Quick lime ore crushing process

Limestone Crushing Process JXSC Mineral

The limestone crushing process involves several stages, each with specific machinery and equipment The typical limestone crushing process is Primary Crushing > Secondary Crushing > Screening > Conveying > Storage2023年2月15日 From lime production from limestonequick, you can get quick lime and hydrated lime Jaw crushers, hammer crushers and rotary kiln are necessary equipment for making limeLime Production Process and Required Equipment2023年12月8日 Quicklime absorbs moisture or adds water to become hydrated lime The main component is calcium hydroxide Ca (OH)2, which is used in environmental protection, medicine, food and other industries Limestone or Limestone crushing technology and equipment SBM Quicklime can be processed into hydrated lime by crushing the quicklime, adding water to the crushed lime (water accounts for approximately 1% of raw hydrate), and then classifying the How Lime is Made

.jpg)

Quicklime SMA Mineral

Quicklime is produced by heating crushed limestone to around 1,100 degrees Celsius in a shaft furnace or rotary kiln The heating of limestone releases carbon dioxide, leaving calcium oxide 2021年12月1日 Lime is added, usually in dry quicklime form, to crushed ore via a screw feeder from a lime silo onto the conveyor belt feed of a ball mill Lime dose rates are typically Lime use in gold processing – A review ScienceDirect2019年11月1日 Automated lime dosage control provides tangible advantages to operations Lime (calcium oxide or calcium hydroxide) is arguably the most common reagent used in the Lime use and functionality in sulphide mineral flotation: A review1998年5月14日 Principles of Lime Burning Development of Lime Kilns Modern Kilns Selection of Lime Kilns Kiln Control Mass and Heat Balances Instrumentationa Production of Calcined Production of Quicklime Lime and Limestone Wiley Online Library

Production European Lime Association

Crushing and washing The trucks tip the limestone into a large primary crusher which usually relies on either impact or compression to break the rock Depending on the size of the feed 2019年11月1日 Quicklime (CaO) is produced Lime is often added into the semiautogenous (SAG) mill together with the ore feed and process water Sulfide minerals are, In flotation plants, lime additions are common in different points of the circuit, such as comminution (crushing and grinding), flotation, and dewatering/thickeningLime use and functionality in sulphide mineral flotation: A review2014年1月18日 Generally when the complete stone crushing plant has been set up, it needs the commissioning process And the commissioning process consists of noloading commissioning and loading commissioning +86371 Stone Crushing Plant Commissioning Process2013年12月10日 Microstructure of iron ore pellet at 200x showing (1) hematite phase, (2) voidage, (3) slag bonding and (4) unreacted phase Effect of Lime coating of iron ore pellets on Iron

Crushing in Mineral Processing 911Metallurgist

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing" Although there is no limit set, the downsizing process over 3 mm is considered as "crushing What Is The Crushing Process MEKA2016年2月29日 Some of the metallurgical relationships that must be considered from the testwork program as follows: ore grade relationship to gold recovery, crushing and grinding parameters and their relationship to the ore variability in the ore body, effect of other minerals on the process, minerals and/compounds that negatively impact processing cost such as oxidized Gold Extraction Recovery Processes 911MetallurgistWhen iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe six main steps of iron ore processing Multotec

.jpg)

Crushing Plant Flowsheet DesignLayout 911Metallurgist

2016年3月11日 It was felt by some that crushing to this fine size is only possible if the ore is friable and is relatively soft in comparison to the harder ores Our results show that some of the copper ores are as hard as taconite and are crushed to ball mill feed all passing 13MM (½”)quick lime, is an exothermic process releasing a great quantity of heat This hydration process when done with just the right amount of water is called “Dry Hydration” In this case the hydrate material is a dry powder If excess water is used for hydration, the process is called “Slaking” In this case, the resultant hydrate is in aAn Overview of Lime Slaking and Factors That Affect the Process2024年4月26日 The crushed ore obtained from the crushing stage is typically in larger size fractions and needs to be further processed through screening 2 Screening Screening is the process of separating the crushed ore into various size fractions It involves passing the crushed ore through a series of screens with differentsized openingsIron Ore Processing: From Extraction to ManufacturingCalcium oxide (formula: Ca O), commonly known as quicklime or burnt lime, is a widely used chemical compoundIt is a white, caustic, alkaline, crystalline solid at room temperatureThe broadly used term lime connotes calciumcontaining Calcium oxide Wikipedia

.jpg)

Lime in Gold Ore Mining Process Flotation, Cyanidation JXSC

2019年8月3日 Lime in Gold Ore Mining Process by JXSC Mining Lime is a lowcost item that is widely used in gold beneficiation plants Lime (CaO), also known as quick lime, which is obtained by calcining limestone (CaCO3) at 900~1200 °C CaCO3→CaO + CO2 2024年6月13日 The copper ore crushing adopts threestage closedcircuit crushing, which can complete the crushing and partial dissociation of the ore Skip to content JXSC Mineral The third stage: ore dressing – mixed Copper Introduction And Ore Crushing JXSC MineralAbout Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite It is a kind of stone widely found in nature Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated limeLimestone Crushing Process JXSC MineralLime is made from indigenous limestone or chalk rock, one of the most abundant materials in the Earth’s crust Limestone and chalk are both sedimentary rocks and are chemically known as calcium carbonate When crushed or ground, they are widely used as aggregates and building products As a raw material, calcium carbonate can also be processed []Production European Lime Association

.jpg)

Iron Ore Pelletizing Process: An Overview IntechOpen

The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the 2023年6月3日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for MeasurementControl for Crushing and Screening Processmineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other Mineral processing Metallurgy, Crushing Grinding Britannicasilica from bauxite ore and for causticization in the manufacturing of alumina Dolomitic quicklime is used to produce metallic magnesium by thermal reduction which reduces magnesium oxide Lime is also used in the processing of ores and the subsequent smelting and refining of copper, zinc, lead, and other nonferrous ores EnvironmentalQUICK LIME AND BYPRODUCTS PEC Consulting Group

.jpg)

What Is Lime? Lime Association

2024年2月1日 Lime (CaO), also known as quicklime, is a white, crystalline, alkaline substance produced by heating limestone (calcium carbonate) to high temperatures During that process, The steel industry used lime everyday Nevertheless, the process is relatively simple: locate or create (minimal) breaks in the stone, remove the stone using heavy machinery, secure the stone on a vehicle for transport, and move the material to storage A flow diagram of typical quarrying operations is shown in Figure 1 Figure 1 Process flow diagram for limestone quarrying operationsLimestone Quarrying and Processing: A LifeCycle Inventory2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Types of Crushers: Choosing the Right One for Each 2023年7月22日 The ore crushing process includes four types: ore coarse crushing, ore medium crushing, ore fine crushing, and ore superfine crushing Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500–1500 mm to 125–400 mm The maximum crushing ratio of coarse crushing is about three The main force in the coarse Ore Crushing SpringerLink

Limestone crushing, sand making and grinding process

2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished 11171 Process Description 15 Lime is the hightemperature product of the calcination of limestone Although limestone deposits crushing and sizing; (3) calcining limestone; (4) processing the lime further by hydrating; and (5) miscellaneous transfer, storage, and 1117 Lime Manufacturing US EPAThe invention discloses a quick lime desiccant, which solves the problems that a quick lime desiccant in the prior art is prone to being caked, so that the granularity of the quick lime is lowered, and a drying effect is influenced The quick lime is prepared by mixing the following components in percentage by weight: 01%05% of sodium tripolyphosphate, 01%05% of Quick lime desiccant and production process thereofThe processing of limestone is mainly crushing, grading and producing quicklime, slaked lime, precipitated calcium carbonate, ultrafine (nano) calcium carbonate, carbon dioxide, etc Limestone generally adopts dry crushing process For metallurgical and construction use limestone, only the ore needs to be crushed and screenedLimestone Crushing Solution Eastman Rock Crusher

.jpg)

Limestone Crushing And SandMaking Plant Eastman Rock

2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for industries such as airport construction, water conservancy power stations, tall buildings, concrete mixing plants, etc2019年2月11日 The Bayer process is used for producing alumina (Al 2 O 3) from bauxite oreThe process was developed and patented by Karl Josef Bayer in 1887 [], which led to a dramatic reduction in the cost of aluminium metalThe process involves the following operations: mining, dissolution of the alumina at elevated temperatures, the addition of flocculants, Investigation of lime usage impacts on bauxite processability at using a batch process However, if a continuous or semicontinuous process is used, then care must be taken that the mass of fuel used and the mass of quicklime produced correspond directly In our example, we will take a figure for the coal used as 200 kg/tonne of quicklime produced Figure 1: American Society of TestingHOW TO CALCULATE EFFICIENCY OF YOUR LIME BURNING PROCESS2022年8月3日 1 Iron ore crushing process: In the iron ore crushing process, the feeder, first crushing, secondary crushing, screening, fine crushing and dry selection are generally used For the sake of economy, generally the finer the Iron ore crushing and screening process SBM

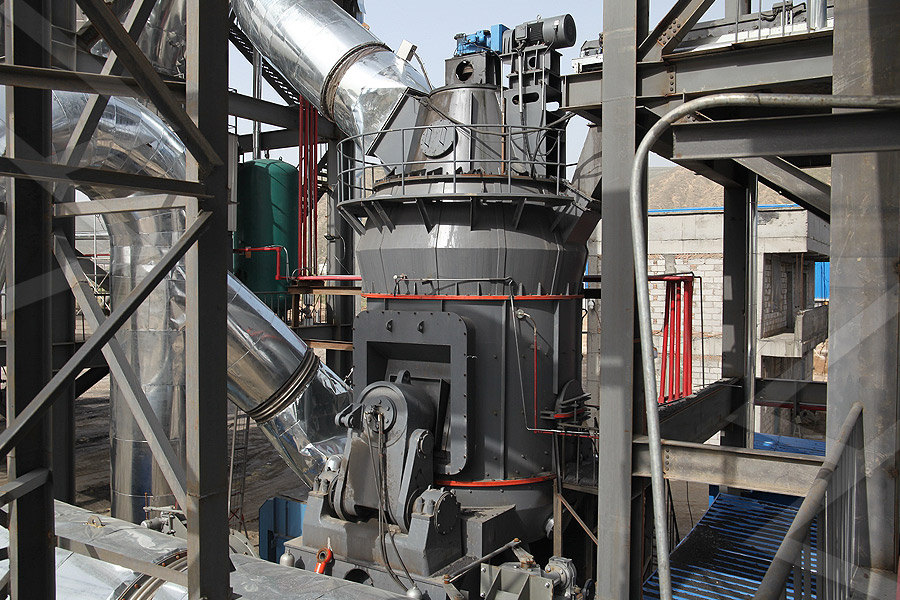

制粉项目-2023.11.17.jpg)

Influence of quick lime on pore characteristics of high

2021年10月1日 Request PDF Influence of quick lime on pore characteristics of hightemperature zone in iron ore sinter based on XCT technology The pore structure of the bed has an important influence on the 2019年11月4日 The compressive strength of limestone is generally around 150 MPa, which belongs to soft rock The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc JXSC custom makes limestone crushing plant for different requirements to meet high efficiency, energysaving performanceLimestone Rock Crushing Flow Price JXSC Machine2014年1月1日 2 ORE CRUSHING PLANT The Cayeli mine is the first fully mechanized [Show full abstract] this, the framework about coal flow in circular process of coal production and usage is put forwardFactors affecting the performance of crushing plant operations2024年1月31日 Quick Lime Production project in Pakistan Publication date: 13:48:49 article and also saves the waste of powdered materials that cannot enter the rotary kiln in the crushing process Cement Projects Active Lime Project Magnesium Project Oil Fracturing Proppant Projec LECA Project GGBS Project Ore Dressing Project Quick Lime Production project in Pakistan

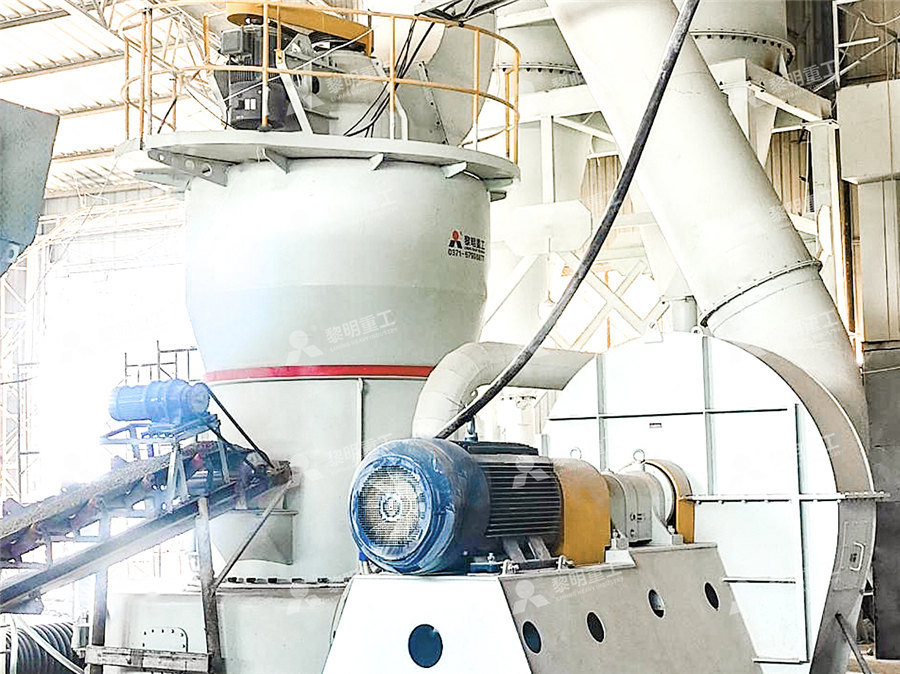

Hydrated, Quick, and PCC Lime Processing Plant Chanderpur

Quick Lime Calcination Plant In calcination process, lime is cooked/calcined at 800°c in a kilnWe are providing shafts kilns and rotary kilns for calcining of limestone/lime sludge with multi fuel options Prior to calcination, exhaust gases of kiln preheat limeMedia Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using openpit mine methods (Figure 815 in Section 81)Creating a giant hole in the ground is generally cheaper than making an underground 82: Mining and Ore Processing Geosciences LibreTexts1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for fine crushing and then uses a vibrating screen for screening operation, and the qualified materials flow into the next process, and the Limestone Aggregate Crushing JXSC Machine2022年1月23日 Chemical Processing of Bauxite: Alumina and Silica Minerals—Chemistry, Kinetics and Reactor Design(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals