Heavy calcium carbonate synthetic mica production line

Synthesis of precipitated calcium carbonate: a review

Papers are generally made of cellulosic pulp fibers, a derivative of renewable natural bioresources comprising wood and nonwood lignocellulosic constituents In the production of paper grades such as papers for printing and writing, fillers are commonly the second most essential piece of the paper stock provided 展开2017年1月1日 The method (solubilization) involved heavy dilution of the slurry at 0 o C, and reaction of the solution with carbon dioxide to produce calcium carbonate, the precipitated product isPrecipitated Calcium carbonate production, synthesis 2020年10月1日 In this work, the precipitation of highquality calcium carbonate (PCC) from synthetic Carich solutions was investigated A mixture of Ca and Mg salts were considered to Production of calcium carbonate with different morphology by 2016年10月1日 The mineralization of calcium carbonate on the bare mica surface and on the mica supported EPS obtained from Rhodococcus opacus bacterial strain was investigated It Calcium carbonate formation on mica supported extracellular

SYNTHETIC MICA TECHNOLOGY

• Production of raw synthetic mica and finished effect pigments in one plant • Standard global distribution via full load sea container transportation Customer impact • Higher valueinuse Calcium carbonate processing plant is a production line that obtaining ground calcium carbonate powder by grinding limestone or marble Usually there are a complete set of machinery Customize Suitable Calcium Carbonate Plant DASWELL2005年11月1日 Integrated pulp and paper mills use carbon dioxide (CO 2) from the lime kiln stack gas to manufacture precipitated calcium carbonate (PCC), which is synthetic calcium Production of precipitated calcium carbonate from calcium 2012年3月28日 Sizecontrolled CaCO 3 particles were obtained using a carbonatecontrolled addition method with a carboxylateterminated hyperbranched poly (amidoamine) (HYPAM Synthesis of calcium carbonate particles with carboxylic

.jpg)

Synthetic calcium carbonate improves the effectiveness of

2019年10月24日 Three synthetized polymorphs of calcium carbonate have been tested in combination with the suspension of nanolime particles as potential consolidating agents for 2021年12月20日 The Importance of Calcium Carbonate Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by Calcium Carbonate Manufacturing Process and Specification: +4 mesh, 4mesh, 200mesh, 325mesh, 600mesh, 800mesh, 1000mesh, 1250mesh or customize Comparative Analysis:Synthetic Mica, Natural Mica Powder, Synthetic Mica 2024年6月25日 IntroductionIn this blog we be exploring the differences between natural mica powder and synthetic mica We will take a look at the problems associated with the production of natural mica powder We will also be Synthetic vs natural mica powder: the differences and

The potential use of green mussel (Perna Viridis) shells for synthetic

2021年8月1日 Although the mineral calcium carbonate has a calcite crystal structure with hydrophobic behavior, the calcium carbonate found in the MS composition has an aragonite crystal structure with 4 Technology Background PCC Production by CO 2 mineralization • Capture CO 2 into stable solid form • Low energy input and can use flue gas asis • Potential to achieve negative lifecycle CO 2 emission Market potential • Fine calcium carbonate (PCC/GCC): $230$400 per ton • Coarse GCC: $60 per ton • Current market size: $59 B per year (additives for Synthetic Calcium Carbonate Production by Carbon Dioxide 2022年5月5日 Recommended calcium carbonate grinding mill Most of the production process of calcium carbonate is inseparable from the milling process Common calcium carbonate powders include 300 mesh, 400 mesh, 600 mesh, 800 mesh, 1200 mesh, 1500 mesh, and 2000 mesh Their uses are more extensiveCalcium Carbonate Grinding Mill Powder Modify SBM Product Information: Name: Synthetic Mica, Fluorphlogopite Mica, Artificial Mica Appearance: High whiteness, purity and transparence Features: Clear Transparent surface; High purity; Lower Iron content; No heavy metal; Heat resistance Acid Alkali Resistance; Resistant to corrosion of noxious gas; Stable performance and good insulation Available sizes: 100 Synthetic Mica, Synthetic Fluorphlogopite, Alternative to Natural Micas

.jpg)

Calcium Carbonate IMA Europe

Almost every product in our daily lives either contains calcium carbonate or has some association with the mineral during its production The Earth’s crust contains more than 4% calcium carbonate As a result, the three calcium carbonate minerals – calcite, aragonite and vaterite – are among the most important rockforming minerals2024年7月12日 Sealants: The products filled with light calcium carbonate have good fluidity and high hardness, while heavy calcium carbonate has slightly lower hardness Papermaking: Light calcium carbonate has more advantages in improving the whiteness of paper, and thermal paper, highend cigarette paper, lightweight paper, etc prefer light calcium carbonateHeavy calcium and light calcium, 10 essential differences2024年5月17日 Application of biological carbonate in wastewater treatment Preparation process of discarded oyster shell calcium carbonate particles and their adsorption curves for heavy metal ions (Lin et al 2020) (a)SEM images and EDS element mapping of Pb fixation by biological calcium carbonate and geological calcium carbonate, as well as schematic diagram of their Application and mechanism of carbonate material in the Heavy calcium carbonate (heavy calcium) is obtained by directly pulverizing natural limestone, calcite, etc by a mechanical method (Raymond mill or the like) Light calcium carbonate (light calcium) is obtained by calcining limestone at calcium carbonate grinding mill, calcium carbonate

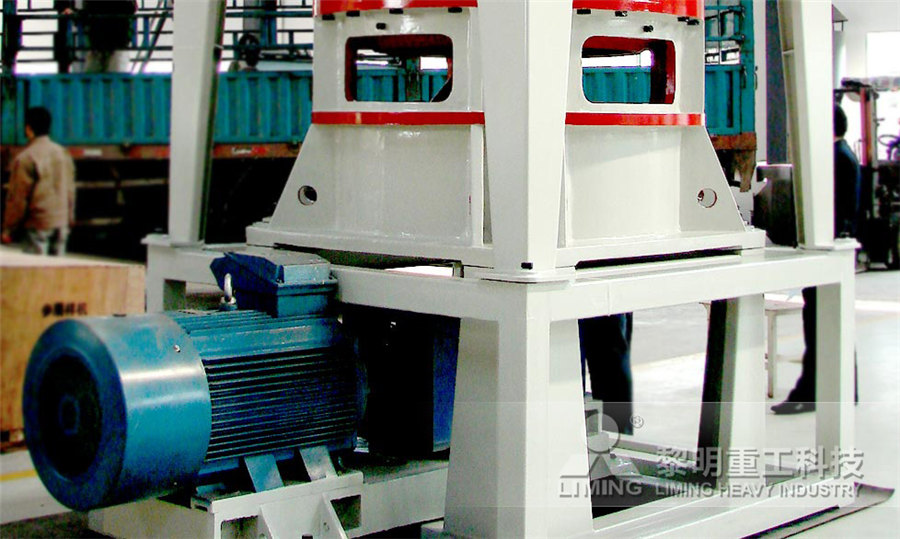

What is the steps in the Calcium Carbonate Liming

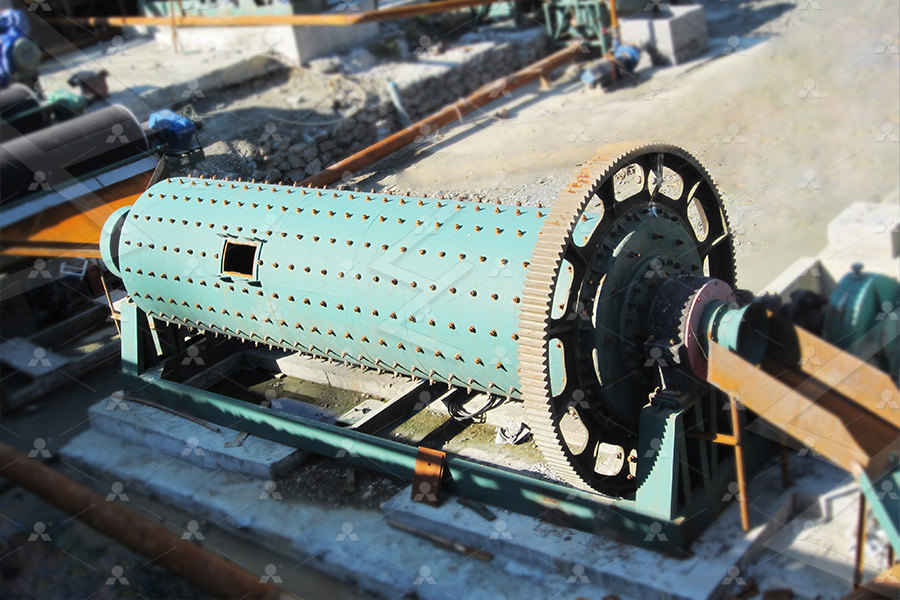

2023年12月7日 Calcium carbonate is used in a wide variety of applications, including papermaking, plastics, paints, and food There are two main types of calcium carbonate: natural and synthetic Natural calcium carbonate is mined 2024年7月10日 Heavy calcium carbonate production process and equipment Taking heavy calcium carbonate for coating industry as an example, The ball mill + classifier production line is mainly used to produce heavy calcium carbonate fine Heavy calcium carbonate grinding, surface modification China Calcium Carbonate Production Line wholesale Calcium Carbonate Powder Modification for Mica Dolomite Pyrophyllite Mineral Phosphorite Marble Powder Production Line US$ 100050000 / set Shanghai DingBo Heavy Industry Machinery Co, Ltd Calcium Carbonate Production Line MadeinChinaThe calcium carbonate ball mill plant has the lowest energy consumption and the best particle size distribution, The scale of the heavy calcium ball mill production line we can design can be as small as 10,000 tons/year and as large as 500,000 tons/yearCalcium Carbonate Ball Mill Plant DASWELL

.jpg)

【Technical analysis】How to choose “industrial monosodium

2020年12月10日 What is the difference between heavy calcium carbonate and light calcium carbonate? a single production line D97: 10 μm can produce tons of products annually, and the power consumption per ton of products can reach 150 degreesSuitable Suitable minerals include talc, graphite, mica, wollastonite, fibrous brucite 2019年9月15日 China Gwell Machinery is a hightech enterprise dedicating to the manufacture of plastic extrusion lines for Film, Sheet and Profile The company has two production bases located in scenic Taicang of Suzhou and Dafeng of Yancheng, very close to Shanghai The two bases cover more than square meters, the total registered capital is 50 million RMB Stone Paper, Synthetic Paper(PE+Calcium Carbonate)Extrusion Line2022年8月22日 Calcium carbonate (CaCO3) is an important inorganic mineral in biological and geological systems Traditionally, it is widely used in plastics, papermaking, ink, building materials, textiles (PDF) Calcium carbonate: controlled synthesis, surface Calcium carbonate ultrafine grinding mill is a kind of high efficiency milling equipment, mainly used to process nonmetallic ores +17 [ protected] The production line can flexibly adjust the output ratio of each finished material according to the market situationCalcium Carbonate Ultrafine Grinding Mill

Role of calcium carbonate in the process of heavy metal

2022年10月21日 The effect of calcium carbonate on the removal efficiency of cations of the selected heavy metals Cu, Zn and Pb from aqueous solutions using various biosorbents (BS) was investigated under Following that, it may come as no surprise that the most popular functional fillers are calcium carbonate, talc, kaolin, mica and glass There are many types of speciality filler available but these common types are a good starting point for Functional Fillers Specialty Minerals for Plastics2023年9月19日 CALCIUM CARBONATE MILLING PROCESS Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill Calcium carbonate milling process SBM Ultrafine 2020年7月30日 The calcium carbonate was synthesized with the temperatures of 65, the production of calcium carbonate [12] the potential for heavy metal concentration is increasing day by day(PDF) Calcium Carbonate Synthesis, Optimization

.jpg)

17 Calcium Carbonate Manufacturers in 2024 Metoree

It is categorized into heavy calcium carbonate (natural) and light calcium carbonate (synthetic or precipitated), each produced through distinct processes Other Information on Calcium Carbonate 1 How Calcium Carbonate Is Produced Production involves 2015年6月25日 This paper describes the status of heavy calcium carbonate industry at home and abroad , reveals the world as well as the development trend of China's heavy calcium carbonate industry Through the demand of downstream industry , pulp and paper industry , coating industry , rubber industry , plastics industry , the heavy calcium carbonate for Present Situation and Development Trend of Heavy Calcium Carbonate EPIC Powder Machinery is a highquality calcium carbonate production line manufacturer in China with more than 20 years of experience Skip to content Products Menu Toggle Ultrafine powder grinding Menu Toggle High quality calcium carbonate production linemanufacturer in China Providing with green, highvalue calcium carbonate ultrafine Calcium Carbonate Powder Production Line ManufacturerCalcium Carbonate, Heavy Unleash the potential of your pharmaceutical formulations with the heavy pharmaceuticalgrade purity of Calcium Carbonate from Dr Paul Lohmann GmbH Co KGaA Meticulously crafted to exceed industry standards, this excipient undergoes rigorous quality control testing, ensuring steadfast consistency and full compliance with pharmaceutical Calcium Carbonate Pharma Excipients

.jpg)

Analyzation of Calcium Carbonate (CaCO3) in Eggshells and

Download Citation On Jan 1, 2020, Mr Suraj Kolekar and others published Analyzation of Calcium Carbonate (CaCO3) in Eggshells and their Applications Find, read and cite all the research you 2024年5月24日 The new technology of microbially induced calcium carbonate precipitation (MICP) has been applied in construction materials as a strategy to enhance their properties In pursuit of solutions that are more localized and tailored to the study’s target, this work focused on isolating and selecting bacteria capable of producing CaCO3 for posterior application in Comparison of calcium carbonate production by bacterial 2020年10月1日 Aqueoussoluble aminebased organic solvents for CO 2 absorption enable highly efficient removal of CO 2 from flue gases in a process better known as amine scrubbing for CO 2 capture [32]The amine is regenerated by stripping with water vapour at temperatures between 100−120 °C, and the water is condensed from the vapour, leaving pure CO 2 for Production of calcium carbonate with different morphology by USB2 US14/412,514 US4A USB2 US B2 US B2 US B2 US 4 A US4 A US 4A US B2 US B2 US B2 Authority US United States Prior art keywords calcium carbonate heavy calcium treated resin measured Prior art date Legal status (The legal status USB2 Heavy calcium carbonate, production method therefor

.jpg)

Calcium Carbonate Fillers SpringerLink

2017年3月1日 Calcium carbonate fillers have ideal properties for many polymer applications and the world consumption is over ten million tonnes annually Both natural (ground (natural) calcium carbonates, GCC) and synthetic forms are in use and can be derived from abundant and widely occurring natural depositsCharacteristics and application of heavy calcium carbonate Heavy calcium carbonate, referred to as heavy calcium, is a white powder made from highquality calcite Its main component is CaCO3, which is insoluble in water and ethanol It has the characteristics of high whiteness, good purity, soft color and stable chemical compositionThe Difference between Heavy and Light Calcium Carbonate2022年6月27日 Installation site of heavy calcium carbonate grinding powder production line with an annual output of 200,000 tonsIn the whole ultrafine calcium carbonate prHeavy calcium carbonate grinding powder production line with 2016年8月1日 Mineral carbonation can contribute to climate change mitigation through the production of synthetic limestone (CaCO3) from calcium silicate minerals and gaseous CO2Production of carbon negative precipitated calcium carbonate from

.jpg)

(PDF) Fillers for Papermaking: A Review of their Properties, Usage

2016年2月2日 All content in this area was uploaded by Martin Hubbe on May 06, 年6月1日 An increase in nucleation rate was observed just for ordinary water but not for heavy water (Madsen, 2004) and carbonates and phosphates with diamagnetic metal ions (Madsen, 1995 (Madsen, , 2004 Crystallization of calcium carbonate in magnetic field in ordinary D97: 10μm calcium carbonate powder production line The calcium carbonate powder production line is also known as calcium carbonate processing or grinding plant It is a production line Factories make ground calcium carbonate powder there The customer is a wellknown ore processing company based in Serbia They are seeking a new coating processCalcium carbonate production line EPIC PowderCalcium carbonate is a versatile material used in applications covering fuels, agriculture, pharmaceuticals, and printing materials The two methods of production are ground calcium carbonate (GCC) – where chalk,limestone, and dolomite are ground to the desired particle size – and precipitated calcium carbonate (PCC),where calcinated limestone is recarbonized with Using online particle size analysis to improve precipitated calcium

Calcium Carbonate Manufacturer, Calcium Carbonate Granules,

2015年6月29日 Our company uses the international advanced technology and production equipment, highquality limestone and big calcite as raw materials to produce the highquality of calcium carbonate products, the main products are Nano (active) calcium carbonate, light (active) calcium carbonate, light (ultra fine )calcium carbonate, heavy (superfine) calcium carbonate,