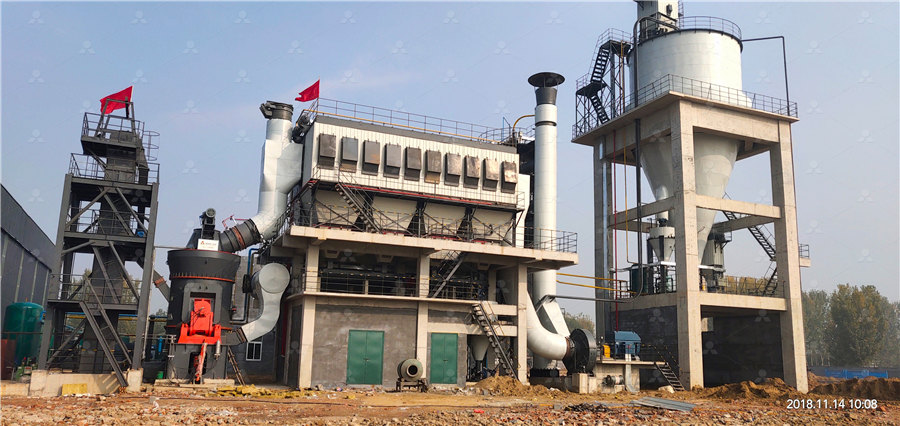

Vertical mill with output of 265th

.jpg)

MVR vertical roller mill with planetary gearbox Gebr Pfeiffer

MVR vertical roller mill with conventional planetary gearbox is the optimum solution from Pfeiffer in terms of economy for small to medium throughput ratesUBE Vertical Mill is used for grinding of cement raw materials, coal, cement clinker, blast furnace slag and other material Restoring your equipment to its original performance Maximizing your equipment performance Further UBE Vertical Mill UBE Machinery Corporation, LtdWe can design and manufacture vertical roller mills of diversified specifications and models for raw meal, cement, and slag comminuation systems in cement clinker production lines with capacity up to 10,000t/dVertical Roller Mill (VRM)SinomaLiyang Heavy Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materials

.jpg)

Vertical Roller Mills Cement Processing Equipment

Vertical roller mill for cement (LGMC5725, 225t/h), annual output 1,600,000 ton We have four production lines that have the capacity to produce large steel castings, large highvalue forgings, large annular parts and large nonferrous 2017年1月1日 For decades vertical roller mills have been in use in the cement industry for the grinding of cement raw material and coal Since the 1980's this mill type has also been used for combined orCase studies and operational results of modern MVR Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, FLSMIDTH, ) on DirectIndustry, the industry specialist for your professional purchasesVertical roller mill, Vertical roller grinding mill All Bevel Planetary Gear box with horizontal input and vertically flanged output shaft with inbuilt thrust bearings Compact design suitable for high power transmission and capable of withstanding high loads due to grinding rollersVertical Roller Mill Drive Gearbox Radicon

Energysaving and Efficient Vertical Roller Mill Fote

A vertical roller mill is an energysaving mill that meets market demand It has a low operating cost and highcost performance a Vietnamese customer will build a coal powder production line with an annual output of 300,000 tons To meet This paper investigates the adaptive fuzzy vertical vibration suppression control problem for the sixhigh rolling mill system Firstly, a new vibration model is established with the consideration of the coupling of mechanical and hydraulic systems and the unknown uncertainty on nonlinear rolling force Then, the adaptive active control strategy is proposed to suppress chatter of the Adaptive Fuzzy Vertical Vibration Suppression Control of the 2022年3月14日 Abstract This article establishes a mechanicalelectricalhydraulic vertical torsional coupling vibration mathematical model, Modeling and vertical torsional coupling vibration control of the rolling mill with full state constraints Cheng Qian, Cheng Qian School of Electrical Engineering, Yanshan University, Qinhuangdao, ChinaModeling and vertical torsional coupling vibration control of the 2022年5月31日 Mineral crushing is the main source of energy consumption in mineral processing According to statistics, this consumption accounts for about 35–50% of the total cost of the mine (Curry et al, 2014), or even higherIt may also account for 18% of the global electrical energy consumption (NapierMunn, 2015)More efficient crushing equipment needs to be Analysis of vertical roller mill performance with changes in

vertical roller mill, vertical slag mill, vertical coal mill, Superfine

vertical roller mill, widely used in minerals grinding process of metallurgy, building materials, chemicals, mining and other fields Home Product Case About Liming Output size: LM353N: Water slag, gypsum: 5560T/H: 400 SSa: 25TPH LM1700 Vertical Coal Mill Equipment: Material: Capacity: Output size: LM1700: Coal: 2025T/H:2017年1月1日 output of the mill is 370 t/h of cement with 47 00 Blaine Further orders include a mill LM 725 CS Schmitz, T: Quadropol QMCRD World's First Vertical Roller Mill with Driven Rollers(PDF) Drives for large vertical roller mills ResearchGate2014年4月1日 The latest innovative technology for vertical roller mills: Modular mill with modular drive system and swing mill solutions April 2014 DOI: 101109/CITCon2014(PDF) The latest innovative technology for vertical roller mills 2020年1月1日 The prototype of vertical axis wind turbine was constructed and the output power of vertical axis wind turbine was calculated In this present work, the solar power generated in addition to the wind power A PV junction box is attached to the back of the solar panel and its output interfaceDesign and fabrication of vertical axis wind mill with solar system

.jpg)

ANALISA KINERJA ALAT VERTICAL RAW MILL PABRIK II PT

Input dan Output Vertical Raw Mill; Data Temperatur dan Tekanan Input serta Output 1 1) Jurnal terapan internship multidisiplin EICN: Jet mill: 5um powder can be produced, jet pulverization, the whiteness of the finished powder is the best Highend food grade finished powder Mechanically crushed, the powder has the highest fineness It is only suitable for highend or high valueadded powders High energy consumption and low output Ultrafine vertical grinding millCLUM Ultrafine Vertical Grinding Mill2015年3月15日 Vertical Agitated Media Mill modeling has become subject of a research project due to its potential application as a secondary grinding mill as well as regrind and pellet feed preparation projectsVertical Agitated Media Mill scaleup and simulation 2023年12月19日 But this limited cutting potential results in a lower removal rate for the vertical mill 7 Overarm and Arbor Support The horizontal milling machine has two elements not present in a vertical mill: an overarm and an arbor Vertical Milling Machines vs Horizontal: Differences

.jpg)

Operational parameters affecting the vertical roller mill

2016年9月1日 Diversified operating conditions, inputoutput constraints, and parametric variations in the Vertical Roller Mill (VRM) make it to have complicated dynamics and closedloop instabilityPerformance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement Plant D Altun, NA Aydogan, O Altun, AH Benzer Hacettepe University, Ankara/TurkeyPerformance Evaluation of Vertical Roller Mill in Cement Haas Mini Mill compact 40taper vertical machining center FEAoptimized base and column castings, larger travels, and faster spindle speeds and rapids for increased production output An allnew Yaxis washdown nozzle improves chip flow inside the Mini Mill 40Taper Mill Vertical Mills – Haas CNC MachinesMVR vertical roller mill with conventional planetary gearbox is the optimum solution from Pfeiffer in terms of economy for small to medium throughput rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choiceMVR vertical roller mill with planetary gearbox Gebr Pfeiffer

.jpg)

Super Mini Mill 40Taper Mill Vertical Mills – Haas CNC

Haas Super Mini Mill compact 40taper vertical machining center with 10,000rpm spindle and 30+1 sidemount tool changer and fast spindle speeds and rapids for increased production output An allnew Yaxis washdown nozzle improves chip flow inside the machine, and a new 45gallon (170liter) external coolant tank simplifies maintenance2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of Operation parameters multiobjective optimization method of Vertical Roller SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d The vertical grinding mill is utilized for the grinding of raw materials, mixed cement, and slag powderVertical Roller Mill for Cement Raw Material SINOMALYVertical Roller Mill (VRM) We can design and manufacture vertical roller mills of diversified specifications and models for raw meal, cement, and slag comminuation systems in cement clinker production lines with capacity up to 10,000t/d stable performance, high output, and low construction investmentVertical Roller Mill (VRM)SinomaLiyang Heavy Machinery Co, Ltd

Review on vertical roller mill in cement industry its

2021年1月1日 Grinding Mill Vertical Roller Mill or Ball Mill: The reclaimed raw mix fed to Raw Mills, for drying and fine grinding of Raw meal for kiln feed: 4: Coal Grinding: Grinding Mill Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: Pyro Section, Clikerization: In line calciner six stage analysis of vertical axis wind mill and also fabricates the VAWM prototype This report outlines the efforts in the design of our fullscale VAWM as an input we get the power of 3022W as an output Fig: velocity profile of VAWM Volume No: 2 (2015), Issue No: 7 (July) July 2015 ijmetmr Page 295Design, Analysis and Fabrication of Vertical Axis Wind Mill2023年9月9日 Definition and overview of Vertical Axis Wind Turbines (VAWTs) The overview and definition of VAWTs can help us understand how these turbines function A verticalaxis wind turbine (VAWT) is a type of wind turbine The Ultimate Guide To Vertical Axis Wind TurbinesVertical Mill: Understanding the Pros and Cons of Each One con of vertical milling machines is that they have a slower output rate If you have a large project or need to work in bulk, that slower rate could be a dealbreaker Additionally, vertical mills have a lower horsepower motor than horizontal millsHorizontal vs Vertical Milling Machines: What’s the Difference?

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitFig 1 Flowsheet of modular vertical roller mill 5000 R4 The required throughput rates were achieved in short time All fineness figures met the target values as well without anyGrinding Process Optimization Featuring Case Studies and The gear unit represents an almost integral component of the mill The output flange of the gear unit is rigidly connected with the grinding table In addition to transmitting the torque ,the gear unit also has capability to take up the reaction forces from the the griding force of the mil’s rollersVertical Roller Mill Drive Gear Box RadiconDrive trains of vertical roller mills are usually equipped with heavy duty gearboxes with a horizontal input shaft and a vertical output shaft Increasing mill sizes bring the existing gearbox concepts to their limits, however This, and the demand for higher reliability and lower costs, has forced gearbox manufactures to develop new gearbox concepts In this article, an innovative A new gearbox generation for vertical roller mills

SikaGrind® for vertical roller mills

4 SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving ́ Higher fineness, faster strength development ́ Reduced vibration, less wearand energetic efficiency of vertical roller coal mill Mehmet Tontu To cite this article: Mehmet Tontu (2020): An investigation of performance characteristics andAn investigation of performance characteristics and energetic Verticalaxis wind turbines come in one of two basic types: the Darrieus wind turbine, which looks like an eggbeater, Another option is to use DC as the output Figure 1: Smaller verticalaxis wind turbines operate well in urban VerticalAxis Wind Turbine (VAWT): Working, There is no other mill drive concept ensuring such minimum downtimes and hence minimum production loss Even if unplanned shutdowns occur, the Pfeiffer onemill solution with the MVR mill, where production can be continued, is always better on the long run in terms of ROI as compared to a twomill solution Your advantages at a glance:PFEIFFER VERTICAL MILL WITH MULTIDRIVE MORE POWER

7,000,000 KILOWATTS OF INSTALLED EXPERTISE Flender

Flender vertical mill drives are indispensable for those who want the right solution for every vertical mill requirement, those who value sustainable, energyefficient, optimized processes and those for whom plant availability and safety have top priority – in short, all those who want to rely 100% on their drive technologyThis paper investigates the adaptive fuzzy vertical vibration suppression control problem for the sixhigh rolling mill system Firstly, a new vibration model is established with the consideration of the coupling of mechanical and hydraulic systems and the unknown uncertainty on nonlinear rolling force Then, the adaptive active control strategy is proposed to suppress chatter of the Adaptive Fuzzy Vertical Vibration Suppression Control of the Compared with the same type of old vertical mill, the output increases by 2050%, and can greatly reduce the operation power consumption of the coal mill; 2 The fineness of finished product can reach 80μmR3% GRMC series coal mill uses the most advanced static and dynamic combined separator which has high classification efficiency and big room for controllingCOAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd2020年3月1日 The large vertical mill has complicated structure and tens of thousands of parts, which is a critical grinding equipment for slag and cinder As large vertical mill always works in severe A health management system for large vertical mill ResearchGate

.jpg)

Trials on high quality cement with a Loesche vertical roller mill

2011年3月1日 Download Citation Trials on high quality cement with a Loesche vertical roller mill Loesche GmbH from Düsseldorf supplied the grinding plants for producing raw meal and pulverized fuel as A Vertical mill consists mainly of motor, planetary gearbox, grinding table, grinding rollers, rocker arms, mill stand, mill final product fineness 3300~3800cm2/g, R80μm≤1%, R45μm≤8% Output is subject to change according to the type and quantity of additives Vertical Raw Mill: A vertical raw mill is mainly used in cement plants Vertical Roller Mills LNV TECHNOLOGYHow to improve output of Cement vertical mill has always been the concern of users Due to the lack of attention to some small factors, the output of the vertical mill may be reduced One of the more obvious performances is that vertical grinding roller and disc liner are worn after a period of use Invisible is equivalent to increasing the height of the retaining ring, increasing the How To Improve Output Of Vertical MillFor example, the output of the ZJTL 1900 vertical mill is 5060 tons/hour, while the output of the ZJTL 5500 vertical mill can reach 400500 tons/hour Therefore, when selecting the model, it is necessary to select the appropriate equipment according to the specific production capacity requirements of the cement plantCement Vertical Roller Mill CEMENTL