine and uniform particle size The manganese ore of 012 mm is sent to the ball mill for grinding, and it can be ground into manganese powder of 01 mm Estimated cost: $5,000 / Set Get Quote5 Easy but Efficient Steps to Realize Manganese Ore Processing2021年2月26日 Milling is among the most energyconsuming technological stages of copper ore processing It is performed in mills, which are machines of high rotational masses The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading One method for increasing the energy efficiency of ball mills is to optimize their drive systemsEnergy Efficiency Analysis of Copper Ore Ball Mill Drive 2023年12月28日 7 Powder selection efficiency The powder selection efficiency of a closedcircuit mill greatly influences the output of the mill Generally speaking, the powder separator’s efficiency is high and can improve the grinding efficiency of the mill However, the powder separator itself cannot perform the grinding function, so the function of the Factors Affect The Output and Quality of Ball Mills And How to

.jpg)

(PDF) The Effects of Blasting on Crushing and Grinding Efficiency

2003年1月1日 This research project has been done in Sungun copper open pit mine in seven different benches and investigated the effects of increasing powder factor on work index and mill energy consumption Product introduction:YGM high pressure micro powder mill is referred to as micro powder mill or super fine grinding mill The high pressure micro grinder is mainly used for the ultrafine powder processing of more than 500 kinds of materials such as feldspar talc barite marble limestone carbon black and clayYGM High Pressure Grinding MillVanguard MachineryOur Company Changsha Samy Instrument Equipment Co, Ltd is a professional hightech company, engaged in the research development, manufacturing and marketing of laboratory instrumentsWe have centrifuge, planetary ball mill, vacuum glove box, vacuum furnace, plasma nitriding furnace, pill make machine and others relative medical and hospital productsFactory Price Laboratory High Efficiency Mining Equipment Ore MR series higheffcient mill is developed with the method of mixed powder jetting, used in pharmaceutics, chemical, and foodstuff etc +86 Request A QuoteHigheffcient Mill Machine China Mill Powder Technology

Ultra Fine Grinding Mill SBM Ultrafine Powder

Brief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been Benefits of Clirik Limestone Powder Grinding Mill Machinery 1 High efficiency:Under the same final size and power, the product capacity of ultrafine mill is twice than jet mill and agitation mill 2 Longer lifetime of spare parts:The roller and ring are made of special material, which improve the grinding efficiency a lotFor same material and final size, the lifetime of its wearing Limestone Powder Grinding Mill MachineryHGM100A professional ultra fine powder grinder is the new type mining equipment for making micro powders, fine powders, which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory ultra fine powder grinding mill Shanghai Clirik The nominal mill efficiency, at optimum speed, is 80 Mg/h The dimensions and the high mass of the rotating elements cause the drive system to be overloaded when the mill filled with copper ore is started For this reason, the mill is stopped only in Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

.jpg)

Effect of ball and feed particle size distribution on the milling

2018年6月1日 A number of researchers (Deniz, 2012; Bwalya et al, 2014; Petrakis et al, 2016) carried out studies about the effect of feed particle size and grinding media size on the grinding kinetics of different oresKhumalo et al, 2006 postulated that generally larger sized grinding media would break larger particles quicker but a finer product would be obtained by use of 2021年11月1日 Semantic Scholar extracted view of "Highefficiency and energyconservation grinding technology using a special ceramicmedium stirred mill: Published in Powder Technology 1 November 2021; Engineering, Materials Science, Environmental Impact of ball filling rate and stirrer tip speed on milling iron ore by wet stirred mill: Highefficiency and energyconservation grinding technology Shunky high pressure suspension mill is a new RD mill It is designed by engineers based on many years’ industrial mill research and the needs of mill industry The adoption of world leading powder processing technology makes Shunky high pressure suspension mill start a new era of mill industry with high efficiency and low consumptionYGM HighPressure Grinding Mill Shanky MachineryThe increased capacity of high capacity ball mills enables iron ore processors to handle larger ore feed rates, meet production targets, and reduce overall operational costs 2 Advantages of High Capacity Ball Mills for Iron Ore Grinding: The use of high capacity ball mills in iron ore grinding offers several advantages:Enhancing iron ore grinding efficiency with high capacity ball mills

SBM micro powder technology leads the market, HGM ultrafine mill

2024年2月23日 The mill operates stably and with high efficiency, effectively reducing the customer’s production costs ★ Shanxi customerused for lime desulfurization A power plant in Shanxi uses SBM’s HGM ultrafine mill for ultrafine grinding of limestone and lime desulfurizationChina Powder Grinding Mill wholesale Mining Use Stone Powder Making Plant Ore Grinding Mill Machine for Sale US$ 6000065000 / Piece 1 Piece (MOQ) High Efficiency Industrial Automatic Sulfur Powder Sugar Salt Spices Crushing Machine and Pepper Grinding Hammer MillPowder Grinding Mill MadeinChina