Ultrafine powder processing can use sedimentation chamber

.jpg)

Effect of jet milling on microstrain behavior and rupture behavior

2019年10月1日 The results show that the microstrain of the jetmilled WC powders decreases significantly compared with that of the ballmilled WC powders, and that the cemented carbides prepared by jetmilled WC powders exhibit excellent properties with a transverserupture 2020年1月1日 To avoid aggregation of ultrafine particles and improve powder flow for better discharge from the milling chamber, a dry lubricant commonly known as a process control Properties and applications of ultrafine powders produced from 5 Preparation of Ultrafine Particles by Nanopowder Process The fine powder of 02 11m (sedimentation method) could be obtained with the mixing of a raw material powder and the Preparation of Ultrafine Particles by N anopowder Process t Grinding ultrafine powder (W 14) is processed in the fluidizedbed jet mill (LNC1205, in a series of five classifiers) with two, three or four nozzles in the experiment[11] As can be seen from H:\Work\China\017Zhangpmd ipme

Online characterization of particle size during an ultrafine wet

2002年12月18日 Firstly, the grinding chamber and the tubes are filled with the suspension Due to the sedimentation of particles, in the absence of shear, the initial backscattering level is First, we determine the optimum dispersion conditions to obtain deflocculated slurries It’s possible by the control of the solid load, of the pH, or by addition of dispersant in order to (PDF) Ultrafine grinding of powder oxides aqueous slurries with a 2020年12月2日 In the present contribution, ultrafine particulate matter (PM) emitted during laser processing of stainless steel powder materials is characterized in detail by transmission and Characterization of ultrafine particles emitted during laserbased 2024年5月18日 With the microngrade highpurity iron ore concentrate processed by sand mill fine grinding as raw material, hydrogen reduction can produce microngrade ultrafine iron Production of ultrafine iron powder by lowtemperature hydrogen

.jpg)

Effect of Ultrafine Powders Obtained by Mechanical Grinding on

2024年5月15日 According to sedimentation analysis, the powder dispersion was highly correlated with the stability of the aqueous suspension over time Mechanical grinding of ZrO 2 2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for EnergyEfficient Advanced Ultrafine Grinding of Particles Using2019年11月28日 A fourfactor, threelevel orthogonal test method was used to study the sedimentation characteristics of ultrafine tailings with four common curing agent materials, including polyacrylamide Analysis of the Sedimentation Characteristics of Ultrafine Tailings 2023年1月1日 Powder coatings contain no volatile solvents and have ecological, excellence of finish, economic, and energysaving advantages when compared with liquid coatings [1], [2], [3], [4]For example, the oversprayed powder can be reclaimed and reused [5]The elimination of costly solvents generates fewer voids and pores inside the coatings, creating a denser coating Ultrafine powder coating: Smooth surface, dense structure and

Material classification for fine powders Processing

2021年10月18日 F ine powders often need to be separated by particle size to ensure uniformity and effectiveness in a mixture or product However, because many material classification technologies are available, determining which Some researchers have proved that ultrafine WC powders have better activation in plating binderphase mental coat on the WC particles Such as, Luo et al (2011) have studied the activation technique of ultrafine powders and prepared a uniform Nicoated WC composite powder, taking less than 1 μm WC as a matrix As shown in Figure 4B, ultrafine WC powders after ultrasonic Frontiers Preparation Technology of UltraFine Tungsten Carbide ⑤ Used for processing pipelines, oxygen cylinders, glass fiber reinforced plastic safety helmets, handicrafts, etc It is widely used in railway, construction, aerospace, advertising, and display industries ⑥ The mixture of glass and plastic waste can be molded into synthetic slate products ⑦ Can be used to produce sewage pipesUltrafine Glass Powder Making Machine2023年12月1日 The low flowability of ultrafine powder coating can be originated from its small particle size, which is around 20 μm in diameter, much smaller than that of current powder coatings (35 to 45 μm) The reduced particle size leads to a decreased shear force and increased voids between particles, thereby inhibiting smooth powder flow during the spraying process [ Boosting flowability and curing reaction of ultrafine powder

.jpg)

Temperature Variation Characteristics and Model Optimization of

2022年5月20日 In order to study the effect of temperature on the settling characteristics of overflow ultrafine iron tailings, the settling velocity of overflow ultrafine iron tailings at eight different temperatures at 10–80 °C was experimentally studied The results show that, with the increase in slurry temperature, the flocculation settling velocity of overflow ultrafine iron 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder The body cavity is cylindrical, the upper part is ultramicro classifier, the lower part is ultramicro mill The grinding chamber is composed of grinding disc and grinding block which are used to grind the material into ultrafine powder; The classification chamber is composed of a classification wheel, which can divide the fine powder into two specifications of particle size as qualified Graphite Anode Materials Processing Technology ALPA Powder2021年12月1日 Fabrication of ultrafine powder using processing control agent, and investigation of its effect on microstructure and thermoelectric properties of ptype (Bi, Sb)2Te3 alloysFabrication of ultrafine powder using processing control agent,

]@S0{UDKK%G24F3JGHC.jpg)

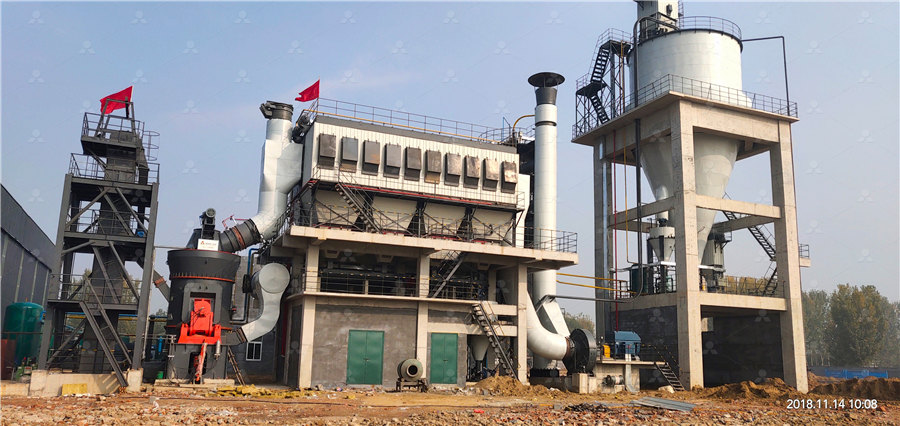

HCH Ultrafine Grinding Mill, Micro powder grinding mill, Ultra fine

It is an energysaving high fine powder processing equipment It can be used for ultrafine grinding mill of various nonmetallic minerals such as limestone, talc, calcite, calcium carbonate, dolomite, potassium feldspar, bentonite, kaolin, fluorite, etc with Mohs hardness below 7 and humidity within 6%2020年5月1日 The slurry was moved into the interaction chamber of the Microfluidizer® machine under high pressure and the Beckman Coulter, USA), sedimentation experiment (sedimentation for 5, 7 and 10 min using especially when the UHTC powder contained a small amount of oxygen which can consume excess carbon in the powder by carbo Effect of residual excess carbon on the densification of ultrafine 2024年4月1日 Ultrafine copper powders were prepared by the airjet milling of copper oxide (CuO) powders and a subsequent hydrogen (H2) reduction After milling, the particle size and grain size of CuO powders decreased, while the The Preparation of an Ultrafine Copper Powder by the Figure \(\PageIndex{1}\): Schematic illustration of how sedimentation is used to determine particle size The four rectangular sample cells show the state of sedimentation as a function of time, with the large red particles falling to the bottom of the sample cell more quickly than the medium green particles and the small blue particles343: Measuring Particle Size by Sedimentation

Temperature Variation Characteristics and Model Optimization of

2022年5月20日 Temperature Variation Characteristics and Model Optimization of Flocculation Sedimentation of Overflow UltraFine Iron Tailings2019年11月14日 SIMEC innovative Ultra Fine Pulverizer is equipped with pulverizing rotor grading impeller made of corundum ceramics, as a result, ultra fine pulverizing and particulate sorting can be completed simultaneously Corundum ceramics are characterized by high temperature resistance, corrosion resistance, wear resistance, and low density (about 1/2 of Ultra Micro Pulverizer2016年7月1日 In order to accelerate the sedimentation of superlargescale argillized ultrafine tailings with bad features such as low settling velocity, muddy overflow water, and large flocculant dosage, a Dynamic experiments on flocculation and sedimentation of 2001年3月1日 The results show that small amount of Y 2O 3:Eu ultrafine powder in polypropylene can induces the crystallization into β spherulitic structure, and small amount of that is beneficial for the Research on the composite dispersion of ultra fine powder in the

Influence of processing conditions on property of ultrafine powder

2011年8月1日 Request PDF Influence of processing conditions on property of ultrafine powder of transparent Sc2O3 ceramics The influence of reaction temperature, aging time, washing methods and calcination 2019年11月1日 Laser Powder Bed Fusion (LPBF) is an additive manufacturing (AM) or 3D printing process that is increasingly being adopted by various industrial sectors to lower the cost of production of devices with complex shapes, particularly for high value low volume manufacturing [1]The LPBF system consists of a laser source with a typical power of at least Laser powder bed fusion of a pure tungsten ultrafine single PTFE ultrafine powder can be prepared by irradiation at room temperature, followed by ultrafine grinding Fresh PTFE material, scrap or recycled PTFE waste, etc, can be used to fabricate ultrafine powder The use of recycled PTFE or waste to produce ultrafine powder can reduce the cost and achieve the recycling of resourcesUltrafine Grinding an overview ScienceDirect Topics2022年8月1日 It can be seen from Table 1 that the main mineral components of the tailings sample are quartz, feldspar, montmorillonite, and kaolinite Montmorillonite and kaolinite are clay minerals that constitute 346 % of the mineral composition of overflow ultrafine tailings, and, thus, are the main contributing minerals to the poor settlement performance of overflow ultrafine Coagulation sedimentation performance and model optimization

Processing Chamber an overview ScienceDirect Topics

Vapor Processes By Bethanie Joyce Hills Stadler, in Materials Processing, 2016 A processing chamber has an aperture with area 100 cm 2 connected directly to a pump According to Example 74, this aperture has a conductance of 1,170,000 cm 3 /s (1170 liter/s) If the pump is attached to the chamber using a pipe with an area of 100 cm 2, determine what length pipe would cut the 2020年6月1日 With the increasing use of food powder in the world, it is increasingly important to understand the processing methods of food powder and the changes in physicochemical properties after processing Recent advances in processing food powders by using2017年7月7日 The wide chamber contrarotating impact pin mill was originally designed for processing cocoa powder, but has since found many uses beyond that industry Wide chamber mills perform troublefree, ultrafine grinding of difficult products, even in continuous operationTop 5 productspecific milling technologies used in industrial 2022年3月14日 Synthesis of Multiscale Ultrafine Copper Powder via Radio Frequency Induction Coupled Plasma Treatment(PDF) Synthesis of Multiscale Ultrafine Copper Powder via Radio

(PDF) Ultrafine grinding of powder oxides aqueous slurries with a

Electroceramics IX P 222 Ultrafine grinding of powder oxides aqueous slurries with a controlled viscosity Houivet David, Bernard Jerome, Haussonne JeanMarie LUSAC, Laboratoire Universitaire des Sciences Appliquées de Cherbourg (EA2607), Université de Basse Normandie, BP78, 50130 Cherbourg Octeville, France I 2018年3月1日 Aluminum powder is commonly used in a wide variety of applications like rocket propellant additives [1], [2], thermite mixtures [3], paints [4] and hydrogen generation [5]The use of micron sized Al powder as propellant additive leads to incomplete combustion, high ignition temperature and ignition delay [6]This results in deposition of unburnt or partially burnt metal Propellant grade ultrafine aluminum powder by RF induction 2021年3月1日 Two heat treatments, namely 955°C/2h/AC (AC = air cooling) and 955°C/4h/FC (FC = furnace cooling), were carried out on a powder metallurgy (PM) Ti–6Al–4V alloy fabricated by hot extrusion of Ultrafine Grained Metals and Metal Matrix Nanocomposites 2014年1月1日 Thus, the heating operation is developed in an easily deformable and thermally stable powder material in two ways: (a) the degassed green compact of particles, poured into a steel can, is heated up at T [°C] and then the compaction pressure acts on the can by the means of a hydraulic press in low thermal conductivity powder, eg, talcum (Fig 61a and b) the semi Powder Processing of Bulk Components in Manufacturing

Advances in dewatering and drying in mineral

2021年4月13日 Dryers that have been traditionally used in the mineral processing industry are hearth, grate, and shaft type of dryers For the hearth type dryer, drying is done by means of conduction2021年4月1日 Ultrafine comminution of plant materials can produce ultrafine powders suitable for direct use in advancedtechnology applications as an engine, becoming a sustainable powdered biofuel(PDF) Comparative comminution efficiencies of rotary, stirred and 2010年1月31日 Chocolate milk can be defined as a complex multiphase that contains fine solid particles from ingredients used for its preparation, such as cocoa, sugar, and certain milk components in a Ultrahightemperature processing of chocolate 2023年8月31日 Lithium compounds used in lithium batteries have specific particle size distribution requirements, and the use of ultrafine lithium powder can improve battery performance, including higher available capacity, longer service life, faster charging rate, higher efficiency, consistent discharge rate, and reduced size and weightDry ultrafine grinding and classification process: realize integrated

.jpg)

Talc Ultra Fine Powder Grinding Mill

2021年8月13日 Finally, the talc is ground into powder in the grinding chamber The grinding host here can use SBM talc ultra fine powder grinding mill 3 Classification stage: The talc powder after grinding is classified by the classifier along with the system airflow2021年9月6日 The Mohs hardness of marble is 255, and it can be ground with SBM industrial powder mill (marble ultrafine powder grinding mill) SBM is a professional manufacturer of mine ore grinding equipment The products cover multiple fields such as crushing, sandwashing, sand making, and milling machinesMarble Ultrafine Powder Grinding Mill2014年10月1日 This paper Introduced A horizontal Sanding Machine That is used for powder processing, it is supported by frame, main shaft components, mixing grinding mechanism, cooling circulation system of The Research of Equipment for Wet Processing Ultrafine PowderBrief introduction Micro powder roller mill is also known as ultrafine powder grinding mill It is a new type of powder processing equipment, mainly used for crushing and processing nonmetallic minerals such as calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite and other nonmetallic minerals with Mohs hardness less than 5 and water Micro Powder Roller Mill for Getting Ultrafine Powder DASWELL

Numerical simulation and experimental study on ultrafine powder

2024年5月8日 First, ultrafine MoO2 powders are successfully prepared via reduction of commercial MoO3 by carbon black with the molar ratio of C/MoO3 ranging from 05 to 07 in the temperature range of 550 °C 2018年4月1日 Zhang et al (2018) found that the ultrafine powder of black tea has higher utilization ratio than coarse powder Ultrafine powder has the advantage of convenient use as condiment, colorant, and The effect of ultrafine and coarse grinding on the suspending and