Calcium carbide mud mill quotation Xinxiang glass limestone deep processing equipment

Limestone mill, Limestone grinding mill All DirectIndustry

Find your limestone mill easily amongst the 34 products from the leading brands (SIEBTECHNIK, Liming, NEUE HERBOLD, ) on DirectIndustry, the industry specialist for your professional This report presents a cost analysis of Calcium Carbide production from limestone and coke The process examined is a typical process In this process, limestone is calcinated to lime, which Calcium Carbide from Limestone (Electrothermic Process) Intratec2019年3月1日 This column is based on “Calcium Carbide Production from Limestone – Cost Analysis,” a report published by Intratec It can be found at: intratecus/analysis/calcium Technology Profile: Calcium Carbide Production from Limestone2022年5月1日 Life cycle assessment is employed in this study to provide a comprehensive analysis of the environmental performance of CaC2 production in China The results show that Life cycle assessment and sustainable production evaluation of

Life cycle assessment and sustainable production evaluation of

2022年8月1日 Life cycle assessment is employed in this study to provide a comprehensive analysis of the environmental performance of CaC 2 production in China The results show The construction and operation of comprehensive utilization production lines in SXBYCHEM completely realized the 100% use of calcium carbide slag instead of limestone production, Application technology of calcium carbide slag: a case study ZKG2022年2月1日 The aim of this paper is to: (i) propose a new type of calcium carbide production method and analyze the relationship between the input and output energy transfer and loss, Energy and exergy analysis of a new calcium carbide production 2020年9月21日 A type of calcium coke was developed for use in the oxythermal process of calcium carbide production The calcium coke was prepared by the copyrolysis of coking coal Development of calcium coke for CaC2 production using calcium

.jpg)

114 Calcium Carbide Manufacturing US EPA

The process for manufacturing calcium carbide is illustrated in Figure 1141 Moisture is removed from coke in a coke dryer, while limestone is converted to lime in a lime kiln"Limestone" means any rock formed mostly of calcium carbonate (CaCO 3), but to geologists, limestone is only one of several types of "carbonate rocks" These rocks are composed of more than 50% carbonate minerals, generally the Limestone: The Calcium Carbonate Chemical This report presents a cost analysis of Calcium Carbide production from limestone and coke The process examined is a typical process In this process, limestone is calcinated to lime, which reacts with coke in an electric arc furnace, producing calcium carbideCalcium Carbide from Limestone (Electrothermic Process) Intratec2022年5月1日 Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride is produced from coalbased CaC 2CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are generated annually in China, among which only a Recycling and utilization of calcium carbide slag ScienceDirect

.jpg)

Limestone Processing Equipment FEECO International Inc

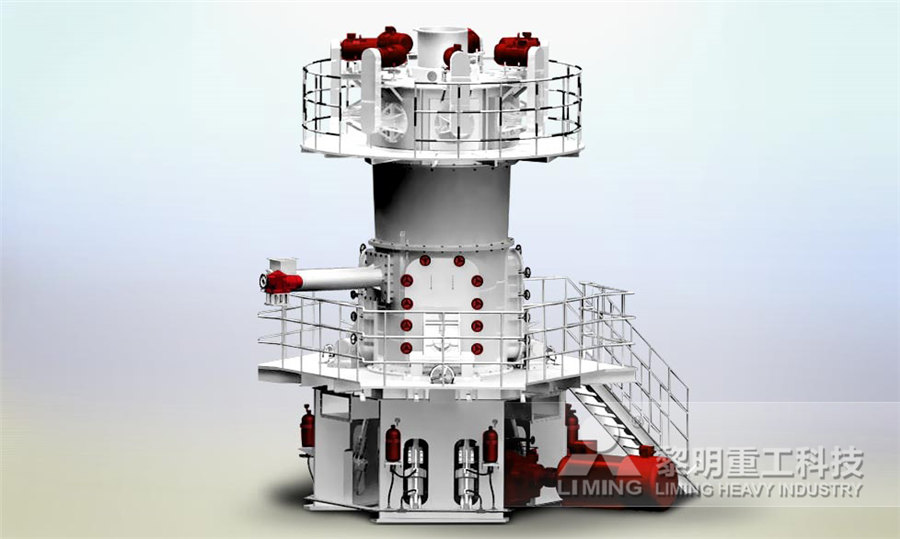

Limestone Processing, Pelletized (Pelletised) Limestone Pelletized (Pelletised) Limestone Limestone pellets offer reduced dust, more accurate application, improved handling, and less product lost to dust Limestone Processing Challenges7TPH MTW145G Limestone Grinding Mill In Sichuan, China Output size:180 meshSolution Grinding Mill, mineral mill, limestone mill, calcite mill Project Name: Ultrafine Vertical Limestone Powder Production Line Finished fineness: 1500 mesh Finished product use: The main filler in rubber industry, plastic industry, paper industry, paint industry, coating and feed industry Optional equipment: Limestone ultrafine vertical mill, Crusher, Bucket Elevator, Vibrating Feeder Project Benefits 1 Highquality particle shapeChina Henan limestone ultrafine vertical mill production lineprocess flow diagram for limestone processing operations 3 list of tables 6 6 table 1 gross energy to produce one ton of limestone products table 2 water consumption for limestone quarrying and processing table 3 lci inputs for limestone quarrying and processing table 4 lci outputs for limestone quarrying and processing table 5Limestone Quarrying and Processing: A LifeCycle Inventory

Technology Profile: Calcium Carbide Production from Limestone

2019年3月1日 Processing Handling Decrease Size Default size Increase Size Print View Comments PDF Technology Profile: Calcium Carbide Production from Limestone March 1, 2019 By Intratec Solutions This column is based on “Calcium Carbide Production from Limestone – Cost Analysis,” a report published by IntratecLimestone is made from calcium carbonate in the form of calcite or aragonite, sometimes with minor amounts of magnesium It is common for limestone to form as aragonite before converting to calcite Fossils are a common building block of limestone Sand, silt, and clay are sometimes found in minor amountsLimestone: Identification, Pictures Info for RockhoundsCalcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C 2Its main use industrially is in the production of acetylene and calcium cyanamide [3]The pure material is colorless, while pieces of technicalgrade calcium carbide are grey or brown and consist of about 80–85% of CaC 2 (the rest is CaO (calcium oxide), Ca 3 P Calcium carbide WikipediaConsult Xinxiang Great Wall Machinery Co, Ltd's The importance of vertical roller mill in limestone grinding brochure on DirectIndustry Page: 1/2 Exhibit with lime and calcium carbide It is an indispensable flux limestone in the metallurgical industry After being ground, highquality limestone is widely used in the manufacture of The importance of vertical roller mill in limestone grinding

.jpg)

National carbon emissions from the industry process:

2016年3月15日 4 Results On the basis of the methodology, the activity data and emission factors discussed above, we calculated the CO 2 emissions from the production of alumina, plate glass, soda ash, ammonia and calcium carbide for the period 1990–2013 The CO 2 emissions from these five industrial productions rose rapidly over the studied period: the total CO 2 2024年10月29日 The production of one ton of calcium carbide results in the generation of about 12 tons of calcium carbide slag (CCS) [23] CCS can be utilised as a raw material for the production of cement, modified for use as a waterproofing material, Preparation and Performance Assessment of Calcium Carbide 2020年8月5日 Lime mud, a kind of industrial waste that produced in paper mill, was proposed as CO 2 sorbent in calcium looping process The carbonation performance of the lime mud was investigated in a dualfixed bed reactor (DFR) and a thermogravimetric analyzer (TGA)Kinetic analysis about the CO2 capture capacity of lime mud Calcium Carbonate Powder Mill for Limestone, Calcite, Dolomite, Suitable for processing of nonmetallic minerals such as calcium carbonate,clay,barite,talc,gypsum,limestone,calcium oxide,bentonite,dolomite etc Equipment sizing assistance based on customer's demand 2)Calcium Carbonate Powder Mill for Limestone, Calcite, Dolomite,

Strength development and microstructure of sustainable

2022年11月1日 Download Citation Strength development and microstructure of sustainable geopolymers made from alkaliactivated ground granulated blastfurnace slag, calcium carbide residue, and red mud Red 2011年12月1日 The influences of calcium carbide residue and highsilicon limestone on the mineral composition and performance of belitebarium calcium sulphoaluminate cement were studied by means of Xray Effects of Calcium Carbide Residue and HighSilicon Limestone Today, NorthGlass have developed into a hightech industry group with complete industrial chain and continuous innovation capability, composed by 5 production bases respectively in Luoyang, Shanghai, Tianjin, Beijing and Guangdong, with the integrated abilities of RD, manufacture, sales and service in the fields of glass deep processing equipment and upscale processed Glass Processing Equipment NorthGlass2024年5月23日 Circulating uidized bed y ash (CFBFA) is the solid waste generated in the circulating uidized bed combustion (CFBC) processOptimization of proportions and solidification mechanism of all

(PDF) Natural and enhanced carbonation of lime in its different

2021年1月1日 Natural Carbonation Rate (NCR) over time for pure airlime mortars (top left), mixed airlime mortars (top right), hemplime (bottom left) and steel slags (bottom right)2020年2月18日 Explore the environmental hazards of limestone mining and learn about adaptive practices for effective environment management(PDF) Environmental Hazards of Limestone Mining 2022年5月1日 Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride is produced from coalbased CaC 2CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are generated annually in China, among which only a Recycling and utilization of calcium carbide slag ScienceDirect114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US EPA

.jpg)

Utilization of lime mud from paper mill as CO2 sorbent in calcium

2013年4月1日 Lime mud (LM), a solid waste that results from the causticization reaction in alkali recycling process of paper manufacture industry, was utilized as CO2 sorbent in calcium looping process in this 2024年10月30日 Sedimentary rock Limestone Formation, Calcium Carbonate, Fossils: Limestones originate mainly through the lithification of loose carbonate sediments Modern carbonate sediments are generated in a variety of environments: continental, marine, and transitional, but most are marine The presentday Bahama banks is the best known modern Sedimentary rock Limestone Formation, Calcium Carbonate, 114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US EPA2022年5月11日 The basic chemistry of limestone is calcium, magnesium, iron, and silica Calcium and magnesium are essential for glass making, while silica is mainly from sand Iron is the primary impurity found in limestone, and glassmakers need to know what its effects might be before choosing a limestone for their processHow Is The Processing Of Limestone Processed? Shanghai Clirik Mine Mill

.jpg)

Calcium Carbonate Grinding Mill

Carbonation method calcining the raw materials such as limestone to generate lime (ingredient for calcium oxide) and carbon dioxide; then adding water to digest lime to generate lime milk (ingredient for calcium hydroxide)and then passing into the carbon dioxide carbide lime milk for calcium carbonate precipitation; lastly, the calcium carbonate precipitation by dehydration, 2021年9月1日 China produced 2792 million tons of calcium carbide in 2020, which amounted to 96% of the global capacity (Huo et al, 2022) Approximately 81% calcium carbide is used to produce acetylene as a Life cycle assessment of acetylene production from calcium carbide 2020年1月9日 Purpose The purposes of this study were to quantify the resource consumption intensity of cement clinker production using natural mineral in China and to determine the influence of the utilization of calcium carbide sludge (CCS) for cement clinker production on the resourceaccounting result Methods Exergybased resource accounting method was adopted Exergybased resource consumption analysis of cement clinkerA laboratoryscale spoutfluid bed reactor with a dc plasma torch was used to study the solidphase synthesis of calcium carbide Calcium oxide powder with a mean particle size of 170 μm was reacted with graphite powder (130 μm) Argon was used to initiate the plasma and hydrogen gas was then added to increase power and raise the plasma jet enthalpy Experimental results SolidPhase Synthesis of Calcium Carbide in a Plasma Reactor

.jpg)

Raymond Grinding Precipitated Calcium Carbonate

The Hotsale Models and Capacity 3r2115, 4r3016, 5r4128 are the popular models we recommend to our customers The output size of the final product can be 075mm (80mesh) to 0045mm (325mesh)2020年6月5日 Limestone calcined clay cements (LC3) are blended cements that combine clinker, limestone, calcined clay and gypsum The availability of the materials required to produce LC3 and the good Limestone calcined clay cements (LC3): raw material processing, 2020年9月1日 Calcium carbide can be obtained by cyclic technology using lime (calcium carbonate and calcium oxide) and various sources constructing closed carbonneutral cycles is provided by atomeconomical Calcium Carbide: Versatile Synthetic Applications, Green Methodology The results show that the main component of calcium carbide slag is calcium hydroxide, and the particle size is concentrated below 75 μm The morphology of the slag is polyhedral and loose sheetlike The residual amount of calcium carbide in the slag fluctuates from 0 to 071%Properties analysis of dryprocess calcium carbide slag and study

Emission Factor Documentation for AP42 Calcium Carbide

1 megagram (2,205 lb) of calcium carbide Calcium carbide is used primarily in generating acetylene and desulfurizing iron The Standard Industrial Classification (SIC) code for calcium carbide manufacturing is 2819, industrial inorganic chemicals, not elsewhere classified The sixdigit Source Classification Code (SCC) for calcium carbide2022年5月1日 Request PDF Recycling and utilization of calcium carbide slag current status and new opportunities Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride Recycling and utilization of calcium carbide slag ResearchGate2013年4月1日 Every year, large amount of lime mud is produced in China About 05 ton LM is obtained when 1 ton of pulp is produced in a paper millAbout 10 million tons LM is produced in 2011 in China and the production amount is increasing with the expanded need for papersUntil now, most of LM cannot be reused and the main disposal is landfill, resulting in land Utilization of lime mud from paper mill as CO2 sorbent in calcium 2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Limestone Grinding Mill That You Need To Know Mortar Plant

Limestone Ultrafine Grinding Mill

Features: The limestone ultrafine grinding mill is a piece of energysaving and consumptionreducing equipment for processing limestone ultrafine powder Small footprint, strong complete set, wide application, simple operation, convenient maintenance, stable performance, highcost performance, it is an economical and practical ultrafine powder processing equipment