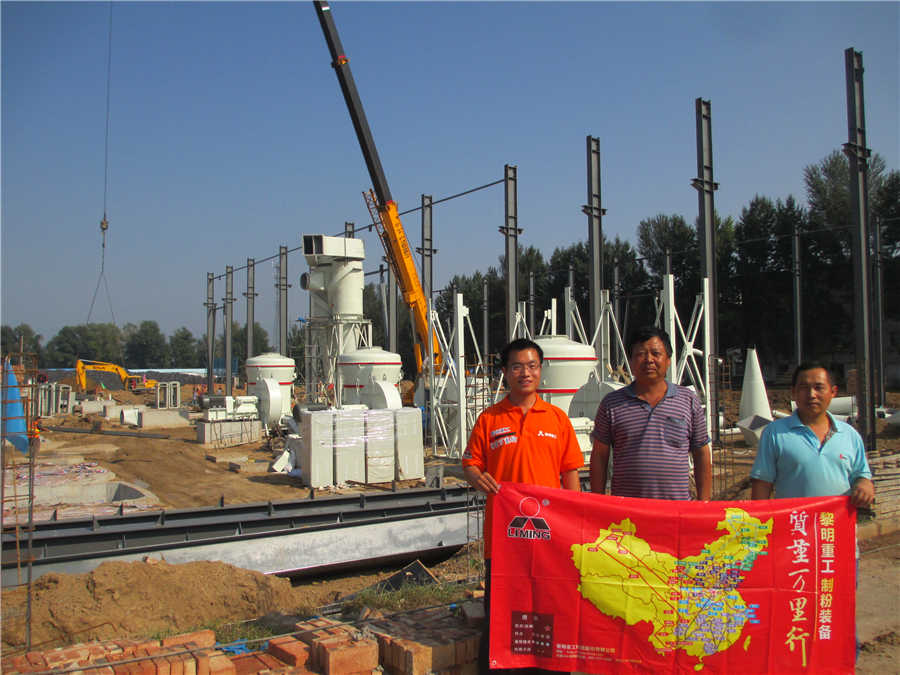

Raymond mill in stone yard of thermal power plant

Coal mill pulverizer in thermal power plants PPT

2012年11月17日 The document discusses coal mill/pulverizers used in thermal power plants It describes how pulverized coal is dried, ground, circulated, and classified within the mill to produce a fine powder that is then transported to 2019年5月8日 Basic and detailed discussion on Coal Mill (Raymond) and Air Fans Performance in a Thermal Power Plant Gives an idea as to how the performance of Coal Mills and fans can be improvedTPS Coal Mills and Fan Performance PPT SlideSharePosts Related to process of thermal power plant bowl mill thermal power plant template for ppt; use of ball mill in thermal power plant; The Hindu Business Line : BHEL develops bowl mill for thermal CERAYMOND BOWL MILL FOR THERMAL POWER PLANTIntroduction The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling system through coal feeder into a predetermined size in order to increase the surface area of the coal If Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

Thermal Power Plant: Definition, Layout, Working,

2021年3月25日 Thermal Power Plant is an electric producing power plant in which fuel (such as coal, liquefied fuel, uranium, and natural resources) is used to generate heat and that heat is further utilized to heat the water to make steam 2011年12月31日 Dual drums head actuations Fig3 Head and tail actuations 1 actuation drums one; 2 coupling; 3 peed reducer; 4 motor; 5 fluid coupling; 6 actuations drum twoOperation and Maintenance of Coal Handling System in Thermal Power PlantThe Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERYSometimes, the thermal power plant is also known as a stealturbine power plant or coal power plant Related Post: Hydropower Plant – Types, Components, Turbines and Working; Working of Thermal Power Plant The thermal power plant works on the Rankine cycle A oneline diagram or layout of the thermal power plant is as shown in the below figureThermal Power Plant Components, Working and Site Selection

List Of Coal Mill In Thermal Power Plant Crusher Mills

Gulin machine in iron ore processing plant, raymond coal mill pulverizer in thermal power plant ppt Gulin provide the raymond coal mill pulverizer in thermal power technical equipment specification of 500 mw coal based held stones, where the weight of the stone provided a boost to muscle power, used against a stone anvil Querns and mortars are types of these crushing devices Coal Crushing Operation In the thermal power plant coal handling system, Conveyors leading to crusher house have facility for manual stone picking, at a suitable location after OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL HANDLING IN THERMAL Raymond Mill: Desulfurization in Thermal Power Pants oxygen in the slurry, and finally forms gypsum In this way, the sulfur dioxide in the exhaust gas discharged by the power plant is separated out, which can be described as killing two birds with one stoneRaymond Mill: Desulfurization in Thermal Power PantsIn this video you will get a live overview of ball and tube type coal mill used in thermal power plantLive Working of Ball and Tube Coal Mill in Thermal Power Plant/

Coal Mills in Thermal Power Plant PDF Mill

Coal Mills in thermal power plant Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online This document discusses coal pulverization in power plants It covers various 2020年6月3日 The heated water that comes from a thermal power plant has an adverse effect on the aquatic lives in the water and disturbs the ecology The overall efficiency of the thermal power plants is low like less than 30% Final Thermal Power Plants: Components Working An Industry Internship Report At National Thermal Power Corporation (NTPC) On “GENERATION IN THERMAL POWER PLANT” In the fulfillment of the seventh semester Industry Internship ELECTRICAL AND ELECTRONICS (PDF) Generation in Thermal Power PlantRaymond Mill: Desulfurization in Thermal Power Pants oxygen in the slurry, and finally forms gypsum In this way, the sulfur dioxide in the exhaust gas discharged by the power plant is separated out, which can be described as killing two birds with one stoneRaymond Mill: Desulfurization in Thermal Power Pants

TYPICAL LIST OF CRITICAL SPARE PARTS FOR THERMAL POWER STATION

xli Mill gear box 2 Nos May be pooled xlii Mill shaft/yoke 2 Nos xliii Set of all bearings for coal pulveriser 3 Sets xliv Mill discharge valve assy 3 Sets xlv Pump assy for mill lube oil system 2 Nos xlvi Cooler assy for mill lube oil system 2 Nos xlvii Feeder belt 6 NosELECTRICAL SYSTEM OF THERMAL POWER PLANT × Close Log In Log Awarded Turbine Rated/Max Load Inlet/Exhaust Pressure Main Steam and reheated steam temperature Main Steam Flow Lime stone requirement 3 COAL HANDLING PLANT Wagon Tippler Apron Feeder CR House Coal Bunker TP2 CR House Reclaiming Coal Coal Stock Yard Coal is unloaded (PDF) ELECTRICAL SYSTEM OF THERMAL POWER PLANTOne mill slurry tank and one slurry pump is supplied for one wet ball mill The mill slurry pump will send limestone to ball mill classifier to classify big size limestone Then, the overflow of the ball mill classifier shall go to the central slurry tank The agitator is provided to keep the slurry solids in suspension during tank usage 3Flue Gas Desulfurization (FGD) Working Thermal Power PlantCoal Mill in Thermal Power Plant Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free This document discusses coal pulverizers/mills which are critical components that convert the stored energy in coal into electricity There are various types of pulverizers that primarily utilize grinding, drying, classification and circulation processesCoal Mill in Thermal Power Plant PDF Mill (Grinding) Scribd

Raymond Mill TAYMACHINERY

The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system 2022年5月1日 The NTPL coal fueled thermal power plant located at tamilnadu, tuticorin is of 1000 MW capacity it features two 500 MW power generation stations The cold start up flow data of coal, air, steam and feed water in the measure of Tonnes/hr every minute was recorded starting from 0800 h to 1700 h a dayImprovement in efficiency of thermal power plant using The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY2023年6月14日 Conducting Regular Seminar on Thermal Power Plant Problems faced and its solutions done will When mill A tripped PA demand got reduced but PA fan A blade pitch did not operate as A PROJECT REPORT ON TRIPPING AND THEIR

Thermal Power Plant Sector Bureau of Energy Efficiency

THERMAL POWER PLANT Under Perform, Achieve and Trade vii 433 Verification Process 116 434 Primary and Secondary source of Documentation 119 5 Ex GtG boundary and metering details for Wood based Pulp and Paper Mill 190 Figure 21: Ex GtG boundary and metering details for Agro based Pulp and Paper Mill 198 Figure 22: Ex GtG 2023年7月9日 Conclusion That’s it Thanks for reading I hope I have covered everything about the “Thermal Power Plant Diagram” It would be helpful if you could let me know if there was anything I missed or if you have any doubts about anything I wrote Please share this article with your friends if you find it interestingThermal Power Plant: Diagram, Layout, Working Construction2013年6月9日 Since last 91 post i have discussed various aspect of thermal power plant Mainly i have written my experience on civil , mechanical , boiler etc R stands for Raymond ( inventor of Bowl Mill) P stands for Pressurised Mill with Primary Air Fan 100/110 stands for Bowl diameter ( inches) ABC OF THERMAL POWER PLANT: MILLS IN A THERMAL POWER STATION PART I2019年5月8日 Basic and detailed discussion on Coal Mill (Raymond) and Air Fans Performance in a Thermal Power Plant Gives an idea as to how the performance of Coal Mills and fans can be improved Read less Read more 1 of 51 Raymond Bowl Mill 5/8/2019 Manohar Tatwawadi 4 5TPS Coal Mills and Fan Performance PPT SlideShare

What is Thermal Power Plant? Basic, Definition, Parts, Working

The efficiency of the thermal power plant is less, around 3035% Application of Thermal Power Plant A thermal power plant produces electricity and that electricity is used in many industries, residential, and all other cases In a survey, it is shown that around 66% of electricity is produced by thermal power plants in India2019年10月26日 Kant, K, Chakarvarti, S K (2003) Environmental impact of coal utilization in a thermal power plant Journal of Punjab Academy of Forensic Medicine Toxicology, 3, 15–18 Google Scholar Mishra, U C (2004) Environmental Handling and Utilisation of Fly Ash from Thermal Power Plantsbe maintained by individual power plant is shown as indicated above, so that in case of any interruption in supply of coal or during high demand period, the coal stock available at the plant may be utilized As, these norms are advisory in nature, at times, power plants do not maintain coal stock as per the above norms 2REVISED COAL STOCKING NORMS FOR COAL BASED THERMAL POWER 2022年2月24日 Curves of mill productivity, power consumed, specific surface of coal dust in terms of the relative rotational speed of the ball drum mill Composition of the balls loading the mill with a standard Improving the efficiency of the coal grinding process in ball drum

Thermal Power Plant: Design and Operation ResearchGate

2015年1月1日 Thermal Power Plant: Design and Operation deals with various aspects of a thermal power plant, providing a new dimension to the subject, with focus on operating practices and troubleshooting, as Among thermal based power generation, coal based power plants are highest in: Air pollution, Waste generation ,Water consumption ,Emission of mercury ,Greenhouse emission Impact of Thermal power plant on water source Water Intensive New thermal power plant of 500 MW installed capacity requires – around 14 million m3 of water per annumEnvironment Impact Assessment of Thermal Power Plant for 2024年6月6日 Coal conveyor in thermal power plant efficiently transport large quantities, reducing costs and supporting seamless operations in thermal power plants : [ protected] Phone:+86 Coal Conveyor in Thermal Power Plant Handing 2020年10月28日 In India, a coalbased thermal power plant generates 93,91838 MW approximately of total energy production A coalbased thermal power plant converts the chemical energy of the coal into electrical energy The company is operating coalbased 2 × 300 MW thermal power plant which is driven by steam and generates electricity by expanding and Hazard Identification and Risk Assessment of 2 × 300 MW Thermal Power

Pulverised Coal Flow measurement in Thermal Power Plant

mill model and to estimate the pulverised coal flow using real time onsite plant data 2 COAL MILL MODELLING In thermal power plant, pulverization of coal is carried out by coal mill Raw coal is moved from the storage to the mill by conveyor mechanism The type of coal mill envisaged for our model is bowl mill which is shown in Fig1The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY2011年1月1日 Keywords: Thermal Power Plant; Coal Handling System; Belt Conveyor Corresponding author Tel: +0086432 the important part includes unloading coal mechanical, coal yard, transport and accessory equipment, are collectively called coal handling mechanical Accessory equipment includes crushing and sieving, coal Operation and Maintenance of Coal Handling System in Thermal Power PlantThermal power plant uses coal as fuel for their working 23217308 Chain Pulling Accidents in Thermal Power plant Plate cutting Coal Yard 5085 339 Coal Mill 8474 5085 Crusher House 5085 Ash Hopper 339 Welding 6779 Conveyor Belt 5085 Bucket Elevator 8474 Weight Lifting 5085 Struck by object 339 Slip and trip on the IDENTIFICATION OF OCCUPATIONAL DISEASES, HEALTH RISK, HAZARD

STANDARD DESIGN CRITERIA/ GUIDELINES FOR BALANCE OF PLANT

wagon tippler and unidirectional yard conveyer) CEATETDCHP002 Typical coal flow diagrams for 2 x 500MW thermal power plant (with A coal based thermal power plant consists of large number of integrated plants/systems and equipment having mechanical, electrical, instrumentation control and civil