Equipment for making quicklime Equipment for making quicklime Equipment for making quicklime

.jpg)

The Right Grinding Machines for Your Quicklime Industry Liming

Offer tailored grinding mills for quicklime Wide application, highquality, energysaving and environmentally friendlyQuicklime milling is generally divided into four types: coarse powder processing (03mm), fine powder processing (20 mesh400 mesh), ultrafine powder processing (400 mesh1250 mesh) quicklime processing plant, quicklime grinding machine, quicklime 2024年11月7日 This video case study on the stone dust making machine for 325 mesh quicklime demonstrates the capabilities of the HGM ultrafine grinding mill in producing a high Stone Dust Making Machine For 325 Mesh Quicklime Grinding Plant2022年12月22日 New environmental protection and energysaving equipment such as YGM highpressure mill, HGM ultrafine mill, and CLUM vertical mill have been widely used and Type Selection of Quicklime Deep Processing Equipment

.jpg)

Vertical mill: The preferred equipment for quicklime production

The vertical mill stands out as the preferred equipment for quicklime production due to its high efficiency, energy savings, environmental protection, and ease of maintenance Its advanced We have innovative processes for limestone grinding and separating as well as for lime hydration with Pfeiffer mills, hydrators, high efficiency separators, and distribution table separatorsQuicklime preparation Gebr PfeifferCaCO3 + Heat → CaO + CO2 or Limestone + Heat → Quicklime + CO2 This process is called "calcination", main equipment to calcinate limestone is lime shaft kiln, which is the most How to make quicklime? SINOLIME MACHINERY2024年4月16日 One of the biggest pieces of equipment you’ll need in making quicklime is a stove or kiln Your stove or kiln should be up to the task of cooking the amount of quicklime How to Make Quicklime: 10 Steps (with Pictures) wikiHow

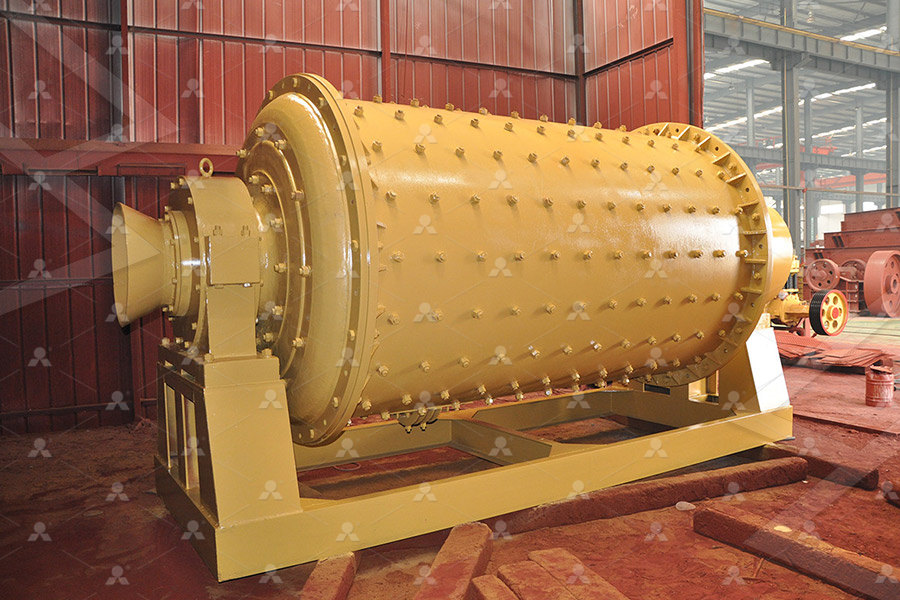

What machine is good for quicklime grinding?

As one of the basic raw materials, quicklime has a growing demand for its powder formHow to grind quicklime into powder efficiently and finely has become the focus of attention of many compared (eg BET vs quicklime reactivity, BET vs bulk density and BET vs expansion) With this knowledge, as well as a demand for higherquality hydrated lime production, a need for Developing a modular lime plant CimprogettiWhat is Lime Slaker The lime slaker equipment is used to convert quicklime into slaked lime powder, and it has applications in various industries such as metallurgy, chemical, and construction Lime slaker is designed into various models with different capacities and types, such as rotary drum lime slaker and ushape tank slaker, 3 stage lime slaking systemBest Practices for Operating and Maintaining Lime Slaker EquipmentYogurt Making Equipment Find innovative production technology for making yogurt and connect directly with worldleading specialists Yogurt makers start with raw milk from animals like cows and goats and produce yogurt by Yogurt Making Equipment Making

Type Selection of Quicklime Deep Processing Equipment

2022年12月22日 CLIRIK has been committed to the research and development of energysaving and environmentally friendly grinding equipment The vertical mills, highpressure mills, and micropowder mills developed and produced by CLIRIK have won high praise from users in quicklime processingCaCO 3 + Heat → CaO + CO 2 or Limestone + Heat → Quicklime + CO 2 This process is called "calcination", main equipment to calcinate limestone is lime shaft kiln, which is the most efficient and economical equipment to produce quicklimeHow to make quicklime? SINOLIME MACHINERY2024年6月23日 QuickLime, also known as burnt lime or calcium oxide, is a versatile substance with a vast array of applications Use appropriate tools and equipment to minimize risks First Aid Knowledge: Ensure you have thorough knowledge of first aid procedures in case of exposure to Quick Lime to respond promptly to any accidentsQuickLime 101: Everything About This Super Substance ZMEWarum ist Quicklime in der Stahlproduktion wichtig? Die Rolle von Quicklime in der Stahlproduktion ist von zentraler Bedeutung Es dient als Reduktionsmittel und Entschwefelungsmittel Quicklime hilft dabei, unerwünschte Elemente wie Phosphor und Schwefel aus dem Roheisen zu entfernen, um die Qualität des fertigen Stahls zu verbessernQuicklime Explanation of terms

Differences between Hydrated lime and quicklime Sodimate Inc

2012年1月27日 The main differences between hydrated lime and quicklime are their reactivity their chemical composition Hydrated lime and quicklime are both calcium compounds In its hydrated state, calcium is called calcium hydroxide, and in its pure state it is called calcium oxide, or quicklime Calcium oxide has a heavy density (65lb/ft³) and is more reactive than hydrated Quicklime, the product of calcination, consists of the oxides of calcium and magnesium, and in this country it is available in three forms: • High calcium quicklime (CaO): containing 05 to 25% magnesium oxide • Dolomitic quicklime (CaO • MgO): containing 35 to 40% magnesium oxide • Magnesian quicklime: containing 5 to 10% magnesium High calcium quicklime Dolomitic quicklime Magnesian quicklime hydrated lime, the amount to use is based on the dry weight of the soil For quicklime, you must use the formula in Section 225 to get the correct amount Since quicklime contains no water, the amount of lime required is slightly less than that of hydrated lime (see formula in Section 225 Specification) IV Are There Any Weather Limitations?Guidelines for Lime Stabilization Georgia Department of Learn about Quicklime topic of Chemistry in details explained by subject experts on Vedantu Register free for online tutoring session to clear your full personal protective equipment should be worn before handling this compound If quicklime comes in contact with the eyes, it is advised to thoroughly wash the eyes and contact the Quicklime Properties, Uses and Application Vedantu

.jpg)

What Is Quicklime And How Does It Work? Medium

2023年2月10日 Quicklime, also known as calcium oxide (CaO), and can damage equipment if it is not handled properly It has a very low moisture content, usually around 05–1%Calbux 90 Quicklime is a fine ground high reactivity quicklime It is used to make lime putty and hot lime mortars As quicklime (Calcuim Oxide) is a highly reactive material, please make sure you understand the safety implications and have Calbux 90 QuicklimeSpread the loveQuicklime, also known as calcium oxide (CaO), is an essential component in many industrial and construction applications Though it is a common product, making quicklime requires careful handling due to its caustic nature In this article, we will outline the 10 steps necessary for making quicklime 1 Gather materials: To make quicklime, you will need How to Make Quicklime: 10 Steps The Tech EdvocateQuicklime, often referred to as either calcium oxide (CaO) or lime, is manufactured by heating the raw ingredient ‘limestone’ or ‘calcium carbonate’ in large kilns This process removes CO 2 that is trapped in the stone leaving behind CaO and other minor mineral constituents This CaO molecule is what we consider to be high calcium Lime Slaking Systems Carmeuse

.jpg)

Standard Test Methods for Chemical Analysis of Limestone, Quicklime

Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ftlbf/ft 3 (2,700 kNm/m 3)) 1 This standard is issued under the fixed designation D1557; the number immediately following the designation indicates the year of original The quicklime briquetting process – a process to set up the quicklime briquette plant Most of the quicklime we get are from the two processes Screen process; Dust collect process; In order to make use of the quicklime, the produced quicklime will go through a screen and leave the tiny ones The size left behind normally is less than 5mmQuicklime briquette machine, quick lime briquetting making 2023年2月15日 How is lime produced by limestone? Lime is made of limestone which needs to be calcinated with a temperature over 900℃ Limestone is a kind of sedimentary rock that is alkaline, and the main component is calcium carbonate, calcium magnesium carbonate, or a mixture of calcium carbonate and magnesium carbonateLime Production Process and Required Equipment2024年7月28日 Quicklime fines are usually brought to the job site on pneumatic trailers, EPATarpcompliant dump trailers, or supersacks Pulverized Quicklime Fines, a fine grade material with similar physical properties to cement The ultrafine sizing ensure the material will flow through spreader equipment easily and quicklyWhere to Buy Quicklime STONE POST GARDENS

Quicklime OSRS Wiki

Quicklime is made by putting limestone in a furnace while wearing glovesIf the player isn't wearing gloves, the limestone will corrode the player's skin and damage the player for 8 HitpointsQuicklime is used in the Regicide quest for making the barrel bomb With an empty pot in inventory, the quicklime is used with a pestle and mortar to make a pot of quicklime2024年9月16日 CQL Offers All the Benefits of Quicklime – and Then Some Quicklime has long been a staple in the construction industry, known for its ability to stabilize soil and improve the durability of construction projects Traditional quicklime, however, comes with certain limitations, such as longer mellow periods and less efficient mixingIntroducing Construction Quicklime (CQL) Mintek ResourcesQuicklime is key in the foaming process, as it reacts immediately with cement, gypsum, water, and aluminium powder when making aerated autoclaved concrete blocks Quicklime is also used to produce lime putty, which is used in mortar Explore our Quicklime for AAC Blocks and Lime Putty Find Quicklime Suppliers Request for quotations and connect with carbonates, oxides and hydroxides of calcium, silicon, magnesium, aluminium, and iron predominate Application: Steel Making, FGD, Construction, Masonry Mortars, Water All the equipment were put into production and goodquality product are ensured Quicklime Suppliers and Manufacturers go4WorldBusiness

.jpg)

Quicklime The RuneScape Wiki

Quicklime is made by putting limestone in a furnaceQuicklime is used in the Regicide quest for making the barrel bomb With an empty pot in backpack, the quicklime is used with a pestle and mortar to make a pot of quicklime 2020年2月27日 Spirotech Group has recently completed a full turnkey design, manufacture and installation of a quicklime storage and make up system project for a UK water authority The 50m3 silo for holding quicklime was designed to transfer the quicklime into a Brand new quicklime storage and make up system for water Quicklime is one of many reagents offered by Mintek Resources Quicklime, also referred to as lime (calcium oxide (CaO)), is derived from high quality, natural deposits of limestone (calcium carbonate (CaCO 3)) or dolomitic limestone (calcium magnesium carbonate (CaCO 3 + MgCO 3))Quicklime is produced by heating the stone to almost 2000 degrees FahrenheitQuicklime (Calcium Oxide) Mintek ResourcesHigh calcium quicklime (CaO) is produced when limestone, or calcium carbonate (CaCO 3), is heated in a kiln through the process of calcination CaCo 3 + heat > Cao = CO 2 After limestone with high calcium content is sourced from our quarries and underground mines, it is transported and processed through a series of crushers to reach a desired sizeHigh Calcium Quicklime Carmeuse

Magnesium Enhanced Quicklime Carmeuse

Magnesium enhanced lime (MEL) plays a critical role in keeping coalfired boilers in compliance with environmental regulations It is used in wet flue gas desulphurization (FGD) to reduce sulfur dioxide and other acid gases MEL is derived from a high calcium limestone that is naturally higher in magnesium content, but not enough to be classified as dolomitequicklime are lower than the shipping costs per ton of hydrated lime or per ton of dry lime equivalent in slurry That all seems clear cut But it is not quite so simple Quicklime may be the cheapest of the three products, but it requires the highest initial capital investment in equipment and the highest ongoing expenditure inQUICKLIME, HYDRATE OR LIME SLURRY? CarmeuseThe production of quicklime is one of the oldest chemical processes developed by mankind But there is often a lot of confusion between terms like lime and quicklime Are you wondering what quicklime is, and what it is made of? Then you've come to the right page! ScienceStruck gives you a lot of information about quicklime, and explains how it is industrially madeWhat is Quicklime and How is it Made? Science StruckQuicklime may be the cheapest of the three products, but it requires the highest initial capital investment in equipment and the highest ongoing expenditure in terms of maintenance and labor Why? Because you are going to need to make up the process steps between quicklime and slurry on site (remembering that lime is almost always added to water/wastewater treatment Quicklime, hydrate or CalSafe® lime slurry? Carmeuse

.jpg)

Quicklime ROBLOX Bad Business Wiki

Quicklime is a throwable grenade unlocked via the Medieval Weapons Pass or 5,000 CR Upon impact with terrain or an enemy, it will deal 30 damage to enemies within a small area and generate a thick cloud of visionobscuring EQUIPMENT USED FOR THE SLAKING PROCESS It is not the intent of this paper to evaluate the slaking equipment described below The intent is to show the types of equipment available for slaking process There are basically four types of lime slakers available on the market They are: A Slurry Detention Slakers B Paste Slakers C Ball Mill SlakersAn Overview of Lime Slaking and Factors That Affect the ProcessQuicklime was used in the infamous Holocaust The Nazis would place a thick layer of quicklime on the floor of the cattle cars before loading the Jews This would burn the skin of the victims on contact Quicklime, also known as burnt lime, is a chemical compound called The Amazing Uses of Quicklime You Probably Didn’t KnowSlaking requires specialized equipment The cost of equipment and the operator time required to run the equipment usually make quicklime use uneconomical in small plants However, since the chemical cost of quicklime is less than the cost of hydrated lime, quicklime is Lesson 10: Softening Mountain Empire Community College

.jpg)

What is Quicklime Drying? Vulcan® Drying Systems

2023年10月29日 Explore the crucial process of quicklime drying, its benefits, and wideranging applications Enjoy a generous 50% discount on select used equipment such as Gencor Burners, Clay Feeder, and Quench Tower This fantastic offer is valid from November 24, 2024 through November 30, 2024The Quicklime shall be spread in one operation to the required width, grade and cross section Quicklime shall be evenly spread at the designated rate and shall not vary more than 10 percent on any area Only a calibrated spreader able to provide a uniform distribution of the Quicklime throughout the treatment area shall spread the QuicklimeQUALITY CONTROL AND GUIDE SPECIFICATIONS for Dolomitic Quicklime2023年10月27日 Quicklime can be useful, but must be handled carefully to prevent an adverse reaction that can cause skin and eye burns as well as inhalation hazards for anyone making or working with it As such, workers must utilize full personal protective equipment including goggles, head hood, polyurethane or rubber gloves, and a cotton work suit with leather boots and dust Quicklime: A Primer2024年4月15日 In terms of handling, lime is relatively safe to handle, posing minimal health risks Quicklime is much more hazardous; it can cause severe burns upon contact with moisture, requiring careful handling and proper safety equipmentLime vs Quicklime — What’s the Difference?

.jpg)

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Quicklime (Calcium Oxide) is a highly reactive and quite dangerous material, please make sure you understand the risks and have taken suitable safety precautions before ordering This material must be stored in a cool dry environment away from direct sunlight Note: Our powdered Quicklime comes in a 25kg bagBuy Quicklime Online Powder Pebble Cornish Lime