Use of ultrafine grinding equipment

Ultrafine Grinding an overview ScienceDirect Topics

In principle, high energy can be supplied to quite fine media, making these devices attractive for ultrafine grinding applications By very careful matching of media size, powder size, and energy input (based on vibrational amplitude and frequency) it should be possible to achieve quite Ultrafine grinding is used to liberate gold finely disseminated in metallic sulfides KCGM is the first gold mine using ultrafine grinding followed by cyanidation (Ellis and Gao, 2002) The gold Ultrafine Grinding an overview ScienceDirect TopicsThe use of UFG grinding in the minerals processing industry is a relatively new development being based on the smaller low mass, batch UFG mills being used by other industries for high Ultra Fine Grinding A Practical Alternative to Oxidative Treatment Metso HIGmill™ is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind HIGmill high intensity grinding mill Metso

Ultraprecision grinding ScienceDirect

2010年1月1日 Ultraprecision grinding is primarily used to generate high quality and functional parts usually made from hard and difficult to machine materials The objective of ultra Ultrafine grinding is a technology, which can be used to process inorganic nonmetallic materials High quality surfaces with a low roughness, and high flatness are achievable in a low Ultrafine grinding of inorganic nonmetallic materials using 2007年10月24日 Stirred ball mills are used in ultrafine grinding because of their high unit outputs, while the low amplitude vibroenergy mills are used because of their low specific Superfine and Ultrafine Grinding— A Literature Survey2023年7月20日 Ultrafine grinding process is a kind of mechanical grinding, in which the commonly used devices include ball grinder, tower grinder (vertical roller grinder), stirred Ultrafine Grinding Process SpringerLink

.jpg)

Powder Equipment Manufacturer ALPA

The equipment and solutions provided by ALPA tackle the complicated processes of dustfree feeding, magnetic separation, ultrafine grinding, classifying, powder conveying, metering, packaging, automatic batching, and intelligent control of 2023年4月25日 Under the opportunity of 'Made in China 2025', in the field of ultraprecision, China has broken through many key bottleneck technologies, achieved many remarkable scientific research results, built a number of high Ultraprecision grinding and polishing processing Our ultrafinegrinding system uses the cooling power of liquid nitrogen to remove heat produced in the grinding process by controlling the temperature of your product or the mill Key benefits include the following: • Ultrafine particle size • More uniform particle distribution • Higher yields of particles in your target rangePolarFit™ UltraFineGrinding Mill Air Products ChemicalsThe VXPmills are designed for fine and ultra fine grinding applications In practice, the mill performs best when the feed has a normal distribution However, the mill has been used to preferentially grind the coarser “hump” in bimodal distributions without over grinding the finer part of the distributionVXPmill for fine ultra fine grinding FLSmidth

Ultrafine grinding of nonmetallic minerals ALPA Powder Equipment

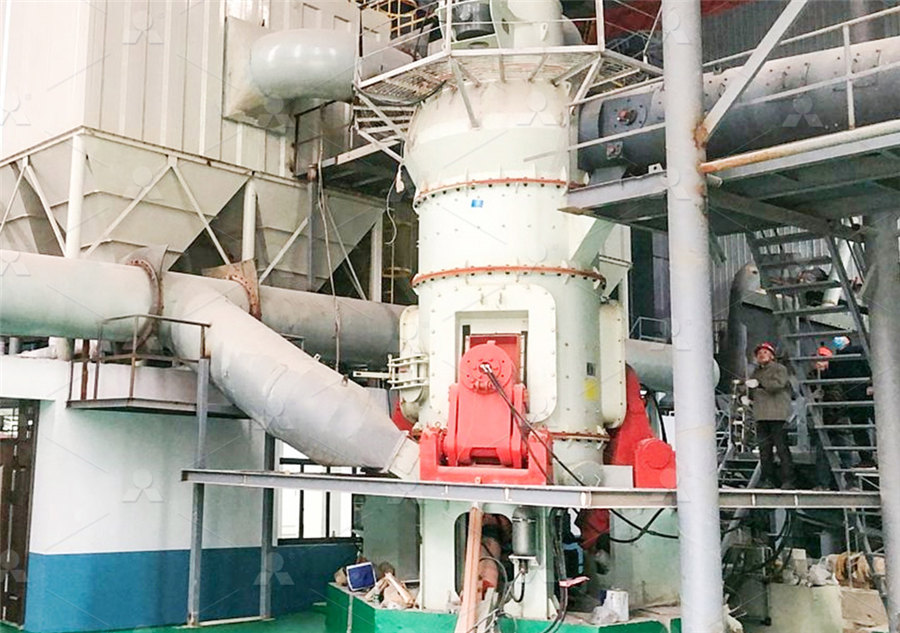

2021年11月25日 Therefore, ultrafine grinding equipment mainly refers to various grindingrelated equipment that mainly produces ultrafine powder by mechanical methods Commonly used ultrafine grinding equipment includes jet mill, mechanical impact mill, vibration mill, stirring mill, colloid mill and ball mill2024年9月1日 With an increase in the fine grinding time, a corresponding increase in the C contents on the sample surfaces was observed During the initial 30 min of fine grinding, the C content increased from 6779 % to 7256 %, after which the rate of increase decreased, and eventually, a C content of 7435 % was acquired after 60 min of fine grindingMechanistic study of the effects of ultrafine grinding on the 2023年9月13日 The ultrafine grinding unit operation (ie onestage ultrafine grinding) currently used in industry has the following process flows: Opening process Generally, airflow mills such as flat or disc type, circulating tube type, etc often use this open circuit process because they have selfgrading function7 basic process flows of ultrafine grinding ALPA Powder EquipmentUltra fine grinding mill is a ultra fine grinding equipment that is highly efficient, energysaving and especially suitable for deep processing of nonmetallic minerals After longterm market application practice and user verification, the mill has small footprint, complete set, wide application, simple operation, convenient maintenance, stable performance and high cost The use of ultra fine grinding millGrinding Mill,Grinding Equipment

.jpg)

Ultra Fine Grinding A Practical Alternative to Oxidative

Ultra Fine Grinding UFG mills overcome these limitations by the use of rotating stirrers inside a stationary mill shell Ultra fine grinding mills have been in use for many years in a large number of every day applications such as pharmaceuticals, dyes, clays, paint and pigments before being used in the mineral processing industry2020年8月20日 Ultrafine grinding is a technology, which can be used to process inorganic nonmetallic materials High quality surfaces with a low roughness, and high flatness are achievable in a low processing (PDF) Ultrafine grinding of inorganic nonmetallic materials using 2017年9月1日 With the continual depletion of high grade simple ore bodies, more complex, finely disseminated ore bodies are being processed, which has led to an increase in the prevalence of fine grinding (Sinnott et al, 2006)This has been evident in the platinum group element (PGE) industry in South Africa, where the Bushveld Complex hosts 70% of global Fine grinding: How mill type affects particle shape characteristics 2023年10月16日 With the support of wet grinding and ultrafine grinding technology, three types of grinding and milling equipment namely, spiral, rod, and pan mills have gradually gained recognition in the UltraFine Grinding Equipment for Major NonFerrous Mining

.jpg)

Ultrafine Grinding in Contemporary Flow Diagrams for Mineral

2015年7月21日 Modern grinders designed for fine grinding – in particular, vertical and horizontal bead mills (Fig 1) – came to the miningmetallurgical sector from the paint industry The grinders have stationary grinding chambers and make use of fine grinding media (beads) Mixers rotating at high speeds are also located inside the grinders2024年5月15日 The results of grinding powdered and solid zirconium and aluminum oxides in various grinding units, ie, ball, planetary, and bead mills, are presented The grinding materials were PSZ55Y brand partially yttriumstabilized zirconium dioxide (USA) and Almatis CT 3000 GS brand alumina with an αphase content of >990 wt% (Germany) The use of bead mills Effect of Ultrafine Powders Obtained by Mechanical Grinding on Ultrafine grinding mill equipment has become a cornerstone in various industries due to its ability to produce particles with a diameter of less than 10 micrometers These machines offer unparalleled precision and efficiency in the production of ultrafine powders, The advancements and applications of ultrafine grinding mill equipment2021年8月13日 Selfgrinding often works in conjunction with grinding equipment such as fine crushing, ball milling, gravel milling, and so on According to its connection mode, it can form a variety of technological processes Grinding and grading equipment The grinding equipment widely used in concentrators are ball mills and rod millsGrinding and grading equipment in beneficiation JXSC Mining

.jpg)

Fine Grinders, Hammer Mills, and More for Particle Size Reduction

Our FullScreen, ‘Gseries’, design is a proven system that ensures maximized use of the entire available screen area to enhance endproduct quality and equipment productivity If your application needs reduction whether it is 6inch to submicron size, choose from Prater’s superior fine grinders , air classifying mills , hammer mills , and lump breakers to meet all of your 2015年4月9日 These mills are suited primarily for very fine grinding of soft materials They are normally used with wet grinding but can also be used for dry grinding Product size is as small as 0005 mm Fluid energy millsGrinding Mills and Their Types – IspatGuru2013年3月1日 Request PDF Energy Use of Fine Grinding in Mineral Processing Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizesEnergy Use of Fine Grinding in Mineral ProcessingJet milling technology is a superfine pulverization technology that has developed rapidly in recent years Because of its advantages such as high crushing strength, fine particle size, narrow distribution, low product pollution, and the use of inert gas, it is widely used in medicine, chemical raw materials and It has been widely used in the preparation of special powdersUltrafine grinding equipment "Jet Mill" ALPA Powder Equipment

.jpg)

PolarFit® UltraFine Grinding Mill

Our PolarFit® ultrafine grinding mill is a versatile grinding system that provides a costeffective way to reduce hard to grind materials to smaller particle sizes than can be achieved with conventional impact mills Produces particle sizes 2023年7月10日 Ultrafine grinding mills were once utilised in numerous Energies 2023 , 16 , 5277 6 of 37 commonplace industries, including manufacturing medications, dyes, clays, paint, and(PDF) EnergyEfficient Advanced Ultrafine Grinding of Ultrafine grinding is an advanced technology that can grind materials down to the micron or even nanometer level, with significant advantages of material savings, fast grinding speed, and uniform and fine powder particle size Recently, it has gradually been applied in the pretreatment of grain crops, which has positive significance for the production of food with good taste, a high Research progress on the effects of ultrafine grinding 2021年8月31日 As an ultrafine grinding equipment, ultrafine grinding has the following characteristics: Compared with air flow mill, it has a wider application range Compared with other similar mills, the grinding roller has stronger grinding pressure on materials Energy savingSuperfine Grinding Use Maintenance Eastman Rock Crusher

Full article: Potentials of superfine grinding in quality modification

2023年8月29日 Superfine grinding is an emerging technology that reduces particle size and modifies surface properties (Hu et al, Citation 2012)It is a novel processing method that is capable of degrading the organization of plant materials and thereby modifying the performance and the release of nutrients (Gao et al, Citation 2020a) To boost the use of dietary fibre in HCH ultrafine ring roller mill is a new type of ultrafine grinding mill equipment developed by Guilin Hongcheng with many years of production and research experience It has comprehensive mechanical crushing properties such as rolling, grinding and impact, and is a truly efficient and energysaving ultrafine crushing equipment, especially suitable for deep processing of non HCH Ultrafine Grinding Mill, Micro powder grinding mill, Ultra fine 2021年7月30日 – finer grinding due to elimination or drastic reduction of aggregation of fine particles during grinding through the use of surfactants, leading to good wetting of the surface of the particles to be ground and to propping of micro and macrocracks (Rebinder’s effect) and – suitability for grinding heatsensitive materialsTwoStage Grinding as the Most CostEffective Option for Ultrafine grinding of inorganic nonmetallic materials using various types of bonds and processing strategies Christian Schulze1,*, Sebastian Henkel1, and Jens Bliedtner1 1ErnstAbbe University of Applied Sciences Jena, CarlZeissPromenade 2, 07745 Jena, Germany Abstract Ultrafine grinding is a technology, which can be used to process inorganic nonmetallic materialsUltrafine grinding of inorganic nonmetallic materials using

PolarFit® UltraFine Grinding Mill Air Products Chemicals

Our PolarFit® ultrafine grinding mill is a versatile grinding system that provides a costeffective way to reduce hard to grind materials to smaller particle sizes than can be achieved with conventional impact mills and may eliminate the need for additional grinding equipment to improve efficiency High Efficiency Less Operating Costs2021年11月17日 The ultrafine grinding method must be used to produce paintgrade highgrade kaolin products with D90≤2μm during wet ultrafine grinding Before the wet superfine grinding, the kaolin is pulped by a masher, and at the same time, it can be purified, whitened, and classified in the process, and then superfine grinding is carried out with equipment such as a peeling Ultrafine grinding of kaolin ALPA Powder EquipmentLONGLY Intelligent has a variety of ultrafine nanoscale sand mills, which use special machine seals, no leakage, stable and reliable, low energy consumption, low heat generation, no dead ends in grinding, and more thorough grindingGrinding Equipment Manufacturer Supplier Factory, Ultrafine grinding demands a lot of it But, by choosing energyefficient mills and optimizing the grinding process (think smart planning and operation), you can save on those bills In short, while grinding to get those ultrafine particles presents its fair share of The Role of Grinding Mills in Achieving UltraFine Dispersion in

.jpg)

Grinding Hosokawa Alpine

From precrushers for the comminution of coarse materials to jet and ball mills for ultrafine grinding: Hosokawa Alpine offers mills for a wide range of fineness levels The mill type that is best suited to your application depends not only on 2023年6月9日 At present, ultrafine pulverization equipment can be divided into two categories: mechanical type and air flow type according to its working principle The use of ultrafine grinding technology can significantly improve the taste and absorbability of fiber foods through micronization of fiber, Fine grinding of high valueadded powders ALPA Powder Equipment2022年5月1日 This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of 59 μm from a feed size of 244 μm while having a specific energy (SE) input of 309 kWh/ton Nonetheless, the least energy Optimization of operating conditions on ultrafine coal grinding Ideal for use at any time of the day without disturbing others, perfect for early morning coffee grinding or latenight cooking COMPACT AND PORTABLE: Despite its compact size, this grinder boasts a large 600ml capacity, allowing you to grind more at onceIdeal for small kitchens, travel, or camping, providing convenience without compromising on capacitySmall Household Ultrafine Grinding Equipment – swarous

Fine grinding of wood – Overview from wood breakage to

2018年6月1日 Besides the established uses of wood powder, like cofiring with coal and biofuel production, there are also novel uses and process applications, eg, advanced woodplastic composites and biochemical production are emerging for which the pulverization or fine grinding of wood is an essential pretreatment stepUltra Fine Grinding Mill Working Principle Raw materials are sent into the ultrafine powder grinder by elevator or other equipment (the bucket elevator, belt conveyor or chain elevator can be used according to the needs of the site), and there is Ultra Fine Grinding Mill Ultra Fine Powder Grinder AGICO2023年11月22日 Ultrafine grinding refers to the unit operation of crushing coarsegrained materials to a particle size of less than 10~25 μm When the material is crushed to a particle size of less than 10 μm, the ultrafine particles have high surface activity, void ratio and surface energy, thus giving the material Excellent solubility, adsorption, fluidity and unique optical, Application of ultrafine grinding technology in cosmeticsVsunny, as a company specialized in manufacturing grinding equipment, was founded in Dongguan in 2012 We mainly provide powder grinding mill which is used in the grinding of nonmetallic ore USA Choose Country Ultra Fine Powder Grinding Machine Line Manufacturer of Grinding Equipment Ultrafine Grinding Mill