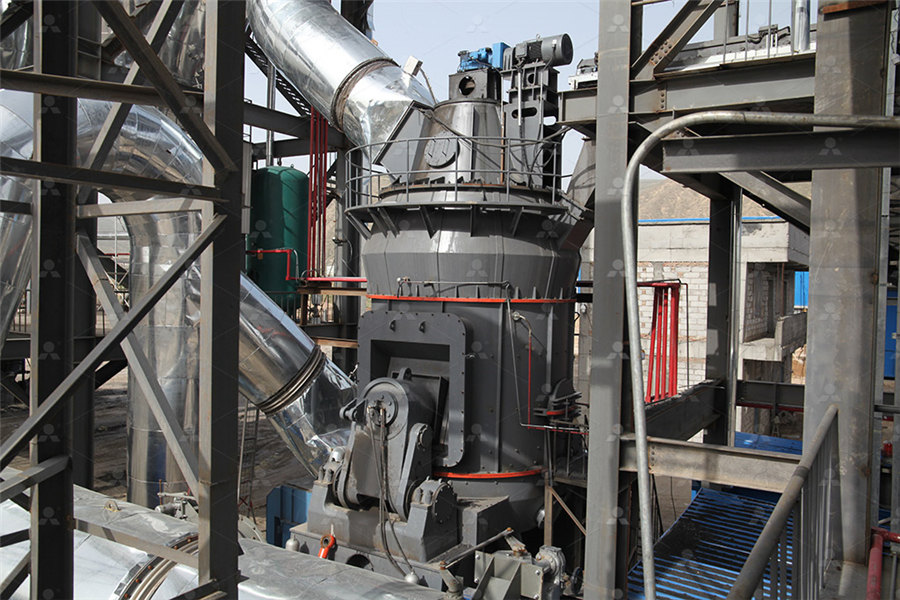

Guangxi Fangchenggang Calcite Pendulum Mill Model Parameters

.jpg)

Advances in Mechanical Engineering 2023, Vol 15(7) 1–14

2022年11月23日 Pendulum mill is a widely used grinding equipment in powder processing industry Less indepth studies have been carried out especially for grinding efficiency and 2023年7月19日 Multiobjective optimization determines a spindle speed of 110 rev/min and a spade angle of −12° at a wind velocity of 46 m/s to achieve maximum grinding efficiency and Research of grinding efficiency and main duct wear of pendulum HC1700 Pendulum Grinding Mill is the first large Raymond mill in China, comparing to the traditional 5R type Raymond mill, the capacity is about 25 ~4 times higher than traditional mill Technical Innovation Calcium Carbonate Pendulum Grinding Mill 2022年1月1日 Various factors affect grindability, which can be generally divided into three main categories such as material properties (mineralogy, physical properties, etc), machine The effects on the grinding parameters of chemical, morphological

The effects on the grinding parameters of chemical, morphological

2022年1月1日 Recently, the kinetic model commonly uses the specific rate of breakage (Si) and the cumulative breakage distribution (Bi,j) functions to explain the grinding behavior of the 2024年4月1日 At the optimal blade parameters of 36°227 mm, the grinding rate is 767%, 8% higher than that of the industrial blade parameter (32°205 mm, 687%) This study provides a Blade parameters optimization of pendulum mill based on discrete 2023年7月19日 Multiobjective optimization determines a spindle speed of 110 rev/min and a spade angle of −12° at a wind velocity of 46 m/s to achieve maximum grinding efficiency and Research of grinding efficiency and main duct wear of pendulum In this study, calcite (CaCO3) samples provided by Micron ’S Company (Ni ğde, Turkey) were used in the grinding tests, and their density was determined by using a helium pycnometer The Influence of Stirred Mill Orientation on Calcite Grinding

An Energy T 75 Size Reduction Model for Ball Mills Springer

2022年12月22日 In this paper, based on the energyparticle size model, quartz and calcite, two materials with distinctly different hardness, were used as test samples in a conical ball mill At 2016年11月22日 The commonly used AE feature parameters for grinding AE are statistic parameters such as number of AE pulses, probability density of pulse amplitude, the peak of Effect of different parameters on grinding efficiency and its 2023年7月19日 vides a digital analysis basis for opt imizing the operating parameters of the pendulum mill Keyw ords Pendulum mill, CFD DEM cosimulation, grin ding efficiency, wear , response surface analysisResearch of grinding efficiency and main duct wear of The HC series large grinding mill is a large Raymond mill, a large pendulum millThe output is 3040% higher than that of traditional Raymond mill It is a product with the advanced technology, it has obtained several patents, Large Raymond Mill Large Pendulum Mill Large

Blade parameters optimization of pendulum mill based on

2024年4月1日 In the grinding process of pendulum mills, blade parameter design significantly influences production efficiency Blades throw the particles to the grinding area for grinding, also the blades design controls the particle movement trajectory By using discrete element analysis software Rocky DEM, the grinding process is simulated in this paper A response surface The HC3000 Super Large Grinding Mill, the largest Pendulum Mill in Asia, Technical Revolution of Pendulum Mill Industry, Upgraded Production of Traditional Raymond Mill Welcome to Guilin HCM Machinery Official WebSite!HC Large Grinding Mill, Raymond Mill, Large Pendulum MillHC Grinding Mill HC Series Grinding Mill widely applied in mineral grinding processing of metallurgy, construction material, chemical industry and mine fields, and is widely used to grind minerals with Mohs hardness below 7 and moisture below 6%, such as limestone, calcite, active carbon, talc, dolomite, titanium dioxide, quartz stone, bauxite, marble, feldspar, barite, fluorite, HC Grinding Mill, Raymond Mill, Pendulum Powder Mill, Non Phase one: raw material crushing Calcite blocks will be crushed to 15mm50mm by crusher Phase two: grinding Crushed calcite material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding Phase three: classifying Ground material will be classified, coarse powder will fall back to the main mill to be ground Main mill model selection scheme of calcite powder processing

.jpg)

RM Series Pendulum Mill Grinding Mill Fertilizer production

1 The grinding mill is in stereochemical structure, consume small floor space The equipment has strong systematic because it can organize an independent and complete production system of raw material crushing, transporting, grinding to production collecting, storing and packingDOI: 101016/japt2023 Corpus ID: ; Operation parameters multiobjective optimization method of large vertical mill based on CFDDPM @article{Huang2023OperationPM, title={Operation parameters multiobjective optimization method of large vertical mill based on CFDDPM}, author={Rongjie Huang and Yao Ma and Hao Li and Chunya Sun and Jun Liu and Operation parameters multiobjective optimization method of 2023年11月8日 Introduction Fangchenggang is situated in the Guangxi Zhuang Autonomous Region, China, renowned for its rich biodiversity and ethnically diverse population The Zhuang people, constituting the largest minority group in the area, possess a wealth of traditional knowledge concerning wild edible plants (WEPs) owing to the region's favorable environment Wild edible plants and their cultural significance among the 2021年11月14日 The inverted pendulum system is highly popular in control system applications and has the characteristics of unstable, nonlinear, and fast dynamicsBackstepping Sliding Mode Control for Inverted Pendulum

.jpg)

Effect of Operating Parameters on the Breakage Process of Calcite

2018年9月24日 One of the most energyintensive processes for producing submicron range calcite is stirred media mill In the present work, numerous operating parameters such as solid mass fraction, grinding media size, media filling ratio, and grinding time have been investigated using a vertical type stirred media mill The results are evaluated on the basis of mean particle 2023年3月15日 Product pictures and parameters about models, data, performances and specifications on this website are for reference only There is a chance that SBM may make changes on abovementioned information For MRN Pendulum Roller Grinding Mill SBM MillChina Pendulum Mill wholesale Select 2024 high quality Pendulum Mill products in best price from certified Chinese Mining Machine manufacturers, China Crusher suppliers, wholesalers and factory on MadeinChinaPendulum Mill MadeinChina2013年1月1日 This paper investigates the production of calcite suspensions by a wet grinding process in a stirred media mill The experimental setup allows the circulation mode process in the presence of Grinding of calcite suspensions in a stirred media mill: Effect of

PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER BASED

2021年6月17日 Abstract The authors analyze the influence of the semiautogenous (SAG) mill parameters on the mill grinding efficiency, energy consumption and the tangential cumulative contact energy This paper provides a new liner parameter design and optimization method, which offers theoretical guidance for the optimization design of liner parametersHotsale modified models:GKLM series vertical mill, GK series Raymond mill, GKH series ultrafine ring roller mill, GKW series micro powder mill, GKHG series slaked lime separator, GKHG series slaked lime powder production line, and powder related supporting equipmentFrom the smallest model of 2R2613 to the Aisa largest model of GK2500, now GUIKUANG has owned the most About Us – gkmill2002年12月1日 This paper discusses the combined state and parameter estimation of SAG mill inventories and model parameters Recognised simulation models are utilised for the rock and water charge state equationsInferential measurement of SAG mill parameters II: State estimationDownload Table Relaxed lattice parameters of CaCO 3 in aragonite, calcite, and γ phase structures Aragonite Pmcn Total energy per unit formula −2067234 eV Cell parameters a = 4896Å896 Relaxed lattice parameters of CaCO 3 in aragonite, calcite, and γ

Effect of Milling Parameters on DEM Modeling of a Planetary Ball Mill

PDF On Jan 1, 2023, Mohsen Mhadhbi published Effect of Milling Parameters on DEM Modeling of a Planetary Ball Mill Find, read and cite all the research you need on ResearchGate2013年7月1日 A selective ensemble multisource information approach that can effectively fusion the shell vibration, acoustical and mill motor current signals with improved model generalization is proposed Due to complex dynamic characteristics of the ball mill system, it is difficult to measure load parameters inside the ball mill It has been noticed that the traditional singlemodel and Modeling Load Parameters of Ball Mill in Grinding Process Based 754 Physicochem Probl Miner Process, 54(3), 2018, 751762 Table 2 Test conditions for dry grinding of calcite Mill speed tests Parameters Variable Mill Speed (% of Nc) 60, 65, 70, 80, 85 Ball filling ratio (J) 035 Ball size distribution of 40, 32, 20, 12 mm (%) 30302020 (3rd group) Powder filling ratio (fc), (U) 0125, 100 Grinding aid dosage (g/Mg) 0Influences of operating parameters on dry ball mill performance2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Modeling and Parameter Identification of Coal Mill

Mill, material, and process parameters – A mechanistic model for

2019年8月1日 This enhanced model allows the direct prediction of the process parameters of the production mill without labscale experimental process parameter optimization However, the predictions of the grinding times and specific energies required to reach a certain product fineness were insufficientHCQ Reinforced Grinding Mill,the Upgrade Product of Traditional Raymond Mill, calcite, talc, dolomite, quartz stone, bauxite, marble, feldspar, barite, phosphate rock, coal mine, clay, Model: Number of grinding rollers: Nominal diameter HCQ Reinforced Grinding Mill, Large Pendulum Mill, Raymond Mill2024年10月10日 Thus, we establish a GDP prediction model based on PCASSASVM and evaluate its performance on test samples Results indicate an average prediction accuracy of 9576% Compared with the SVM model, PCASVM model and PCAGASVM model, the prediction accuracy of the PCASSASVM model increased by about 15, 94 and 43 Guangxi GDP Prediction Model Based on Principal Component 2024年7月22日 Lying along the southwest end of China's continental coastline, Fangchenggang is a unique port, border and bay city It is located in the south of Guangxi and neighbors to Nanning, Qinzhou and Vietnam Fangchenggang is the most convenient gateway for the hinterland of China to enter ASEAN as it shares land, sea and rivers with the countries of Fangchenggang Guangxi: With the Largest Port in Western China

.jpg)

The effects on the grinding parameters of chemical,

2022年1月1日 Then, Si and Bi,j equations were determined from the size distributions at different grinding times, and the model parameters (Si, aT,α,γ, and φj) were compared for five different mill speed 2009年9月1日 The coal mill used in the coalfired power plants is modeled in view of the controller design rather than the educational simulator The coal mass flow and the outlet temperature are modeled by reinvestigating the mass balance and heat balance models physically The archived data from a plant database are utilized to identify the model Modeling and Parameter Identification of Coal MillPDF On Dec 9, 2020, Maki K Habib and others published Modeling and Control of a Double Inverted Pendulum using LQR with Parameter Optimization through GA and PSO Find, read and cite all the Modeling and Control of a Double Inverted Pendulum using LQR HC1700 Grinding Mill is a newly developed largescale roller mill by Guilin Hongcheng The equipment referenced the operating principle of pendulum mill and improved the swinging method Without changing other parameter, the centrifugal HC1700 Grinding Mill, Raymond Roller Mill, Pendulum Roller Mill

.jpg)

HC1700 Grinding Mill

HC1700 Grinding Mill HC1700 Grinding Mill is a newly developed largescale roller mill by Guilin Hongcheng The equipment referenced the operating principle of pendulum mill and improved the swinging method Without changing other parameter, 2020年7月7日 In this work, planar free vibrations of a single physical pendulum are investigated both experimentally and numerically The laboratory experiments are performed with pendula of different lengths, for a wide range of initial Estimation of parameters of various damping 2015年2月1日 In this study, the grinding characteristics of waste printed circuit boards (PCBs) were evaluated using a population balance model (PBM) The grinding characteristics under various conditions (PDF) Effects of mill design and process parameters 2018年12月7日 Analysis of Water Cycle in Weizhou Island of Beihai City, Guangxi Province, Part I: Theory and Model Parameter Identification December 2018 MATEC Web of Conferences 246(12):02032Analysis of Water Cycle in Weizhou Island of Beihai City, Guangxi

Optimization of Wet Grinding Parameters of Calcite Ore in Stirred Ball Mill

Çukurova Üniversitesi Mühendislik Mimarlık Fakültesi Dergisi, 33(3), ss 225236, Eylül 2018 Çukurova University Journal of the Faculty of Engineering and Architecture, 33(3), pp 225236, September 2018 ÇÜ Müh Mim Fak Dergisi, 33(3), Eylül 2018 225 Optimization of Wet Grinding Parameters of Calcite Ore in Stirredand = +!!!Nonlinear ModelBased Parameter Estimation and Stability Analysis DOI: 101016/JMINENG200901001 Corpus ID: ; Inferential measurement of sag mill parameters IV: Inferential model validation @article{Apelt2009InferentialMO, title={Inferential measurement of sag mill parameters IV: Inferential model validation}, author={T A Apelt and Nina F Thornhill}, journal={Minerals Engineering}, year={2009}, volume={22}, pages={1032 Inferential measurement of sag mill parameters IV: Inferential model Model Owner Operator 11 Operating: 2016: 1086 MW: Pressurized water reactor: Fangchenggang, Guangxi, China: 21, 108 (exact) 36 Guangpo, Gangkou District, Fangchenggang, Guangxi, China: 21, 108 (exact) The map below shows the exact location of the nuclear power plant:Fangchenggang nuclear power plant Global Energy Monitor

Discuss on the metallogenic model for Gaolong gold

2012年1月1日 Download Citation Discuss on the metallogenic model for Gaolong gold deposit in Tianlin County, Guangxi, China As one of the most classical deposits in DianQianGui area, Gaolong gold deposit 2020年11月13日 Digital models for pressurebased metal treatment are also necessary for calculating the rollingmill power parameters during the development of new assortments at the operating millsCalculating Power Parameters of Rolling Mill Based on Model