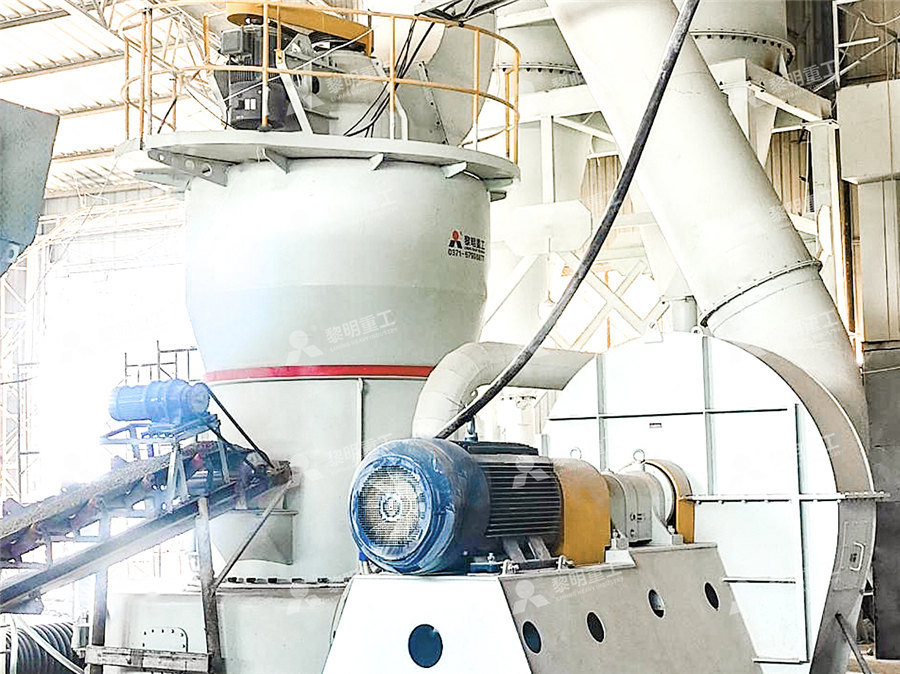

Manganese ore equipment superpressure trapezoidal mill

Optimizing Manganese Ore Process Flow and Equipment

5 天之前 Before manganese beneficiation, it is necessary to first understand the properties and composition characteristics of the ore, and JXSC support customize the best manganese ore MTW138 trapezoidal grinding mill is particularly suitable for processing mineral raw materials with moderate hardness and low humidity, such as manganese ore Its unique trapezoidal grinding 815t/h Manganese Ore Grinding Plant In Iran2024年11月21日 Separating and classifying manganese ore in processing plants involves specialized machinery, including shaking tables, spiral chutes, jigs, flotation machines, magnetic separators, etc A rotary scrubber and Equipment Required To Build A Manganese Ore 2016年4月27日 Concentration—Gravity Methods of treating Manganese Ore The mill feed, drawn from one or more bins, is sampled at the ore feeder Manganese Ore Processing 911Metallurgist

Top 10 Manganese Beneficiation Machines for Efficient Processing

2024年4月28日 To extract and process manganese effectively, beneficiation machines play a crucial role These machines are designed to separate and concentrate manganese ores, This paper seeks firstly to describe some design considerations of sinter plants; secondly, to report on results from testwork performed with a specific series Manganese ore blends; and Optimizing Manganese Ore Sinter Plants:Process Parameters and 2020年8月21日 Work at a laboratory scale demonstrated the possibility of reducing manganese ores to manganese carbides in the temperature range 1000–1200°C using methane gas or From Ore Body to High Temperature Processing of Complex Ores: 2020年11月1日 The ferrosilicomanganese production by using mixture of manganese ore and copper smelting slag has been experimentally studied The metal size and the metal recovery Ferrosilicomanganese production from manganese ore and

.jpg)

Manganese Ore Process Plant JXSC Mineral

Manganese Ore Processing The commonly used manganese ore beneficiation methods are mechanical beneficiation methods (washing, screening, gravity separation, strong magnetic separation, and flotation), as well as special Manganese ore beneficiation is extracting valuable minerals and removing impurities from manganese ore It usually includes crushing, grinding, washing, gravity separation, flotation or magnetic separation to improve the grade and Manganese Ore processing JXSC MachineryJ Cent South Univ (2014) 21: 3485−3491 DOI: 101007/s1177101423264 Strengthening pelletization of manganese ore fines containing high combined water by high pressure roll grinding andStrengthening pelletization of manganese ore fines containing 2023年4月23日 Manganese is a chemical element with the symbol Mn and atomic number 25 It is a hard, brittle, silverygray metal that is commonly found in the Earth's crust Manganese is an essential trace element that plays a crucial Manganese (Mn) Ore Minerals, Occurrence, Deposits

What Equipment is Used for Manganese Ore Beneficiation

2021年5月5日 Manganese Ore Processing Equipment Manganese ore jigging machines are mainly designed for the properties of manganese oxide ore Commonly used manganese ore beneficiating jigging machines mainly include the following three types 1, 2LTC6109/8T jigging machine 2LTC6109/8T jigging machine is also called trapezoidal jigging machine2021年8月6日 1 Main equipment of manganese ore process plant The main manganese mining equipment is 2 sets of PE400 mm×600 mm jaw crusher, 2 sets of CXK1 600 mm×7 630 mm tank washing machine, 2 sets of ZD150 mining singleshaft vibrating screen, FG 12 highgrade spiral classifier 2 Existing problems in the manganese mining processManganese Ore Processing Plant Solution Design JXSC MiningApplicable equipment: Lowspeed coal mill, mediumspeed coal mill, highspeed coal mill, Raymond mill, vertical mill, highpressure suspension roller mill, mediumspeed fine powder mill, overpressure trapezoidal mill, Raymond mill Models such as mills, coal silos, and silos Main material: High manganese steel, new composite materials Promotion Coal Mill Liner EB Castworld2021年4月22日 The machine has a large processing capacity and strong adaptability It is suitable for the beneficiation of mediumgrained and finegrained ores, and the effective recovery limit is 53 microns Trapezoidal jigs have been widely used in gravity concentrators for iron ore, manganese ore, tin ore, etc around the world Diamond Separation EquipmentDiamond Beneficiation Equipment Henan Forui Machinery

Manganese: Mining Transport International Manganese

China consumes 65% of the global output of Manganese ore (including 16% produced domestically), so around half of global Manganese ore production is imported by China from other countries, almost entirely by ship in bulk Manganese alloy: Manganese alloy is mostly transported in bags of 1,000kg, by trucks and ships (sometimes in containers)The production process of electrolytic manganese using manganese ore powder (mainly containing MnO2, Mn2O3, and Mn2O3) as raw materials will generate a large amount of solid waste electrolytic manganese slag, abbreviated as manganese slag Manganese slag is an acidic waste residue that contains a certain amount of sulfur element During the calcination process, Which Type Of Desulfurization Agent Grinding Mill Machine 2021年3月1日 The chemical compositions of manganese ore and mill scale scrap are listed in Table S1 The manganese ore contains 4558 wt% total Mn (TMn) and 1192 wt% total Fe (TFe), while the hydrothermal technique [27], etc Although these methods can prepare ideal nanoparticles, they either have complex equipment and long preparation Innovative methodology for cotreatment of mill scale scrap and 2024年4月9日 After crushing to a fraction of 020 mm and averaging carbonate manganese ore, a belt conveyor feeds it into an intermediate bin with a batchweighing feeder for grinding in a ball mill Grinding manganesecontaining raw How is Manganese Processed: An InDepth

.jpg)

5 Easy but Efficient Steps to Realize Manganese Ore

2023年4月10日 4 Manganese ore dressing process and equipment According to the manganese ore plant, different types of manganese ore have the different process flows To choose different beneficiation equipment: Manganese oxide Manganese (Mn) is the twelfth most abundant element in the Earth’s crust Amongst some 300 minerals containing manganese, only about a dozen are of economic significance Manganese is a silverygray metal that resembles Manganese Ore Process Plant JXSC Mineral2024年11月3日 Bulk Manganese Ore Manganese Ore is used as an alloy of iron (ferromanganese) and is essential to steelmaking and for certain other industrial processes, acting as a toughener and a cleanser, removing sulphides and oxides Manganese Ore is widely available and exported in dust or in lumps in some quantity from West and South Africa, India and Bulk Manganese Ore Shipping HandyBulkManganese ore has high industrial value Manganese ore can be ground into fine powder by dry mill equipment The fine manganese ore powder processed by manganese ore grinding mill is the main raw material for making metal manganese and alloy additives It is also one of the important auxiliary materials for the production of cement retarders, and can also be used to make News Which is Better Between Manganese Ore Wet Mill Or Manganese Ore

.jpg)

A Comprehensive Guide to Manganese Processing Equipment

2024年3月27日 Manganese processing equipment plays a crucial role in extracting, refining, and processing manganese ore into usable products By understanding the different types of equipment available, their functions, and key considerations when choosing equipment, you can ensure optimal performance and efficiency in your manganese processing operations2023年4月28日 The manganese ore is blasted from an open pit mine The size of the ore is reduced using large machinery called crushers The ore is crushed into smaller pieces, usually no larger than six inches in diameter The crushed ore is then transported to a concentrator or a smelter for further processing Manganese Ore Grinding: After the manganese Manganese ore crushing, grinding, processing – Mining Equipment 2014年5月7日 Chemical studies of manganese during the 16th through 19th centuries led to the realization that the addition of manganese to iron orebased steel made it even harder In today’s world, manganese is often used for cathodic shielding in the battery industry The Basics of Manganese Mining and ProcessingManganese Mining and Processing: Everything you Need to Know2014年9月6日 Pelletization is one of useful processes for the agglomeration of iron ore or concentrates However, manganese ore fines are mainly agglomerated by sintering due to its high combined water which adversely affects the roasting performance of pellets In this work, high pressure roll grinding (HPRG) process and optimization of temperature elevation system were Strengthening pelletization of manganese ore fines containing

HighPressure Suspension Mill greatwallcrusher

The Highpressure Suspension Mill is used to grind materials in the fields kaolin, pyrophylite, shale, violet arenaceous stone, feldspar, quartz, garnet, silicon carbide, bauxite, phosphate ore, manganese ore, coal, coke, carbon black The residual air generated during the operation of the equipment enters the dust collector through the As an important industrial raw material, manganese and its compounds are more and more widely used in metallurgy, chemical industry, light industry, medicine, machinery, national defense, communications, agriculture and other industries in today's social development Therefore, how to choose manganese carbonate ore grinding mill equipment?How To Select Manganese Carbonate Ore Grinding Mill Equipment?In terms of traditional pendulum roller mill, the Manganese Mineral Ore Raymond Roller Mill has been upgraded in many aspects All of the technical parameters takes the leading role in China mill industry It ranges from 2R to 6R, including 2R2713, 3R3220, 4R3216, 4R3218, 4R3220, 5R4121, 5R4125, 6R5127 The fineness of Manganese Mineral Ore Raymond Mill can be Manganese Mineral Ore Raymond mill2024年4月26日 Specialized mining equipment, such as drills, loaders, and haulage vehicles, is used to extract the ore from underground The extracted ore is transported to the surface for further processing It's important to note that Iron Ore Processing: From Extraction to Manufacturing

Manganese Ore Processing Plantmanganese ore production line with ball mill

2021年6月23日 Shanghai Clirik Machinery Co,Ltd specializes in manufacturing manganese ore processing equipment For more information about manganese ore production line, manganese ore crushing line, manganese ore grinding line, manganese ore beneficiation, please call or leave a message online : [ protected] WhatsApp: 7829/ Ball Mill Vibrating Screen Dewatering Screen Belt Conveyor Jaw Crusher Ball Mill Wet Providing complete set processing equipment Manganese ore conditions: The manganese ore is rock type with clay, maximum input size 100mm, manganese concentrates size is 025mm, the Mn grade in raw ore is around 18%, Fe2O3 accounts for 10% to 15%, Manganese Ore Processing Plant JXSCTeam2024年11月21日 Ore washing, gravity separation, magnetic separation, and flotation are all common beneficiation processes for manganese carbonate ore Skip to content JXSC Machinery Us +86 Wet Pan Mill; Raymond Mill; Spiral Classifier; Hydrocyclone; Gravity Separation General ore washing equipment includes vibrating What Processes For Beneficiation Of Manganese Carbonate OreManganese metal is divided into metal manganese produced by fire reduction and electrolytic metal manganese produced by wet electrowinning The pyrometallurgical manganese is massive and difficult to crush; The wet electrolytic manganese metal is flake, easy to crush and high purity At the same time, the production scale of manganese metal powder is generally large, but the How To Select Equipment For Producing Manganese Powder From Manganese

Five Common Types Of Manganese Ore Processing Solutions

2023年8月7日 Manganese is a type of common metal mineral in nature More than 150 types of manganese minerals have been discovered so far, but only a small portion of manganese ore with mining and utilization value, mainly including pyrolusite, psilomelane, bog manganese ore, etc Manganese has become an essential strategic mineral resource among countries and apply in 2023年3月2日 Manganese deposits are very important Not only in industry but also because of its medical and life applications Based on geochemistry, the exact Mnforming process can be known if it's (PDF) Geochemistry of Manganese Ore Deposits of Mnhosting 2021年3月1日 Mill scale scrap and manganese ore were used as the iron and manganese resources, respectively, for the preparation of manganese ferrite The chemical compositions of manganese ore and mill scale scrap are listed in Table S1The manganese ore contains 4558 wt% total Mn (TMn) and 1192 wt% total Fe (TFe), while the mill scale comprises 7117 wt% Innovative methodology for cotreatment of mill scale scrap and 2020年10月1日 Request PDF Innovative methodology for cotreatment of mill scale scrap and manganese ore via oxidization roastingmagnetic separation for preparation of ferrite materials Mill scale scrap Innovative methodology for cotreatment of mill scale scrap and

.jpg)

HighPressure Suspension Mill greatwallcrusher

The Highpressure Suspension Mill is used to grind materials in the fields kaolin, pyrophylite, shale, violet arenaceous stone, feldspar, quartz, garnet, silicon carbide, bauxite, phosphate ore, manganese ore, coal, coke, carbon black 2021年6月29日 Highsulfur manganese ore is a metamorphic manganese sulfidemanganese carbonate ore The purpose of roasting is to remove carbon dioxide and desulfurize The roasting of manganese carbonate ore is heating 5 Commonly Used Manganese Processing Methods2022年5月17日 Flowchart explanation Vibrating feeder: The loader or excavator feed raw ore into the hopper, through a vibrating feeder to evenly feed the rotary scrubber; Rotary scrubber: washing off the clay and screening out 05mm,525mm, and over 25mmOur trommel scrubber is configured with the screen at the end, so washed ore go to the screen for sieving out different Customized Manganese Ore Processing Plant Equipment2021年8月16日 The Mn deposits examined in this study are located in the Banswara district, which lies in the southernmost part of the Rajasthan state of India (Fig 1) []The district lies in between 23° 11′ N to 23° 56′ N latitude and 73° 58′ E to 74° 49′ E longitudes while the manganese belt in the district lies in between 23° 10′–23° 20′ N to 74° 15′–74° 25′ E (Fig 2) []Occurrences, Distribution, and Evaluation of Manganese Ores

.jpg)

Current situation of global manganese resources and suggestions

2021年5月18日 Manganese resources are abundant in China, with 155 billion tons of manganese ore reserves and 6th in global ranking in 2016 The manganese deposits in China are mostly concentrated in the Pan 2019年11月13日 The common manganese ores mainly include manganese oxide ore and manganese carbonate ore As for the fine and micro embedded manganese ores, and there are an amount of high phosphate ore, high iron ore and co–(concomitant) beneficial metals, so the manganese processing is quite difficult7 Common Manganese Mining Processes2019年7月15日 Gravity Separation Process back to top Gravity separation process is a beneficiation method according to the difference in density of minerals, whose process can be carried out in a medium such as water or air The density of common manganese oxide minerals ranges from 3,700 to 5,000 kg/m3, the density of manganese carbonate minerals ranges from How to Extract the Manganese Ore? MiningpediaXi’an Dasen Mining Machinery Equipment Co, LTD Tel: +86 29 8113 7393 Whatsapp:+86 133 1927 7356 Address: Yongwei Times Center, Hightech Industry Zone, Xi’an, Shaanxi, China PC: Customized Manganese Ore Processing Plant Equipment

Hydrometallurgical Processing of Manganese Ores: A Review

2011年1月1日 Reductive acid leaching of manganese ores is not selective, some amount of iron also dissolves into the solution along with Mn; hence, this process is limited to the beneficiation of high grade