Lithium carbonate silica grinding machine quotation

.jpg)

Lithium Processing Plant, Equipment JXSC Machinery

2023年1月6日 Lithium beneficiation processing plant includes crushing, grinding, gravity separation, flotation, magnetic separation and combined process According to the nature of lithium ore (spodumene, lepidolite, lithium feldspar), Bepex has been supplying processing technology for lithium carbonate or lithium hydroxide production since the early 1990s Now, with lithium producers straining to fulfill ever increasing demand, Bepex is pioneering systems to streamline Lithium Processing Systems and Equipment Bepex2019年8月23日 When the lithium chloride reaches optimum concentration, the liquid is pumped to a recovery plant and treated with soda ash, precipitating lithium carbonate, which is then Lithium Processing Equipment, Process Flow, Cases JXSC MachineWith the newest technology, backed by years of experience in brine and spodumene extraction methods, we are a full solutions partner for major lithium processing operationsLithium processing technology Complete solutions that FLSmidth

Hard Rock Lithium Processing SGS

Working with the lithium concentrate, SGS’ team uses a standardized flowsheet to produce high grade lithium products such as lithium carbonate or lithium hydroxide These are reagents for Threeinone Lab scale grinding equipment for a battery material company in ShenzhenLithium carbonate grinding production line of a lithium industry The production line for roasting and acidizing lithium ore with lepidolite, spodumene and other raw materials configured by our company has excellent product performance, stable production Lithium Extraction Lithium Production Line Lithium Calcination Achieve optimal mineral ore recovery with minimal impact on the environment The Pineer froth flotation process enables sustainable and costeffective spodumene/lithium ore recovery Lithium Ore Flotation Plant Pineer Mining Machinery

Lithium Processing Equipment FEECO International Inc

FEECO is the world’s leading provider of custom nonpressure (tumble growth/agitation) agglomeration equipment and systems We offer pin mixers, pug mills (paddle mixers), disc 2020年5月9日 Materials preparation Preparation of graphite/silicon composite Graphite powder (100 g, SFG6) was ball milled with pure water (1 kg) for x hours in a grinding dispersion machine (SM120) in air, and the milled sample was correspondingly noted as MGxThe grinding media were ZiO 2 spherules (100 g, 3 mm), and the milling process was carried out at 800 rpmThe preparation of graphite/silicon@carbon composites for lithium A thick liquid lithium carbonate and secondary products attached contains Na2SO4 and other impurities, then wash with clean water to about 90 ℃ for stirring, drove with alkali solution, the centrifuge is used after washing strike isolated wet pure lithium carbonate, then through far infrared drying machine to dry, dry magnetic separation to remove machine fall off the wire Lithium carbonate production process Machine Knowledge2024年8月15日 Lithium plays a pivotal role in shaping the future of the global transportation and energy sectors owing to its use in lithiumion batteries (LIBs) for electric vehicles and energy storage systems (Alessia et al, 2021)In 2017, lithium consumption in LIBs accounted for only 46% of global lithium demand, but it is projected to reach 95% by 2030 (Ambrose et al, 2020a)Life cycle assessment of lithium carbonate production:

Lithium carbonate Wikipedia

Lithium carbonatederived compounds are crucial to lithiumion batteriesLithium carbonate may be converted into lithium hydroxide as an intermediate In practice, two components of the battery are made with lithium compounds: the cathode and the electrolyteThe electrolyte is a solution of lithium hexafluorophosphate, while the cathode uses one of several lithiated structures, the Lithium carbonate has a very wide range of applications in the production of secondary lithium salts and metal lithium products, and is the most critical product in the lithium industry In the current actual production process of lithium carbonate, its main production raw materials come from salt lake brine and ore extracts At present, in the production process of lithium carbonate News Process Flow Of Lithium Carbonate Vertical Roller Mill 5 天之前 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore This flexibility is essential to optimize the grinding process for each specific ore type, thereby increasing cost efficiency and resource sustainabilityBall Mill Is The Key To Grinding Lithium Ore JXSC Machinery2023年7月13日 Precipitation: Lithium carbonate (Li 2 CO 3) is precipitated from the purified lithium sulfate solution by adding sodium carbonate (Na2CO3) or another suitable reagent Drying and Packaging : The lithium carbonate precipitate is filtered, dried, and packaged for sale or further processing into lithium hydroxide, metal, or other lithium compoundsWhat's the Spodumene Lithium Extraction Process?

Detailed Introduction Of Ultrafine Mill Machine For 1250 Mesh Silica

Detailed Introduction Of Ultrafine Mill Machine For 1250 Mesh Silica 09:25; HCM; What grinding mill machine can be used to grind silica powder? The equipment developed by HCMilling(Guilin Hongcheng) can be used to grind 3252500 mesh silica powder It is a special dry ultrafine mill machine for grinding 1250 mesh silica powder 1Different lithium ores have different properties, and the lithium content and mineral composition in minerals are different, so lithium ore beneficiation methods are also different The lithium beneficiation process is mainly used for three lithiumcontaining minerals processing: spodumene, lithium feldspar, lepidoliteLithium Processing Plant, Equipment JXSC MachineryChina Sand Grinding Machine wholesale Processing Object: Lithium Iron Phosphate, Ink, Alumina, Oxide Controlling Mode: Electric Control System Carbonate Quartz Silica Sand Grinding Dry Ball Mill Machine US$ 1000014000 / Set 1 Set (MOQ) Shandong Shangda Machinery Co, LtdSand Grinding Machine MadeinChina2023年4月20日 Life cycle assessment studies of largescale lithiumion battery (LIB) production reveal a shiftofburden to the upstream phase of cell parative Life Cycle Assessment of Lithium Mining,

.jpg)

Silica sand processing plant equipment Metso

Silica Minerals represent the group of minerals being composed of silicon and oxygen forming the chemical formula SiO 2 Silica can occur in macrocrystalline, crytocrystaline and amorphous form Industry predominantly uses the Grinding / Milling Machine Get know to our grinding / milling machine such as Ball Mill for mineral – limestone / calcium carbonate / GCC / PCC / silica, Impact Mill – pin mill, beater or hammer for food – spices / herbs / chili, for chemical – wax / powder coating / paint, and for pharma, Pulverizer, Air Classifier Mill, Jet Mill grinder for recycling purpose – cable / plastic and Machines Hosokawa Micron Malaysia2021年2月1日 The global lithium resource reserves are 22 Mt (metal) (USGS, 2022), of which 34% are from hard rock lithium mines (Li LJ et al, 2018), mainly including Australia Greenbushes, Canada Quebec Processing of lithium ores: Industrial technologies and case studies We Pineer has experience with complete flowsheet development to recover highgrade lithium concentrate powder from hard rock lithium minerals Pineer offers a multidisciplinary team that is involved from the initial stages of the characterization of the lithium deposit to the production of highgrade spodumene concentrate (460%)Lithium Ore Flotation Plant Pineer Mining Machinery

.jpg)

How is Lithium Mined? General Kinematics

2023年10月16日 The most common precipitation chemicals used for extraction are lithium carbonate and lithium hydroxide Filtering and drying: The salts are filtered and dried to produce pure lithium Environmental Impact The primary problem is sustainability—the amount of water it consumes Mining one ton of lithium takes about 500,000 gallons of waterKey benefits More than 20 years of experience in providing marketleading lithium processing solutions Broad equipment offering and customisable solutions Full lifecycle partnership Cuttingedge technology Additional technologies not offered by other providers Bench and pilot testing facilities Superior pyro processing test facilities worldwideLithium processing technology Complete solutions that2023年3月13日 This is usually done by adding a precipitating agent, such as sodium carbonate or sodium hydroxide, to the highpurity lithium solution The resulting crystals are then filtered and dried, producing a final product that contains about 999% lithium carbonate or lithium hydroxideLithium Ore Processing: An Overview You Must Know2023年5月27日 The role of ball milling in lithium ore processing is to break down the lithiumcontaining minerals and release the lithium ions into the solution This is achieved through the mechanical grinding of the ore, which helps to increase the surface area of the material, making it easier for the leaching solution to penetrate and dissolve the lithium ionsBall Milling in Lithium Ore Processing: A Comprehensive Guide

Silica Sand Grinding Machine Zenith Crusher

2023年8月17日 Silica sand grinding machine In silica sand production plant, silica sand grinding machine is the key equipment ZENITH offers the following grinding mill machines for this process stage: MTW trapezium grinding mill Capacity: 345t/h Max Input Size: 50mm Output Size: 80 2023年5月14日 3 Advantages of Lithium Ore Flotation Machine 1) High Efficiency The lithium ore flotation machine is designed to separate lithium from other minerals in the ore It uses the principle of selective attachment of air bubbles to the surface of the lithium mineral particles, allowing them to float to the surface and be collectedFlotation Machine for Lithium Ore: Efficient Separation and Citation Machine® helps students and professionals properly credit the information that they use Cite sources in APA, MLA, Chicago, Turabian, and Harvard for freeCitation Machine®: Format Generate APA, MLA,The resulting slurry containing lithium carbonate is separated using a centrifuge, yielding solid lithium carbonate and a lithium precipitation liquor The lithium precipitation liquor is directed to the powder system for further processing Manufacturing Batterygrade Lithium Carbonate from

.jpg)

Potential Processes for Producing HighPurity Lithium Hydroxide:

2023年1月6日 Causticization of Lithium Sulfate Hard rock consisting of spodumene is one of the potential sources for commercial lithium production Calcination of spodumene concentrate at ~1050 °C for ~30 min followed by sulfuric acid roasting at ~250 °C for 30 min, water leaching, and impurities removal by precipitation and ion exchange have become the main methods to 2023年3月17日 However, silica sand cannot be used directly and must undergo processing to eliminate impurities and isolate silica from other minerals We have mentioned 6 methods for removing iron from silica sand before In this post, we'll cover how to separating silica from sand and setting up a silica sand processing plant step by stepSilica Sand Processing: How to Separate Silica from Sand2019年5月29日 The expected growth rate for lithium carbonate and lithium hydroxide is respectively 10% and 145% until 2025 , since they are two of the raw materials used for LiBs In 2016, lithium carbonate prices were reported to range from 10,000 US $ to 16,000 US $ while lithium hydroxide prices were reported to range from 14,000 US $ to 20,000 US $ Spodumene: The Lithium Market, Resources and ProcessesSilica sand grinding machine In silica sand production plant, silica sand grinding machine is the key equipment ZENITH offers the following grinding machines for this process stage: MTW trapezium grinding mill Capacity: 345t/h Max Input Size: 50mm Output Size: 80425meshSilica Sand Grinding Machine Zenith Crusher

An effective method for directly extracting lithium from α

2023年6月25日 Lithium, the least dense metal element in nature, exhibits high electrochemical activity as well as a large specific heat capacity [1], [2], [3]Lithium is applied in a variety of products, including batteries, ceramics, glass, and lubricating oil, owing to its exceptional properties [4]With the rapid development of power batteries and the application of lithium in Lithium is an element valuable for the production of glass, aluminum products, and batteries It is mined from ores of petalite (LiAl(Si2O 5) 2, lepidolite K(Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl(SiO 3) 2 and also subsurface brines Australia and Chile are the world’s largest producers of lithiumLithium Mining Processing Equipment Flow Chart JXSC4 天之前 SMM brings you LME, SHFE, COMEX realtime Lithium prices and historical Lithium price charts SMM App Android iOS Holiday Pricing Schedule FREE TRIAL Compliance Centre Lithium Carbonate (995% Battery grade CIF China,Japan and Korea) (USD/Kg) 105114 1095005 Nov 29, 2024Daily Lithium price, Lme Comex Shfe Price of Lithium live SMM2023年8月30日 The lithium carbonate extracted from the recovery process still contains impurities that must be removed The purification process usually involves treating the lithium carbonate with hydrochloric acid This process transforms the lithium carbonate into lithium chloride, which is then purified using electrolysis to produce pure lithiumAn InDepth Look at Lithium Mining Mining Pedia

.jpg)

Lithium price today Historical New Energy Price Charts SMM

SMM brings you current and historical Lithium price tables and charts, and maintains daily Lithium price updates SMM App Android iOS Holiday Pricing Schedule FREE TRIAL Compliance Centre Lithium Carbonate (995% Battery grade CIF China,Japan and Korea) (USD/Kg) 105114 1095005Cornish Lithium has worked with Grinding Solutions Ltd and Wardell Armstrong International, both based in Cornwall, together with Strategic Metallurgy, based in Perth Australia to complete concentrator test work on different samples of ore Processing Technology Cornish Lithium Plc2022年7月5日 The three minerals, spodumene, petalite, and lepidolite, can be used for various purposes after beneficiation and concentrationThe cutoff grade and industrial grade of lithium deposits are divided into manual beneficiation and machine beneficiation, and the grade indicators are determined respectivelyThe division between manual and machine Lithium Processing Plant JXSC MachineAs a global leader in grinding machine technology, JTEKT Machinery offers an extensive lineup of highperformance universal, cylindrical, camshaft, and crankshaft grinding machines Originally designed for highproduction automotive manufacturing, these grinders excel in the most demanding applicationsGrinding Machines JTEKT Toyoda JTEKT Machinery North

.jpg)

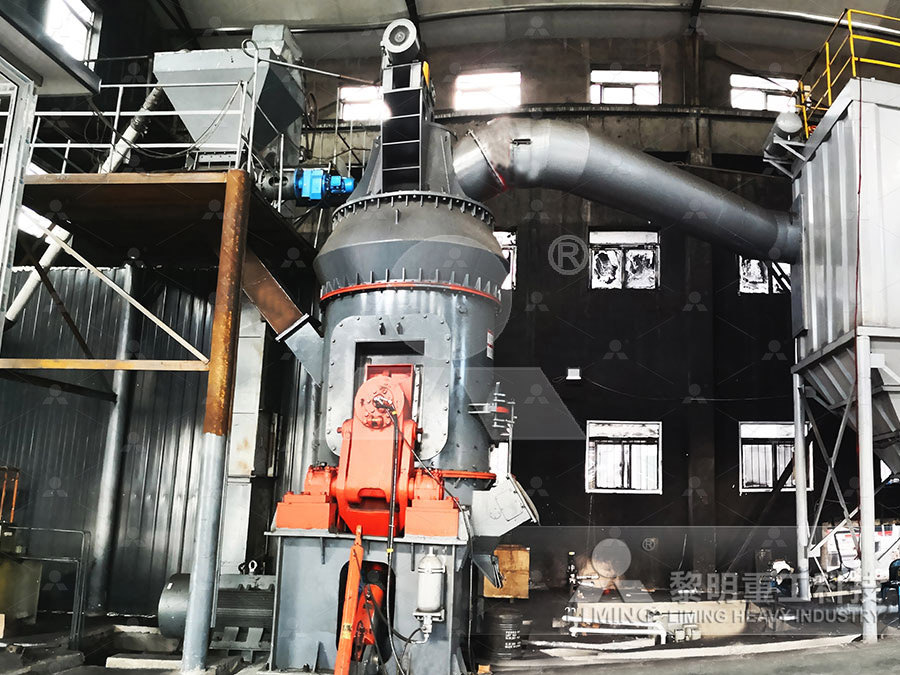

Lithium Carbonate Production Line Pengfei Rotary Kiln Grinding

The cement grinding plant is environmentally friendly and is mainly used to treat industrial solid waste such as slag, coal ash and coal gangue It is also engaged in the crushing and preheating of cement raw materials, grinding and packaging of cement Our company produces cement grinding equipment2024年1月1日 Lithium disilicatebased glassceramics (Li 2 O2SiO 2) are one of the most successful commercial materials in dentistry [7], being widely chosen by many professionals because of their wide range of application in veneers, crowns, and fixed dental prostheses with up to threeunitsThese GCs exhibit a high flexural strength of 300–400 MPa, a high fracture Microstructure and mechanical properties of an experimental lithium 2022年9月11日 Calcium Carbonate Mill Brief Introduction : Calcium Carbonate Mill also is named calcium carbonate grinding mill Calcium Carbonate Mill (Raymond Mill) is suitable for grinding calcium carbonate into fine powder After being grinded by the Calcium Carbonate Mill, the fine powder size can be 40 mesh to 325 mesh for industry usageCalcium Carbonate Mill Powder Making Machine Rotary Dryer, Material for anodes and cathodes in lithiumion batteries When charging and discharging a lithiumion battery, the lithium ions move from the cathode to the anode and back again The cathode and anode of a battery are made of different materials A wide variety of lithium compounds (eg LCO, NMC, NCA or LFP) are used in the cathodeLithiumion batteries Hosokawa Alpine

.jpg)

Zimbabwe Lithium Ore Lithium Cell 125tpd Mining Equipment

Jiangxi Province County Mining Machinery Factory is a leading mining machinery manufacturer with over 30 years experiences,providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore /Diamond/ Coltan ore / Silica sand /Zircon sand/ Black sand/Chrome ore/Cobalt ore/Antimony ore, ect