Raw material vertical mill working principle drying

.jpg)

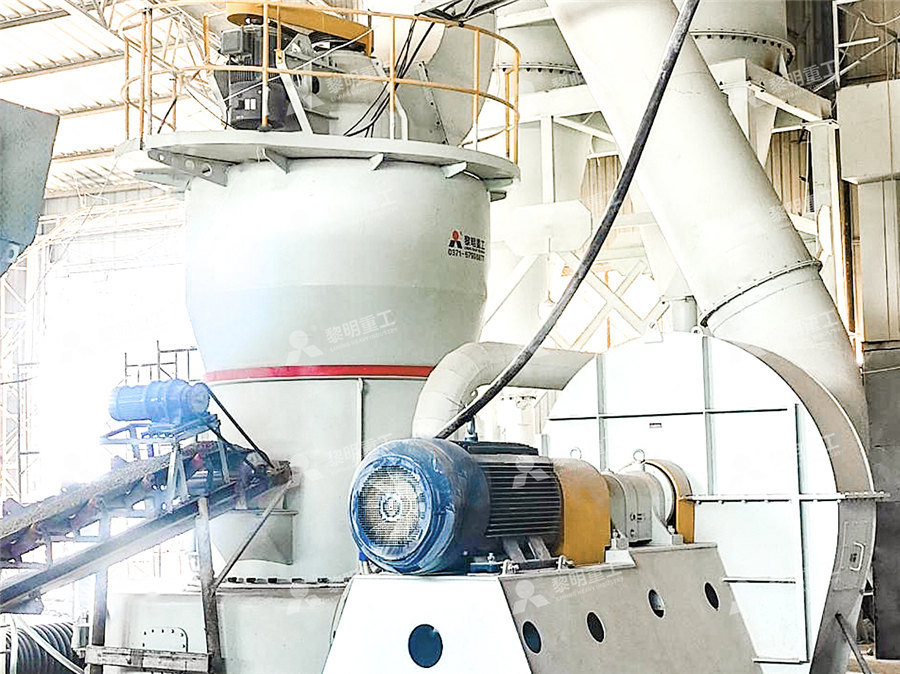

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the The working principle of a vertical mill involves the rotation of a grinding table with rollers attached to it Raw materials are fed into the table and ground between the rollers and table The Working principle and characteristics of vertical mill2021年1月1日 Mill Gas Flow The three roles of the gas flow in the Vertical Roller Mill are: Material drying, Material transport Classification Constant gas flow through the mill to Review on vertical roller mill in cement industry its performance vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

VERTICAL ROLLER MILLS AMCL

This Machine is a vertical type roller mill which performs drying grinding classification and pneumatic transportation simultaneously Material is fed at a constant rate through the chute 2024年1月1日 Working principle: the material is fed by the feeder between two parallel, opposite, and synchronously rotating rollers, subjected to a high pressure of 50–300 MPa, Roller Mill SpringerLink11 The Working Principle of Vertical Mill The material enters the vertical mill from the upper feed inlet, the material is sent between the grinding roller and the grinding disc by the sealing Solid Edge’s Application in Vertical Mill Design SpringerThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process In recent years, the VRM cement mill has been equipped in more and more cement Vertical Roller Mill Operation in Cement Plant

.jpg)

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Working principle Three stationary MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, China MPS 5000 B mill for raw material grinding, Turkey Tracim, Turkey MPS 5300 B mill for cement They are commonly used for grinding raw materials, coal, and clinker, leading to a drying effect After the material has been sufficiently dried, By understanding the working principle of a vertical roller mill, manufacturers can create higherquality cement, reduce energy consumption, and increase overall efficiencyHow does a Vertical Roller Mill Work? ball mills supplierThe LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionVertical Mill Shanghai Zenith CompanyVertical Roller Mill Working Principle The grinding wheel is driven by a motor through a reducer Strong drying capacity: dry and grind raw materials with moisture content as much as 15% 4 Multifunction: crushing, drying, grinding, separating, and conveying 5Vertical Roller Mill SBM Ultrafine Powder Technology

Vertical roller mill DARKO

♦The vertical mill uses the principle of material layering for grinding It has low energy consumption, with powder consumption 20%30% lower than that of a ball mill As the moisture content of the raw materials increases, the powder consumption decreases significantly The vertical mill is 30%40% more energyefficient than the ball mill2016年9月1日 They are usually used as important working parts for crushing raw materials in cement and electric power industries, Keywords Dry comminution, vertical roller mill, gold, platinum group Operational parameters affecting the vertical roller mill 2021年1月1日 Mill Gas Flow The three roles of the gas flow in the Vertical Roller Mill are: Material drying, Material transport Classification Constant gas flow through the mill to ensure constant lift for the internal circulating material and to keep separator performance constant to ensure a consistent product size distributionReview on vertical roller mill in cement industry its AGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System Cement vertical mill, also called roller mill, is another raw mill commonly used in cement pared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw Mill

.jpg)

Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

Working principle Raw mills uses pressure and shear generated between the rollers and rotating table to crush and grind limestone, basalt and sandstone This temperature is used to drying material in vertical raw mill The hot exhaust gases enter the top section of the vertical, Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric Vertical Raw Mill ball mills supplierDue to innovative materialgrinding principle, It offers simplified processing flow, so the structure is compact Our PFRM range of vertical mill combines material crushing, drying, grinding Thus, the installation space and Vertical Raw Mill PENGFEI Groupvertical planetary gear reducer At the same time, raw material is dried by hot gas induced through the louver ring installed at outer side of the table Construction This Machine is a vertical type roller mill which performs drying grinding classification and pneumatic transportation simultaneously Material is fed at aVERTICAL ROLLER MILLS AMCL

.jpg)

VRM In Cement Plant Maximize Energy Saving CNBMSINOMA

Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production This vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materialsVertical Cement Mill Great Wall• Cement raw material • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and most efficient grinding plants for its customers Principle of increasing performance by reducing the range of fluctuationPROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSFor the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice This mill type is by the way the core piece of our modular ready2grind systemMVR vertical roller mill with planetary gearbox Gebr Pfeiffer

.jpg)

quadropol® thyssenkrupp Polysius Grinding Technologies

In addition, the raw material grinding process will be supported by a QMR² 48/24 For the 4,000 tons per day kiln line Shiva Cement Ltd contracted a quadropol® vertical roller mill for grinding pet coke with a QMK² 32/16 The same mill size QMK² 32/16 is running in Indonesia for years now, grinding and drying lignite2022年2月28日 Jet Mill Working Principle Jet Mill Working Principle +86574 Language English; with stronger kinetic energy It is usually used to treat power plant fly ash, steel slag, chemical raw materials, could also produce mini milling machine/small vertical mill for laboratoryJet Mill Working PrincipleThe coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal PulverizationIt moves to the edge of the mill due to centrifugal force and the grinding roller Shredded material overflows from the edge At the same time, wind from the nozzle ring speeds to the efficient separator It is with the vertical mill After the separator, meal returns to the mill wheel and grinds again The fine powder is ground with the air flowTable Roller Mill Vertical Mill

Industrial application of system integration updated

Secondly, concerning the technology updated project of the TRM534 raw material vertical roller mill owned by YongDeng Qilianshan Cement Ltd Co, the industry application scheme adopted in this project is presented, and the Brundick, H, “Drying and grinding of extremely moist cement raw materials in the Loesche mill,” ZKG International, No2, 1998, pages 6471 Brundick, Horst, and Schäfer, HeinzUllrich, “Loesche mills for clinker grinding,” Asian Cement and Everything you need to know about cement Materials The vertical roller mill is used to grind the material by using the principle of material bed pulverization It gathers materials for grinding, conveying, powder selection, drying and separation of metal blocks and medium oreHow to Improve Grinding Efficiency of Vertical Roller Read this indepth blog to learn about the working principle of Vertical Grinding Mill, its application, and its advantages +91 226796 9655 sales@macawberindia 130131, Hindustan Kohinoor Complex, LBS Road, Vikhroli, Mumbai The grounded raw material is then carried through the air from the blower into the Analyzer Machine for screeningVertical Grinding Mill: How it Works, Application And Advantages

.jpg)

How does Vertical Roller Mill Work? ball mills supplier

Vertical roller mills (VRM) have become increasingly popular in recent years, as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet localized rises in cement demand The demand for cement has grown rapidly in recent years, creating a need for a more efficient way to grind clinker and other raw materials used in LM vertical grinding mills is widely absorb the advanced technology in the foundation of international wellknown company, combined with our thirty years of grinding equipment production experience, integrated design and development of a set of crushing, grinding, powder selection, drying, material handling and other functions in one of the five major large grinding LM Vertical Grinding Mills Working Principle PagesBoth the tube mill cement and the steel tube mill operate on a similar working principle, revolving around the rotation of a cylindrical drum containing grinding media These machines efficiently crush and grind the raw material, transforming them into fine powder (in the case of cement) or shaping them into steel tubes with precise dimensionsTube Mill Machine Working Principle Citic Ic Luoyang Heavy 2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the (PDF) Performance Evaluation of Vertical Roller Mill in

.jpg)

What is The Working Principle of Attritor Mill? ball mills supplier

The attritor mill has revolutionized the world of grinding with its unique working principle and many advantages over traditional grinding mills Its high grinding efficiency, fine particle size distribution, versatility, and low maintenance make it an ideal choice for a wide range of mon solution to grind raw materials and cement Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisationBALL MILLS Ball mill optimisation Holzinger ConsultingVertical ball mill can grind and disperse rubber, ceramics, ore, coal, metal, hard alloy and other materials 301300L vertical ball mill, welcome customers to consult Skip to content Home; The transport media in the drytype vertical Vertical Ball Mill can Grind Coarse and Hard Granular Introduction The LM Vertical Grinding Mill , launched by SMMVIK Machinery, integrates five functions of crushing, grinding, powder selection, drying and material conveyingIt is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionLM Vertical Grinding Mill SMMVIK Machinery

.jpg)

UBE Vertical Mill UBE Machinery Corporation, Ltd

The mill motor is rotating the table via a gear reducer Raw materials are supplied onto the table through the chute and spead to the outer table by the centrifugal force STEP2 At the outer of table, the materials are ground by roller which The cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill For drying the material, hot gases are directed into the mill Product fineness can be adjusted within a wide range (0063 to 02 mm)Raw mills for all requirements Gebr PfeifferFIGURE 4 Particle size distributions of collected samples (Survey 2) Bond work indices and breakage characteristics under compression were determinedPerformance Evaluation of Vertical Roller Mill in Cement Application: Cement Plant, Clinker Grinding Unit: Capacity: 21155 t/h: Motor Power: 8003550 kw: Fineness: 3300~3800 cm²/gCement Ball Mill

.jpg)

Vertical roller mill Hengtu Machinery

The working principle of vertical roller mill: Crushing: 400500mm stone material is crushed and broken in two stages and iron is removed into the raw material barrel to be ground Drying of the raw material: After passing through the dam ring at the edge of the grinding plate, Working principle The material to be ground is crushed between the rotating grinding track and the individually guided grinding rollers Grinding is carried out primarily through the application of com pressive force A small amount of shear force supports the dis placement of crystalline layers in the raw material This effectFOR CEMENT RAW MATERIAL2022年4月6日 An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain millThe largest grain mills used worked a Chapter Six: Some Operating Guidelines Vertical Roller MillNoteworthy characteristics of this vertical grinding mill include excellent mechanical properties, easy handling, convenient maintenance, reduced consumption, lower operational costs, capability to process both wet and dry materials, and a design that facilitates simple installation, resulting in lower base equipment costs and strong environmental protection measuresVertical mill,vertical grinding mills,vertical grinding mill working