Lepidolite processing equipment

Lepidolite Flotation Process Plant JXSC Machine

2022年11月7日 This 500tpd lepidolite flotation process plant is configured with a hopper+vibration feeder, jaw crusher, fine jaw crusher, vibration screen, storage The processing plant is responsible for extracting lepidolite from its natural 10TPH Lepidolite Processing 2019年8月23日 Lepidolite and spodumene are other common minerals that contain lithium Commercial quantities of these three minerals are in a special igneous rock deposit that Lithium Processing Equipment, Process Flow, Cases JXSC Machine2023年1月1日 The sodium carbonate autoclave method has obvious advantages for defluorinated lepidolite: Simple process, high lithium leaching rate, and high overall process Lithium extraction from hard rock lithium ores (spodumene,

.jpg)

Processing Technology Cornish Lithium Plc

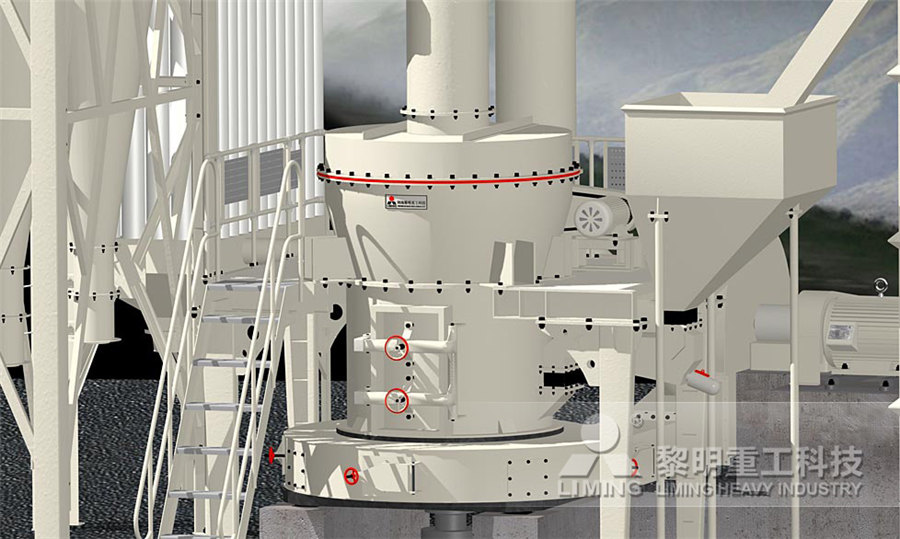

The Lepidico processing technology is a low energy consumption hydrometallurgical process which employs low cost, conventional reagents along with industry standard equipment The process is undertaken at atmospheric We Pineer provides the comprehensive range of equipment required to extract lithium These processing equipment include: Ore feeder, Jaw crusher, Fine crusher / Cone crusher, Vibrating screen, Ball mill machine, Spiral classifier / Lithium Ore Flotation Plant Pineer Mining Machinery2023年5月16日 The processing plant is responsible for extracting lepidolite from its natural sources, such as mines or quarries, and then processing it to obtain lithium carbonate or other lithium compounds The extraction process typically 10TPH Lepidolite Processing Plant JXSC Machine2024年9月1日 Lepidolite is an essential lithium resource with diverse applications in lithiumion batteries, ceramics, glass, and other industrial sectors Efficient flotation of lepidolite is crucial Key technologies and development trends for efficient flotation

Hard Rock Lithium Processing SGS

process involves atmospheric leaching, liquidsolid separation and impurity removal via precipitation and ionexchange Our team expertise can deliver: • High grade market samples 2024年11月11日 The traditional process of lithium extraction from lepidolite has the disadvantages of a low extraction rate, poor selectivity and a long process In this study, the Efficient Extraction of Lithium and Rubidium from Lepidolite by 2020年1月1日 Choubey et al (2016) presented a detailed review of the common methods of processing spodumene, lepidolite, zinnwaldite, amblygonite and brines based on articles published before mid2015 The exorbitant costs of these conventional processes in terms of equipment, energy, A review on methods for liberating lithium from pegmatities2024年11月11日 The traditional process of lithium extraction from lepidolite has the disadvantages of a low extraction rate, poor selectivity and a long process In this study, the efficient extraction of lithium and rubidium from lepidolite was achieved by mediumtemperature chlorination roastingwater leaching process Experimental results indicated that the optimal Efficient Extraction of Lithium and Rubidium from Lepidolite by

.jpg)

Scrutinising the lithium technology boom – Part 3 CRU Group

This is a straightforward, nonchemical, shortduration process that results in limited equipment damage and demands relatively low energy consumption However, the lepidolite requires prior processing under high temperatures that increases energy requirements Due to the processing route, it can only be used on higher grades of lepidolite ore2018年1月1日 Recovery of lithium carbonate by acid digestion and hydrometallurgical processing from mechanically activated lepidolite Author links open overlay panel Nathália Vieceli a, Carlos A Nogueira b, Manuel FC Pereira c, Lepidolite is a valuable mineral resources of lithium, rubidium and cesiumRecovery of lithium carbonate by acid digestion and ZJH minerals supply the whole set of equipment for Lithium Mineral Flotation, most notably for spodumene Spodumene theoretically contains 803% Li2O and therefore the production of this mineral is greatly increasing, especially demand for electric vehicle batteriesLithium Mineral (spodumene, petalite and lepidolite) Flotation2012年6月1日 To solve these problems, a novel technique was developed to extract lithium from lepidolite in this paper The lepidolite was preroasted at 860 °C for 30 min with water steam atmosphere for defluorinationThen the defluorinated ore was leached in a lime–milk autoclave where the leaching temperature is only 150 °C (The absolute saturated vapor pressure of A novel process for extracting lithium from lepidolite

.jpg)

Separation of lepidolite from hardrock pegmatite ore via dry

2022年9月1日 Under the scope of the Flexible and Mobile Economic Processing Technologies (FAME) H2020 project, which focused on improving mineral processing technologies for the recovery of valuable materials from lowgrade ores, a Portuguese lepidolite ore from the Gonçalo deposit was investigated in this study2022年7月5日 The three minerals, spodumene, petalite, and lepidolite, can be used for various purposes after beneficiation and concentrationThe cutoff grade and industrial grade of lithium deposits are divided into manual beneficiation and machine beneficiation, and the grade indicators are determined respectivelyThe division between manual and machine Lithium Processing Plant JXSC MachineLithium ore processing equipment commonly use: crusher, ball mill, classifier, jig, flotation machine, magnetic separator and so onIt is a high technological enterprise that integrated research When lepidolite and spodumene have high grade of the symbiotic tantalum and niobium, gravity separation or strong magnetic separation can Lithium ore Beneficiation Yantai Jinpeng Mining equipment, 2023年11月25日 01 Lepidolite ore flotation technology Flotation technology plays a very important role in extracting lithium from lepidolite Before flotation, lepidolite ore will enter the crushing equipment and grinding equipment for crushing and grinding to reduce the particle size and make it suitable for the flotation process During flotation, the treated ore is mixed with Lepidolite Ore Flotation Technology, Mineral Processing Equipment

Lepidolite Flotation Process Plant JXSC Machine

2022年11月7日 This 500tpd lepidolite flotation process plant is configured with a hopper+vibration feeder, jaw crusher, fine jaw crusher, vibration screen, storage bin+electromagnetic feeder, ball mill, slurry pump, spiral classifier, flotation 2018年1月1日 Recently, an alternative process for extracting lithium from a lepidolite ore, constituted by mechanical activation and sulphuric acid digestion, avoiding the calcination step, was proposed and studied in detail (Vieceli et al, 2017b)The effects of several factors on the structural transformations of the mineral phases were evaluated in this studyRecovery of lithium carbonate by acid digestion and lepidolite The most promising hydrometallurgical procedure for lepidolite processing is sulfuric acid process, because only this process allows complex recovery of valuable components from lepidolite, namely, of lithium, potassium, aluminum, isomorphic impurities of cesium and rubidium present in the mineral, and relatively pure silicaProcedure for Lepidolite Concentrate Processing2022年9月1日 Under the scope of the Flexible and Mobile Economic Processing Technologies (FAME) H2020 project, which focused on improving mineral processing technologies for the recovery of valuable materials from lowgrade ores, a Portuguese lepidolite ore from the Gonçalo deposit was investigated in this studySeparation of lepidolite from hardrock pegmatite ore via dry

.jpg)

Lithium Mining Processing Equipment Flow Chart JXSC

It is mined from ores of petalite (LiAl(Si2O 5) 2, lepidolite K(Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl(SiO 3) 2 We provide equipment and mineral processing solution, we don’t buy them We value your privacy and keep your information safe 2023年9月21日 2 Laboratory hammer crusherLepidolite Ore Testing Equipment The function of a laboratory hammer crusher is to crush small particle materials into fine sand Hammer crushers are suitable for crushing medium hardness materials such as limestone, slag, coke, and coal, and industrial sectors such as cement, chemical, power, metallurgy, etcLab Lepidolite Ore Testing Equipment For Extracting Lithium2023年5月16日 This setup is for processing lepidolite stone ore to recover lithium It is a flotation separation plant with a high recovery ratio for Li2O For lepidolite ore, the lithium concentrate (Li2O) grade can reach about 45% after processing, and the final exact Li2O depends on Li2O in raw material and other minerals conditions10TPH Lepidolite Processing Plant JXSC Machine2023年9月8日 An effective hard rock lithium processing plant includes a crushing line, grinding line, beneficiation line, and drying line The most commonly used lithium mineral processing equipment include crushers (jaw crushers and cone crushers), vibrating screens, ball mills, flotation machines, magnetic separators, and dryersThe Most Effective Lithium Ore Processing Method You Must Know

LEPIDOLITE PROCESSING USING SULPHATION BAKING: A

from the downstream hydrometallurgical processing steps As a possible alternative processing approach, we have examined a hybrid approach involving sulphation baking upfront and downstream processing specifically aimed at readily and cost effectively rejecting the major gangue elements, along with problematic minor and trace impuritiesL40 Gravity Concentrator Gravity concentration plays an important role in mineral processing operations Sepro Labs is uniquely positioned to provide both the benchscale gravity concentrator testing and, if successful, delivery of fullsize gravity concentrators to your operation The L40 Gravity Concentrator is a benchscale mineral testing unit designed to simulate the Mineral Testing Equipment To Help You Make DecisionsThe Lepidico processing technology is a low energy consumption hydrometallurgical process which employs low cost, conventional reagents along with industry standard equipment The process is undertaken at atmospheric Processing Technology Cornish Lithium Plc2016年12月5日 Acidinsoluble sulphates KAl(SO 4 ) 2 , Al(SO 4 )OH5H 2O and Li 2 SO 4 , were generated during the process Similarly, the conversion of lithium to soluble species by alternative means of Optimization of Lithium Extraction from Lepidolite by Roasting

.jpg)

Lithium processing technology Complete solutions that

FLS pyroprocessing technologies We have the largest range of lithium pyroprocessing technologies on the market Our equipment offering includes preheater rotary kiln calciners, flash suspension calciners, fluid beds, and acid roasters Cuttingedge technology, such as preheater cyclones, significantly lowers your operating2023年6月3日 AsiaAfrica International Laboratory lepidolite flotation experimental provides valuable information about this mineral’s chemical composition and properties, a valuable resource for the mining and refining industriesBy providing accurate and detailed analysis of lepidolite samples, these tests can help identify potential sources of lithium and other valuable Start Your Lepidolite Ore Flotation Experimental ProjectOretype lithium ores generally include spodumene, lepidolite, lithium feldspar, etc Flotation is the main sorting process for these lithium ores, and determine the mineral processing process and supporting mineral processing equipment through scientific and reasonable meansA Comprehensive Guide to Lithium Processing Equipment2023年8月2日 The separation and enrichment of lepidolite, an important mineral for extraction of lithium, through froth flotation, have been widely investigated This paper summarizes the latest research progress on lepidolite flotation emphasizing aspects such as cationic collectors and their combination with anionic collectors, as well as the flotation mechanism and application of Research Progress in Flotation Collectors for Lepidolite Mineral:

.jpg)

Lithium extraction from hard rock lithium ores (spodumene, lepidolite

2023年1月15日 Lithium production in China mainly depends on hard rock lithium ores, which has a defect in resources, environment, and economy compared with extracting lithium from brine This paper focuses on the research progress of extracting lithium from spodumene, lepidolite, petalite, and zinnwaldite by acid, alkali, salt roasting, and chlorination methods, and analyzes Processing equipment for spodumene lepidolite mines must remove contaminants such as sulfur dioxide and nitrogen oxide gas while preserving other valuable elements in order to meet environmental regulations The most common method used to remove these gases is flotationWhat is the main processing method of spodumene lepidolite?processing plant and has installed several ancillary equipment in order to produce 204 kTPA of >55% of lithium oxide concentrate Production capacity of 200,000 TPA of lithium oxide at 6% chemical grade spodumene concentrate, 60,000 TPA of mica and 30 TPA of tantalite concentrate is anticipated from this newly upgraded mining facilityMETS Engineering Group Pty Ltd Level 3, 44 Parliament Place, DOI: 101016/jmineng2022 Corpus ID: ; Separation of lepidolite from hardrock pegmatite ore via dry processing and flotation @article{Filippov2022SeparationOL, title={Separation of lepidolite from hardrock pegmatite ore via dry processing and flotation}, author={Lev O Filippov and Inna V Filippova and Gabriel Crumiere and Rui Sousa and Separation of lepidolite from hardrock pegmatite ore via dry

.jpg)

A Review of Lithium Extraction from Lepidolite and

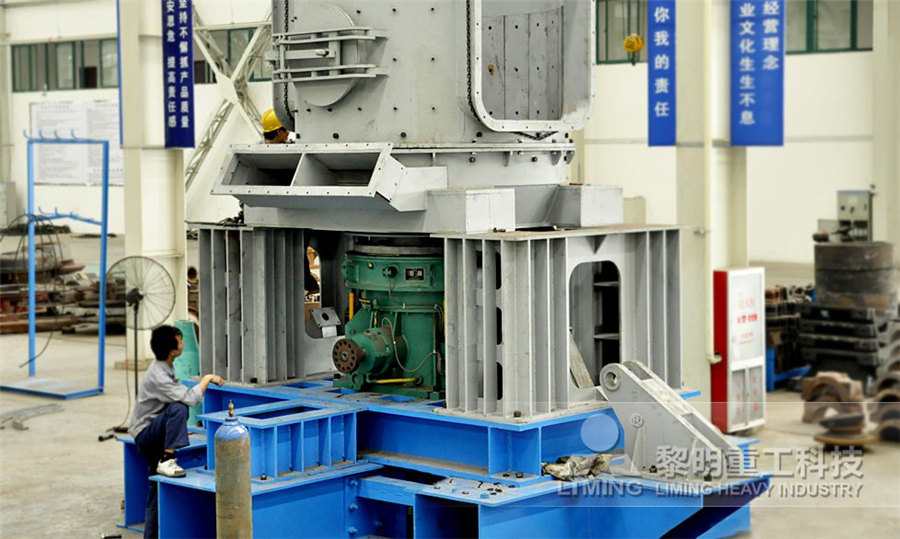

Lepidolite is an important lithium resource in China The development of efficient lithium extraction process is of great significance to ensuring the sustainable development of lithium industry Due to the strong electronegativity of lepidolite without thermal treatment of sulfation and defluorination This study may provide information for the use of low grade lepidolite as a source in Li production 2 Experimental Section 21 Materials The lithiumcontained lepidolite was provided by the Boam mine (Uljin, Korea), and it was upgraded through crushing and optical sorting Extraction of Lithium from Lepidolite Using Mixed Grinding with 2021年2月1日 Request PDF Processing of lithium ores: Industrial technologies and case studies – A review Recently, there has been a steady increase in demand for lithium (Li) and its compounds Processing of lithium ores: Industrial technologies and case studies Lepidolite mineral processing equipment combination: jaw crusher, ball mill, classifier, mixing barrel, flotation machine, concentrator, dryer, etcBasically according to the equipment appears in the production line orderProduction line flow: “Raw ore → crushing → grinding → flotation → dehydration → finished concentrate”Lepidolite crusher,grinding mill,beneficiation equipment

A novel process for extracting lithium from lepidolite

2012年6月1日 This new technique for processing lepidolite could make most with a further 439% of hydrogen chloride and 433% of hydrogen fluoride being driven off and captured by adsorption equipment, 2020年9月3日 Scientific Reports Comparison of three different bioleaching systems for Li recovery from lepidolite Skip to main content higher efficiency and green processing parison of three different bioleaching systems for Li NatureThe processing cost of lithium extraction from lepidolite by sulfate roasting method is higher than that from spodumene by sulfuric acid due to the consumption of highvalue sulfate However, the production costs of both are mainly affected by the price of lithium ores, which is less competitive than that of extracting lithium from brineLithium extraction from hard rock lithium ores (spodumene, lepidolite Various types of equipment are used in a processing system for spodumene lepidolite, each with its own unique set of advantages and disadvantages Vertical impact crushers are the most common type of crushing equipment used in spodumene lepidolite processing plants This type of machine has two main components: the jaw crusher and the impactorProcessing system for spodumene lepidolite crushing and

Equipment Machines For Lithium Extraction From lepidolite

2024年1月20日 1: Lepidolite ore crusher 2: lepidolite ore ball mill (lepidolite ore grinding mill) 3:lepidolite rotary kiln I 4: Acid leaching equipment 5: filtration 6: cooling equipment 7: F removal 8