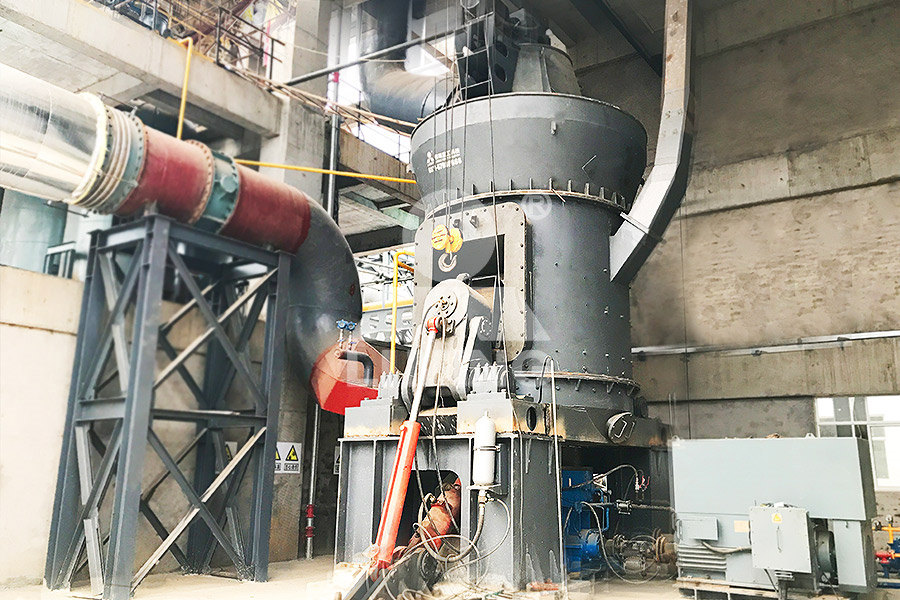

Hydraulic raw coal vertical mill fly ash machine output 2000TH

.jpg)

Vertical Coal Mill YingYong Machinery

Our coal vertical mill utilizes advanced dynamic and static separators for efficient particle separation during coal grinding The advanced control system and grinding structure precisely control key parameters, ensuring the desired Process introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the COAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd2020年8月12日 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources Obtained results indicate An investigation of performance characteristics and energetic Hydraulic grinding roller swingingout device for easier and quicker changing of grinding components Constant product quality in compliance with specification achieved through static LOESCHEMILLS

Grinding Fly Ash Process and Equipment with Vertical Milling

PDF On Jan 1, 2015, Rui fang Li and others published Grinding Fly Ash Process and Equipment with Vertical Milling Machine Find, read and cite all the research you need on ResearchGateVertical Coal Mill is specially used for ultrafine grinding of raw coal and bituminous coal materials in cement, power plants, iron and steel plants and other fields The GRMC coal vertical mill coal grinding machine CHAENGThe MPS ZGM coal mill is a type of coal mill that operates at a speed of 50300r/min This equipment is used to prepare and process auxiliary materials for blast furnace ironmaking It MPS ZGM Coal MillGrinding Equipment YingYong Machinery2023年4月10日 Coal fly ash (CFA) as a coal combustion residue of thermal power plants has been regarded as a problematic solid waste all over the world (Yu et al 2022) CFA utilization Valorization of coal fly ash (CFA): a multiindustry review

.jpg)

An investigation of performance characteristics and energetic

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical Process introduction Vertical coal mill, also known as vertical roller coal mill or vertical coal grinding mill, is a mechanical equipment for crushing and grinding coal into coal powerMainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal power plantcoal grinding machine CHAENGManufacturer of Fly Ash Brick Making Machine Automatic Interlocking Cement Brick Making Machine, Fully Automatic Fly Ash Brick Making Machine, MS Fly Ash Paver Brick Making Machine and MS Hydraulic Cement Brick Making Fly Ash Brick Making Machine Automatic VRM has been widely researched in processing of cement (Ito et al 1997;Jorgensen 2005;Wang et al 2009, Ghalandari et al 2021), coal (Tontu 2020), iron ore (Reichert et al 2015), zinc ore (van The layout of the coal mill with a rotary classifier

(PDF) Industrial Palm Oil Mill Ashes and Coal Fly Ash as Potent

2021年12月1日 retained fly ash, palm oil mill collector fly ash, and coal fly ash) were fixed at 600 and 815°C, according to ASTM E175501 [33] standard as reported by [34] In line with previous literature 2020年6月26日 Compacted fly ash from combustion of bituminous coal in conventional furnaces, despite its macroscopic similarity to noncohesive soils, should always be evaluated taking into account moisture (PDF) Hydraulic conductivity of fly ash as a barrier material: some Fly Ash Processing Plant; VSK Cement Plant; Automatic Cement Storage System; Output: 55250 t/h Power: 12505300kW Highlights: fully automatic, high efficiency, as a cement equipment manufacturer in China, offers different types of vertical mills like coal vertical mills, raw material vertical mills, cement vertical mills, and slag Cement Vertical Mill Vertical Grinding Mill Vertical MillManufacturer of Fly Ash Brick Making Machine FLYASH BRICKS MAKING MACHINE, Fully Automatic Fly Ash Machine, Fly Ash Brick: 08: Shape: vertical: Surface Finishing: 05 Acer: Cycle Hour: 15 seconds Brick Raw Material: Concrete: Method: Hydraulic Pressure: Tolerance: 1 mm: Country of Origin: Made in India:Fly Ash Brick Making Machine FLYASH BRICKS MAKING MACHINE

(PDF) EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill)

1999年4月18日 Recycling fly ash is a good example of valorization of waste It gives a solution the environmental problem by avoiding land filling, and reducing CO2 emission in the atmosphere2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic 2021年1月29日 FlyAsh Blaine: Increase fly Ash Blaine from 290 to 320 Flyash is a major supply for any cement plant now a days because every producer wants to produce more PPC than OPC due to profitability Increase productivity of vertical roller mill using seven QC toolsThe equipment uses moderate squeezing pressure and medium roller surface line speed to achieve extrusion and grinding of materials This avoids the process problems that exist in vertical mills and roller presses The Horomill is suitable Vertical Roller Mill Horomill YingYong Machinery

Sustainable Utilization of Anthropogenic Coal Fly Ash Through

2023年10月28日 Anthropogenic coal fly ash (CFA) ASTM C 61800 (2000) Standard specification for coal fly ash and raw or calcined natural pozzolan for use as a mineral admixture in concrete Bilodeau A, Malhotra V (2000) Highvolume fly ash system: concrete solution for sustainable development ACI Mater J 97:41–482014年4月1日 For decades vertical roller mills have been in use in the cement industry for the grinding of cement raw material and coal Since the 1980's this mill type has also been used for combined or (PDF) The latest innovative technology for vertical roller mills The MPS ZGM coal mill is a type of coal mill that operates at a speed of 50300r/min This equipment is used to prepare and process auxiliary materials for blast furnace ironmaking It provides suitable coal powder for the blast furnace ironmaking systemMPS ZGM Coal MillGrinding Equipment YingYong Machinery2017年5月10日 An experimental apparatus (as shown in Fig 1) is designed and fabricated to investigate the behavior of CGFB during its curing under pressureA transparent acrylic column (Fig 2) that is 150 cm in internal diameter, 160 cm in external diameter and 230 cm in height is used to place the freshly prepared CGFB sample, and the acrylic column is inserted into a Thermal, hydraulic and mechanical performances of cemented coal

.jpg)

Vertical Raw Mill ball mills supplier

Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric Output: Our fly ash brickmaking machines capable of producing a large number of bricks in a short time Consistency: Our fly ash brickmaking machines made the bricks’ size and quality constancy Ease of Use: Our fly ash brickmaking machines have a userfriendly interface for easy operation for everyoneFly Ash Brick Making Machine btmproductFind here Fly Ash Brick Making Machine, Fly Ash Brick Press Machine manufacturers, Automatic Hydraulic Fly Ash Brick Machine ₹ 21,00,000 Get Quote Watch Video Automatic 6kvt Fly Ash Brick Making Machine, 2000 Bricks per Hour ₹ 14,50,000 Get Latest Price Brick Type Solid Method Autoclave Aerated I Deal In New OnlyFly Ash Brick Making Machine Fly Ash Brick Press Machine Grinding Rollers: Grinding roller is the main part for crushing and grinding materials The grinding roller is composed of cast steel roller sleeve, forging shaft and wearresistant surfacing bushing The grinding roller is installed on the rocker arm of the coal vertical roller mill, under the action of external force, it is pressed tightly on the material of the grinding table, as the Coal vertical roller millVertical roller millPRODUCTTongli

HP Vertical Mill Revolutionizing Efficiency and Performance

Fly Ash Ball Mill; Rod Mill; Rod Charger; Xray Intelligent Ore Sorter; Capacity:3171197 T/H Material: The coal vertical mill can be used for grinding bituminous coal, anthracite, lignite, petroleum coke, This improvement significantly reduces the circulation rate of pulverized coal, increases the mill's output, 2023年6月7日 Hydraulic liners are used to restrict hazardous leachates such as acid mine drainage (AMD) from entering the hydrogeological system In this study, we hypothesized that: (1) a compacted mix ratio of natural clay and coal fly ash with a hydraulic conductivity of at most 1 × 10− 8 ms− 1 can be achieved, and (2) mixing clay and coal fly ash in the right proportion can A claycoal fly ash based dual hydraulicreactive liner for Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBMSINOMAFly Ash Processing Process There are different equipment configurations and processes for grinding fly ash On the market, ultra fine ball mill grinding, Raymond mill grinding, and vertical roller mill grinding all exist SINOMA Fly Ash Processing Plant Superfine Final Product

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVRee2015年4月1日 China has ranked first in the coal fly ash emission in the world The multipurpose use of the fly ash from power plant waste is always an important topic for the Chinese environmental protection, which has drawn the concern of the government, scientific research departments, manufacturing enterprises and industry experts This paper introduces an New technology and application of brick making with coal fly ashUnderstanding Vertical Roller Mill Technology Vertical roller mill (VRM) is a type of grinding machine used to grind materials into extremely fine powder, commonly used in the cement industry VRMs are also used in the power generation and steel industries, among othersApplication of Vertical Roller Mill in Cement Production

CFB石灰石脱硫剂制备96.jpg)

Vertical roller mill, Vertical roller grinding mill All industrial

Output: 4 t/h 300 t/h Process introduction The GRMR raw material vertical mill of CHAENG is a kind of new high efficiency, coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type Since the first application using an MPS mill to process pulverized coal in Germany in the mid 1960s, there have been over 2,000 different MPS mill installations operating in coalfired power plants worldwide As one of the most popular coal pulverizers in the utility industry, the MPS mill was first introduced into the US in the early 1970sT186kmk071304qxp Steam Forum7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single millPFEIFFER MILLS FOR THE CEMENT INDUSTRYLM VERTICAL MI Raw materials: The product is also unique in the segmentation of the industry, building for the exclusive market It is dedicated to power plant, steel plant and coal injection boiler industry, exclusive in non metallic mineral powder grinding and the LM VERTICAL MIVipeak Heavy Industry Machinery Group

Conversion of Landfilled Ash into Hydraulic Cements under

activated coal ash It has been observed that grinding of landfilled coal fly ash improves the uniaxial compressive strength of alkaliactivated fly ash from 201 MPa (raw fly ash) to 22 MPa (activated fly ash) [8] Another investigation demonstrated that, after mechanical activation of coal fly ash, NaOHactivated ash could produce a viable Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and Vertical roller mills FLSmidth Cementretained fly ash, palm oil mill collector fly ash, and coal fly ash) were fixed at 600 and 815°C, according to ASTM E175501 [33] standard as reported by [34] In line with previous literature Industrial Palm Oil Mill Ashes and Coal Fly Ash as Potent 2017年3月1日 The substitution of coal by biomass as fuel causes the generation of other biomass ash whose use has also been studied in the manufacture of ceramic clay bricks as rice husk ash [21][22][23 Thermal, hydraulic and mechanical performances of cemented coal

Fly Ash Brick Making Machine from Top Manufacturers in India

2 天之前 Types of fly ash brick making machine Here are the top 5 types of fly ash brick making machines used in construction industry: 1 Hydraulic Manual Fly Ask Brick Machine This is a semiautomatic Machine that can be handled manually Because it relies solely on human muscle power, this model is the least expensive optionAir Swept Coal Mill Working Principle First, the raw coal is fed into the feed chute by the feeding device Then, the hot air with a temperature of about 300 ℃ enters through the air intake pipe and begins to dry the raw coal while they are falling After Air Swept Coal Mill Coal Mill In Cement Plant AGICO GROUPFly Ash Ball Mill ; Lattice Type Ball Mill ; Overflow Ball (mm), and the matching motor power is 45570KW, which can meet 14 16 t/h pulverized coal production Widely used in the preparation of coal powder in electric The airswept ball mill has a similar structure to the ordinary mill, but the input size and the output size are Air Swept Coal Mill Cement Plant Equipment Coal Grinding Mill2017年2月1日 Lime and fly ash treated expansive soil exhibit high hydraulic conductivity (15 × 10 6 and 31 × 10 8 m/s, respectively) This behavior is hypothesized to be due to agglomeration of particles Hydraulic Conductivity of Fly AshAmended Mine Tailings

.jpg)

LM Vertical Grinding Mill SBM Mill Crusher

2023年3月15日 Based on the absorption of advanced technologies of famous international corporations and 30 years’ experience in grinding mill production, SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, grinding, powder selection, drying and material conveying