Steel Slag Mill Selection

Research on the Properties of Steel Slag with Different Preparation

2024年3月28日 The main mineral phases, morphological characteristics, and thermal stability of steel slags are analyzed using XRD, SEM, and TG tests before and after expansion tests The 2011年10月26日 Steel slag is a byproduct of the steelmaking and steel refining processes This paper provides an overview of the different types of steel slag that are generated from basicoxygenfurnace (BOF) steelmaking, electricarc Chemical, Mineralogical, and Morphological Properties 2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking Research on the Properties of Steel Slag with Different 2023年5月15日 On this basis, steel slag and slag composite micro powder (SSCM) technology was proposed, which realized the high added value and utilization rate of steel slag in Comprehensive utilization of steel slag: A review ScienceDirect

Steel Slag—Its Production, Processing, Characteristics, and

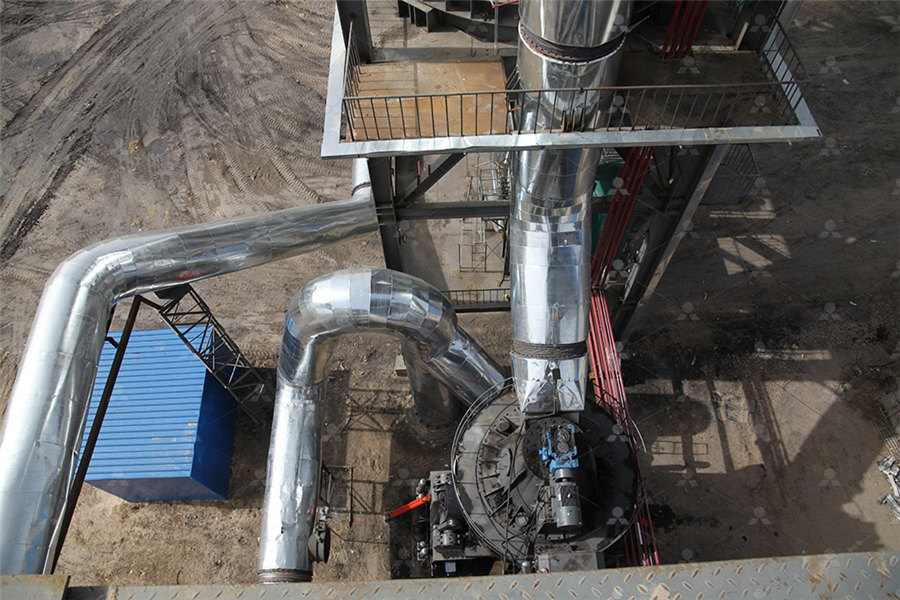

2004年5月14日 Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, or the melting of scrap to make steel in an electric arc furnace This paper 2005年2月1日 Steel slag is a byproduct obtained through the separation of molten steel from impurities in steelmaking furnaces It can be produced by different types of furnaces (blast, basic oxygen (PDF) Industrial uses of slag The use and reuse of iron 2007年3月1日 Pilot plant trials successfully demonstrated the viability of recycling million of tons of steel plant dusts and sludge that are now typically land filled, and typically converting them An overview of utilization of slag and sludge from steel industries2019年5月23日 At present, the main grinding equipment of steel slag at home and abroad include ball mill the highpressure rolling mill, vertical mill, tube mill with internal powder Comprehensive Utilization Technology of Steel Slag

.jpg)

BOF Steel Slag: Critical Assessment and Integrated Approach for

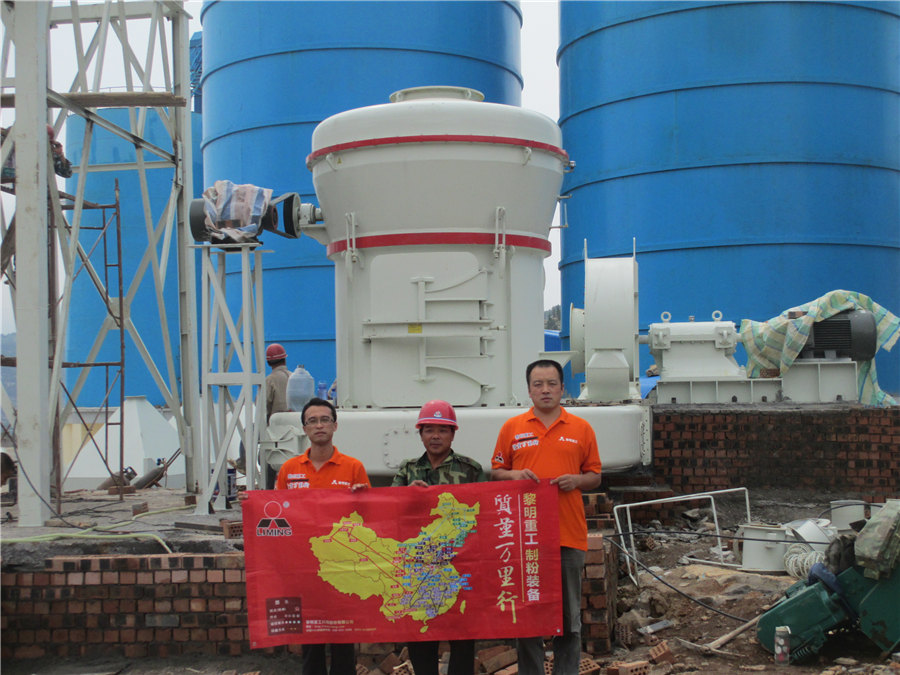

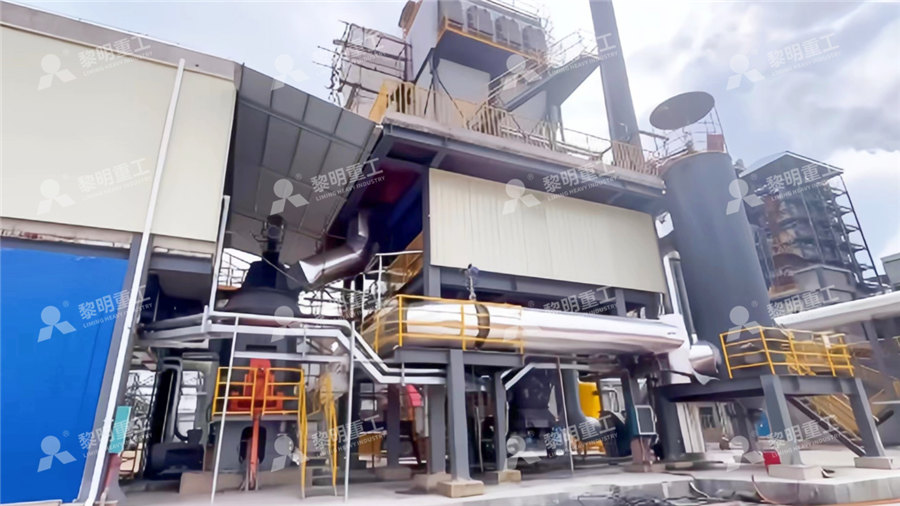

2021年9月24日 Based on the analysis, the authors present a holistic approach toward steel slag utilization beyond the conventional application areas like aggregates, landfilling, etc This 2018年8月1日 Steel slag shows volumetric instability due to the presence of an unstable phase in its mineralogy (Wang et al, 2010, Yildirim and Prezzi, The criteria for steel enterprise selection included the size of production, from megaplant to small plant; the geographic area, such as North China, Northeast China, Steel slag in China: Treatment, recycling, and management1 LM Vertical slag mill integrates drying, grinding, powder selection and conveying together, simple system, compact layout, the area is about 50% of the ball milling system Reduce the cost of investment, low energy consumption, LM Vertical slag mill2017年3月5日 In the USA, steel slag is currently sold and used for various applications, pre could be quite signi fi cant for an individual steel mill [84] References 1(PDF) Iron and Steel Slags ResearchGate

Home Australian Steel Mill Services

ASMS is a joint venture between the Cement Australia Group and the Edward C Levy Co (USA) formed in 1989 to service the slaghandling contract at BlueScope Port Kembla NSW ASMS is contracted to collect and treat molten slag from the blast furnace and the steel making processes We are responsible for the processing and marketing of approximately 18 million tonnes of 2022年2月1日 Steel slag (SS), accounting for about 15–20% of the total steel amount, has been produced in huge quantities worldwide (Han et al, 2015; Shi, 2004)Initially, SS was treated as a waste material and disposed of as landfill, which not only took up land resources but also severely impacted the natural environment and human health due to the highly alkaline leachates Environmental benefit assessment of steel slag utilization and 2015年3月17日 Steel slag is a byproduct of the steel industry Understanding of the chemical, mineralogical, and morphological properties of steel slag are necessary for its use in sustainable practicesSteel Slag; Chemistry, Mineralogy and Morphology ResearchGate2021年9月24日 During steel production, the impurities in the hot metal react with the fluxes forming the steel slag Chemical constituents of this steel slag (SS) are relevant to iron/steelmaking or blended cement manufacture Harmful impurities present in it, however, limit its recycling to these applications Japan, Europe, and the US consume a significant amount of BOF Steel Slag: Critical Assessment and Integrated Approach for

Pelletizing steel mill desulfurization slag ScienceDirect

2002年7月1日 Slag processingSteel mill slags are currently processed by standard methods common to the sand and gravel industry such as crushing and screening Typically, the slag material that is larger than 1 in in diameter is very highly metallic and is recycled as scrap Processing of the remaining finer material results in marketable slag products2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking plants The physical and mechanical characteristics and volume stability of steel slags were analyzed through density, water Research on the Properties of Steel Slag with Different MDPI2024年3月1日 Steel slag is a significant byproduct of the steelmaking process, 1 accounting for 15%–20% of crude steel production 2 In China, the annual production of steel slag exceeds 100 × 10 6 tons, with a utilization rate as low as 295% 3 Comparatively, Japan achieves an impressive utilization rate of 984%, while Europe and the United States reach rates of 870% An airfluidized magnetic separator and its separation 2021年5月10日 Steel slag's usage is related to its physicochemical characteristics The density of steel slag is 33–36 g/cm 3 Steel slag is hard because of its high Fe amount and is highly resistant to corrosion The grindability index of steel slag is 07 [38] Steel slag primarily consists of SiO 2, CaO, Fe 2 O 3, FeO, Al 2 O 3, MgO, MnO, and P 2 O 5 Review Steel slag and its applications in cement and concrete

.jpg)

Recent research progress on recycling metallurgical waste slag

2024年11月1日 The green, efficient, and pollutionfree recycling of metallurgical waste slag has garnered global attention This study reviews the latest technologies for the recycling of steel slag (SS) and ladle refining slag (LFS), as well as the recent advancements in impurity element recovery using an applied electric field2004年5月14日 Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, Shi, C (1999) “Corrosion resistant cement made with steel mill byproducts” Proc, Int Symp on the Utilization of Metallurgical Slag, Steel Slag—Its Production, Processing, Characteristics, and 2023年11月17日 The predominant way of making steel in the United Sates is by using an electric arc furnace (EAF) to melt scrap steel, which results in the formation of a rocklike material called slag Among its various applications, EAF slag is used in a loose or unencapsulated form as ground cover material for residential landscaping However, the slag generated from the Health Risk Considerations for the Use of Unencapsulated Steel Slag2024年7月20日 Geopolymer concrete (GC) utilizes industrial solid waste like steel slag, fly ash, and rice husk ash, offering a sustainable alternative to traditional cement By reducing reliance on cement, GPC helps mitigate carbon footprints and promotes ecofriendly construction practices With its significant commercial potential, GPC is poised to contribute to sustainable Influence of steel slag on strength and microstructural

.jpg)

Thermodynamic modelling on the reaction between steel and slag

2024年9月1日 In the current work, an integrated model for the activity of the steel was proposed, which combined the UIPF and AM The IMCT was employed for the activity calculation of CaO–MgO–FeO–MnO–CaF 2 –SiO 2 –Al 2 O 3 –Fe 2 O 3 eightcomponent slag By integrating these methods, a comprehensive thermodynamic model was established to investigate the 2012年2月8日 Slag accounts for most of the residuals or byproducts of the steel manufacturing process and represents a not inconsiderable amount of energy waste and CO2 emissions Energy recovery from steel mill slags is not actually performed because of the difficulty of the industrial implementation, but the actual demand and the incentives for new electricity generation plants Steel mill slags energy potential: the case of the steel factory of 2019年5月23日 The moisture in steel slag when it enters the mill is 69%, The development of recycling economy, scientific selection of steel slag treatment technology and comprehensive utilization of steel slag to achieve “zero” emissions Baiyin, China scrap steel (6):10–prehensive Utilization Technology of Steel SlagThe Company is also providing steel mill services for handling BOF Slag, etc During the year 201617, BSP reported production of Granulated Slag at 1,531,579 tonnes Tata Steel Plant produced 3,783,844 tonnes of BF Slag During the year 201516, RSP reportedSLAG IRON AND STEEL Indian Minerals Yearbook 2017 IBM

The steel production transformation process in Europe: New slag

The main challenge of the steel industry for the next decade is the steel production transformation process, starting in Europe The CO 2 intensive blast furnace/basic oxygen furnace (BOF) route will be substituted by a combination of Direct Reduced Iron (DRI), based on natural gas, later on “green” hydrogen, with an Electric Arc Furnace (EAF) or a Submerged Arc Furnace (SAF), The steel industry is finding ways and means to utilize the steel slag in other applications like construction road making, soil conditioning, rail ballast However there are problems and issues The steel slag need to be properly aged and ground to very fine size before it can be explored to be utilised, which incur substantial costEnergy Environment Management in Steel Sector2022年8月15日 The selection criteria for ballast materials are compared and test methods for ballast quality quantification are summarised steel slag and ballast gluing The review shows that regarding ballast selection means and criteria, The mill abrasion (MA) test is a relatively new test being proposed for use in North America [18]Railway ballast material selection and evaluation: A review2024年2月2日 It should be noted that the selection of steel slag particle size is mainly based on the following reasons Fine steel slag They all belong to high alkalinity except for the steel slag from the Handan steel mill and Taiyuan steel mill, whose alkalinity is slightly lower than high alkalinity The AI ranges from 025 to 097, with Quantitative characterization and evaluation of key

Magnet Associated Rare Earths in Steel Mill Slags ResearchGate

World of Metallurgy – ERZMETALL 0 (2017) No 5 273 Janina Daul et al: Magnet Associated Rare Earths in Steel Mill Slags REEinput in the slag needs to consider the natural REE2011年1月1日 Steel mill slag produced from electric furnaces or open hearths typically contains onethird to onehalf nonhydrated lime (primarily CaO with some MgO) The lime is added as a fluxing agent during steel production Lime can absorb water through hydration for many years after the slag has been createdSteel Mill Slag At Your Construction Site? GeoEngineersSteel slag, in addition to being a lowcost alternative to its quarriedstone counterparts, is readily available at several facilities in New Jersey and Pennsylvania The NJDEP requires that all clean fill sources be screened and tested in accordance with the Alternative and Clean Fill Guidance Document, dated December 29, 2011Steel Slag Alternative to Crushed Stone and Clean Fill SESIThe Company is also providing steel mill services for handling BOF Slag, etc During the year 201415, VISL, DSP and BSP reported production of BF slag as 25,548 tonnes, 8,16,020 tonnes and 16,14,000 tonnes respectively , while, the production of granulated slag was 25,548Slag Iron Steel 2015 IBM

.jpg)

Slag Availability National Slag Association

Slag Availability Use the map below to find slag near you!Molten slag is carried outside and poured into a dump The general term slag may be a byproduct or coproduct of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced [1] Slag is mainly a mixture of metal oxides and silicon dioxideBroadly, it can be classified as ferrous (coproducts of processing iron and steel), Slag Wikipedia2023年12月20日 Steel slag is a solid byproduct of the steelmaking process, widely generated in the metallurgical industry Due to its alkaline nature and excellent adhesive properties with asphalt, it represents a potential road construction material with outstanding road performance, making it wellsuited for utilization in highway construction This paper conducts a systematic Analyzing the Mechanical and Durability Characteristics of Steel Slag 2021年6月14日 Hightemperature molten steel slag is a large amount of industrial solid waste containing available heat energy and resources This paper introduces an efficient and comprehensive utilization process of hightemperature molten steel slag The waste heat energy in the hightemperature molten steel slag can be fully recovered through the threestage heat ThreeStage Method Energy–Mass Coupling HighEfficiency Utilization

.jpg)

2 µm 5 µm Loesche

a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil2023年8月25日 Steel slag is a solid waste produced in crude steel smelting, and a typical management option is stockpiling in slag disposal yards Over the years, the massive production of steel slags and the (PDF) Application of Steel Slag as an Aggregate inAlmost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process The concept of M and Srollers was established in 1992, which is one of the most cost effective and Cement Blast Furnace Slag Loesche2005年2月1日 Steelmaking slag, an important metallurgical byproduct, is composed of a large amount of valuable components, including CaO, Fe t O, MnO, and MgO, all of which are required in the steelmaking (PDF) Industrial uses of slag The use and reuse of iron and

Steel Slag Material Description User Guidelines for Waste and

2016年3月8日 Steel slag aggregates are highly angular in shape and have rough surface texture They have high bulk specific gravity and moderate water absorption (less than 3 percent) Table 181 lists some typical physical properties of steel slag Table 181 Typical physical properties of steel slagIf you want to further understand the characteristics and structural principles of steel slag vertical mill, please contact mkt@hcmilling or call at +86773, HCM will tailor for you the most suitable steel slag grinding mill program based on your needs, more details please check hcmillingNews Can steel slag Raymond mill be used to processed steel slag Steel slag is one of the most common waste products from the steelmaking industry Conventional methods of slag disposal can cause negative impacts on humans and the environment In this paper, the process of steel and steel slag production, physical and chemical properties, and potential options of slag recycling were reviewed Since steel is mainly produced through an Assessment of Electric Arc Furnace (EAF) Steel Slag Waste’s2024年5月2日 However, careful selection of the optimal steel slag replacement percentage is essential to balance desired properties without compromising other characteristics Figure 2 shows the size particle distribution for slag, coarse, and fine aggregate within upper and lower limits according to ECP 203 [ 6 ]Utilization of steel slag as partial replacement for coarse

Review on the innovative uses of steel slag for waste minimization

2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition