Vertical mill lifting roller and falling roller Principle

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the 2015年3月25日 The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sides of Hydraulic system vertical roller mill operation PDFVertical roller mills are traditionally airswept mills A VRM applies a compressive force using fixed rollers pressing downwards on a rotating grinding table The material to be ground is fed into Vertical Roller Mills used for the comminution of mineral oresa vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

Roller Mill Springer

The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL 2017年4月1日 In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The Operational parameters affecting the vertical roller mill Mills in which the grinding bodies roll on flat, cylindrical, bowlshaped, or conical horizontal or vertical grinding tracks, thereby reducing the material that enters between the grinding track Multiphysics Simulation of a Vertical Roller Mill in Matlab

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE

2019年4月16日 The paper demonstrates why the Loesche VerticalRollerMill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system are VRM's are statePart 1: Structure of Vertical Roller Mill (VRM) Crusher shell: Covers the internal parts of the crusher and creates a crushing cavity The crusher shell is composed of a cylindrical part and a conical part The upper part of the crusher shell is fitted with a separator motor and an exhaust pipe that brings the crushed product to the sump (cyclone) to recover the crushed productOPERATION OF VERTICAL ROLLER MILL (VRM) NATIONAL Atox Vertical Roller Mill, Maintenance and Repair Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses maintenance and repair of an ATOX Vertical Atox Vertical Roller Mill, Maintenance and Repair2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill

.jpg)

Introduction To Vertical Roller Mill PDF Mill (Grinding

Introduction to vertical roller mill Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online This document provides an introduction to vertical roller mills and their production optimization It discusses key aspects of vertical roller mills including their components, operation, controls, maintenance, and The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersAnalysis and Optimization of Grinding Performance of Vertical Roller Raymond Mill Working Principle In the Raymond mill, a Raymond mill spring with a pressure of 10001500 kg is fastened to the grinding roll hanger After starting work, the grinding roller rotates around the main shaft and rolls close to the grinding ring under the action of the Raymond mill spring and centrifugal forceRaymond Roller Grinding Mill Vertical Roller Grinding Mill

Bulgur milling using roller, double disc and vertical disc mills

2007年3月1日 Due to the vertical working principle of vertical disc mill, the vertical disc milled bulgur was more elliptical than the roller milled bulgur; however it was less elliptical than the double disc milled bulgur (Fig 5)The vertical position also decreased the deformation of the bulgur particle surface due to short resistance time in the grinding zone, therefore good Understanding Vertical Roller Mill Technology Vertical roller mill (VRM) is a type of grinding machine used to grind materials into extremely fine powder, commonly used in the cement industry VRMs are also used in the power generation and steel industries, among othersApplication of Vertical Roller Mill in Cement ProductionFig 2 Modular Vertical Roller Mill 5000 R4 Installed in Canada Fig 3 Modular Vertical Roller Mill 5000 R4 Installed in Canada V Operational Experience with Modular Vertical Roller MillsGrinding Process Optimization Featuring Case Studies and 2023年12月4日 When higher rolling resistance is applied due to particle shape complexity at less mill speed, more vertical force is exerted on the roller, and the roller speed is insensitive to rolling resistance This study provides the basis for further experimental investigations on industrialscale VRM and supports the design optimization of the VRMNumerical Investigation of Vertical Roller Mill Operation Using

.jpg)

04 Vertical Roller Mills PDF Mill (Grinding) Turbine

The document discusses vertical roller mills (VRM) which are used to grind raw meal in the cement production process It describes the three main sections of a VRM as the feeding, grinding, and discharge sections Key components of a Compared with the ball mill system, the energy consumption of the vertical mill system can be reduced by 30% to 40% The vertical grinding mill does not have the metal impact sound of the steel balls colliding with each other and the liner in the ball mill, so the noise is low, which is 2025dB lower than that of the ball millIndustrial Vertical Grinding Mill2 With the function of automatic lifting and falling , can realize noload starting 3 Welded type arc plate is used for sealing, it features simple structure, reliable performance, wellsealed structure 4 By means of the roller swingout device, the grinding rollers can be turned out of the mill, which is in favor of maintenance 5Vertical Roller Mill,Vertical Roller Mill of features,Vertical Roller mill is used instead of the former system with two vertical roller mills operating in parallel Based on these investigations Loesche GmbH has developed a mill for producing raw meal that has an arrangement of six rollers on the grinding table This mill, designated the Redundancy and interchangeability – large vertical roller mills

.jpg)

Vertical Roller Mill Operation in Cement Plant

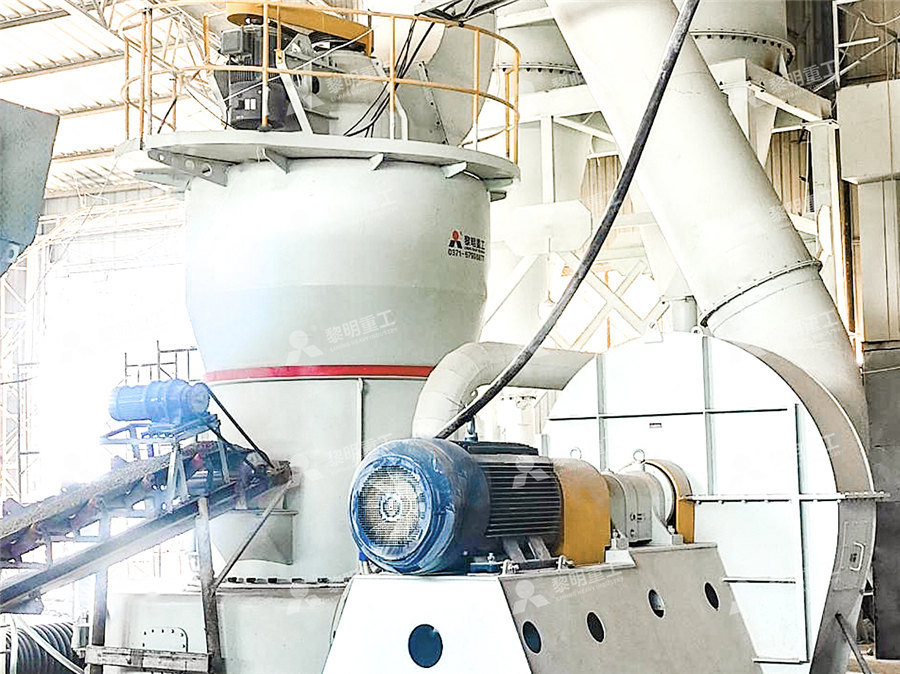

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinderrollermill,highpressurerollermill,Raymond mill, and column mill Vertical Roller MillRoller Mill SpringerBrief description of vertical roller mill operation: The most basic reason why vertical roller mill is widely used is that it has low power consumption, and several units are operated in one machine, and it exhibits excellent operational flexibility and can produce various kinds of The different highquality products are now briefly described as follows:Vertical roller mill Hengtu MachineryVertical Roller Mill 1 Rotary Lock 2 Separator 3 Chute 4 Roller 5 Swing Lever 6 Table 7 Gas Inlet Duct 8 Gear Reducer 9 Motor UM Series A B H Five Roller Roller Arrangement Four Roller UMseries Raw Mill Models with details of structural dimension, productVERTICAL ROLLER MILLS AMCL

.jpg)

Vertical Roller Mill Magotteaux

Vertical roller mills have numerous applications in many different industriesAlthough they are widely used in the cement sector, for example, you are just as likely to find a vertical roller mill being used to handle ores in mining processing plantsThere again, vertical roller mills also have uses within the context of power stations where they are primarily used to pulverize coalVertical Roller Mill Working Principle and sent to the finished product warehouse by the lifting system or the pneumatic conveying system MORE>> Ring roller mill: 2um content is about 20% or more, the highest fineness is 8 CLUM Ultrafine Vertical Grinding Mill2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and CLUM series ultrafine vertical roller millwas produced by Shanghai Clirik Machinery Co, Ltd Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill technologies The top technical team members were joined this project Besides, highquality wearresistant parts are used to develop milling equipment which Ultra fine vertical roller millUltra Fine Millultramillindustrial

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

the capacity of grinding and drying of mill The grindability affects the capacity of grinding, type of mill and roller pressure The capacity of the mill is calculated Using G K * D 251 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table diameter 2 PROCESS CONTROL OF VRM The conventional control system of VRMOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeVertical roller mills FLSmidth Cement2024年8月7日 The development of innovative products increasingly requires interdisciplinary collaboration among the fields of mechanical engineering, electrical/electronic engineering, and software The growing complexity of products, driven by increased automation, poses significant challenges Many equipment manufacturers optimise their development processes using Multiphysics Simulation of a Vertical Roller Mill in The ultrafine vertical mill is currently the superlarge ultrafine grinding equipment in Asia, which has been successfully applied in the market and has mature technology It can replace imported equipment and is an ideal equipment for largescale production of ultrafine powder with high efficiency, high yield, environmental protection and energy savingTable Roller Mill Vertical Mill

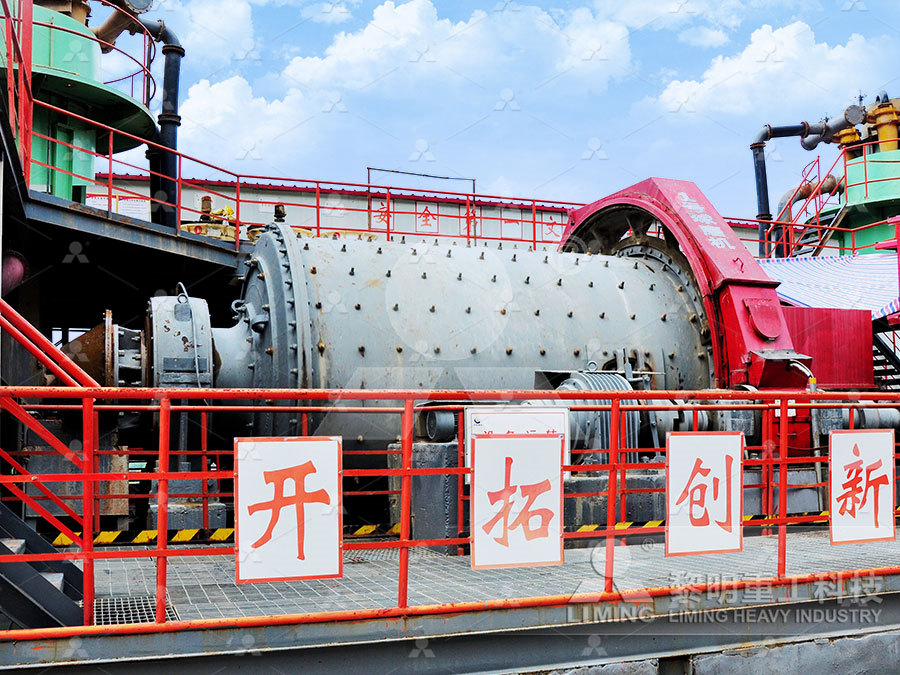

A Comparative Analysis: Vertical Roller Mill Vs Ball Mill

2023年9月21日 This article aims to compare and contrast the key aspects of vertical roller mill and ball mill, highlighting pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: the size The hydraulic system enables the adjustment of grinding pressure and the lifting of the 2022年10月1日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the (PDF) A cement Vertical Roller Mill modeling based on2024年1月1日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinder roller mill, high pressure roller mill, Raymond mill, and column millRoller Mill SpringerLink2023年11月16日 Company Introduction: CNBM Hefei Zhongya Building Material Equipment Co, Ltd is a technologyoriented enterprise with the integration of research development, engineering design, equipment manufacture and Vertical Roller Mill Vertical Roller Mill and Vertical

Usage and maintenance of vertical roller mill PDF

2014年8月25日 1 Usage and Maintenance of vertical roller mill Zenith vertical roller mill is totally different from the common hammer crusher, cone crusher and roller crusher in structure and working principle And it is also quite different 2019年3月3日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the Modeling and simulation of vertical roller mill using population This vertical mill machine is applied in electric power, metallurgy, chemical and nonmetallic industries, such as portland cement and blended cements, limestone, slag, manganese, gypsum, coal, barite, calcite etc HLM vertical grinding mill has proven to be a versatile grinding tool that exhibits many advantages over traditional ball milling, it is also faster to install than a traditional Best HLM Vertical Roller Mill Manufacturer and FactoryThis document provides an introduction to vertical roller mills for production optimization It discusses key aspects of vertical roller mills including: Vertical roller mills grind materials into an extremely fine powder as an energy efficient alternative to ball mills The vertical roller mill uses compression and shear force from multiple rollers to grind material on a rotating grinding Introduction To Vertical Roller Mill PDF Mill (Grinding Scribd

.jpg)

Analysis of vertical roller mill performance with changes in

2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical Compression crushing is also the main crushing mechanism in the VRM, but there is also shear force between grinding roller and particles2012年12月31日 recent years, the vertical roller mill has been wi dely utilized in the world It has lots of merits like drying high efficiency, lower noise, larger feed size, Design and Realization Of Roller Mill Control SystemPDF On May 1, 2017, Caroline Woywadt published Grinding process optimization — Featuring case studies and operating results of the modular vertical roller mill Find, read and cite all the (PDF) Grinding process optimization — Featuring case studies and Vertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementVertical Roller Mill Summary